Reflective silica gel decoration sheet and preparation method thereof

A decorative sheet and silica gel technology, which is applied in the field of reflective silica gel decorative sheet and its preparation, can solve the problems of high equipment precision, harsh operating conditions, and insufficient softness, and meet the requirements of environmental protection, good anti-aging performance, soft material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

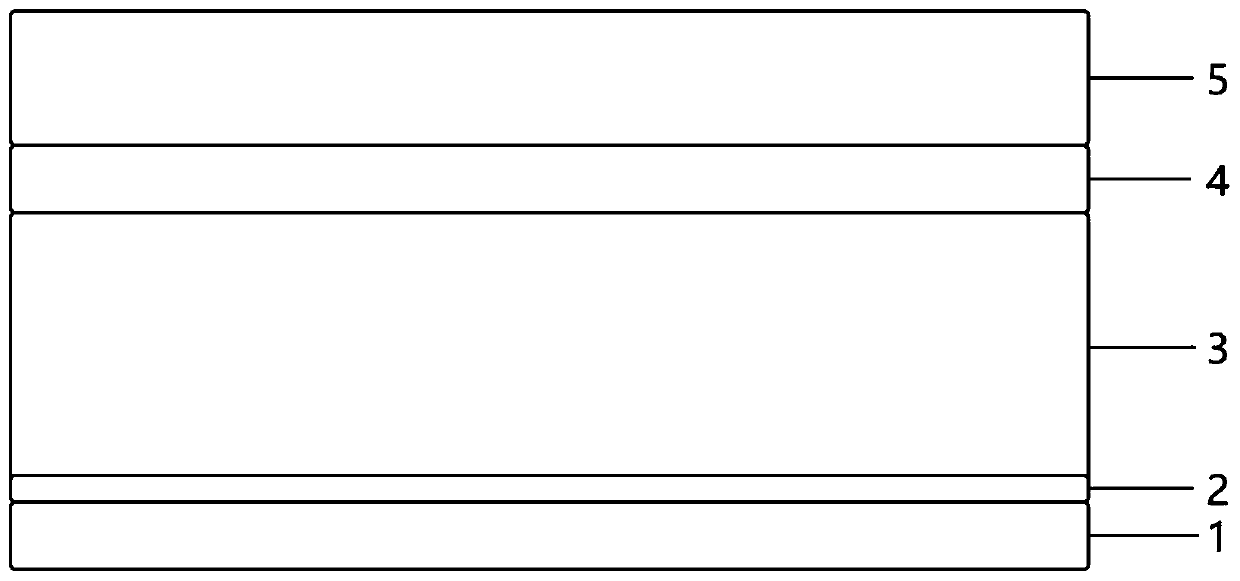

[0032] The reflective silicone decorative sheet of this embodiment comprises a PET protective film 1, a reflective layer 2, a silicone base layer 3, a silicone adhesive layer 4, and a PES film from bottom to top, wherein: the thickness of the PET protective film 1 is 0.05 mm; The thickness of the reflective layer 2 is 0.02mm; the thickness of the silica gel base layer 3 is 0.2mm; the thickness of the silica gel adhesive layer 4 is 0.05mm.

[0033] The reflective layer 2 consists of SiO 2 Powder 12g, silica gel 70g, silicone paint thinner 4g.

[0034] The silica gel base layer 3 includes 5g of silica gel, 4g of silicone paint thinner, and 8g of coloring agent.

[0035] The silica gel adhesive layer 4 includes 35g of silica gel and 4g of silicone varnish thinner.

[0036] The preparation method of the above-mentioned reflective silica gel decorative sheet comprises the following steps:

[0037] A. Mix 70g of silica gel and 4g of silicone varnish thinner, and then evenly coat ...

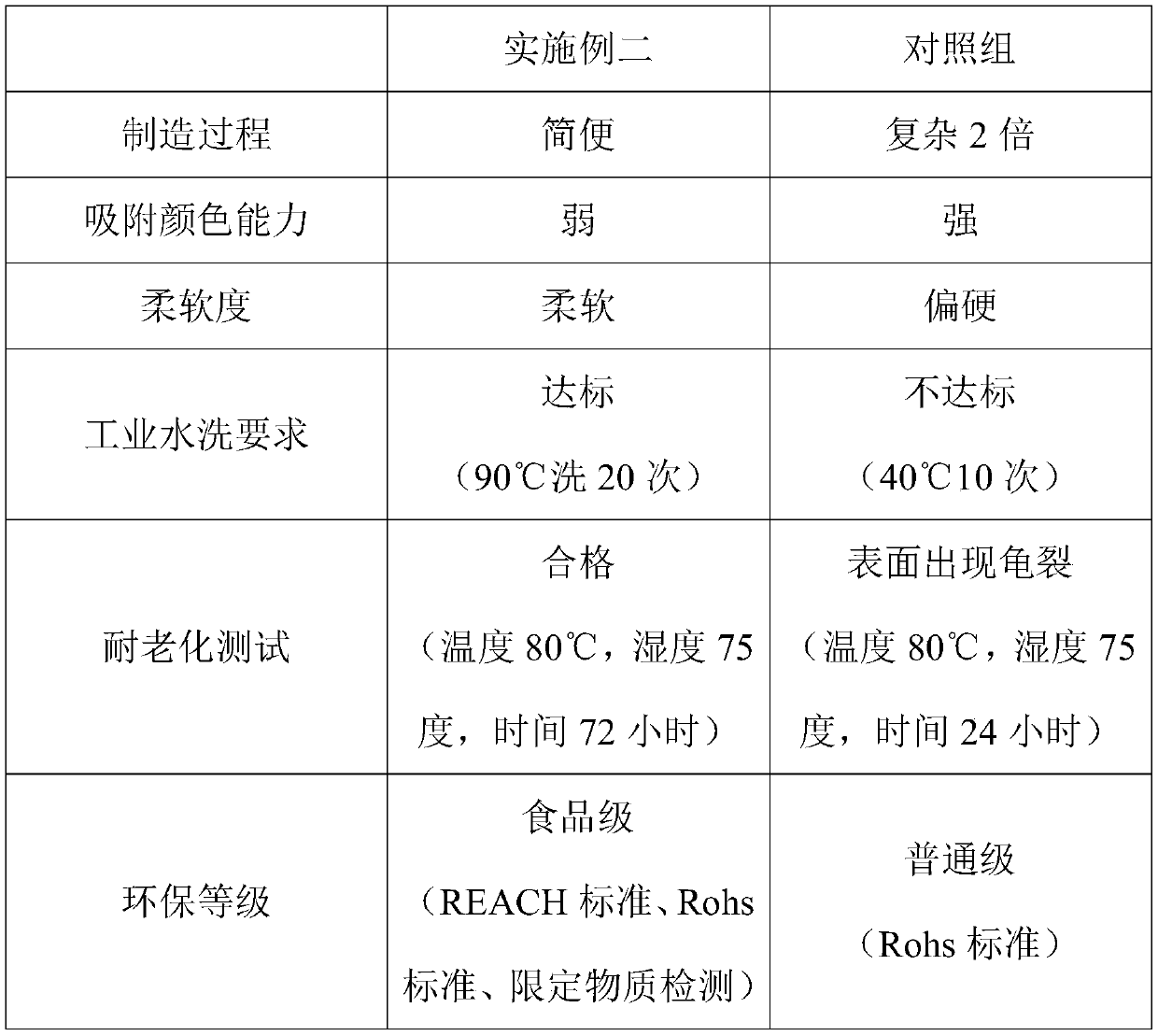

Embodiment 2

[0042] The reflective silicone decorative sheet of this embodiment comprises a PET protective film 1, a reflective layer 2, a silicone base layer 3, a silicone adhesive layer 4, and a PES film from bottom to top, wherein: the thickness of the PET protective film 1 is 0.04mm; The thickness of the reflective layer 2 is 0.01 mm; the thickness of the silica gel base layer 3 is 0.1 mm; the thickness of the silica gel adhesive layer 4 is 0.03 mm.

[0043] The reflective layer 2 includes 15g of CaO powder, 80g of silica gel, and 5g of organic silicon varnish thinner.

[0044] The silica gel base layer 3 includes 6g of silica gel, 5g of silicone paint thinner, and 10g of coloring agent.

[0045] The silica gel adhesive layer 4 includes 43g of silica gel and 5g of silicone varnish thinner.

[0046] The preparation method of the above-mentioned reflective silica gel decorative sheet comprises the following steps:

[0047] A. Mix 80g of silica gel and 5g of silicone varnish thinner, an...

Embodiment 3

[0052] The reflective silicone decorative sheet of this embodiment comprises a PET protective film 1, a reflective layer 2, a silicone base layer 3, a silicone adhesive layer 4, and a PES film from bottom to top, wherein: the thickness of the PET protective film 1 is 0.04 mm; The thickness of the reflective layer 2 is 0.01 mm; the thickness of the silica gel base layer 3 is 0.1 mm; the thickness of the silica gel adhesive layer 4 is 0.04 mm.

[0053] The reflective layer 2 consists of SiO 2 Powder 5g, CaO powder 5g, silica gel 60g, silicone paint thinner 3g.

[0054] The silica gel base layer 3 includes 4g of silica gel and 3g of silicone varnish thinner.

[0055] The silica gel adhesive layer 4 includes 29g of silica gel and 3g of silicone varnish thinner.

[0056] The preparation method of the above-mentioned reflective silica gel decorative sheet comprises the following steps:

[0057] A. Mix 60g of silica gel and 3g of silicone varnish thinner, and then evenly coat it o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com