Marine airbag type fast leak stopper

A leak stopper and airbag-type technology, which is applied in the direction of ship safety, ship, transportation and packaging, etc., can solve the unfavorable plastic forming and folding shrinkage of the airbag sealing structure, which cannot guarantee the sealing performance of the airbag well, purchase cost and maintenance High maintenance costs and other issues, to achieve good plugging effect, strong breach adaptability, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

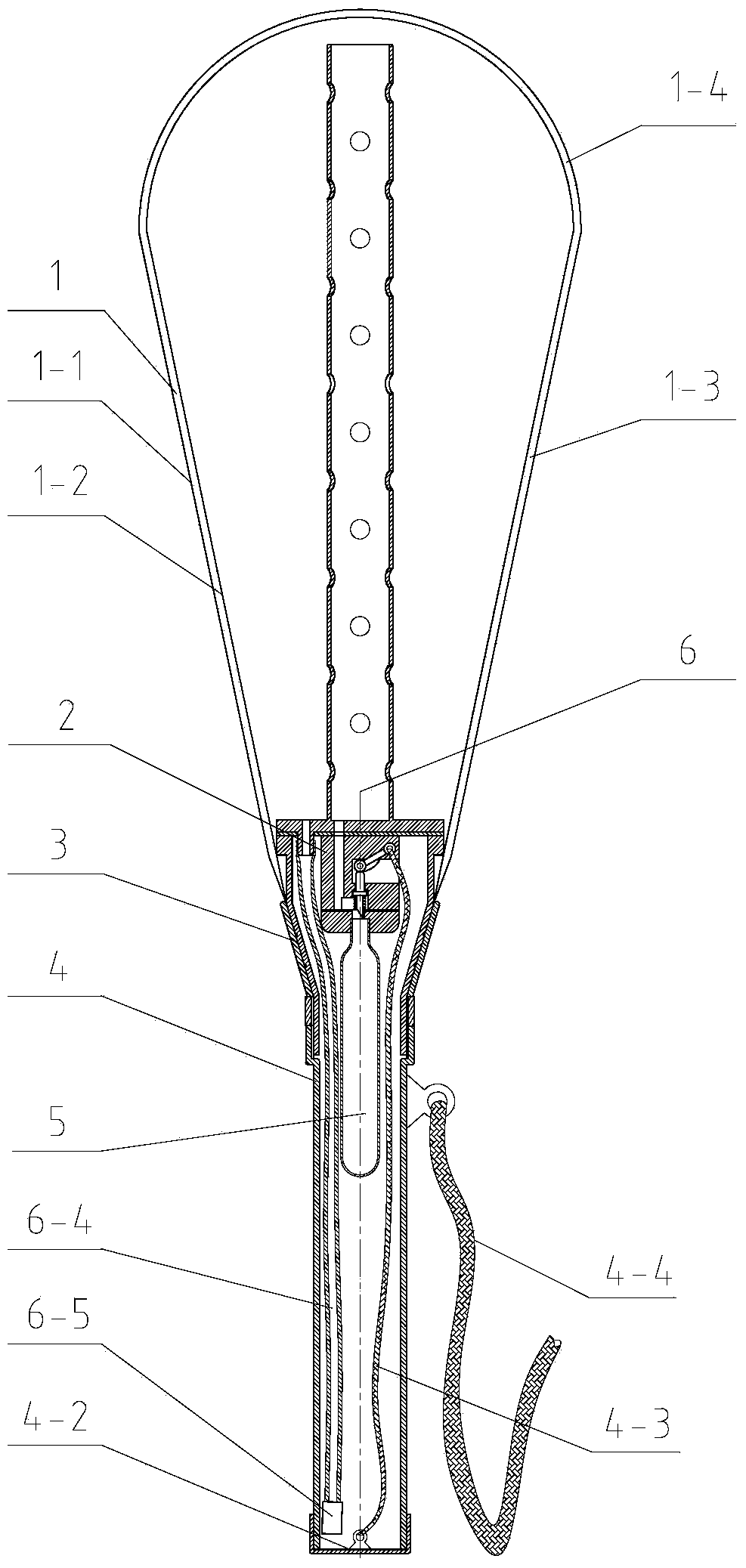

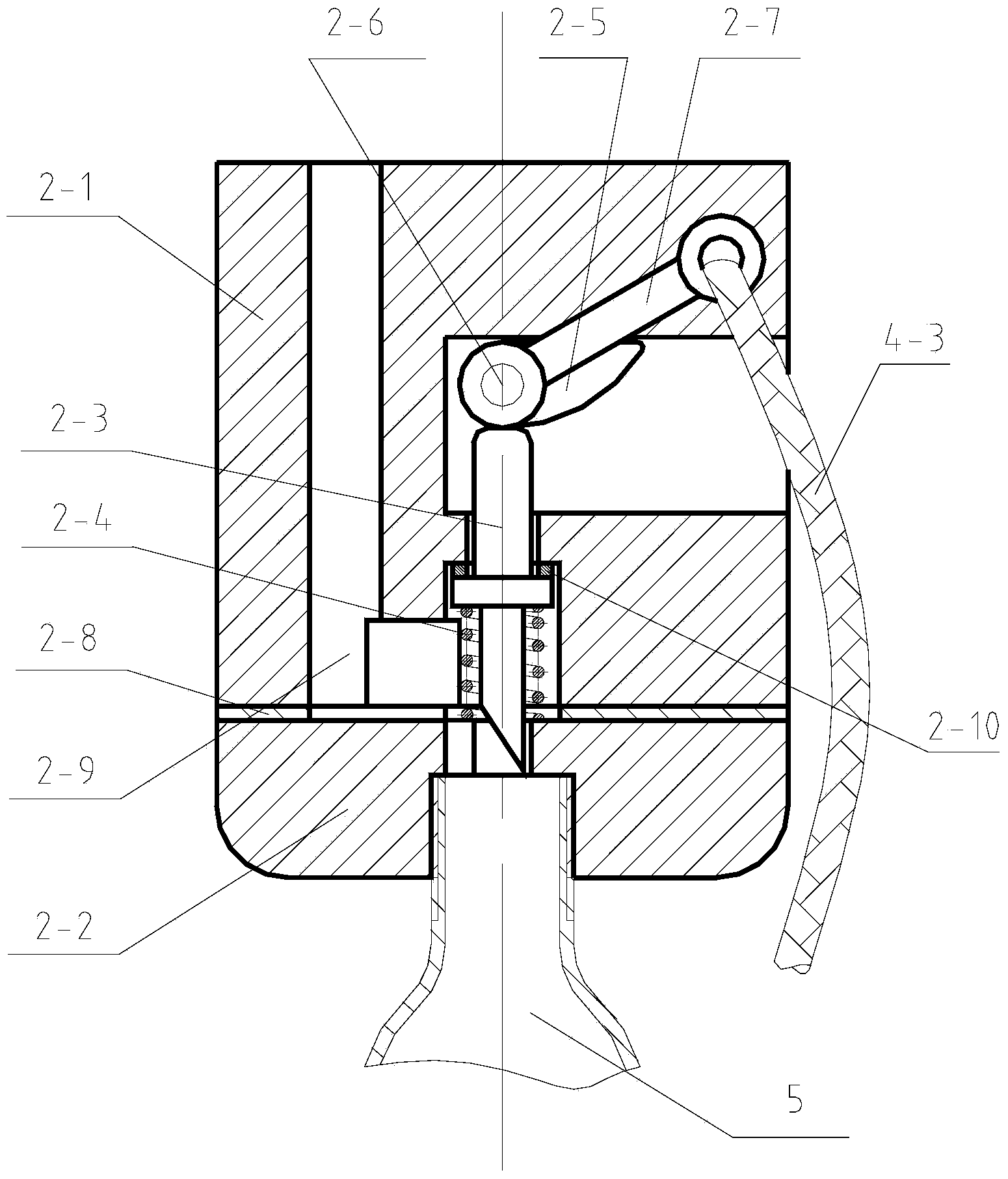

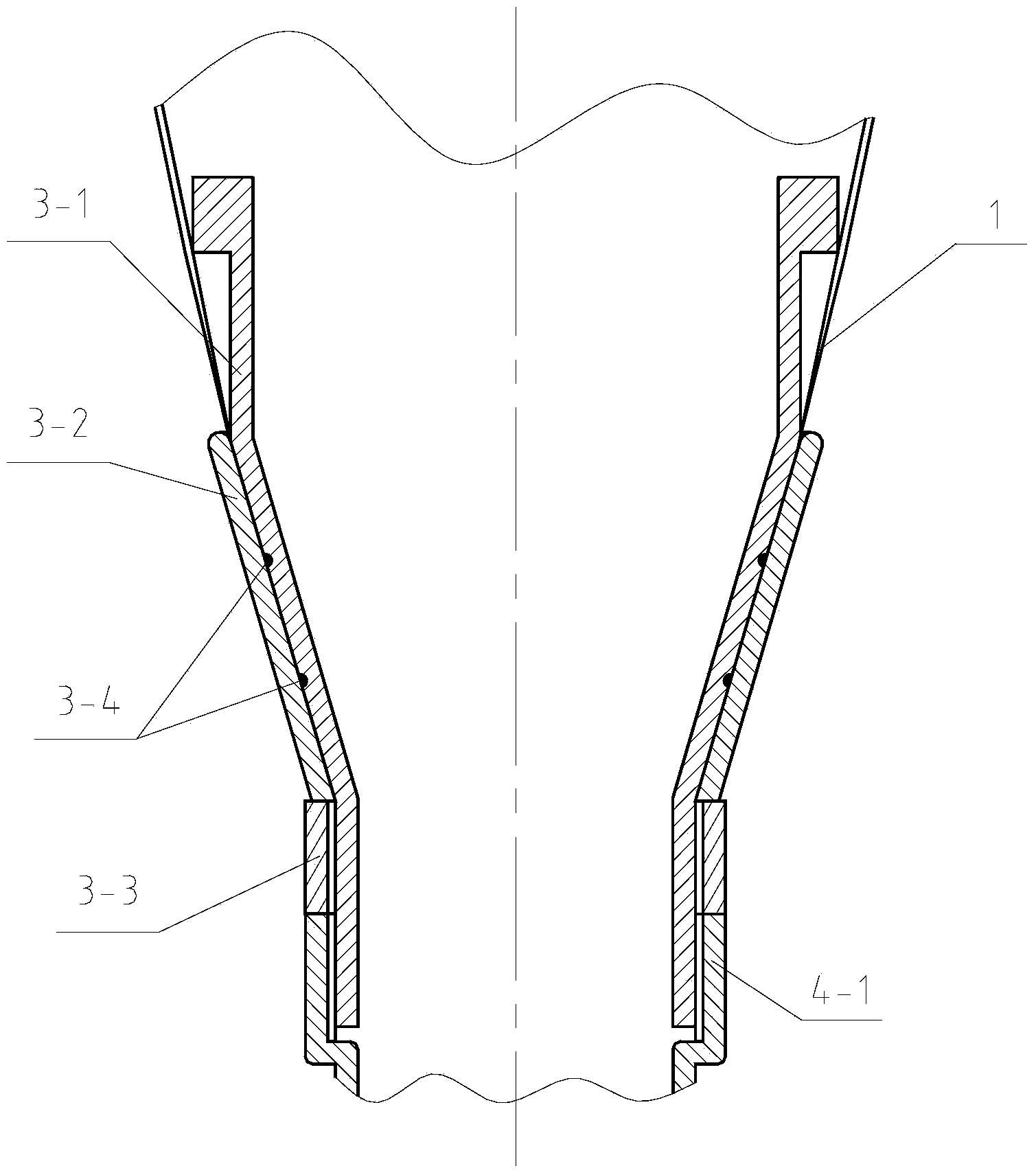

[0023] see attached Figure 1-5, compared with the prior art, the present invention provides a marine airbag type rapid leak stopper, comprising a composite airbag 1, an air intake control valve 2, an airbag fixing sleeve 3, an operating handle 4, a miniature high-pressure gas storage cylinder 5 and Air guiding support rod 6, the composite airbag is composed of an inner sealing capsule 1-1 and an outer high-strength capsule 1-2 to form a thin-walled double-layer composite structure, and the composite airbag is composed of a frustum cavity 1-3 and a hemispherical shell Body 1-4 constitutes the shape of an assembly, the bottom of the composite airbag is fixedly connected to the operating handle through the airbag fixing sleeve, the operating handle is in the shape of a hollow long round tube, and the bottom end of the operating handle is fastened with a safety cover 4-2, so A stay rope 4-3 is fixedly connected to the inside of the insurance cover, and the other end of the stay r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com