Antibacterial laundry detergent and application thereof

A technology of laundry detergent and surfactant, applied in detergent compositions, detergent compounding agents, organic detergent compositions, etc., can solve the problems of poor stability, decreased content of effective substances, and discomfort of aloe vera extract and lemon extract. Laundry liquid and other problems, to achieve the effect of excellent color protection ability, avoid color cross, excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

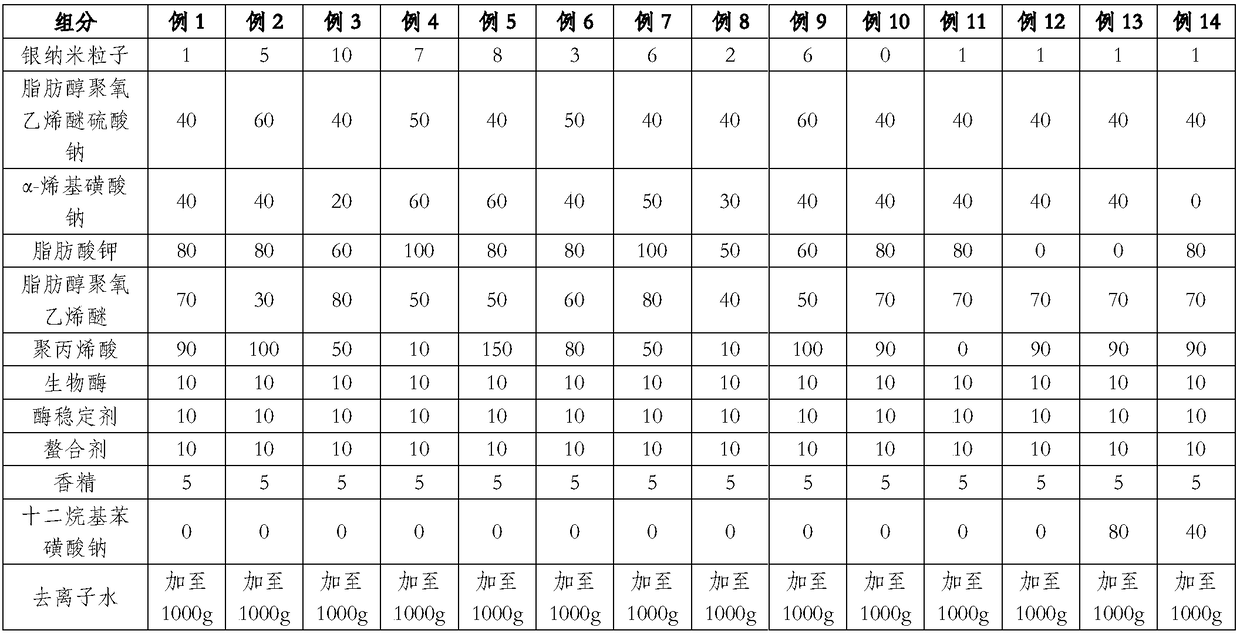

Embodiment 1

[0033] The preparation method of the laundry detergent is as follows: add 40 grams of fatty alcohol polyoxyethylene ether sodium sulfate, 40 grams of α-alkenyl sodium sulfonate, 80 grams of fatty acid potassium and 70 grams of fatty alcohol polyoxyethylene ether into water at 40°C. Then, with rapid stirring, 90 grams of polyacrylic acid was slowly added. After stirring evenly, add 10 grams of biological enzyme (liquid protease), 10 grams of enzyme stabilizer 4-formylphenylboronic acid, 10 grams of chelating agent, and 5 grams of essence. When the temperature is lowered to 30° C., add 1 gram of silver nanoparticles Ag-cit, make up the remaining water, and stir evenly to obtain the laundry detergent with antibacterial properties.

Embodiment 2

[0035] The preparation method of the laundry detergent is as follows: 60 grams of fatty alcohol polyoxyethylene ether sodium sulfate, 40 grams of α-alkenyl sodium sulfonate, 80 grams of fatty acid potassium and 30 grams of fatty alcohol polyoxyethylene ether are added to water at 60°C. Then, with rapid stirring, 100 grams of polyacrylic acid was slowly added. After stirring evenly, add 10 grams of biological enzyme (liquid protease), 10 grams of enzyme stabilizer 4-formylphenylboronic acid, 10 grams of chelating agent, and 5 grams of essence. When the temperature is lowered to 20° C., 5 grams of silver nanoparticles Ag-cit are added, the remaining water is supplemented, and the mixture is evenly stirred to obtain the laundry detergent with antibacterial properties.

Embodiment 3

[0037] The preparation method of the laundry detergent is as follows: add 40 grams of fatty alcohol polyoxyethylene ether sodium sulfate, 20 grams of α-alkenyl sodium sulfonate, 60 grams of fatty acid potassium and 80 grams of fatty alcohol polyoxyethylene ether into water at 50°C. Then, with rapid stirring, 50 grams of polyacrylic acid was slowly added. After stirring evenly, add 10 grams of biological enzyme (liquid protease), 10 grams of enzyme stabilizer 4-formylphenylboronic acid, 10 grams of chelating agent, and 5 grams of essence. When the temperature is lowered to 30° C., 10 grams of silver nanoparticles Ag-cit are added, the remaining water is supplemented, and the mixture is evenly stirred to obtain the laundry detergent with antibacterial properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com