Active oxygen washing machine tank cleaning agent and preparation method thereof

The technology of an active oxygen washing machine and washing machine tank is applied in the directions of surface active detergent composition, detergent compounding agent, detergent composition and the like, which can solve the problems of poor cleaning effect, unsatisfactory decontamination and sterilization effect, etc. Stain bleaching, strong sterilization and decontamination ability, and the effect of enhancing decontamination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

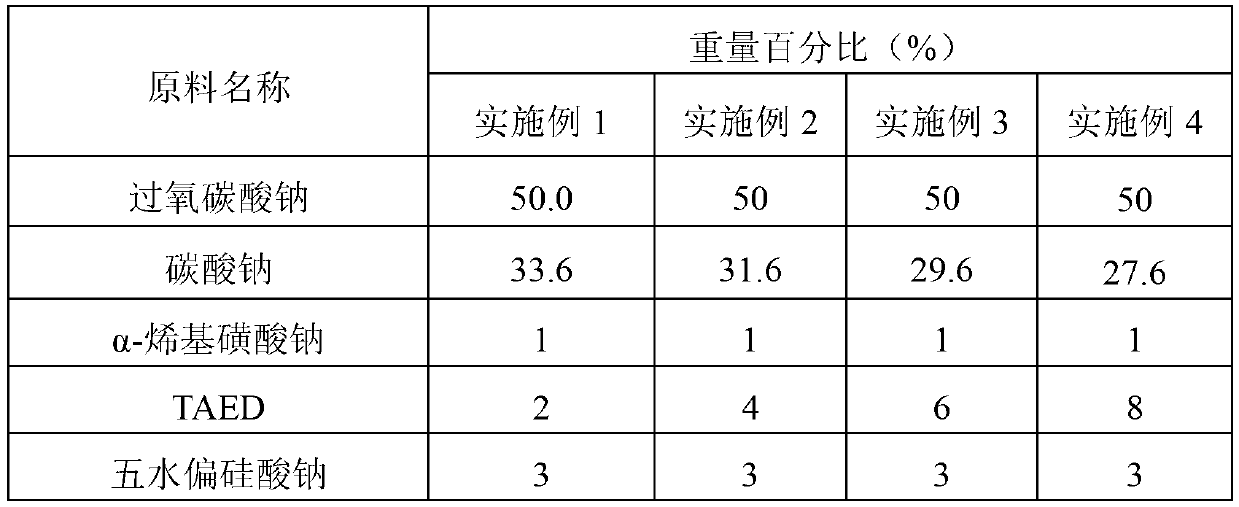

[0038] According to the formula content in Table 2, respectively prepare embodiment 1~4 washing machine tank cleaning agent, its preparation method is: first drop into sodium percarbonate and α-alkenyl sulfonate sodium in the batching pot, stir evenly. Add TAED, sodium metasilicate pentahydrate and Trilon M, and stir evenly. Then put in sodium carbonate, essence and enzyme preparation, and stir evenly. Sieve the evenly mixed material (20-80 mesh), take a sample and inspect it according to the quality standard, and if it passes the inspection, the finished washing machine tank cleaning agent can be packaged.

[0039] The formula composition of the washing machine tank cleaning agent of table 2 embodiment 1~4

[0040]

[0041]

Embodiment 5~7

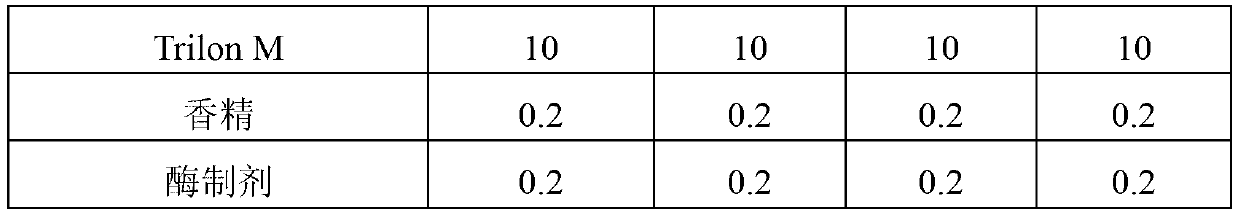

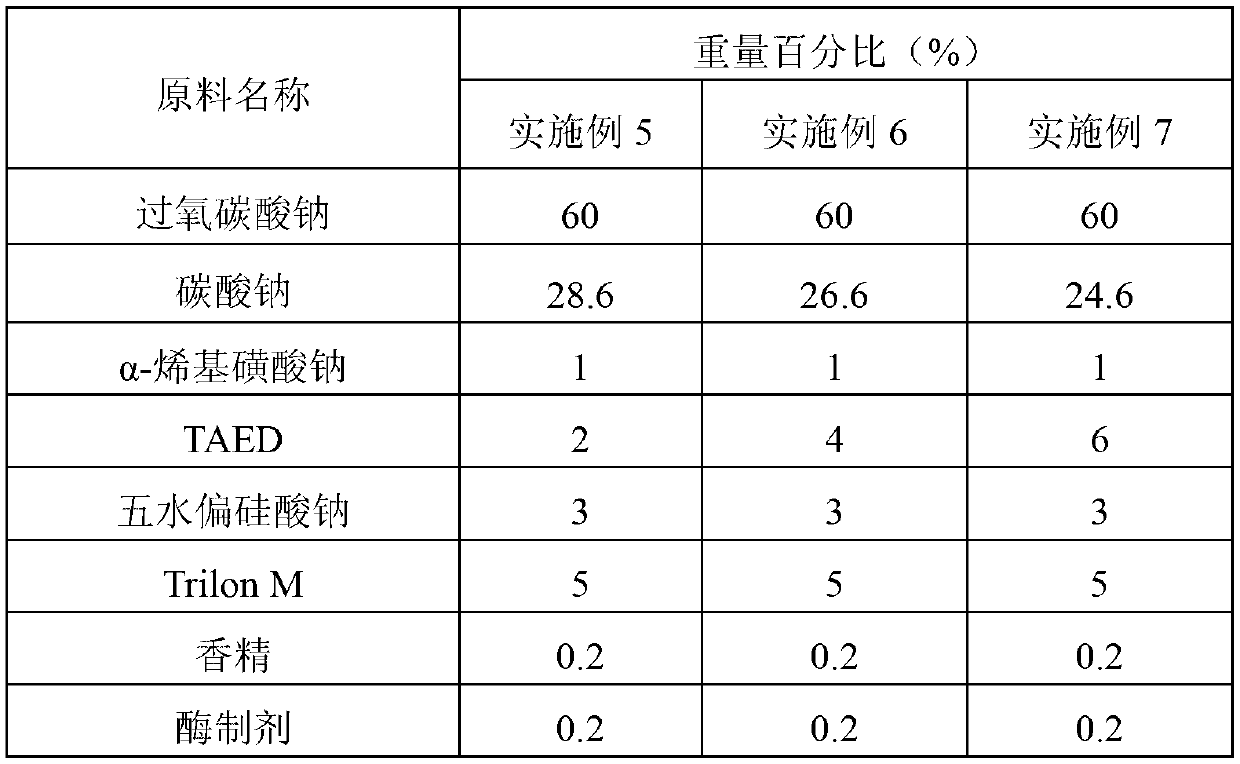

[0043]According to the formula content of Table 3, prepare respectively embodiment 5~7 washing machine tank cleaning agent, its preparation method is: drop into sodium percarbonate and α-alkenyl sulfonate earlier in batching pot, stir evenly. Add TAED, sodium metasilicate pentahydrate and Trilon M, and stir evenly. Then put in sodium carbonate, essence and enzyme preparation, and stir evenly. Sieve the evenly mixed material (20-80 mesh), take a sample and inspect it according to the quality standard, and if it passes the inspection, the finished washing machine tank cleaning agent can be packaged.

[0044] The formula composition of the washing machine tank cleaning agent of table 3 embodiment 5~7

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com