Washing machine for classified washing

A washing machine and washing water technology, applied in the field of washing machines, can solve the problems of complicated procedures, high use cost, and large floor space, and achieve the effects of saving washing time, preventing health damage, and small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

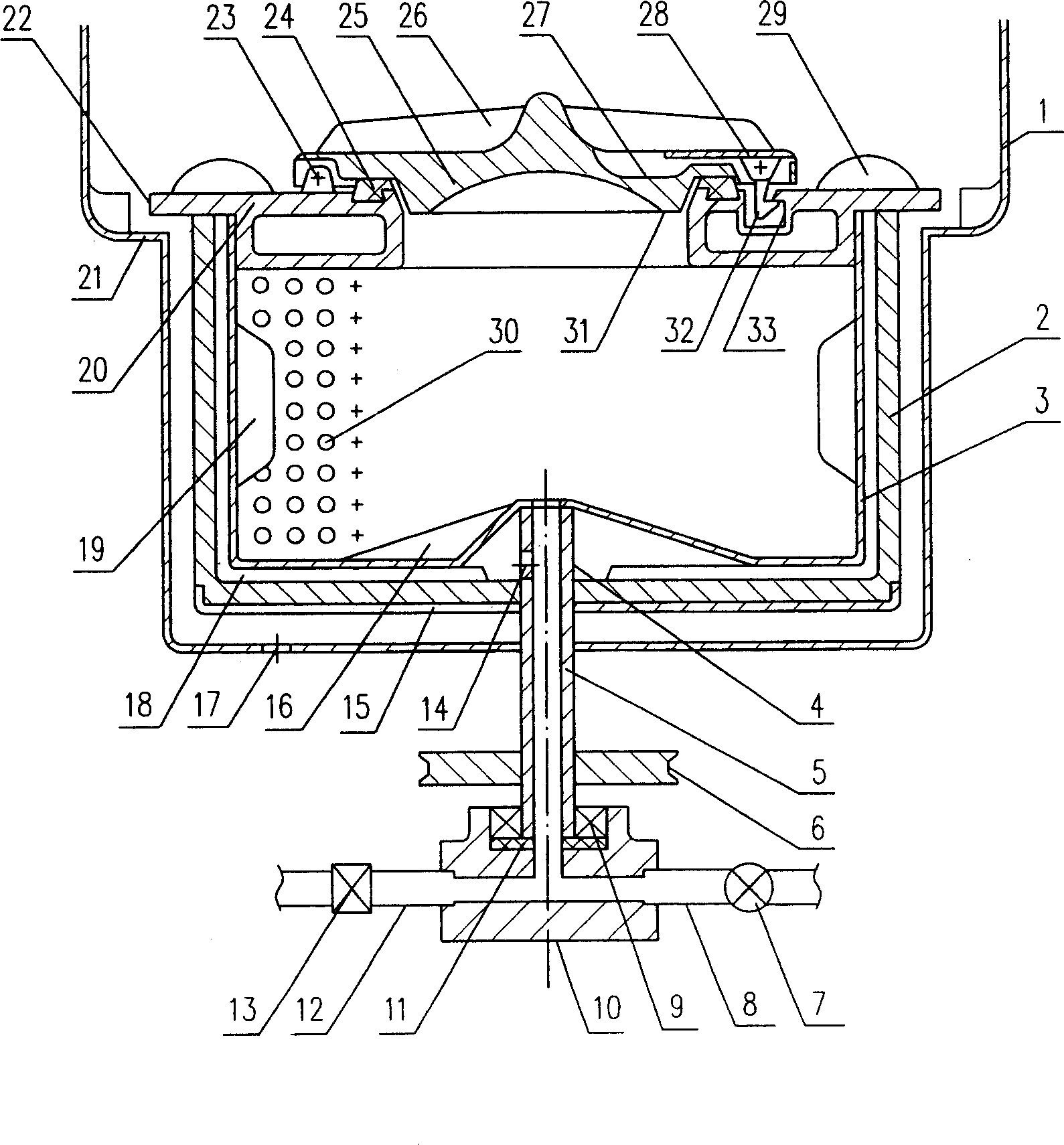

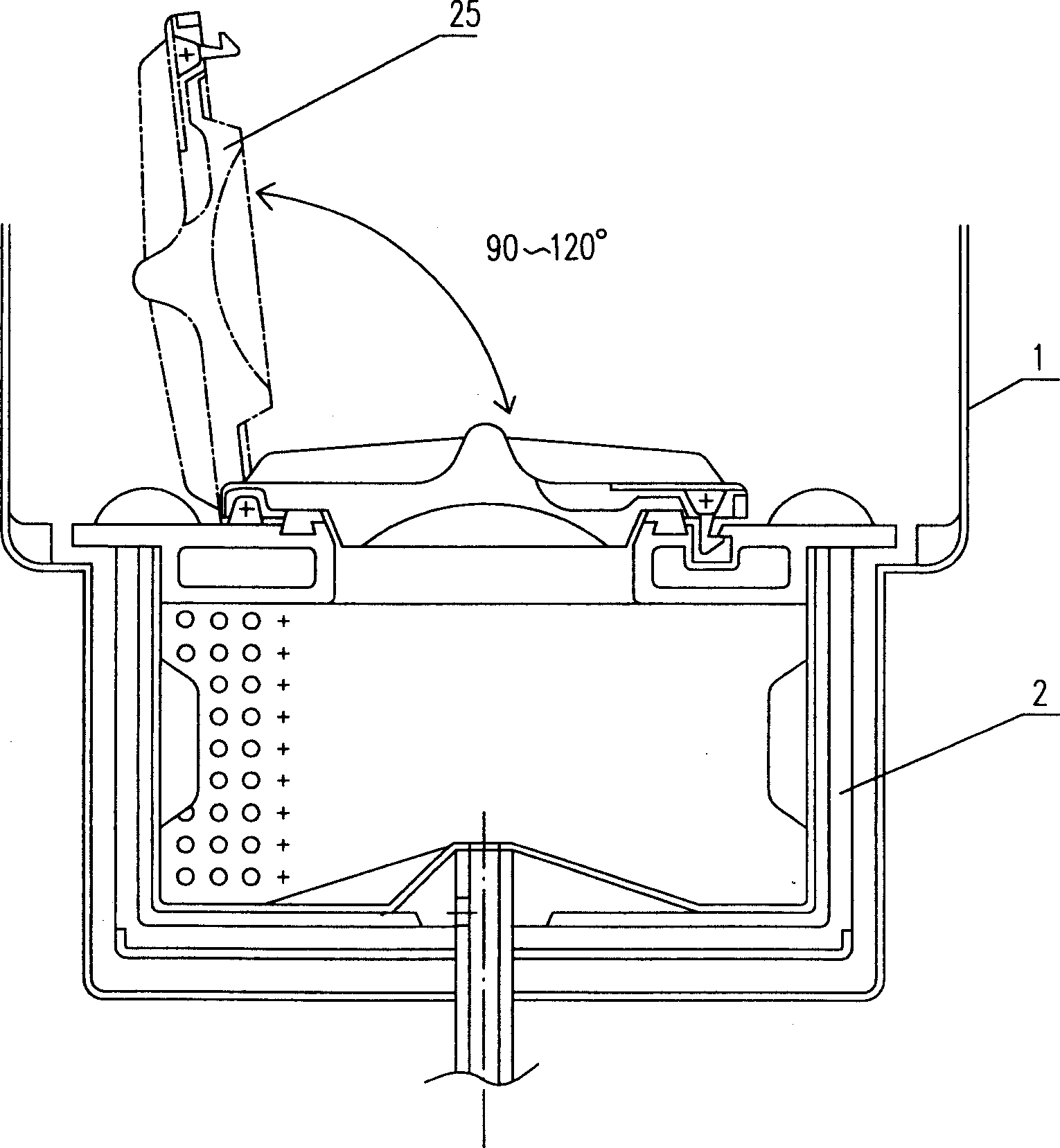

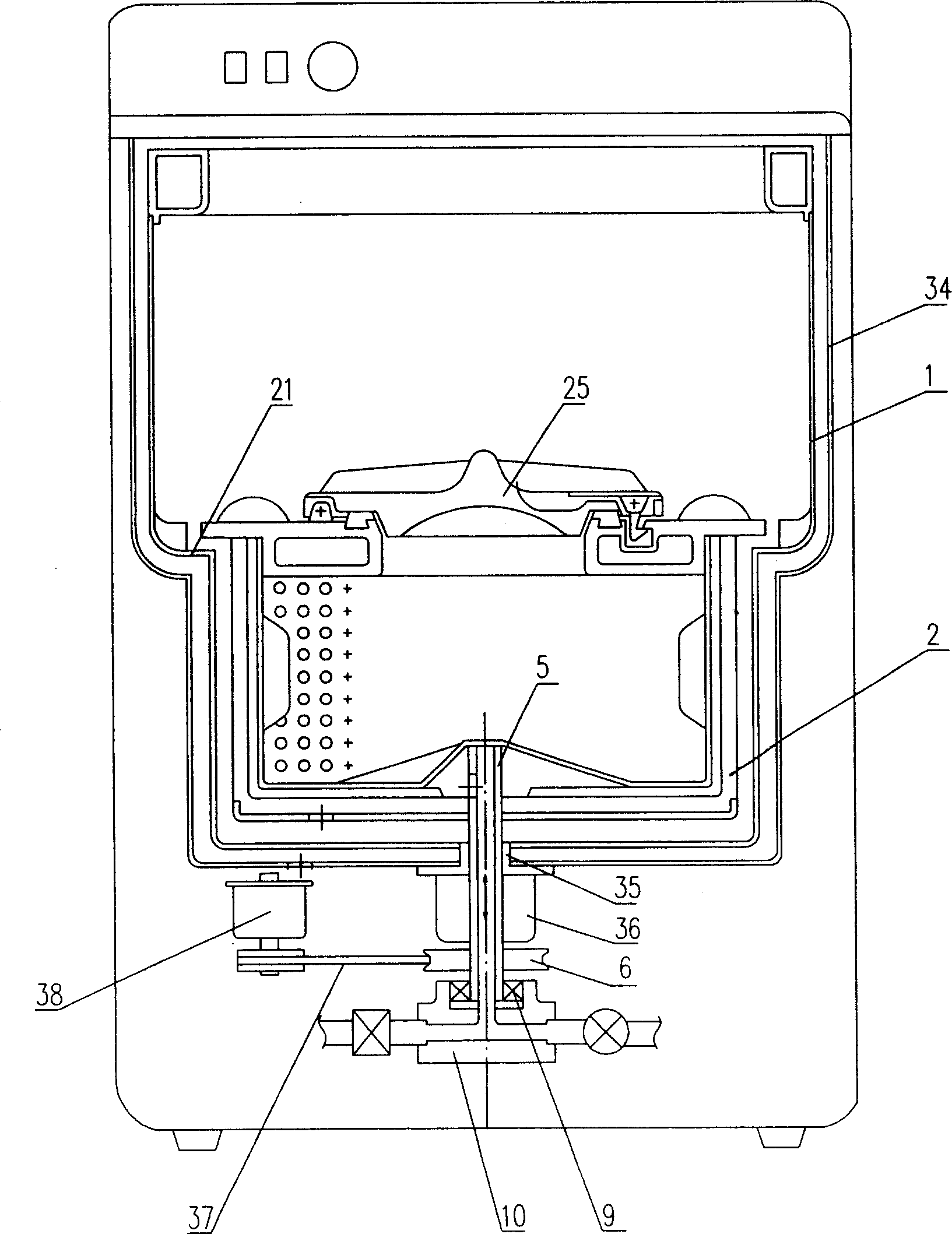

[0032] The washing machine of the present invention includes an inner tub 1, a covered agitator 2 and a water guiding device 10, the inner tub 1 can be a rotatable dehydration inner tub or a fixed washing inner tub; the covered agitator 2 can be a covered basin-shaped or bucket-shaped or Other agitators with lids and chambers; the water guiding device 10 can also be a two-hole or three-hole water guiding device. Below take the barrel agitator 2 with cover and the three-hole water guiding device 10 that matches with it as an example to illustrate as follows:

[0033] exist figure 1 Among them, the bottom of the inner barrel 1 is provided with a circle of ring-shaped boss 21 around the inner wall of the inner barrel 1 and an inner concave cavity surrounded by the annular boss, and an inner barrel drain hole 17 is provided in the bottom of the inner concave cavity. The drive shaft 5 protruding from the bottom of the inner concave cavity and protruding from its inner bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com