Nanoparticles containing organosilicon quaternary ammonium salt and preparation method and application of nanoparticles

An organosilicon quaternary ammonium salt and nanoparticle technology, which is applied in the field of nanomaterials, can solve problems such as fabric cross-coloring, etc., and achieves the effects of low cost, simple preparation, low cost, and simple wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of Nanoparticles Containing Organosilicon Quaternary Ammonium Salts

[0042] (1) Preparation of intermediate products

[0043] method one

[0044] Take 20 parts of tetraethyl orthosilicate (TEOS) and γ-chloropropyltrimethoxysilane (the molar ratio of TEOS:γ-chloropropyltrimethoxysilane is 4:3) and add 75 parts of ethanol and In a three-necked flask of a mixed solvent of isopropanol (ethanol: isopropanol mass ratio 1:1), stir at a constant speed, and then dropwise add 5 parts of glacial acetic acid with a concentration of 99.8% (the addition amount is 0.5% of the monomer mass) . After reacting at room temperature for 10 minutes, raise it to 70°C and react for 6 hours. After the reaction, filter. The obtained solid is washed with toluene and then repeatedly washed with ethanol until neutral, and then placed in a vacuum drying oven to constant weight to obtain the desired intermediate product 1 .

[0045] Method Two

[0046] Take 15 parts of meteorological...

Embodiment 2

[0051] Preparation of color-absorbing film

[0052]Get 5 parts of nanoparticles 1 that contain organosilicon quaternary ammonium salt, place 95 parts of solid content as 20% E51 (bisphenol A diglycidyl ether), then add diethylenetriamine (the mole of E51 and diethylenetriamine The ratio is 3:2), and then the non-woven fabric is soaked twice and tied twice, and the excess rate is 170%, pre-dried at 70°C for 1-3min, baked at 90°C, and 3-6min to prepare the color-absorbing sheet 1- 1.

[0053] Take 5 parts of nanoparticles 2 containing organosilicon quaternary ammonium salt, and prepare color-absorbing sheet 2-1 in the same way.

[0054] Get 10 parts of nanoparticles 1 that contain organosilicon quaternary ammonium salts, place 90 parts of solids in 20% epoxy resin aqueous emulsion E51, then add diethylenetriamine (the mol ratio of E51 to diethylenetriamine is 3: 2), and then use the non-woven fabric to dip twice and tie twice, the excess rate of tie is 165%, pre-dry at 75°C fo...

Embodiment 3

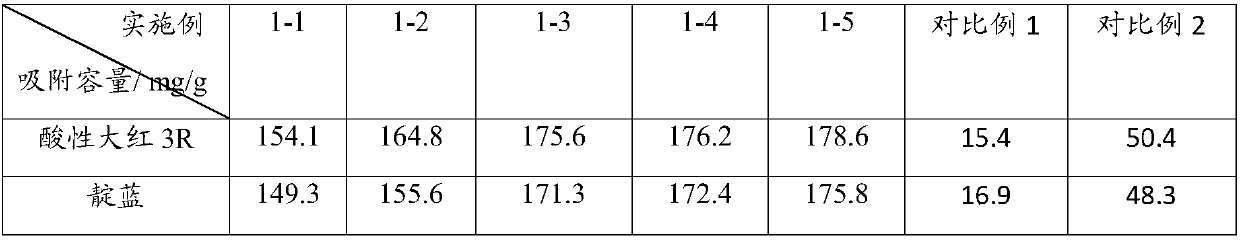

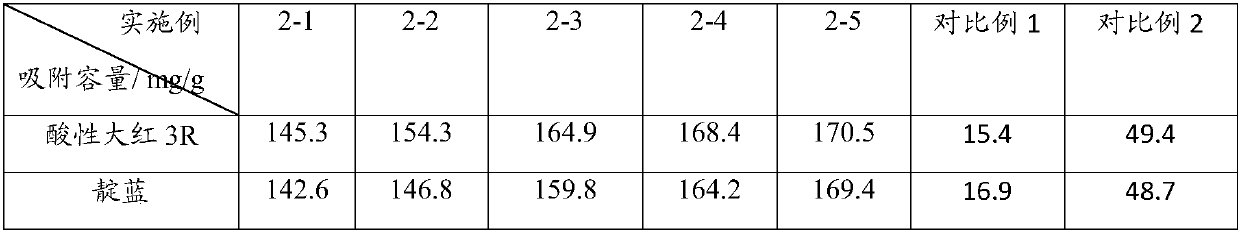

[0063] Performance Testing

[0064] 1. Test of color absorption effect

[0065] Prepare a dye aqueous solution with a concentration of 0.5g / L, simulate the stirring of a washing machine, and characterize the adsorption effect of the pigment adsorbent by visual inspection and calculation of adsorption capacity.

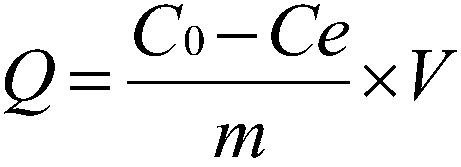

[0066] Simulated washing machine adsorption experiment and calculation of adsorption capacity:

[0067] 1) Drawing of dye solution standard curve

[0068] Prepare the dye solution into solutions of different concentrations (5mg / L, 10mg / L, 15mg / L, 20mg / L, 25mg / L), and use a UV-visible spectrophotometer to measure its absorption at the specific wavelength of the dye molecule and draw a standard curve. According to the standard curve, write the expression of the linear relationship between the dye concentration C and its absorbance A at a specific wavelength

[0069] A=a*C+b

[0070] (a: slope of standard curve, b: intercept of standard curve)

[0071] 2) Calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com