Color film substrate and display panel

A color filter substrate and display panel technology, which is applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problem that the color filter substrate cannot meet the requirements at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

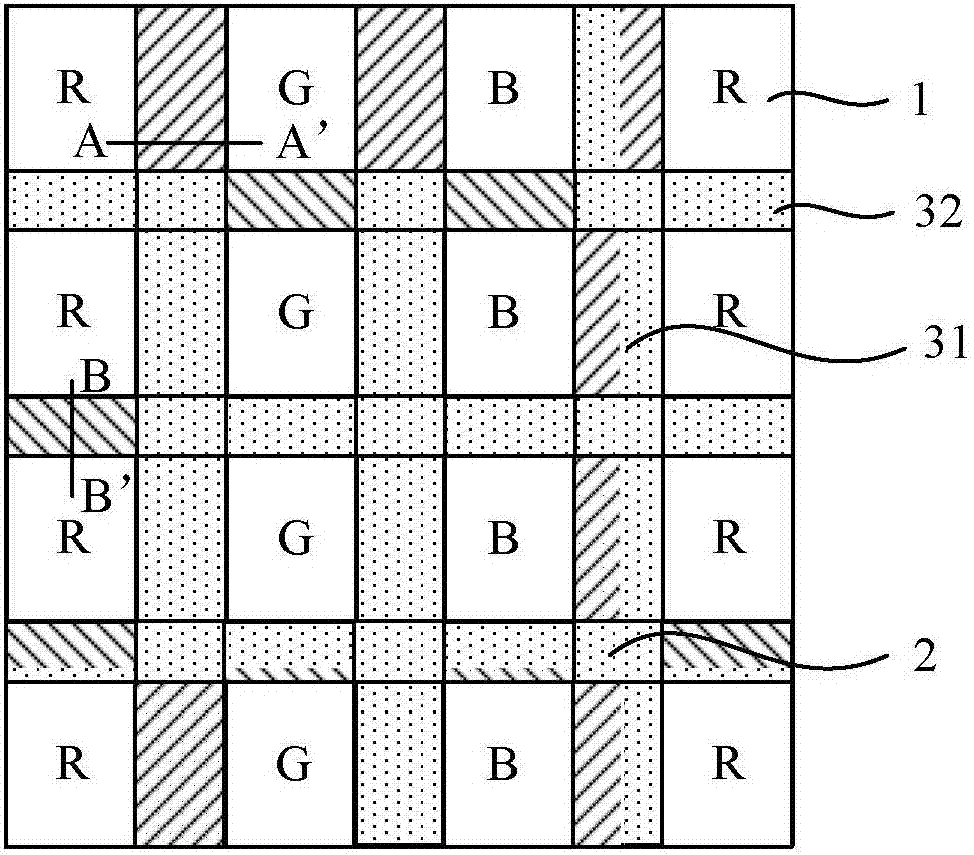

[0033] like Figure 2 to Figure 8 As shown, this embodiment provides a color filter substrate.

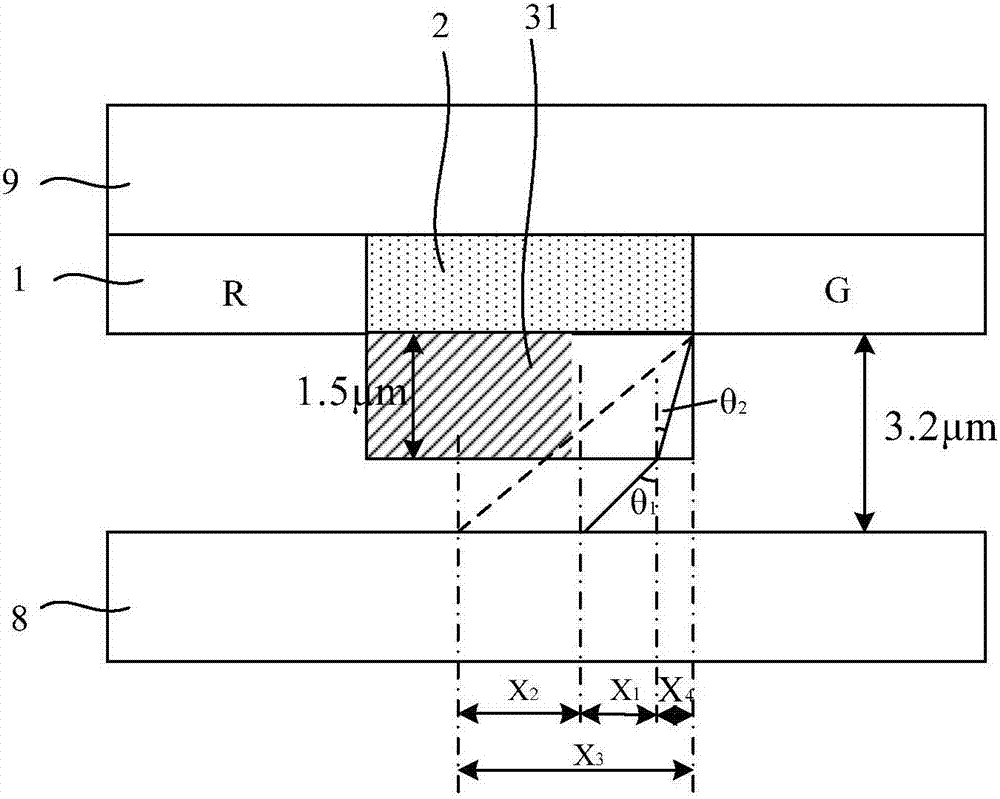

[0034] The color filter substrate is used to form a display panel (such as a liquid crystal display panel) by boxing with a box-matching substrate 8 (such as an array substrate), and an intermediate medium (such as liquid crystal) is filled in the display panel. On the side, that is, the display light is emitted from the display panel after passing through the color filter substrate.

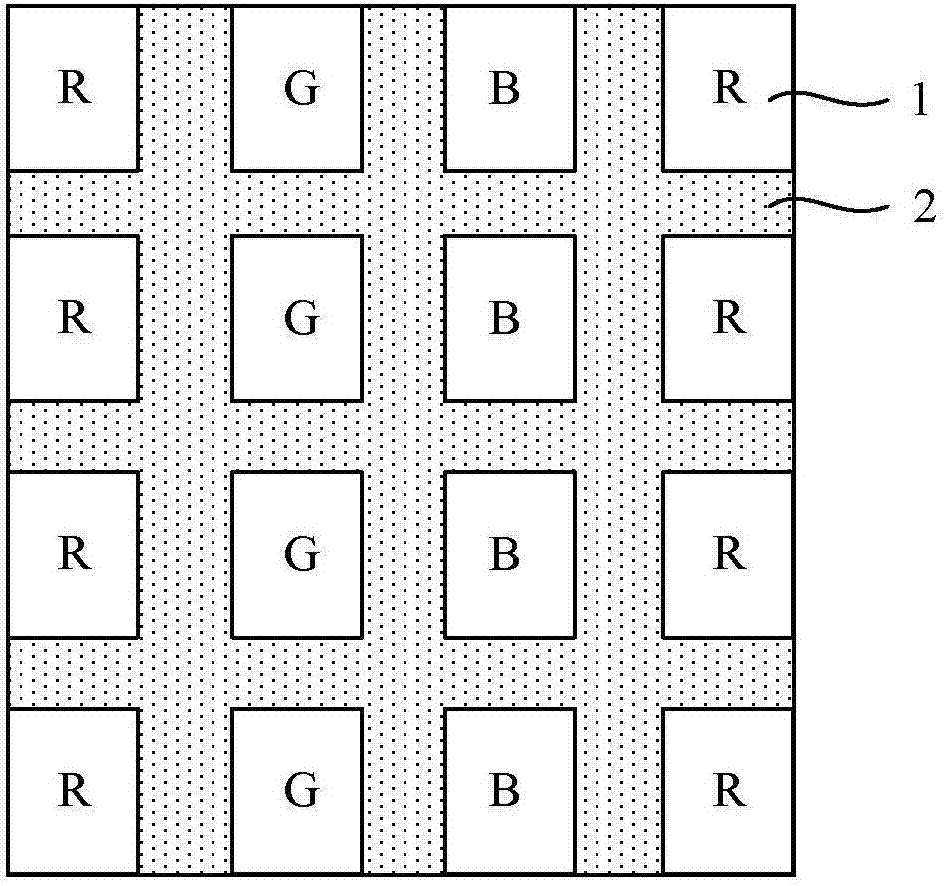

[0035] The color filter substrate of this embodiment includes a base 9 on which a plurality of spaced color filter films 1 are provided, and a black matrix 2 is provided between adjacent color filter films 1 .

[0036] like figure 2 As shown, a plurality of color filter films 1 are arranged on the base 9 of the color filter substrate, and each color filter film 1 corresponds to a pixel and has the same color as the pixel corresponding to it; There is a gap between them, and a black matrix 2 for b...

Embodiment 2

[0065] like Figure 2 to Figure 8 As shown, this embodiment provides a display panel, which includes:

[0066] The box matching substrate 8 and the color filter substrate that are boxed together, the color filter substrate is the above-mentioned color filter substrate and is located on the light emitting side of the display panel;

[0067] An intermediate medium is filled between the cell substrate 8 and the color filter substrate.

[0068] That is to say, the above color filter substrate can be combined with another substrate to form a display panel, and the display panel is filled with the above-mentioned intermediate medium, so that each transparent layer can function.

[0069] Of course, it should be understood that the color filter substrate should be located at the light emitting side of the display panel at this time.

[0070] Preferably, the display panel is a liquid crystal display panel; the cell-to-cell substrate 8 is an array substrate; and the intermediate mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com