Anti-cross color dyeing laundry sheet, preparation method and use method thereof

The technology of laundry sheet and control panel is applied in the field of anti-cross-dye laundry sheet and its preparation, which can solve the problems of inability to realize intelligent life, inconvenience for users in the use process, adhesion of the outer packaging of the laundry sheet, etc., so as to improve the quality of life and save money. Time, moderate foam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

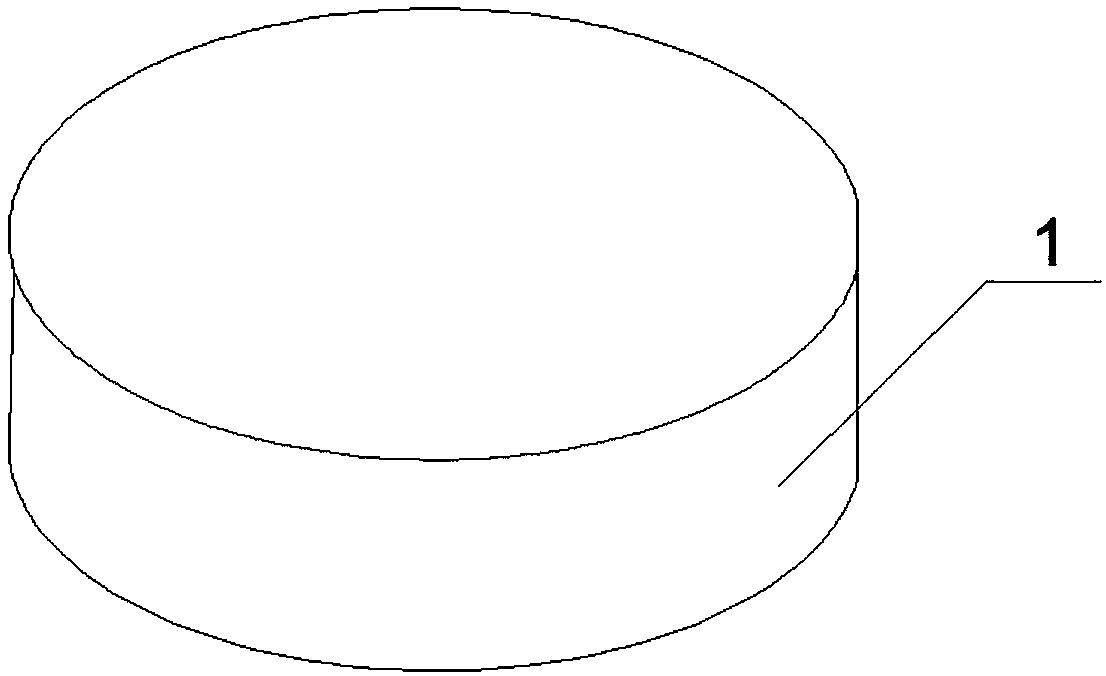

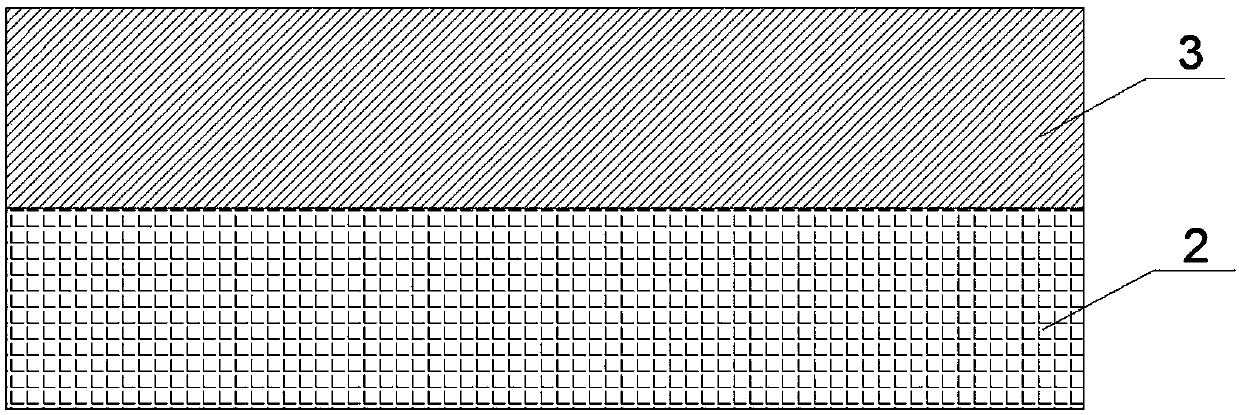

[0042] refer to figure 1 , figure 2 , an anti-cross-dyeing laundry sheet, the laundry sheet is a product in the shape of a compressed towel, the laundry sheet 1 includes a color-absorbing layer 2 and a laundry layer 3 arranged inside the color-absorbing layer, and the color-absorbing layer includes a cationic modification permanent spunlace non-woven fabric, the fiber composition of the spunlace non-woven fabric is a mixture of viscose fiber and polypropylene fiber in a certain proportion, the viscose fiber is a cationic modified fiber, the viscose fiber and polypropylene fiber The mass ratio is 3:1; the viscose fiber is a fiber material regenerated from wood pulp or cotton pulp, and the laundry layer 3 is arranged on the color-absorbing layer 2 by one-side coating.

[0043] In parts by weight, the laundry ingredients of the laundry layer are: 0.05-0.2 parts of EDTA-2NA, 0.05-0.2 parts of Cathone, 8-14 parts of sodium dodecylbenzenesulfonate, 6-10 parts of AOS, 3 parts of LA...

Embodiment 2

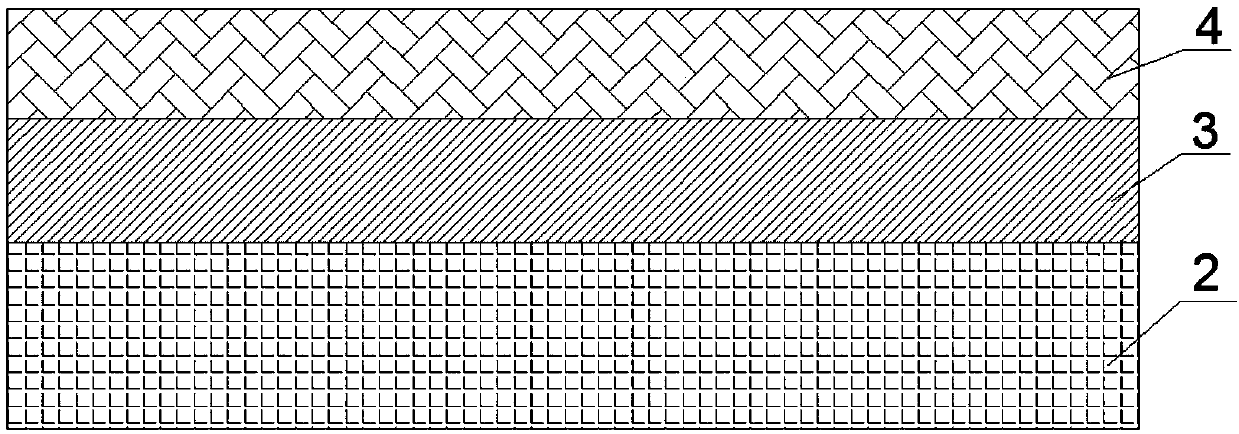

[0045] refer to figure 1 , image 3 , an anti-cross-staining laundry sheet, and others are as described in Example 1, the inside of the laundry layer 3 is laid with an active enzyme layer 4, which can further improve the washing effect.

Embodiment 3

[0047] A preparation method of anti-cross-dyeing laundry sheet, using organically active ion modifier as raw material, carrying out cationic modification on spunlace non-woven fabric, and then applying laundry ingredients (applying detergent) to make anti-cross-staining Laundry tablets, the process is as follows:

[0048] Spunlaced non-woven fabric processing→corona treatment→ion modification→applying detergent→drying slices

[0049] Specifically include the following steps:

[0050] (1) After mixing viscose fiber and polypropylene fiber in proportion, they are opened, mixed, carded, laid,

[0051] The process of high-pressure spunlace entanglement, drying, and rolling makes the fibers into spunlace non-woven fabrics that are tightly entangled and have a microporous structure;

[0052] The optimization of the mass ratio of viscose fiber to polypropylene fiber is shown in Table 1:

[0053] Table 1

[0054]

[0055] (2) Using spunlace non-woven fabric as the basic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com