Wolframite tailing discarding and refining beneficiation method

A beneficiation method and black tungsten ore technology, applied in chemical instruments and methods, wet separation, magnetic separation, etc., can solve the problems of low labor operation efficiency and high labor cost, and achieve the goals of easy operation, reduced energy consumption, and lightened burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

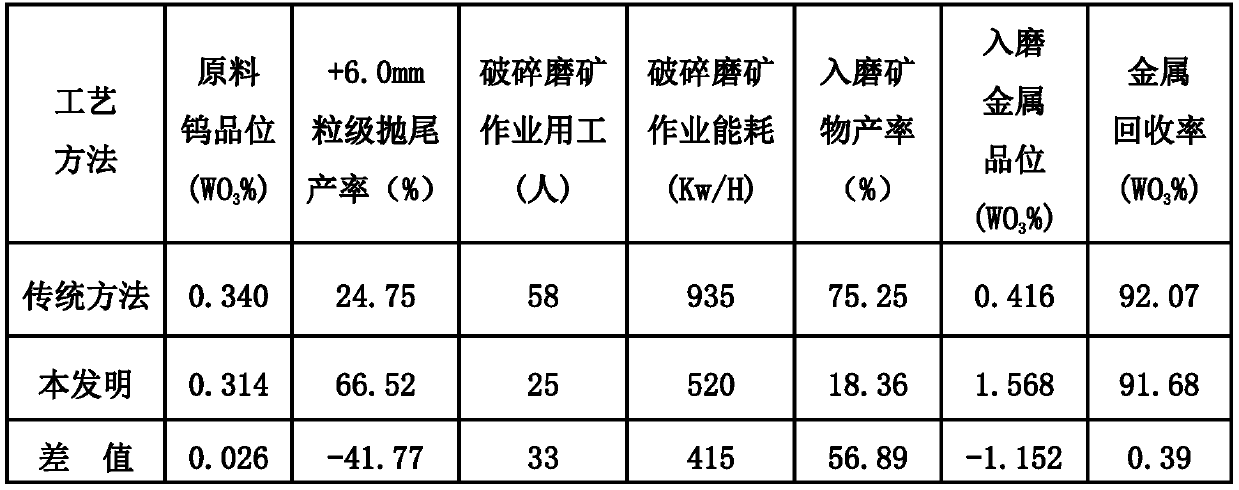

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the technical solutions in the specific embodiments of the present invention will be described clearly and completely below to further illustrate the present invention. Obviously, the described specific implementations The modes are only a part of the embodiments of the present invention, rather than all modes.

[0024] This specific embodiment is to use the wolframite throwing tailings and beneficiation scheme created by the present invention to sort wolframite in a wolframite mine in the south. The wolframite mine processes 2000 tons of wolframite ore per day, and the raw ore tungsten The grade is about 0.31%, the specific steps are:

[0025] A. Crushing-classification operation; the size of wolframite raw ore is 0-350mm, after a jaw crusher crushing operation, the raw ore of -50mm size wolframite is obtained, and then the ore is washed and classifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com