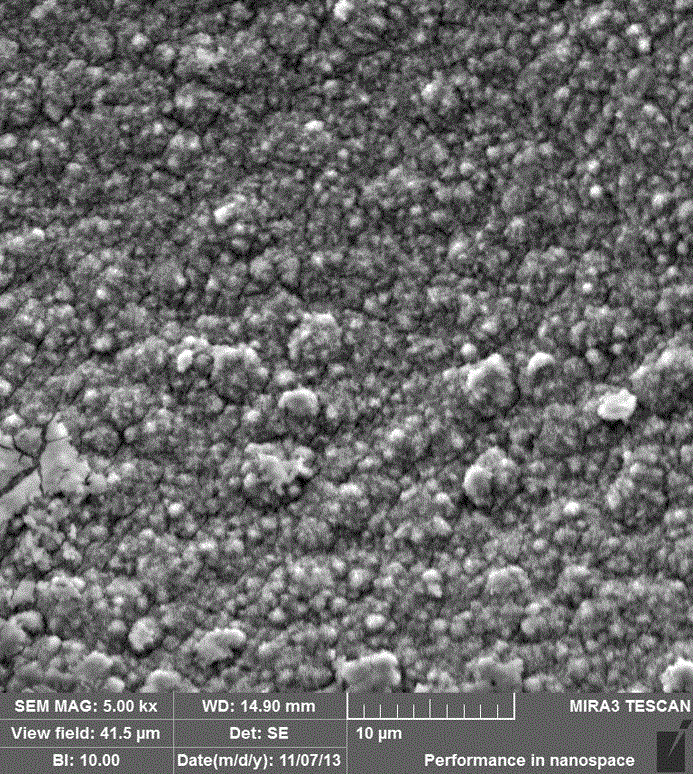

Patents

Literature

40results about How to "Increase contact reaction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

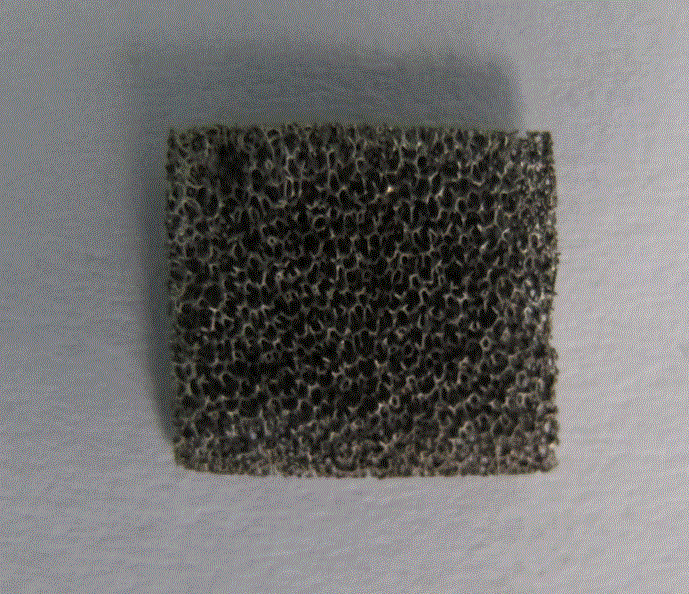

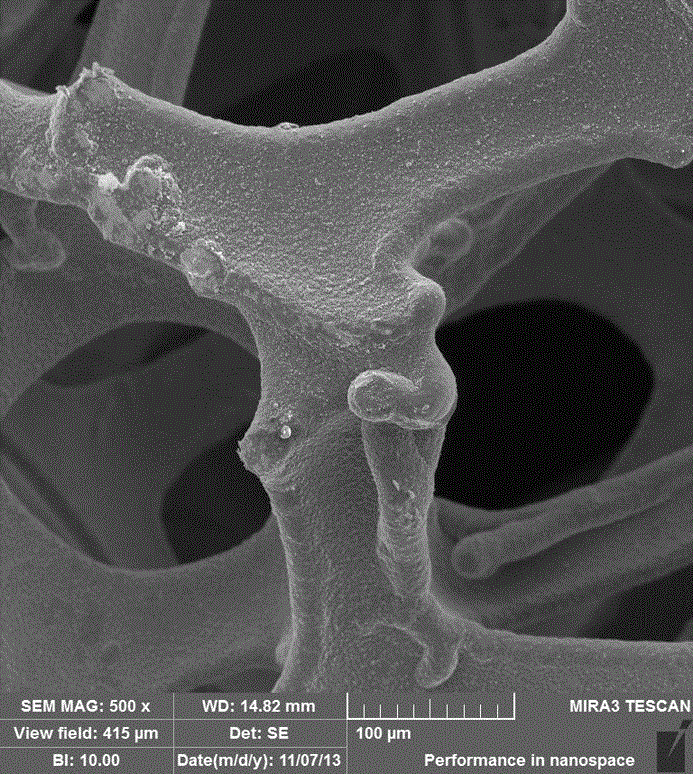

Composite hydrogen evolution electrode with copper and cobalt loaded on three-dimensional foamed nickel and preparation method thereof

ActiveCN103924260AIncrease contact reaction areaReduce hydrogen evolution overpotentialElectrode shape/formsCopperCobalt

The invention relates to a hydrogen evolution electrode with copper and cobalt loaded on three-dimensional foamed nickel, which can be used for an electro-catalysis hydrogen evolution reaction in alkaline solution and is capable of simultaneously loading base metals and a preparation method thereof, and belongs to the technical fields of material science and hydrogen production by electro-catalysis. The technical problem to be solved is to provide the composite hydrogen evolution electrode with copper and cobalt loaded on three-dimensional foamed nickel and a preparation method thereof. A method of plating a composite coating on an electro-mechanical surface is adopted, and copper and cobalt are electro-plated on the three-dimensional foamed nickel in sequence, so that the composite hydrogen evolution electrode is prepared. The prepared electrode has high catalytic activity, is non-toxic, and can keep stable structure and chemical activity under an alkaline condition. In addition, the preparation process of the composite hydrogen evolution electrode is simple, and is suitable for large-scale production.

Owner:TAIYUAN UNIV OF TECH

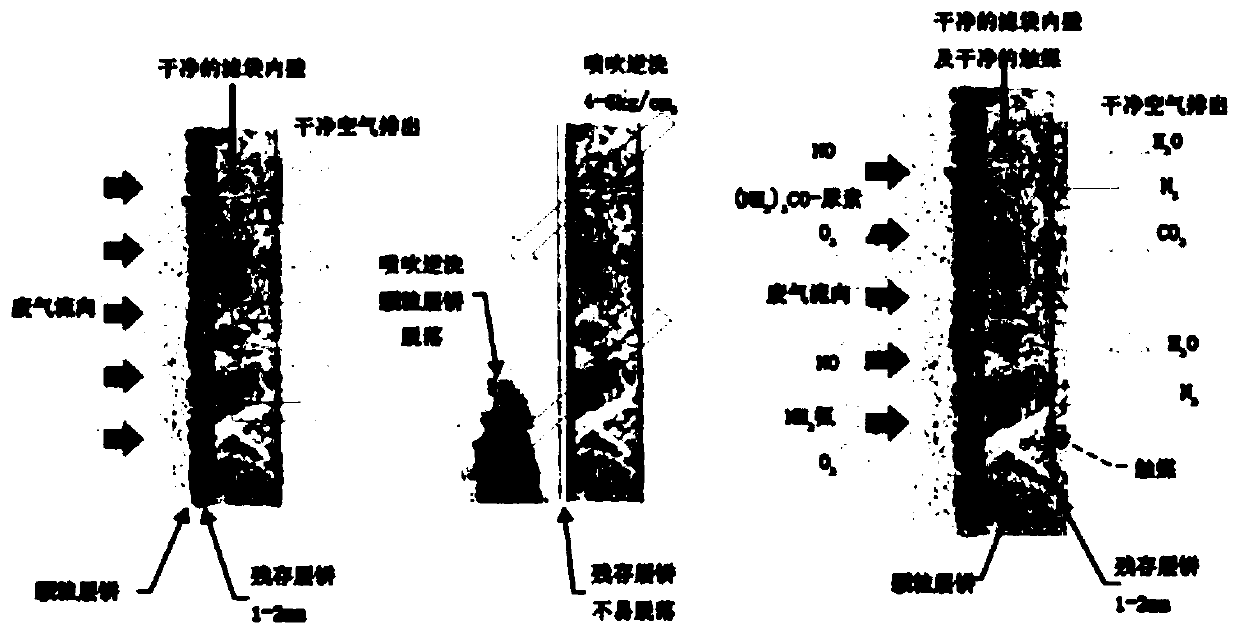

Membrane process dust collection desulfurizer and semi-dry type membrane dust collection desulphurization method

ActiveCN104174278AIncrease contact reaction areaIncreased drift contact timeAuxillary pretreatmentChemistryElectronegativity

The invention discloses a membrane process dust collection desulfurizer and a semi-dry type membrane dust collection desulphurization method. The membrane process dust collection desulfurizer comprises the following components in percentage by mass: 2.5-25% of an electronegativity membrane forming agent, 2.5-25% of a foaming agent and 50-95% of a desulfurizer; the components are uniformly mixed to prepare the membrane process dust collection desulfurizer. The invention also discloses a desulphurization method by using the membrane process dust collection desulfurizer. The membrane process dust collection desulfurizer is wide in raw material source, and simple and convenient to produce; the semi-dry type membrane dust collection desulphurization method is low in equipment investment or technological upgrading investment, simple to operate and good in adaptability.

Owner:长沙紫宸科技开发有限公司

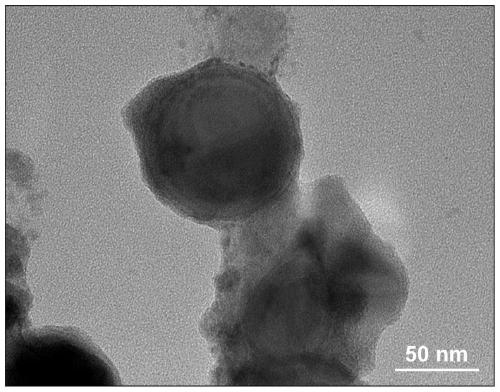

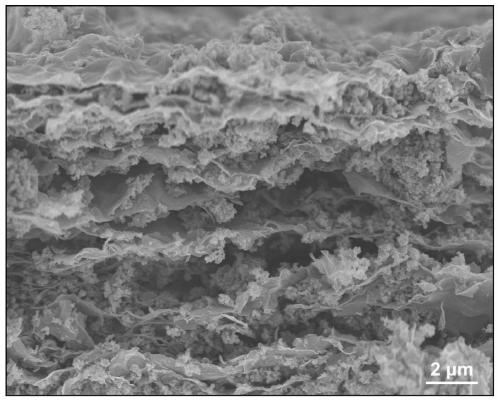

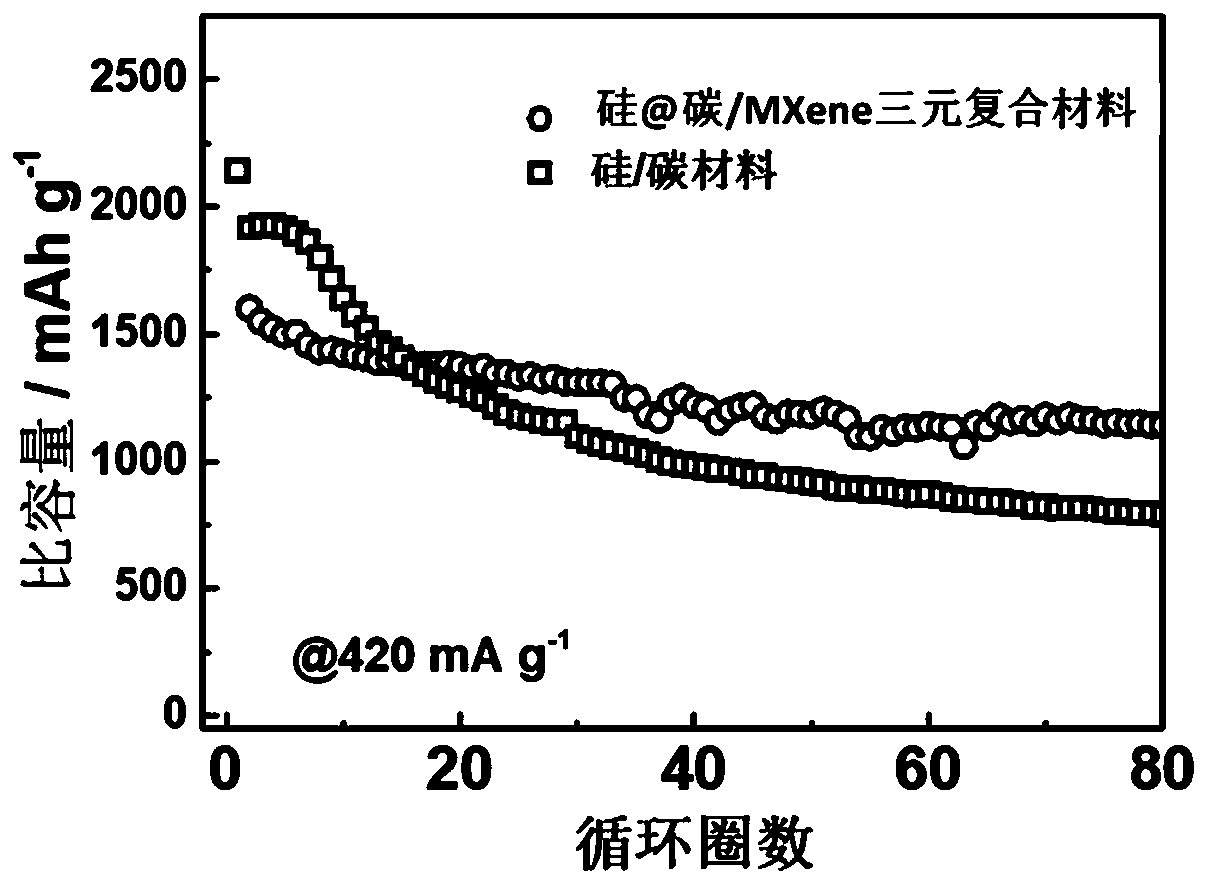

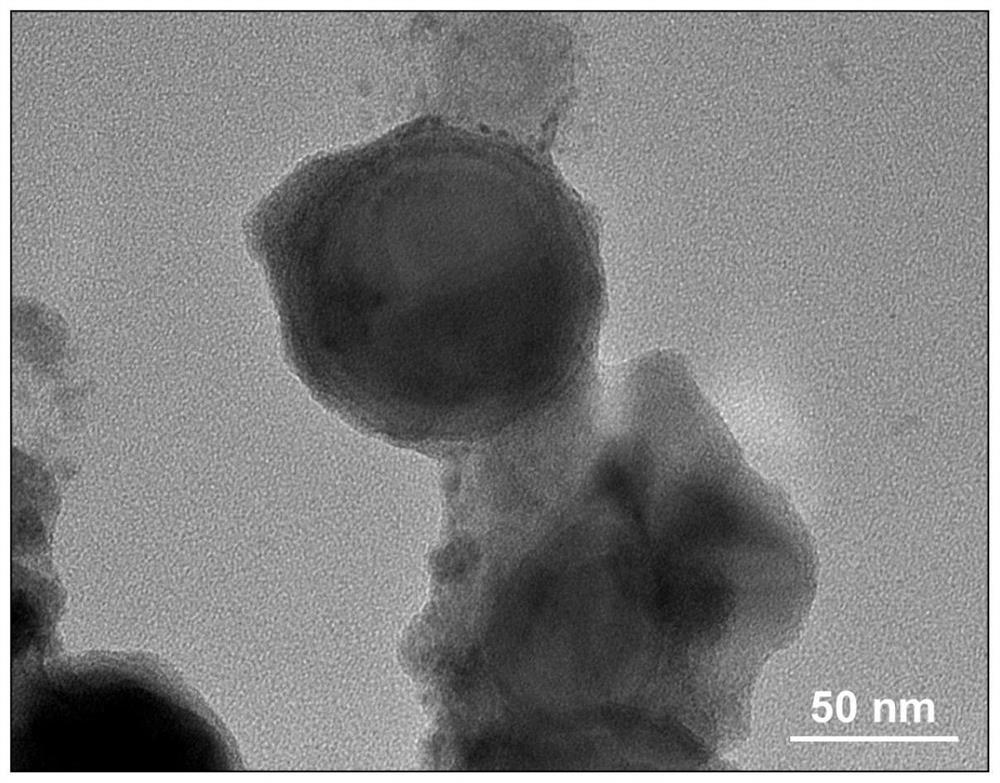

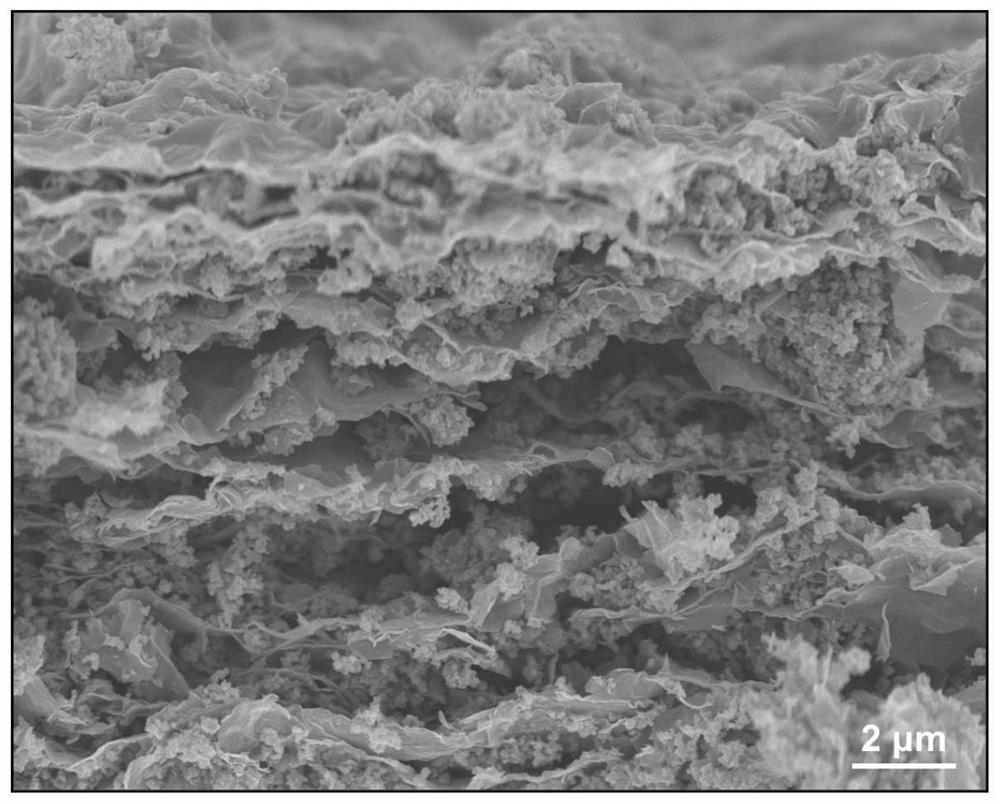

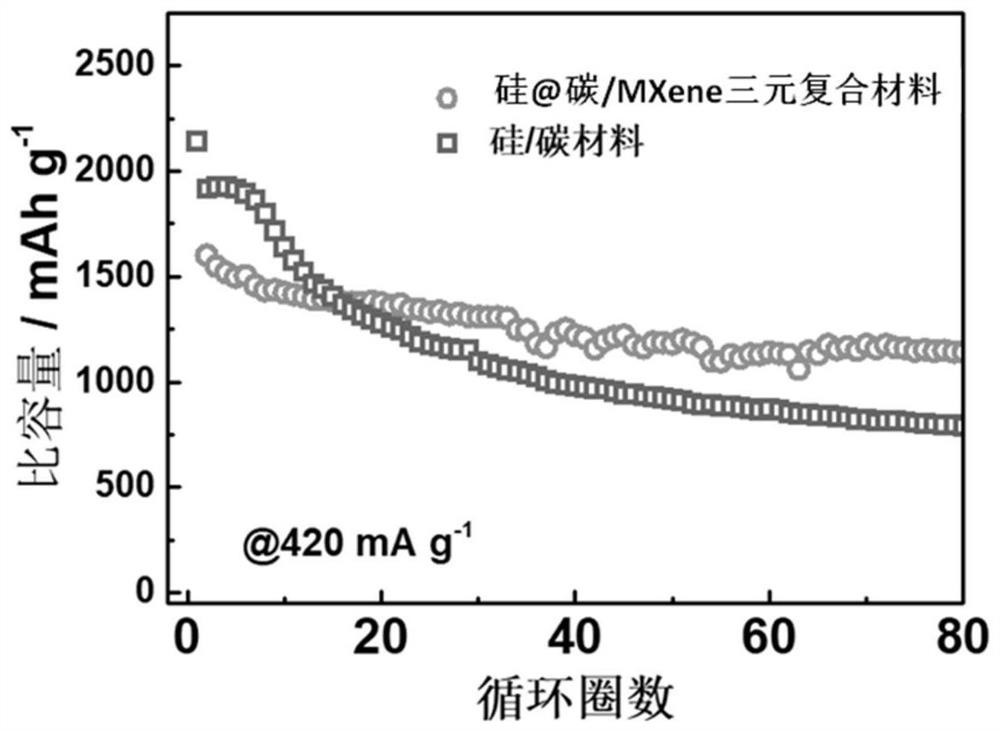

Silicon@carbon/MXene ternary composite material for lithium ion battery and preparation method of silicon@carbon/MXene ternary composite material

ActiveCN111384381AImprove conductivityImproved high current rate performanceSecondary cellsNegative electrodesCarbon coatingElectrical battery

The invention relates to the field of lithium ion battery negative electrode materials, and discloses a silicon@carbon / MXene ternary composite material for a lithium ion battery and a preparation method of the silicon@carbon / MXene ternary composite material. The silicon@carbon / MXene ternary composite material is prepared by the following steps: carrying out dopamine hydrochloride self-polymerization reaction on a silicon material on the surface of the silicon material to form a polydopamine layer, carrying out liquid-phase mixing and crosslinking on the polydopamine layer and MXene, and carrying out high-temperature treatment. According to the method, secondary amino of polydopamine on the surface of the silicon material and hydroxyl on the surface of MXene can be subjected to a cross-linking reaction to form a covalent bond or a hydrogen bond, so the agglomeration phenomenon of the silicon material and MXene is inhibited, and the electrochemical performance of the silicon material isimproved; the size of the silicon material is 20-500 nm, the thickness of the carbon coating layer is 3-10 nm, and the mass ratio of silicon to MXene is (0.5-4): 1. The pore volume of the obtained silicon@carbon / MXene ternary composite material is 0.05-0.3 cm<3> / g, and the specific surface area is 60-120 m<2> / g. The silicon@carbon / MXene ternary composite material is used as a negative electrode material of a lithium ion battery, and shows excellent cycle performance and rate capability.

Owner:BEIJING UNIV OF CHEM TECH

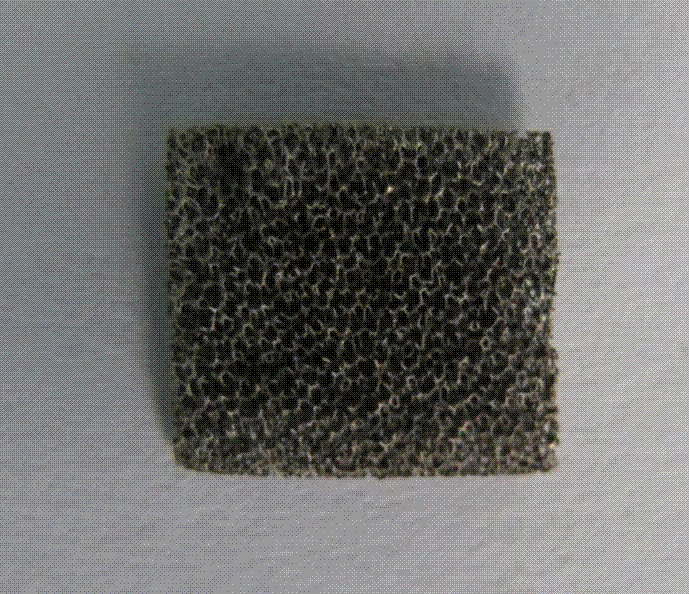

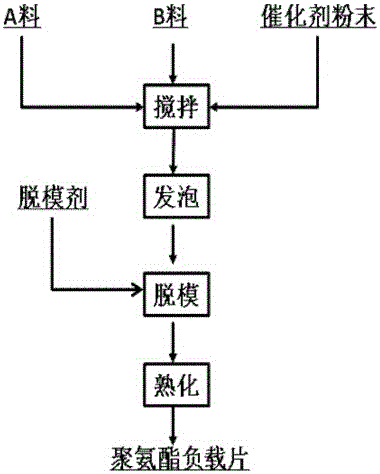

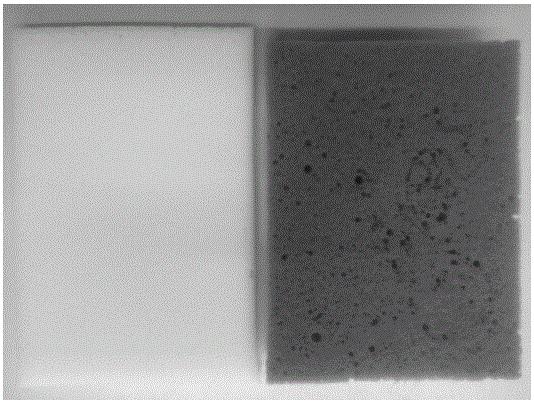

Polyurethane foam air-purification filter screen and preparation method thereof

InactiveCN105797578ALarge specific surface areaImprove purification efficiencyDispersed particle filtrationAir purificationChemistry

The invention relates to a polyurethane foam air-purification filter screen and a preparation method thereof. Polyurethane foam air-purification filter screen with simple synthetic process, firm loading, large specific surface area and high purifying efficiency and the preparation method thereof do not exist in the market at present. The polyurethane foam air-purification filter screen provided by the invention comprises air-purification material powder and is characterized by further comprising polyurethane foam, wherein the air-purification material powder is uniformly fixed in the polyurethane foam. The preparation method provided by the invention comprises the following steps: mixing material A, material B and the air-purification material powder, and then quickly and uniformly stirring and waiting for foaming; at the beginning of foaming trend, putting into a mold, foaming and forming; curing for 3-48 hours, thereby acquiring the polyurethane foam air-purification filter screen with the air-purification material powder uniformly distributed in the polyurethane foam, wherein the material A is used for preparing the polyurethane foam and the material B is polyisocyanate. The polyurethane foam air-purification filter screen has the advantages of simple synthetic process, firm load, large specific surface area, high purification efficiency and small wind resistance.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

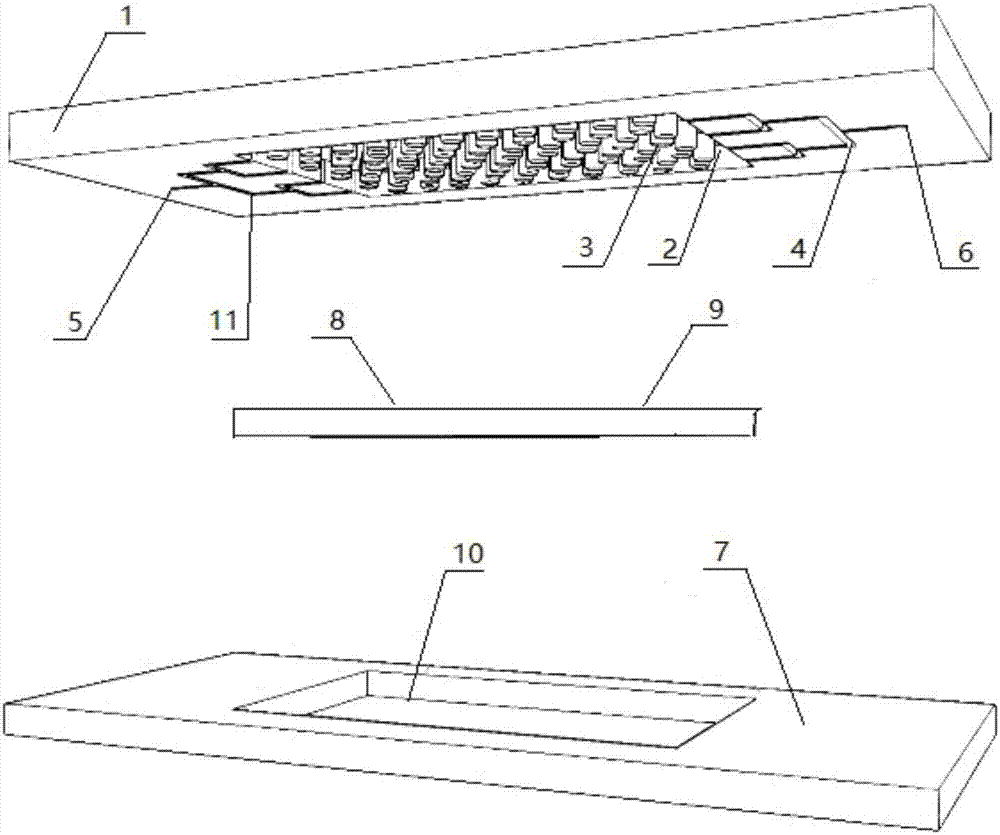

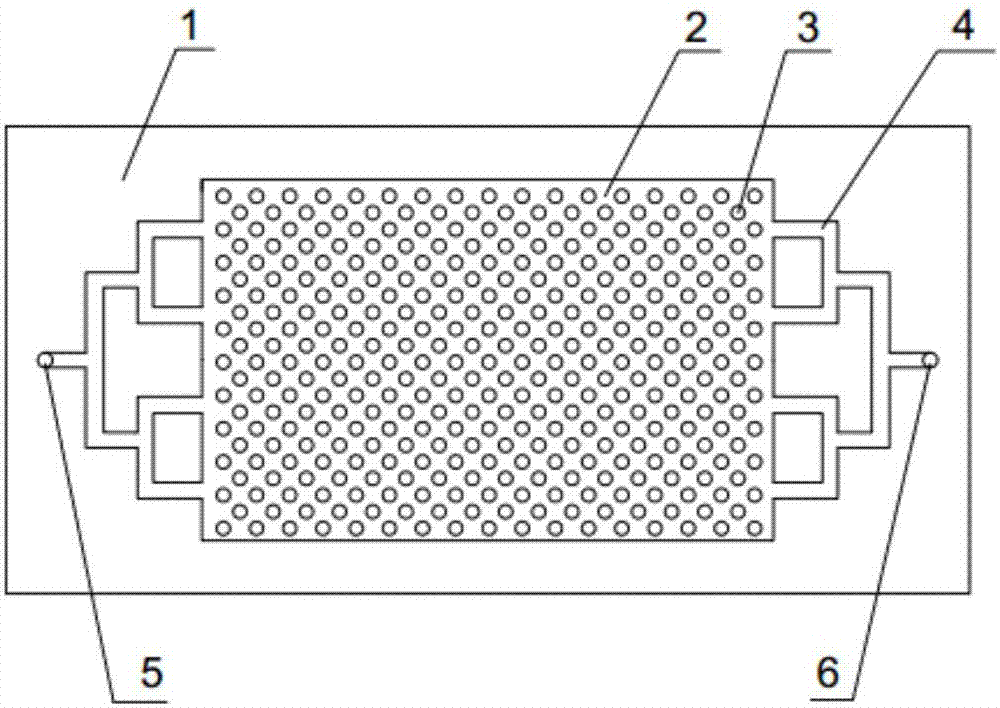

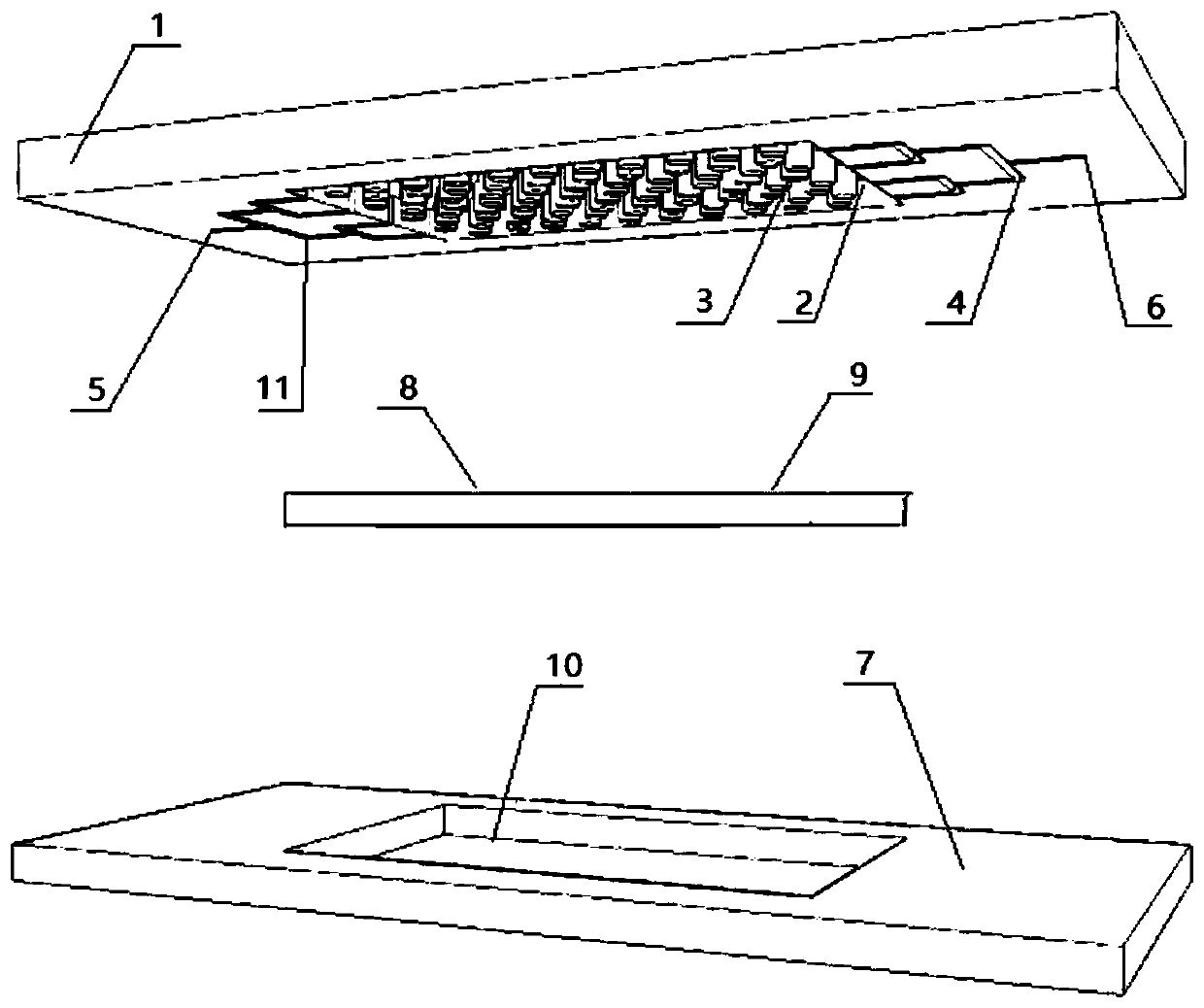

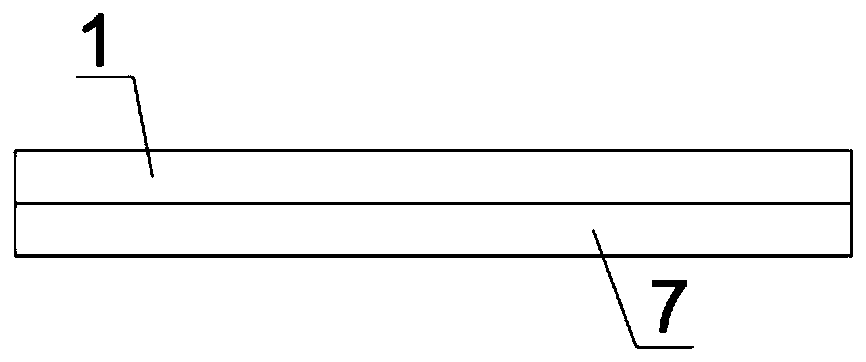

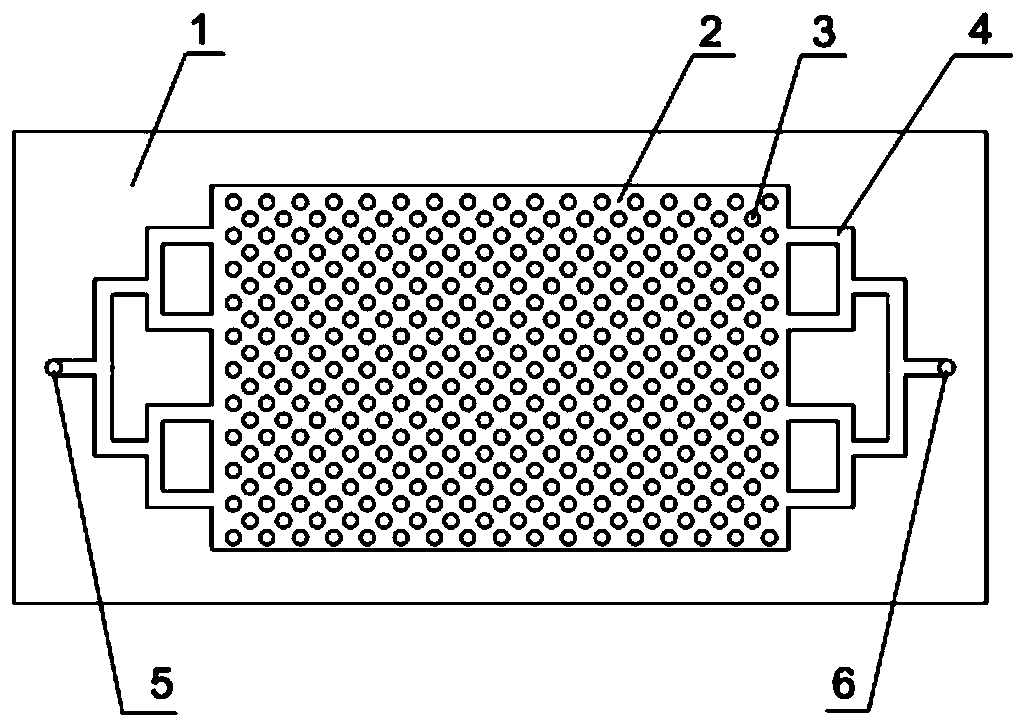

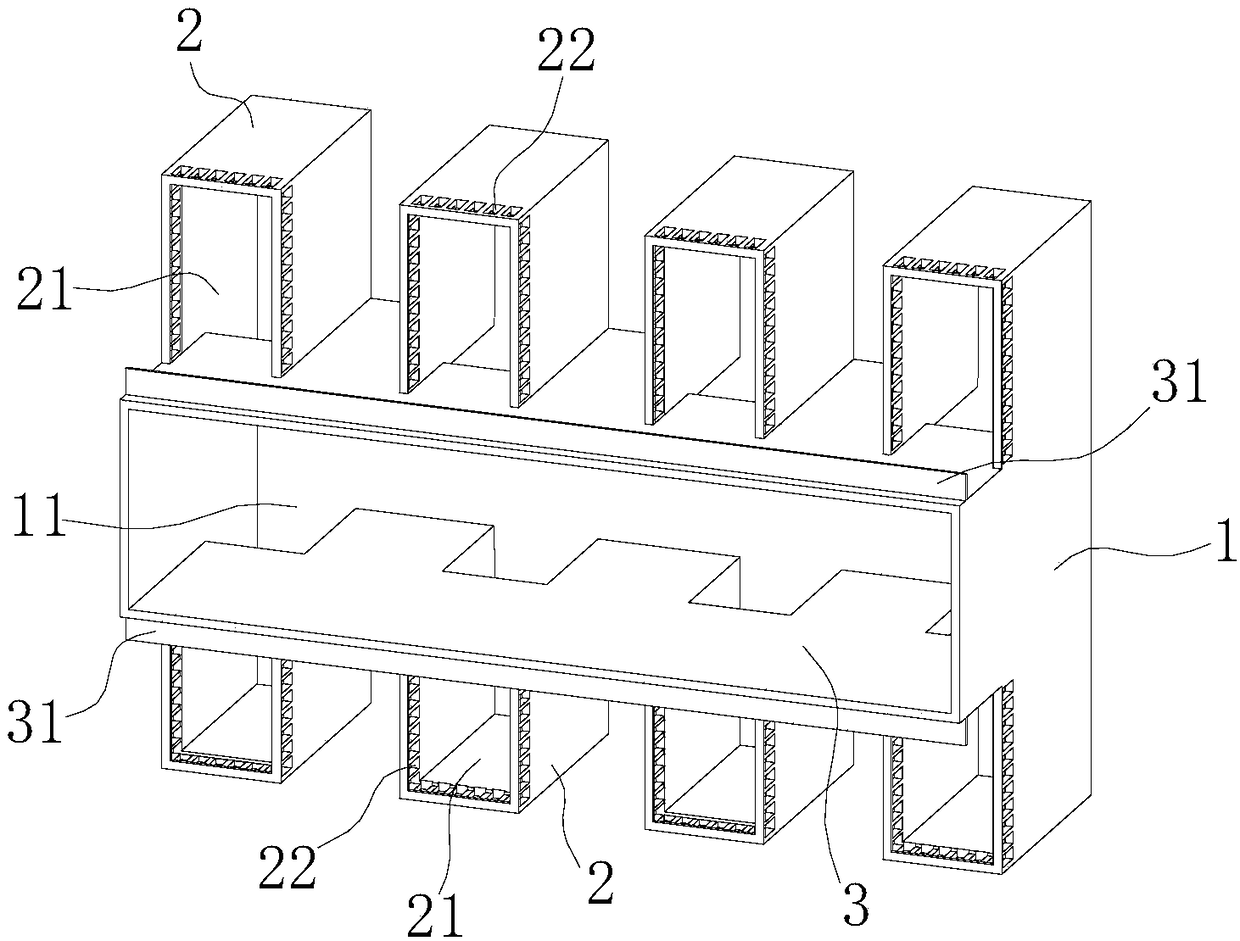

Efficient photo-catalytic reactor

ActiveCN107376799AImprove flow characteristicsImprove transmission characteristicsChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesPhoto catalyticPhotocatalytic reaction

The invention discloses an efficient photo-catalytic reactor which comprises an upper cover plate and a base. The upper cover plate is arranged on the base, the efficient photo-catalytic reactor is characterized in that a first rectangular concave plane is formed in the upper end surface of the base, conducting glass is placed in the first rectangular concave plane, and a photocatalyst is arranged on the upper surface of the conducting glass; the photocatalyst is a nanorod array thin film photocatalyst; a second rectangular concave plane is formed in the lower end surface of the upper cover plate and corresponds to the first rectangular concave plane in position; an inverted micro boss array is arranged in the second rectangular concave plane; the upper cover plate is provided with a fluid inlet and a fluid outlet, and the fluid inlet and the fluid outlet communicate with the second rectangular concave plane through micro fluid input channels and micro fluid output channels correspondingly; and the micro fluid input channels and the micro fluid output channels are formed in the upper cover plate. The efficient photo-catalytic reactor provided by the invention is simple in structure, easy to mount, low in cost, high in reaction efficiency and capable of being widely applied to the fields of energy, environment protection and the like.

Owner:CHONGQING UNIV

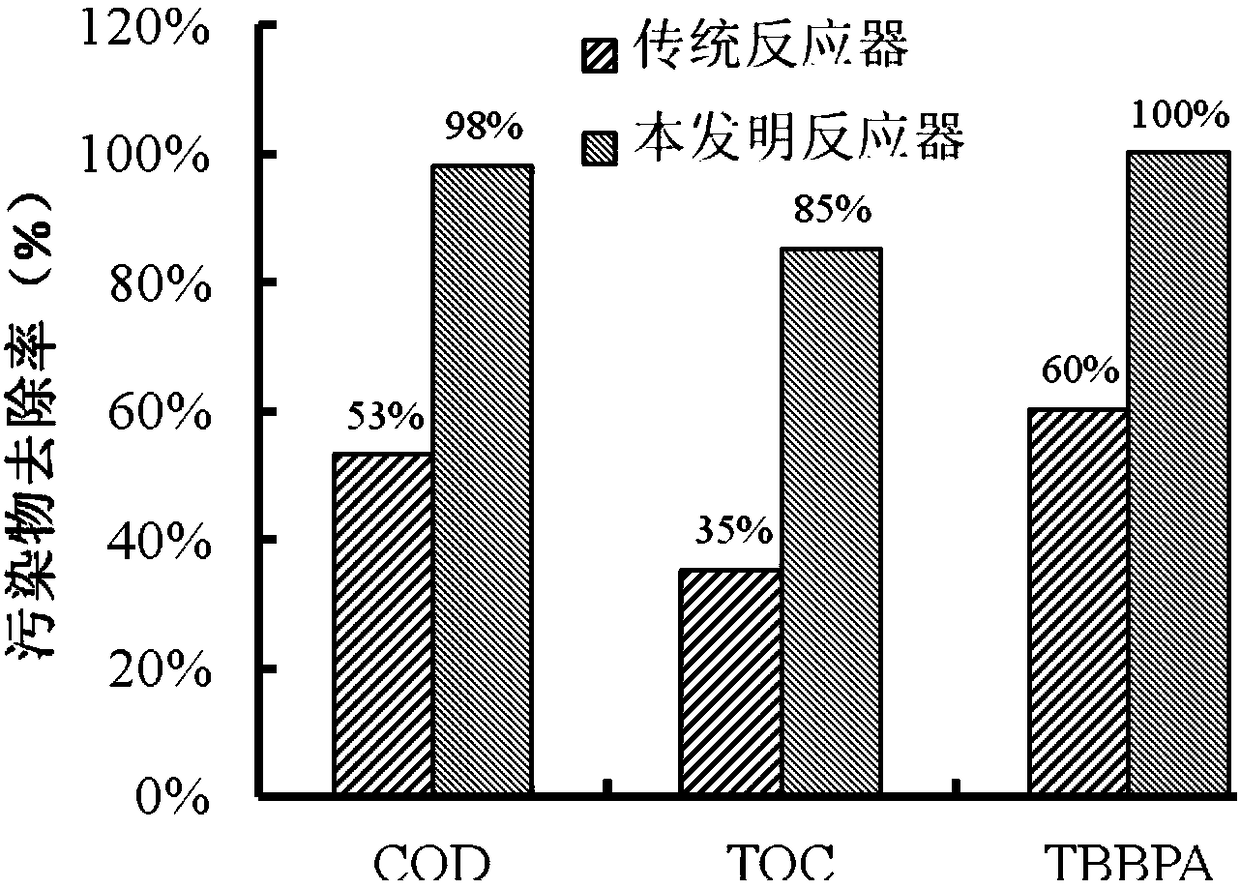

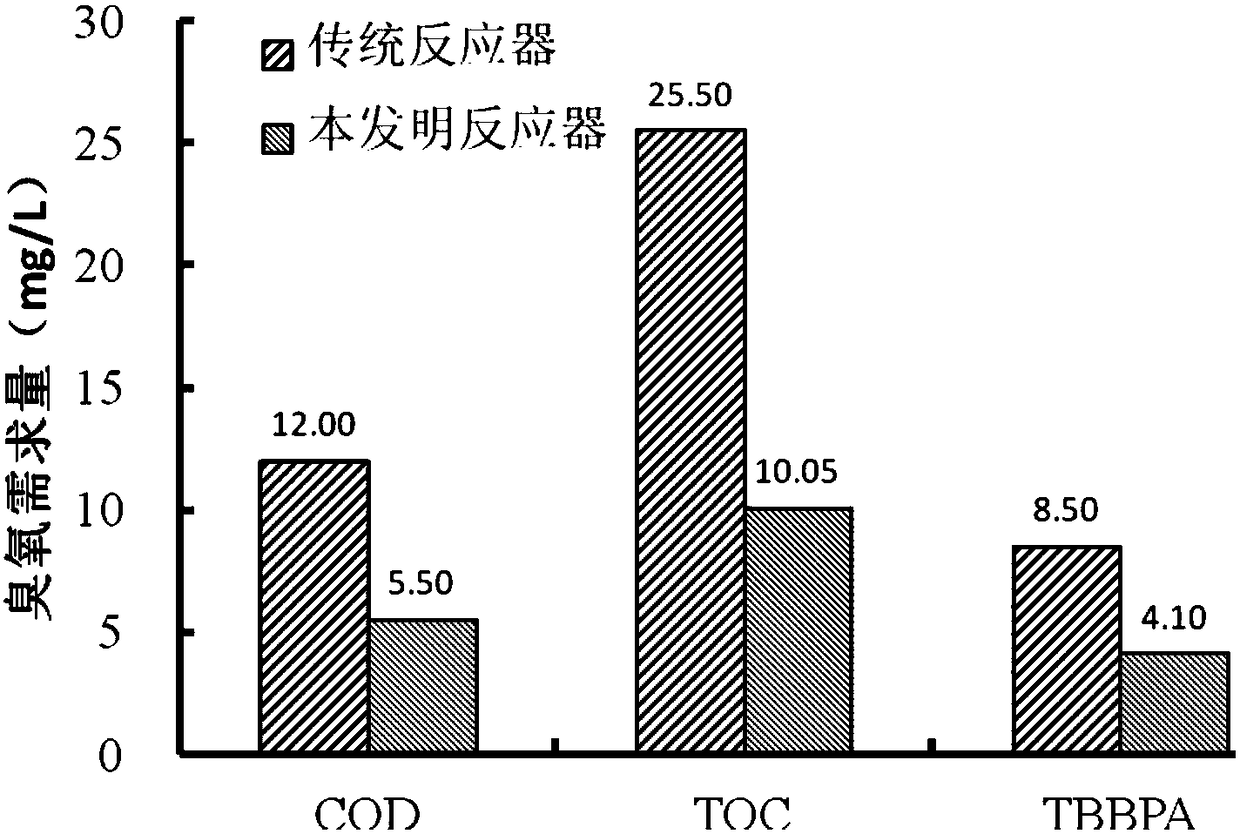

Ozone catalytic oxidation stirring reactor and sewage treatment method

PendingCN108557985AImprove mass transfer efficiencyIncrease profitWater contaminantsWater/sewage treatment apparatusActivated carbonCatalytic oxidation

The invention belongs to the field of organic chemical wastewater treatment, and in particular relates to a novel high-efficiency ozone catalytic oxidation stirring reactor which is obtained by reforming the traditional ozone reactor and is used for treating chemical wastewater. By reforming the internal structure of the ozone reactor (such as arranging a guide cylinder and additionally arranginga stirring device), the ozone residence time is prolonged; furthermore, ozone is combined with a catalytic packing loaded with activated carbon and nano-iron (a mixture of nano zero-valent iron and nano iron oxide) for use, so that the ozone utilization rate is improved, and the process energy consumption and the treatment cost are reduced.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

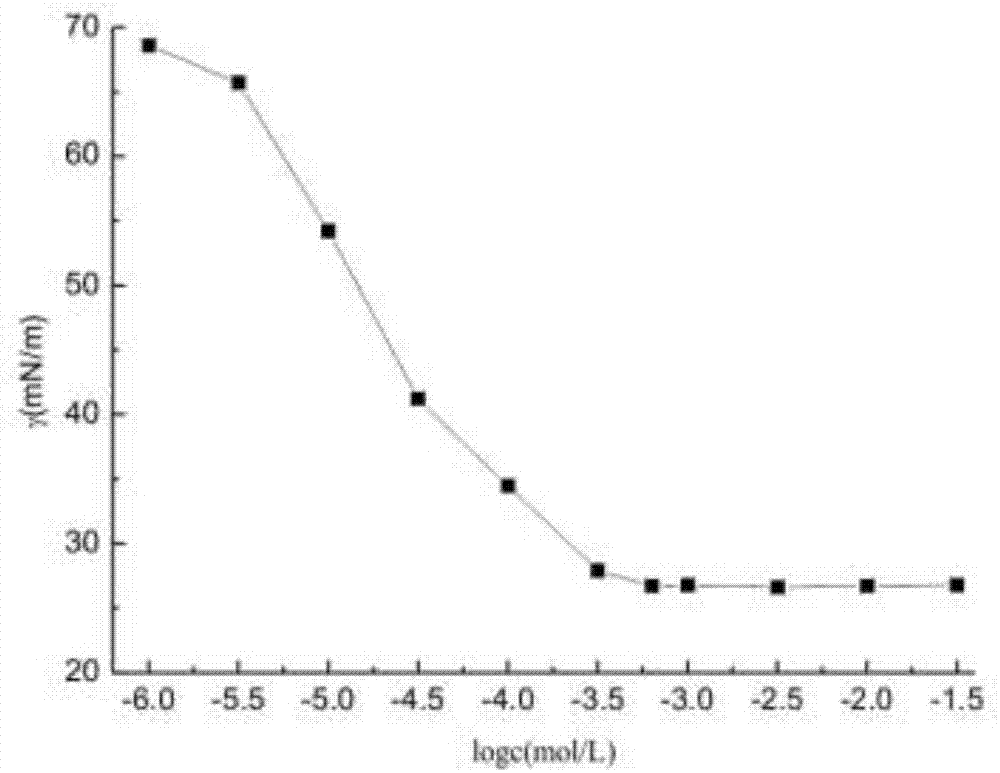

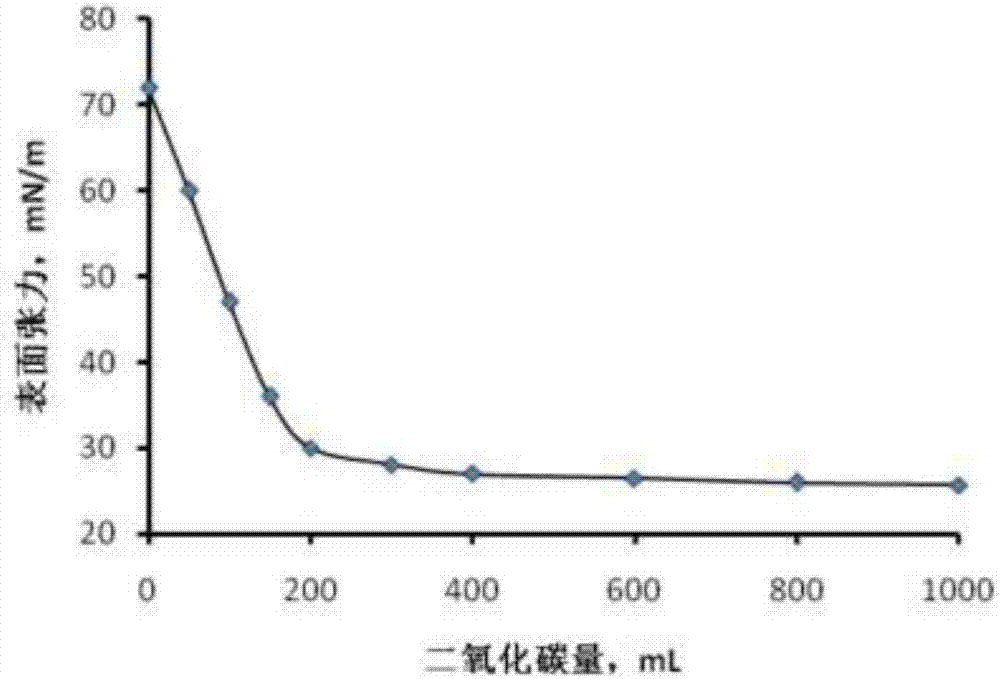

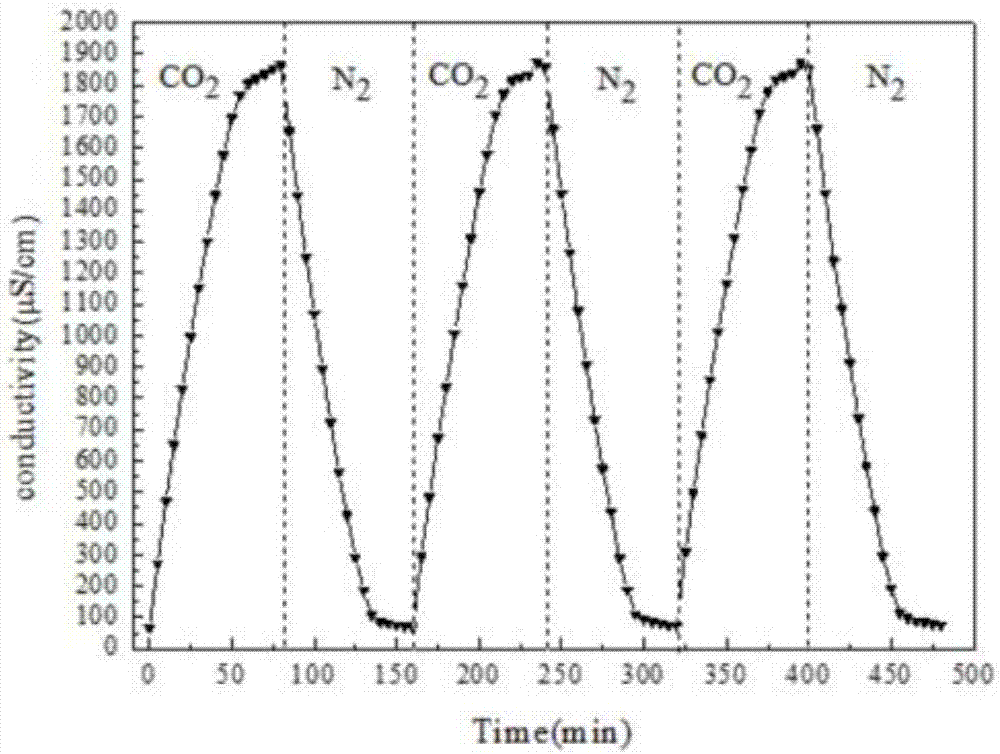

Tertiary amine CO2/N2 switch-type Gemini surfactant and synthetic method thereof

ActiveCN106986775AEasy to separateAchieve mutual transformationTransportation and packagingMixingDodecaneDiamine

The invention discloses a tertiary amine CO2 / N2 switch-type Gemini surfactant and a synthetic method thereof. The synthetic method comprises the following steps: (1) dissolving ethidene diamine in absolute ethyl alcohol, heating the mixture, then adding an ethanol solution where bromododecane is dissolved, and stirring the mixture to obtain a reaction liquid I; (2) cooling the reaction liquid I and filtering and drying the reaction liquid to obtain solid powder; (3) dissolving solid powder in absolute ethyl alcohol, heating the mixture, then separately dropwise adding ethanol solutions where N,N-dimethyl-3-chloropropylamine and potassium iodide are dissolved into the mixture, and stirring the mixture to obtain a reaction liquid II; and (4) cooling the reaction liquid II, washing and drying the reaction liquid II to obtain a target product, adding the target product into a closed pressure container, adding water, introducing a CO2 to obtain a surfactant, and introducing N2 to convert the surfactant into a non-surfactant. The method disclosed by the invention is simple, and can smoothly convert the surfactant and the non-surfactant, so that the surfactant can be repeatedly used, and has a wide application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

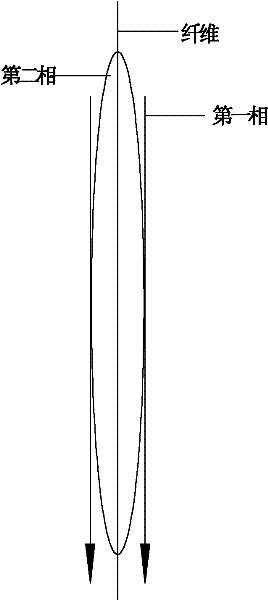

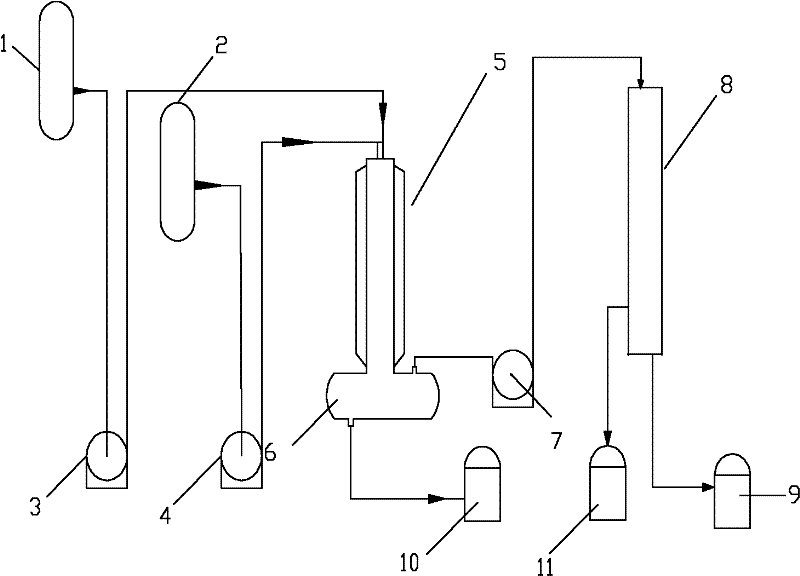

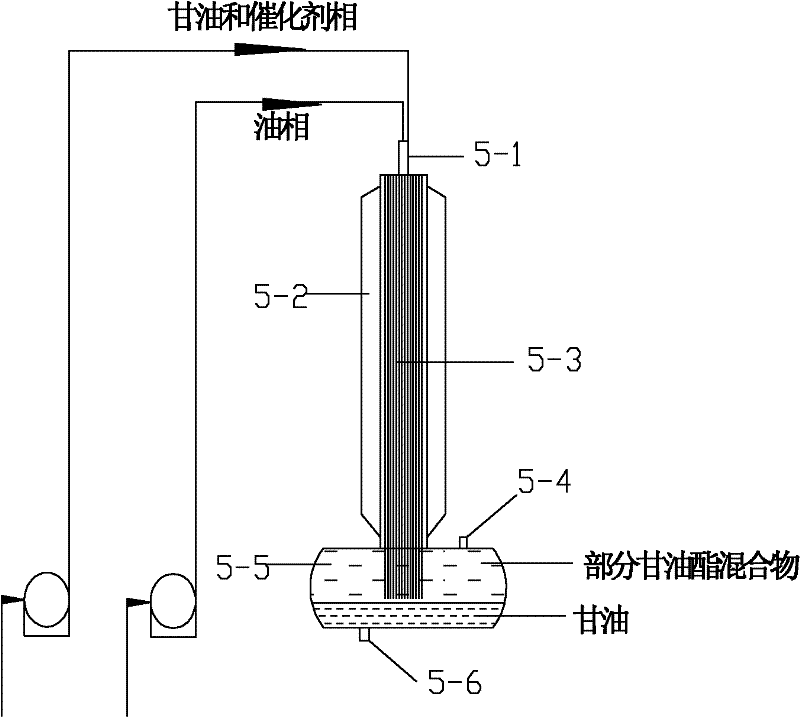

Preparation method of partial glyceride

InactiveCN102191134AIncrease contact areaEnhanced mass transferFatty acid esterificationFermentationFiberMonoglyceride

The invention belongs to the technical fields of chemical food and biological medicine and relates to a preparation method of partial glyceride. The method is characterized by comprising the following steps: mixing glycerin and catalyst to form glycerin-catalyst mixed solution, wherein the catalyst refers to alkali catalyst or enzyme catalyst; separately preheating raw material oil and the glycerin-catalyst mixed solution to 30-200 DEG C according to a ratio of raw material oil to glycerin, pumping the two materials in a fiber reactor at the same time, controlling the temperature of the fiber reactor to 0-200 DEG C, controlling the reaction temperature, using the mixed solution obtained by the reaction to perform molecular distillation or vacuum distillation and obtain monoglyceride and diglyceride. In the preparation method, the raw material oil and glycerin realizes liquid film contact on the surface of fiber in the fiber reactor, ester exchange reaction is performed under the action of the catalyst to prepare partial glyceride; and the reaction system is used to couple the reaction and separation step and ensure that the reaction is shifted in the direction of the product. Fiber contact is adopted to increase the contact area of the reactants, thus the reaction time can be shortened and the conversion rate and the separation efficiency can be increased.

Owner:DALIAN UNIV OF TECH

Improved regeneration technique for decolorizing and deodorizing waste tyre oil and method for preparing diesel fuel thereof

InactiveCN101659878AIncrease contact reaction areaDouble catalysisCatalytic crackingTreatment with plural serial stages onlyEngineeringPower performance

The invention discloses an improved regeneration technique for decolorizing and deodorizing waste tyre oil and a method for preparing diesel fuel thereof, which comprise the following steps: a, mixing 100 parts of waste tire oil, 1-8 parts of hydrogen peroxide and 1-5 parts of core catalyst, and reacting for 2-5 hours after mixing, wherein the core catalyst is the mixture of at least two components selected from Fe2O3, Al2O3, SiO2 and MnO2; b, adding anhydrous materials at the upper layer after reaction in the step a to a reaction kettle, adding the core catalyst, heating, and extracting distillate at 365 DEG C under the normal pressure or at 280-300 DEG C under 0.09 MPA negative pressure; c, adding concentrated sulphuric acid to the distillate obtained in the step b, stirring, adding argil for precipitating, and filtering by a filter press or filter sands to obtain pale yellow primary diesel oil; and d, preparing the primary diesel oil obtained in the step c to a desired type of diesel oil. Compared with the prior art, the invention adopts a more improved reaction principle, and the product oil prepared by the method has the advantages of pale yellow color, stable quality, favorable evaporability and power performance, low temperature flow property, non-corrosiveness, and the like; furthermore, the product oil has the advantage of preparing the diesel oil by mixing with the traditional fossil diesel oil or other fuel diesel oils according to any proportion.

Owner:刘新宇

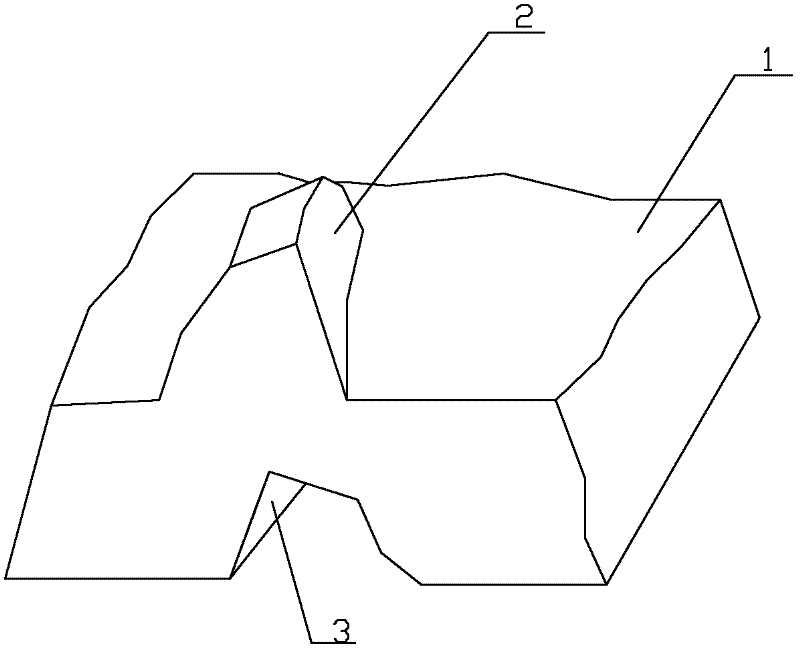

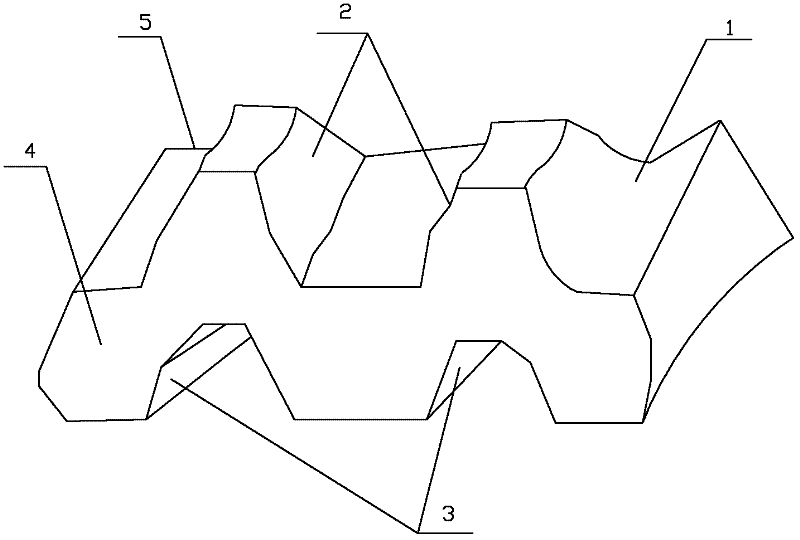

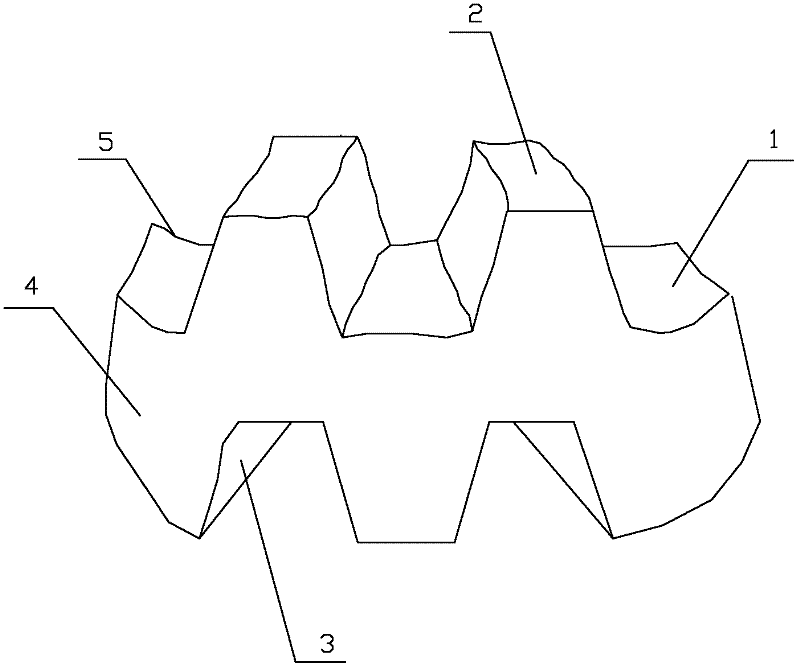

Irregular micro electrolysis iron carbon filling material

ActiveCN102336456AEasy to handleIncrease contact reaction areaWater/sewage treatmentElectrolysisFilling materials

The invention relates to an irregular micro electrolysis iron carbon filling material, which is in a blocky shape. At least one irregular bulge and at least one irregular groove are respectively distributed and arranged on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are correspondingly distributed and arranged at top and bottom on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are approximately in a gear shape, and the whole of the filling material is inclined and / or has the radian. The technology solves the technical problems of the traditional filling material that the production cost is high, the contact reaction area is small, the reverse flushing is not easy, in addition, the effect is poor, the service life is short, and the like. The irregular micro electrolysis iron carbon filling material has the advantages that the large contact reaction area is realized, the sewage treatment effect is good, the reverse flushing is easy, in addition, the effect is good, the labor operation quantity is reduced, and the production cost and the use cost are reduced.

Owner:常州海龙环保设备厂

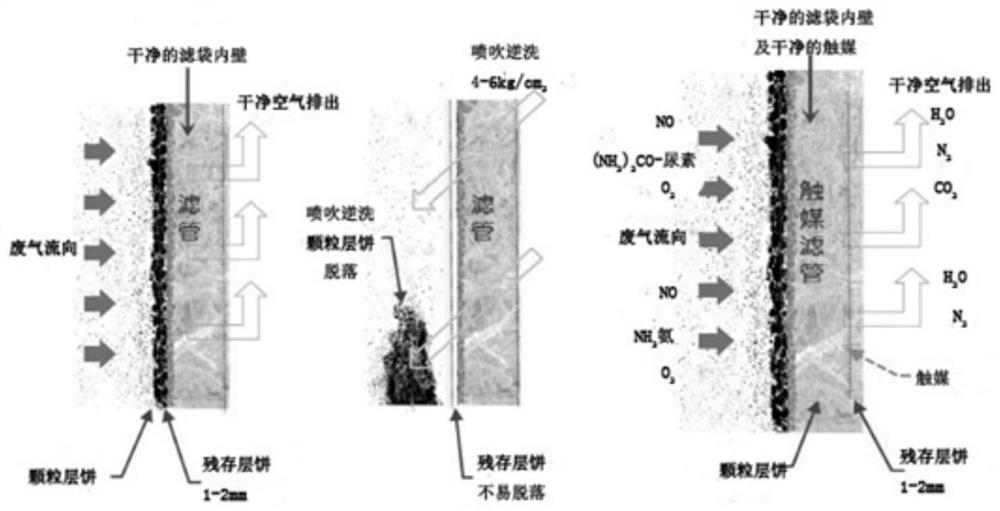

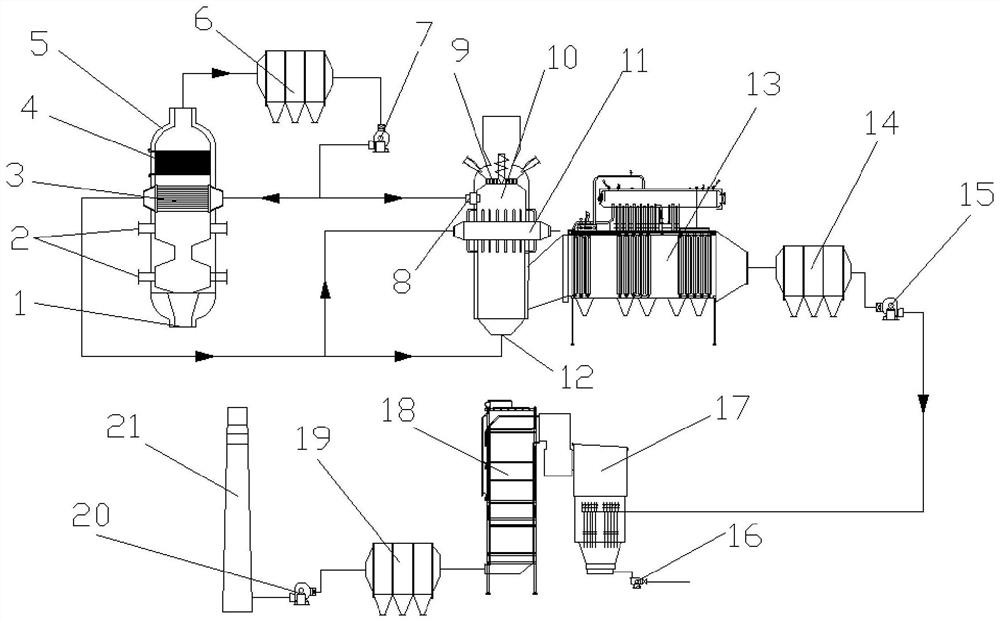

Method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas

ActiveCN110252051AAvoid wastingImprove working conditionsHuman health protectionGas treatmentFlue gasBasalt fiber

The invention discloses a method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas. The method comprises the following steps: extracting flue gas having a temperature of 250-350 DEG C from a boiler, injecting bicarbonate with a size of 600-700 meshes into the flue gas, and carrying out a reaction; and adding a reducing agent into the reacted flue gas, and allowing the flue gas to enter a denitration-dedusting composite device for denitration, dioxin removal and dust removal. The denitration-dedusting composite device comprises a shell, a partition plate and a plurality of basalt fiber filter cartridges, wherein the partition plate is arranged on a cross section of the shell and divides the shell into a first chamber and a second chamber; the sidewall of the shell of the first chamber is provided with a flue gas inlet; the sidewall of the shell of the second chamber is provided with a flue gas outlet; each basalt fiber filter cartridge is a hollow tube body, and basalt fiber cotton is bonded with a catalyst; each basalt fiber filter cartridge is mounted on the partition plate, and the basalt fiber filter cartridges are all located in the first chamber; and the opening of each basalt fiber filter cartridge is in communication with the second chamber.

Owner:山东中琦环保设备制造有限公司

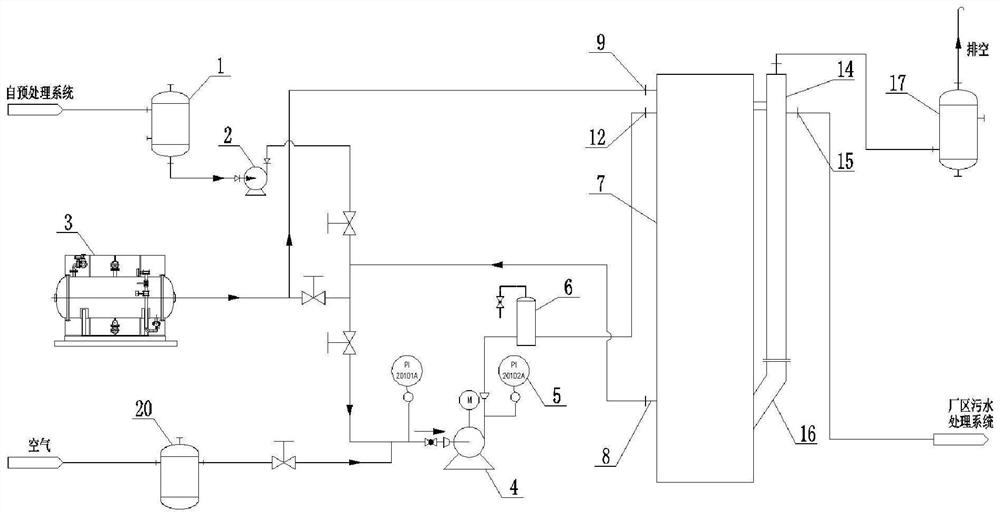

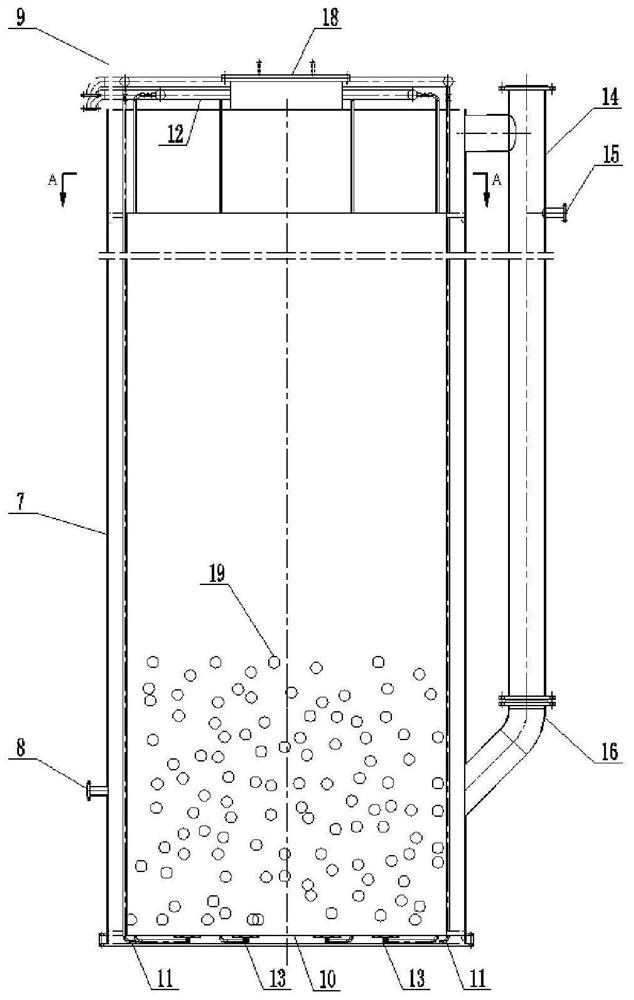

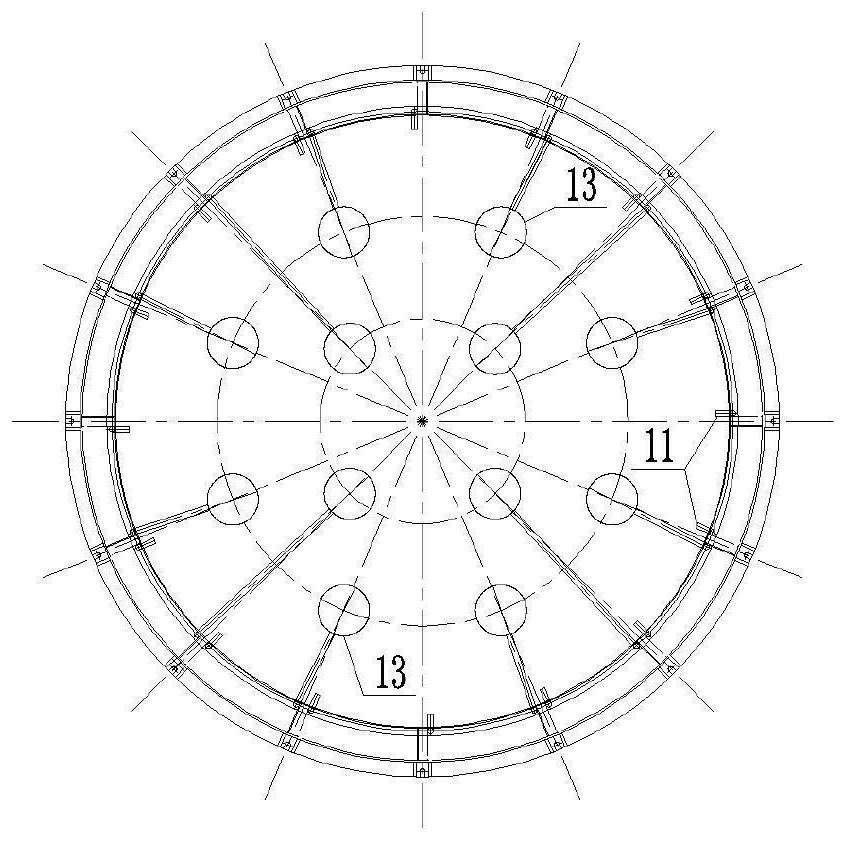

Ozone catalytic fluidized bed device and method for treating high-concentration organic wastewater difficult to biodegrade

PendingCN111825200AIncrease contact reaction areaIncrease profitWater contaminantsWater/sewage treatment by oxidationPtru catalystFluidized bed

The invention discloses an ozone catalytic fluidized bed device for treating high-concentration organic wastewater difficult to biodegrade, and relates to sewage treatment technology in the field of environmental protection. The ozone catalytic fluidized bed device structurally comprises an organic wastewater conveying pipeline and a dissolved air water conveying pipeline which are used for beingconnected with a sewage storage tank, a sewage pressure pump, an ozone generation device, a dissolved air pump, a fluidized bed reactor and a plurality of control valves, a top dissolved air water distribution pipe is arranged at the top of the fluidized bed reactor and is communicated with a dissolved air water distribution head to convey dissolved air water; the invention also discloses a methodfor organic wastewater treatment. The method comprises the following steps: adding the organic wastewater into the sewage storage tank, starting the ozone generation device, and filling a catalyst atthe bottom of the fluidized bed reactor; at least one part of ozone generated by the ozone generation device is mixed with the organic wastewater and then is conveyed to the dissolved air pump to generate dissolved air water; gas-dissolved water enters the bottom of the fluidized bed reactor through a pipeline from the top gas-dissolved water distribution pipe to the gas-dissolved water distribution head and is in contact with the granular catalyst to generate a catalytic degradation reaction.

Owner:成都九翼环保科技有限公司

Waste gas purification system

ActiveCN105498496AIncrease the degree of mixingAchieve cleaning effectCombination devicesGas treatmentWastewaterWater spray

The invention belongs to the technical field of environmental protection and discloses a waste gas purification system. The waste gas purification system comprises a water-gas mixing chamber, a spiral mixing channel, an atomization unit and a water-gas separation chamber, wherein the water-gas mixing chamber is internally provided with a guide device so that water and gas can be mixed for the first time; the spiral mixing channel is used for mixing the water and the gas for the second time; the atomization unit is used for atomizing the water and the gas, thereby mixing the water and the gas for the third time; and the water-gas separation chamber is used for separating the water from the gas. The mixing degree of the water and the gas is gradually improved by at least three times of mixing, and the contact reaction area of the water and the gas is enlarged, so that a washing effect of minimizing an air mass is realized; the purification rate is high, and purified tail gas can be discharged at low altitudes; a vortex formed by waste gas drives washing water to realize mixing, and an extra washing water spraying device is not needed, so that equipment cost is saved; and a tail gas outlet pipeline is provided with a bending section and the middle part of the bending section is communicated with a wastewater outlet pipeline, so that the aim of recycling deposited wastewater in the tail gas outlet pipeline is realized, equipment is protected and the purification effect is improved.

Owner:王建华 +2

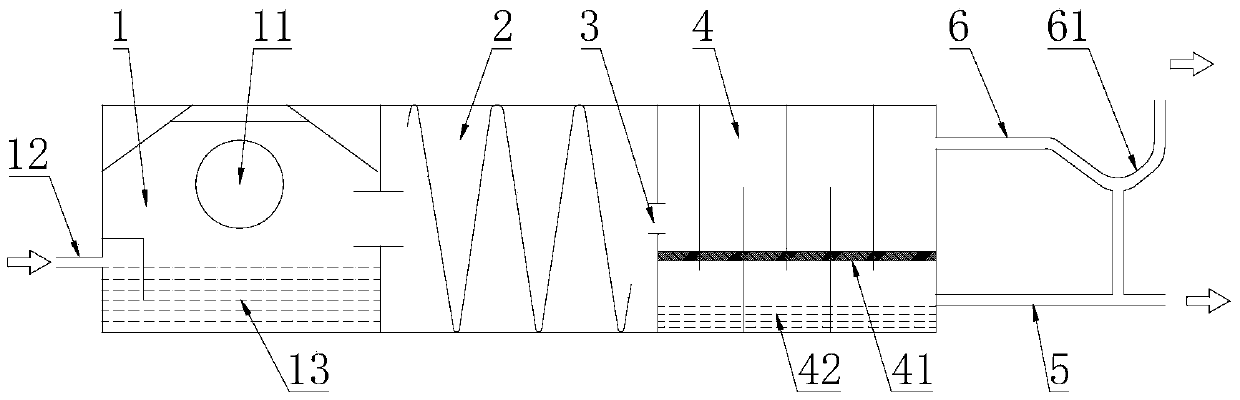

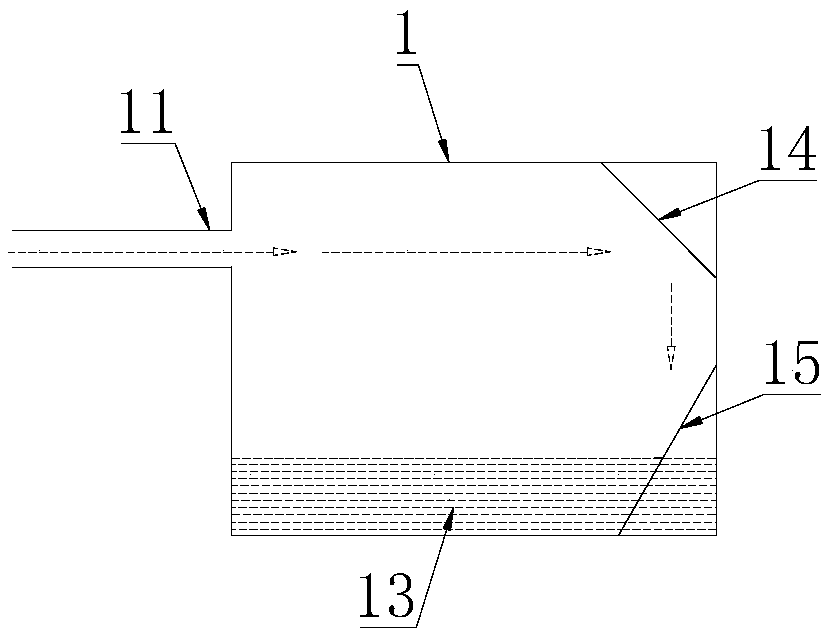

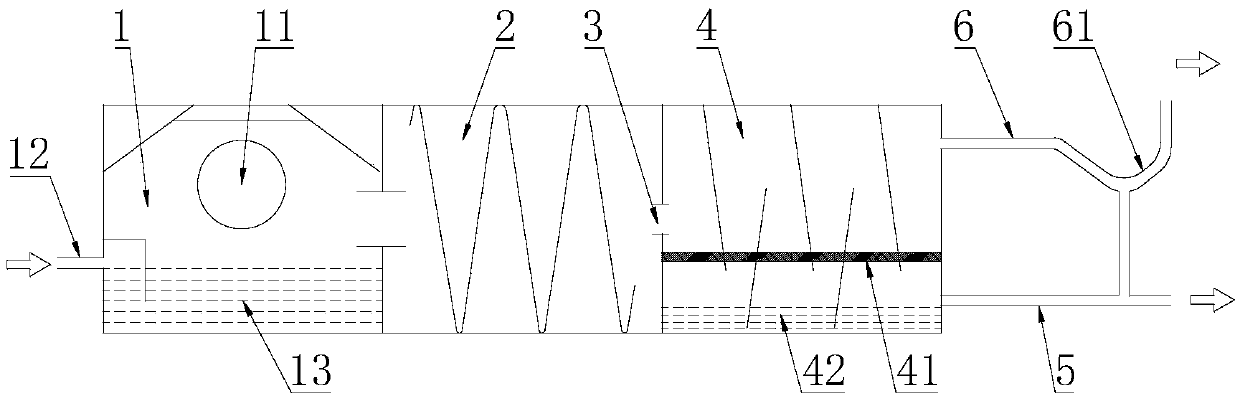

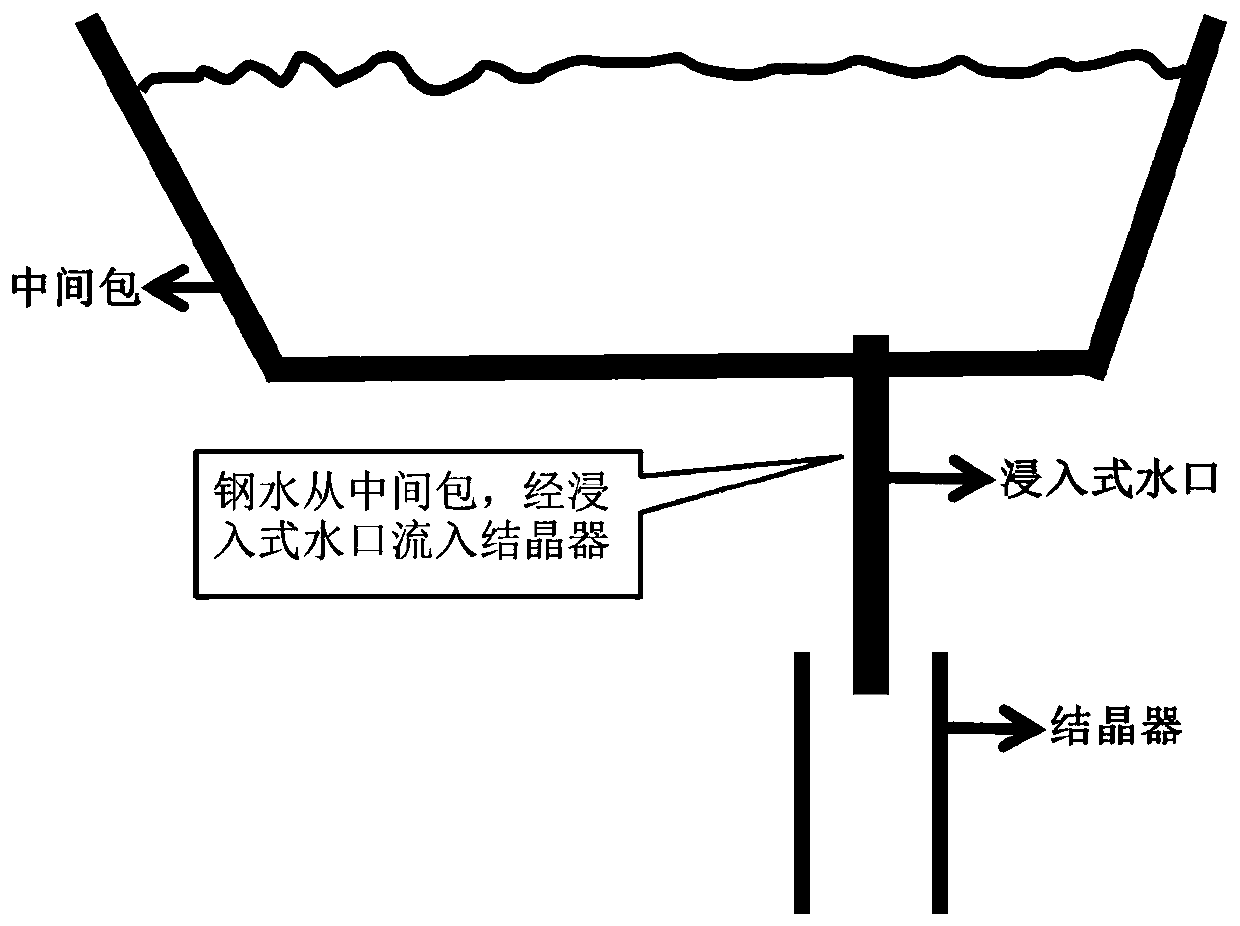

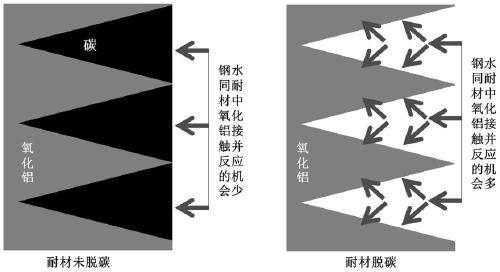

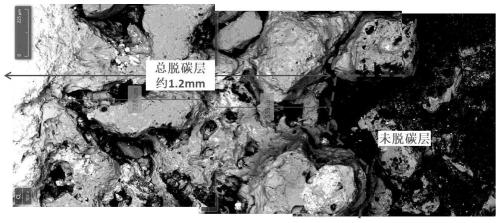

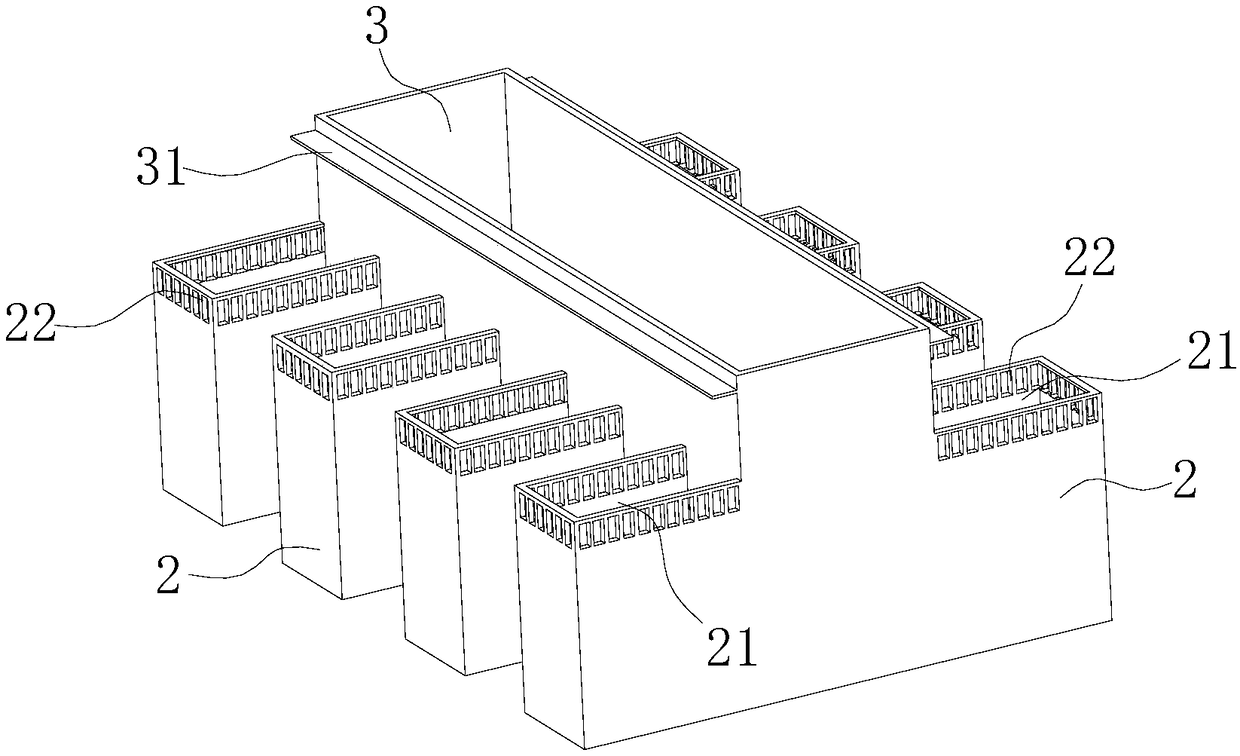

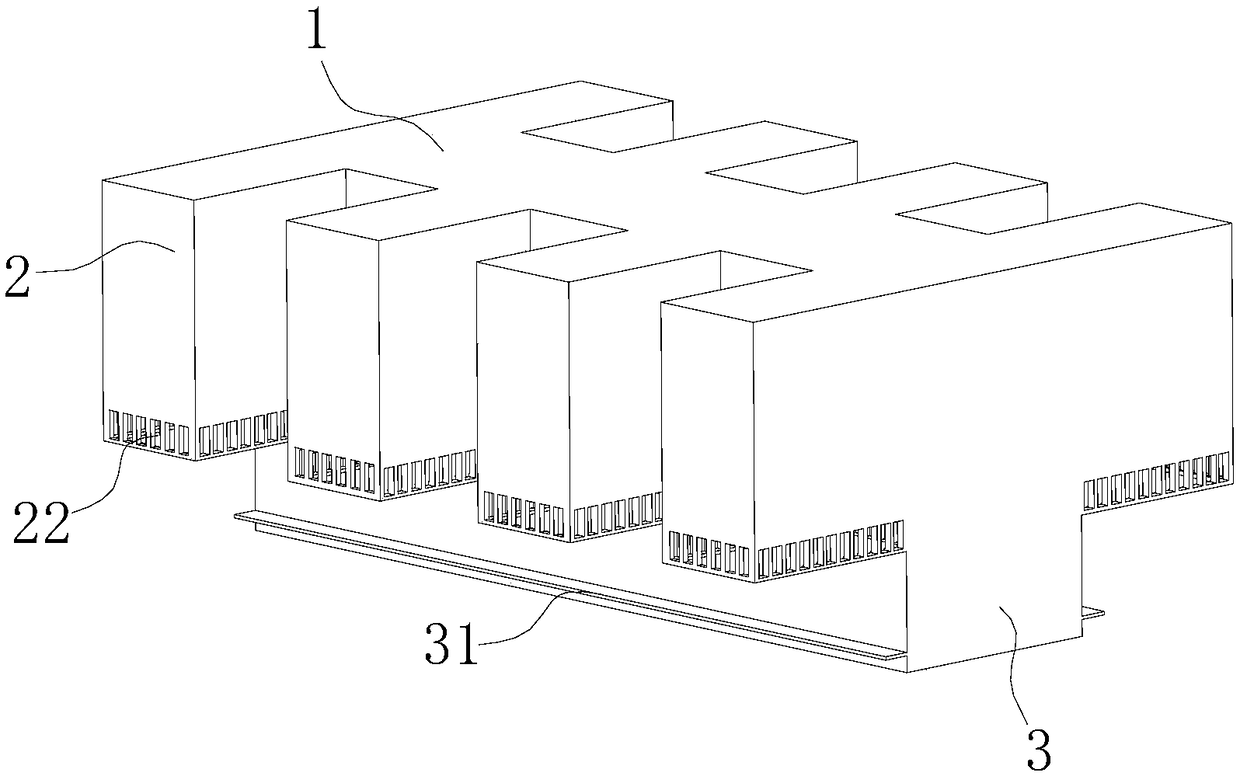

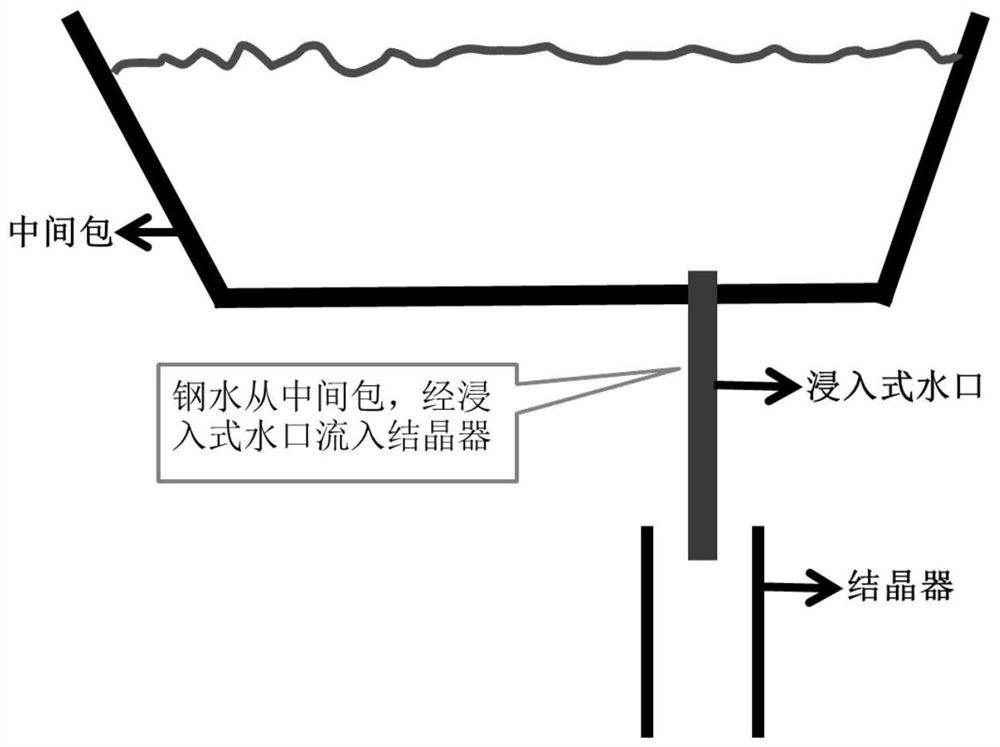

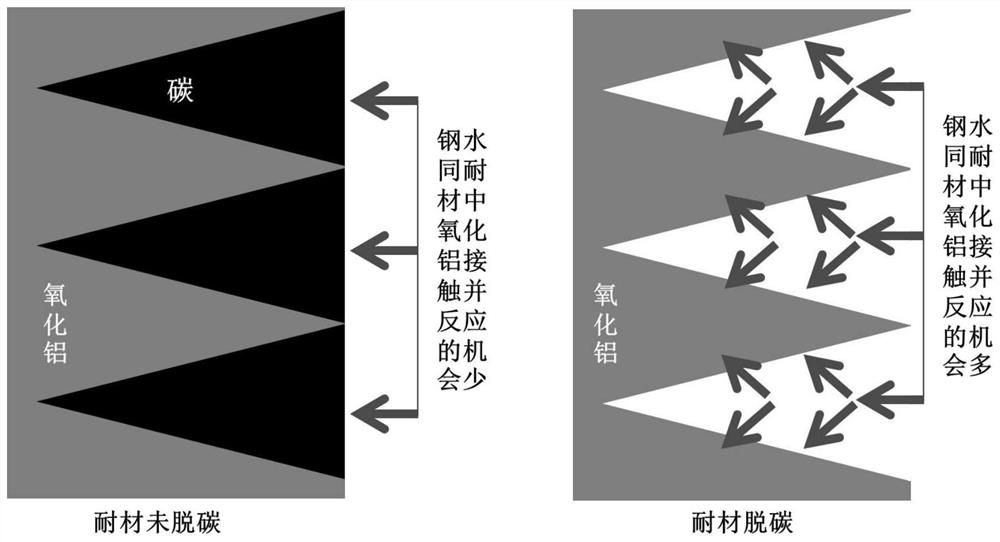

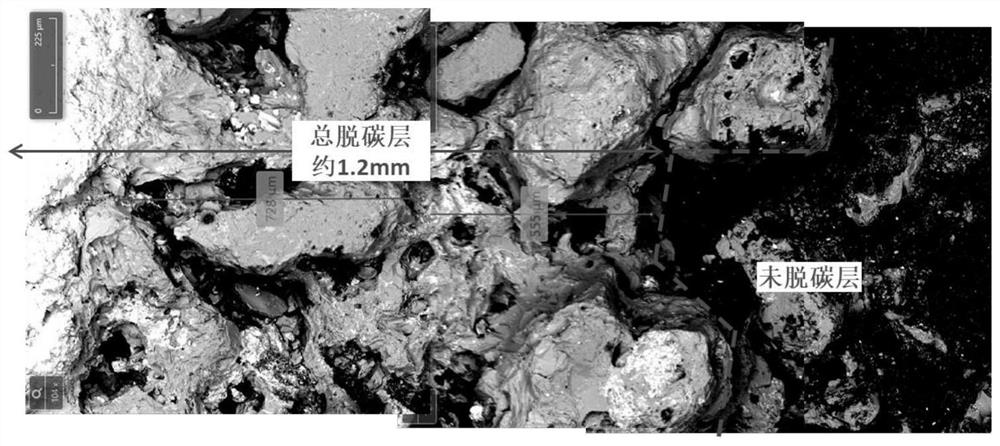

Method for reducing large-size calcium aluminate inclusions in steel

ActiveCN110293219APlay a barrier roleIncrease contact reaction areaMelt-holding vesselsSteelmakingLarge size

The invention discloses a method for reducing large-size calcium aluminate inclusions in steel. According to the method, the aim of reducing the large-size calcium aluminate inclusions is achieved bycontrolling the decarburization depth of an Al2O3-C submersed nozzle refractory material. The related continuous casting refractory material is a tundish submersed nozzle, and main elements of the submersed nozzle refractory material are aluminum oxide and carbon. During steelmaking production, the large-size calcium aluminate inclusions are reduced by controlling the decarburization depth of theAl2O3-C submersed nozzle refractory material. Through the adoption of a steel type produced through the method, the quantity of large-size calcium aluminate can be greatly rediced, and the quality ofthe steel product can be improved.

Owner:ZENITH STEEL GROUP CORP

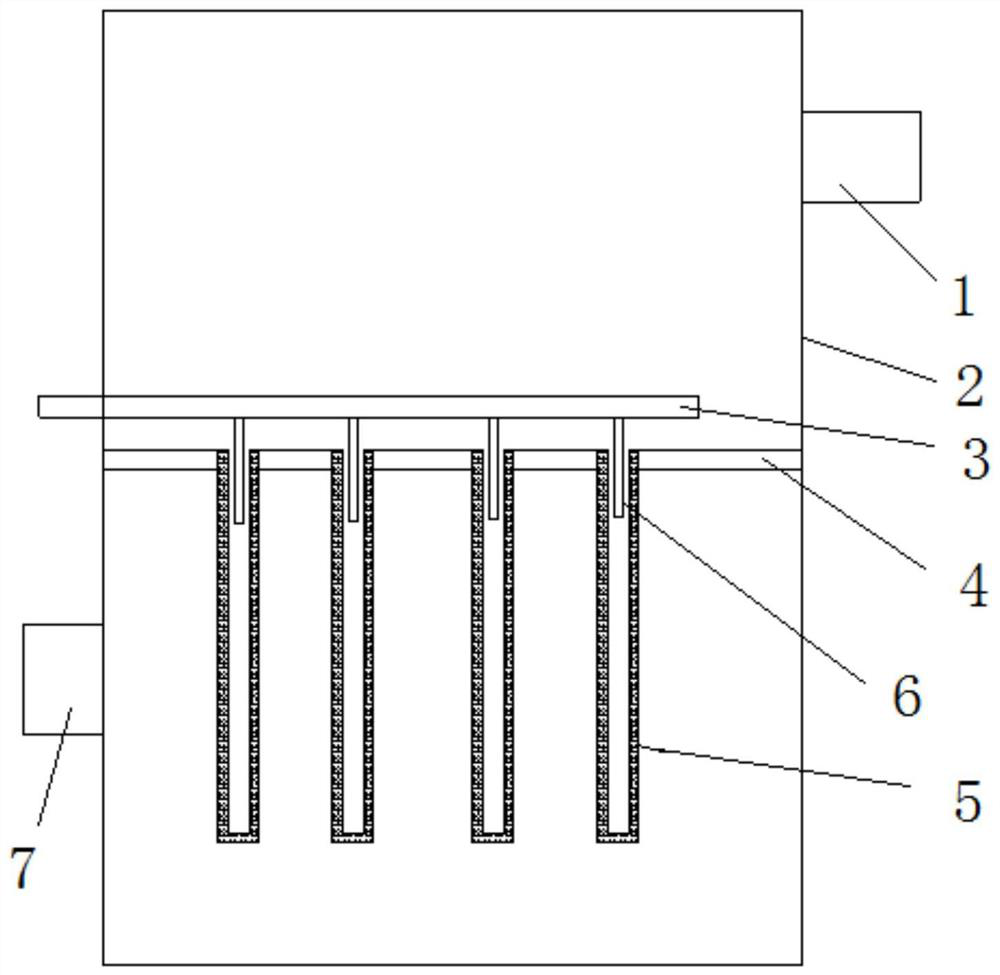

Electric floating wastewater treatment system and electric floating wastewater treatment method

PendingCN110228840AIncrease contact reaction areaImprove processing efficiencyFatty/oily/floating substances removal devicesLiquid separationParticle adhesionMicro bubble

The invention discloses an electric floating wastewater treatment system and an electric floating wastewater treatment method. The system comprises a main cavity body, an electrode device, a residue scraping device, a dosing device, a cleaning device and a control device; an adjustable graphite electrode plate group is arranged in an electrode tank, the adjustable graphite electrode plate group comprises a plurality of graphite electrode plates stacked at intervals, cushion blocks clamped between the adjacent graphite electrode plates and adjusting screws for connecting the graphite electrodeplates, and every graphite electrode plate is provided with one or more first connecting hole and a plurality of reaction holes for easily generating microwave bubbles, so the contact reaction area between the graphite electrode plates and wastewater is greatly extended, the reaction rate and the reaction effect are improved, many micro-bubbles are formed, and the particle adhesion effect is good;and the electrode device, the residue scraping device, the dosing device, the cleaning device and the control device are arranged, so the automatic running of the electric floating wastewater treatment system is realized, the running reliability of the whole system is ensured, and the wastewater treatment efficiency and the purification effect are improved.

Owner:DONGGUAN WOJIESEN WATER TREATMENT

Biochemical reagent and preparation method and application thereof

InactiveCN104845910AStrong on-the-spot operabilityIncrease the concentration of microorganismsBioreactor/fermenter combinationsBiological substance pretreatmentsSolid phasesChemistry

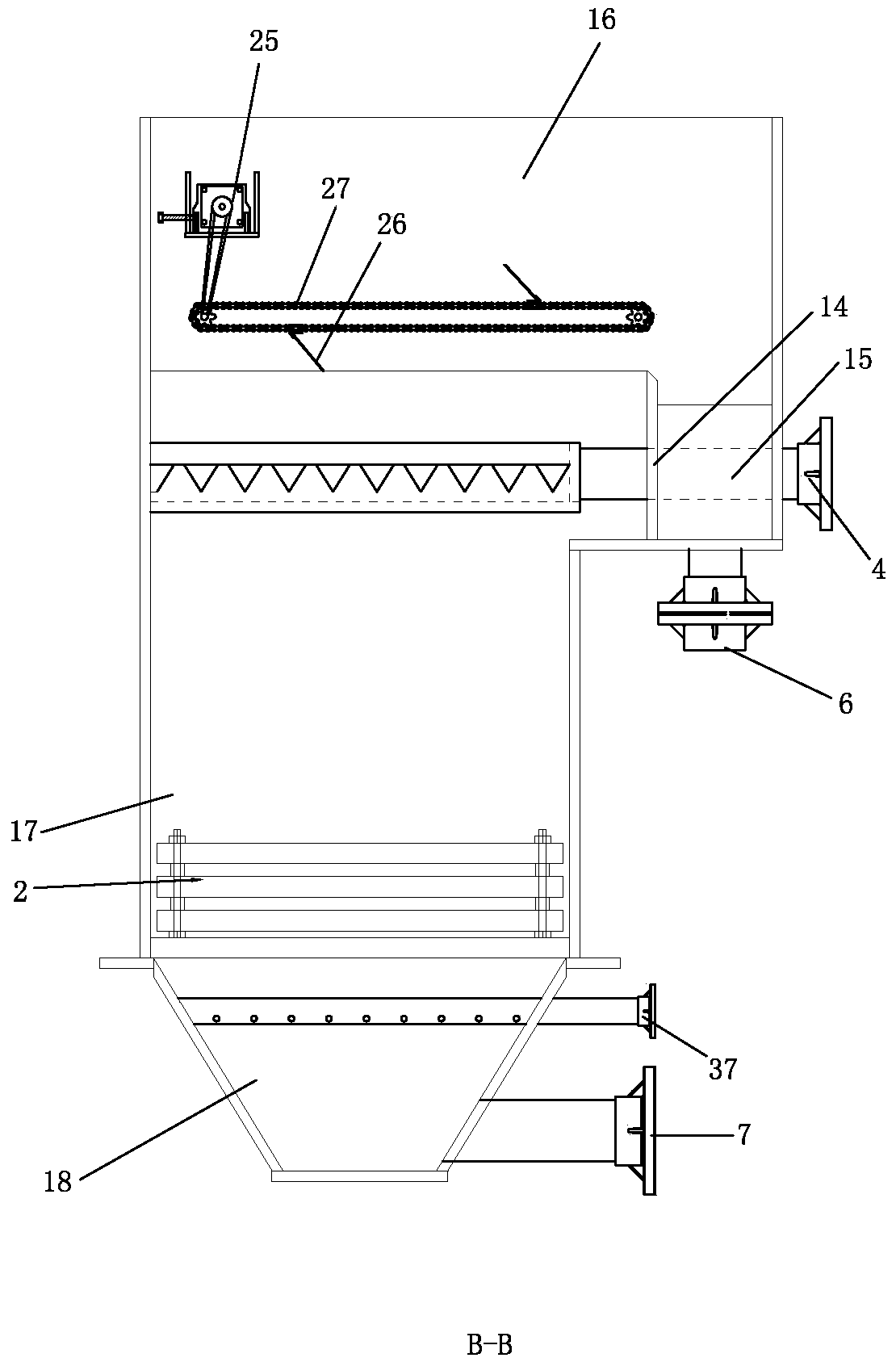

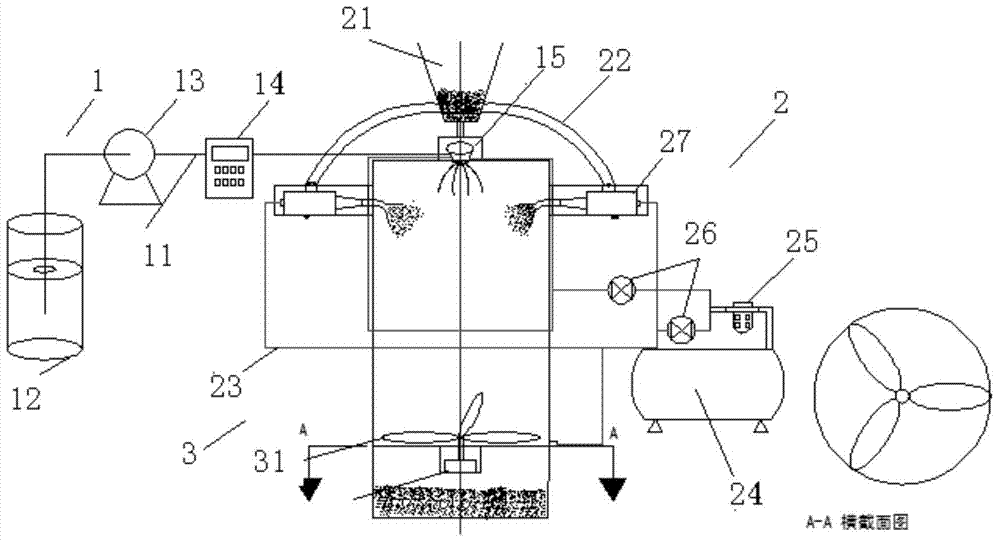

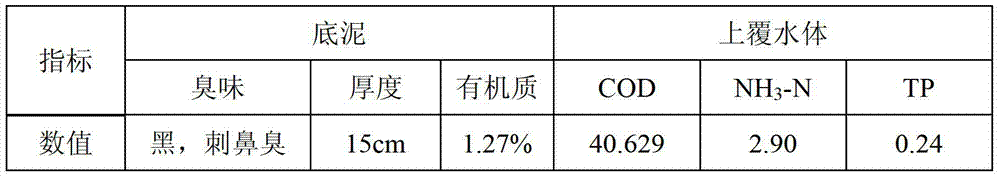

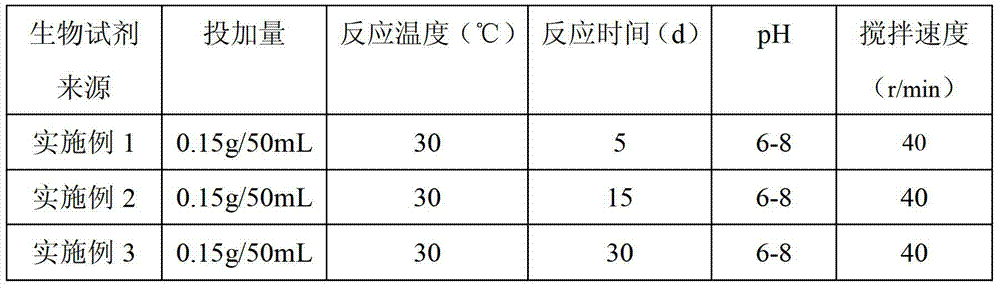

The invention provides a biochemical reagent, which is prepared from solid phase spray and liquid phase spray by mixing spray reaction; the mass ratio of the solid phase spray to the liquid phase spray is 1:0.4-0.6; the solid phase spray is composite non-metallic minerals A (patent number 201310017703.0); the liquid phase spray comprises the following components in parts by weight: 5-15 parts of compound bacteria, 5-15 parts of nutritional agent and 0.05-0.15 parts of binder, wherein the compound bacteria are bacillus subtilis and photosynthetic bacteria of which the mass ratio is 1:4-6. The invention provides mixing spray reaction equipment used for preparing the biochemical reagent and a method for preparing the biochemical reagent by using the equipment. The biochemical reagent prepared according to the invention takes into account two aspects of microorganism loading capacity and substrate mass transfer resistance, low cost and long service life are realized, and thus, the biochemical reagent and the preparation method and application thereof can be used for treating polluted water bodies of a city and used for various water treatment engineering projects, and have a bright prospect.

Owner:HOHAI UNIV

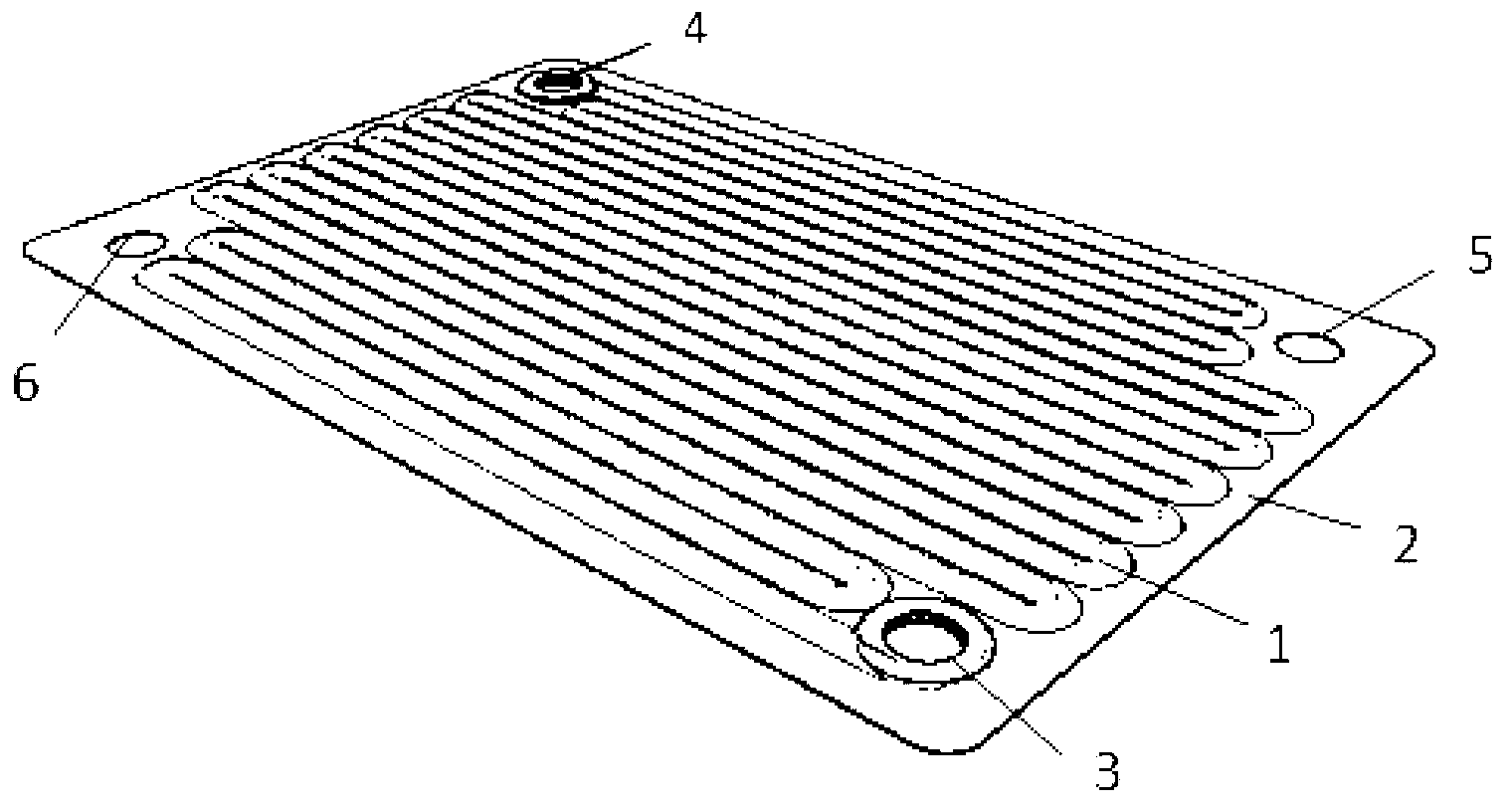

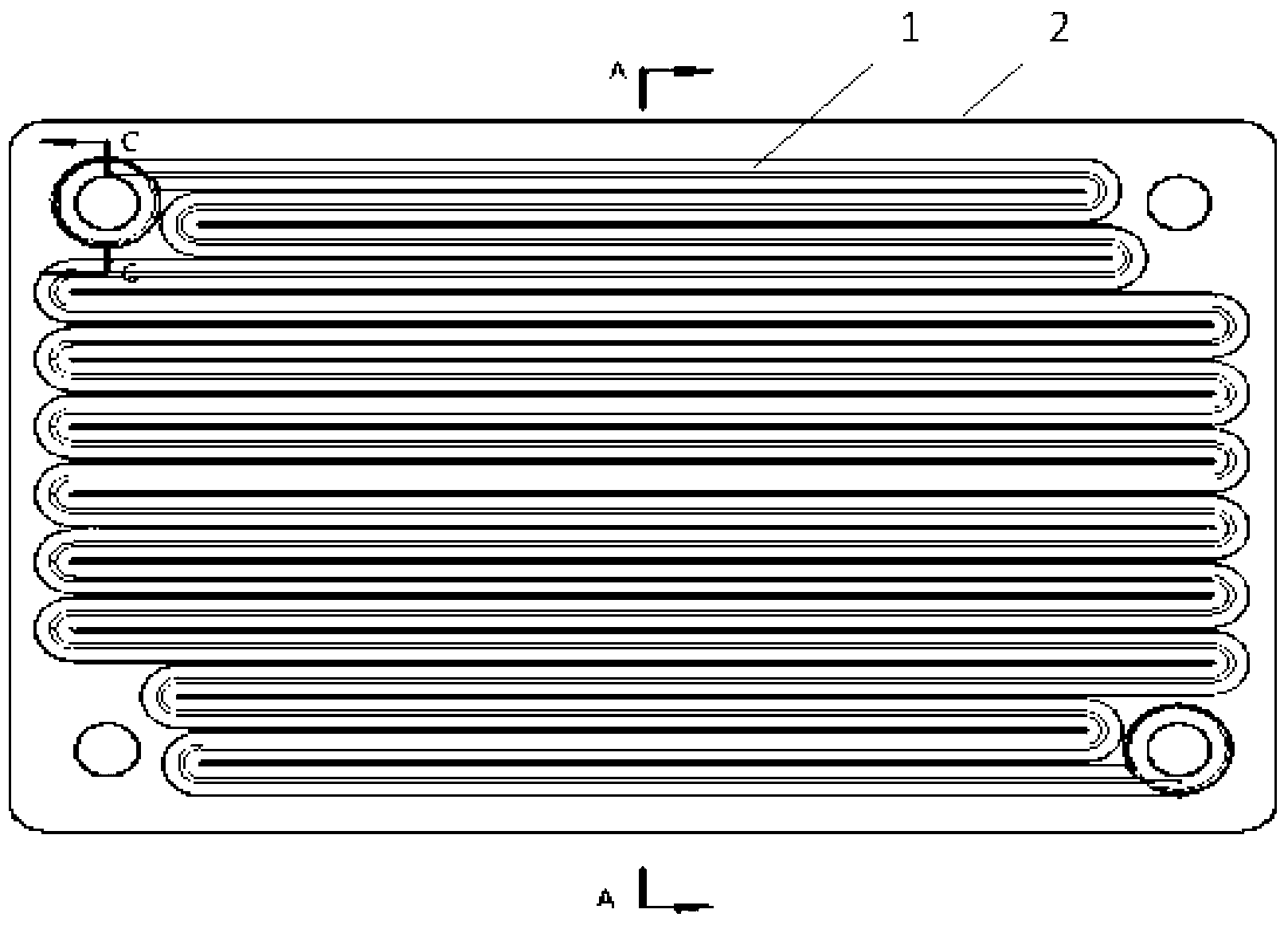

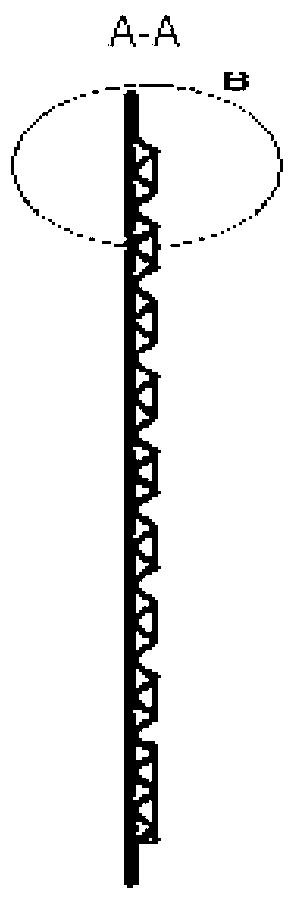

Corrugated air electrode for metal air battery

InactiveCN103268944ALower internal resistanceReduce manufacturing costCell electrodesEngineeringOperating life

The invention belongs to the technical field of a metal air battery, and particularly relates to a corrugated air electrode for a metal air battery. The corrugated air electrode comprises a corrugated air electrode and a flat bipolar plate, wherein the corrugated air electrode is of a corrugated type, one side of the corrugated air electrode is bonded with the flat bipolar plate, an S-shaped air passage is formed between the corrugated air electrode and the flat bipolar plate, one end of the S-shaped air passage is provided with an air inlet, the other end of the S-shaped air passage is provided with a vent port, and the flat bipolar plate is provided with a liquid inlet and a liquid outlet. By adopting the corrugated air electrode, the power of the battery is increased, the mechanical strength of the air electrode is enhanced, the working service life of the battery is prolonged, and the application field of the metal air battery can be enlarged.

Owner:沈阳鑫科能源技术有限公司

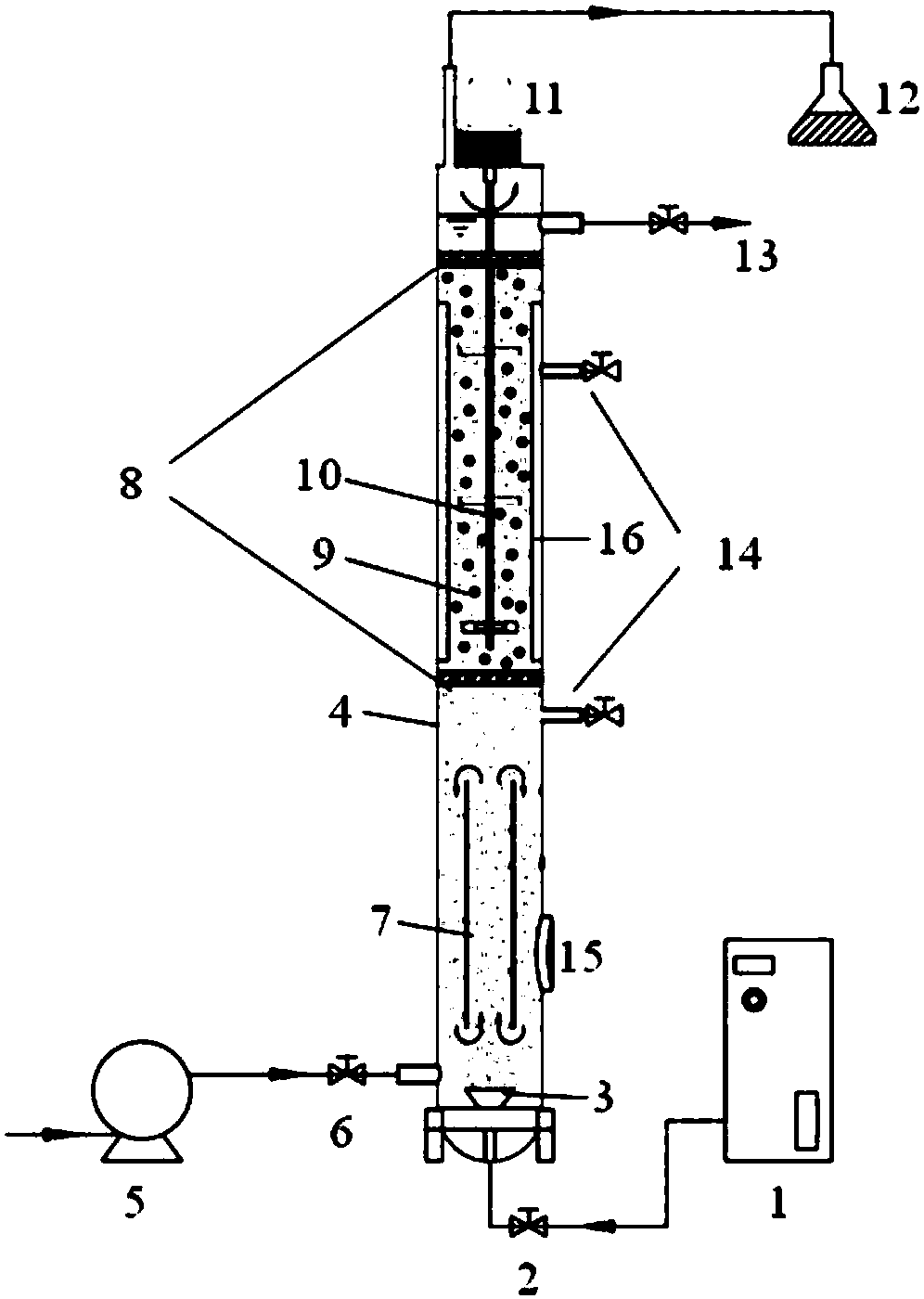

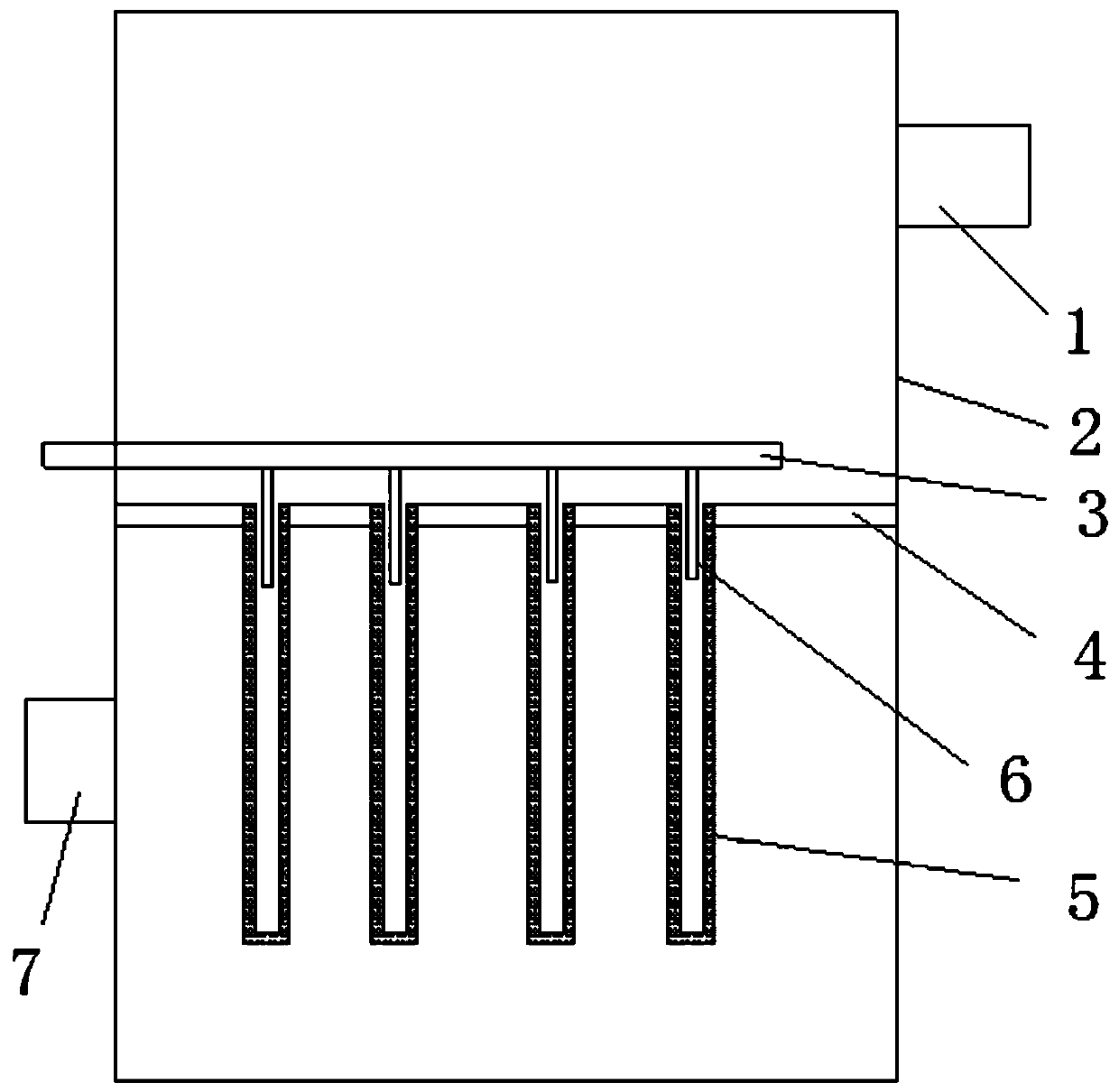

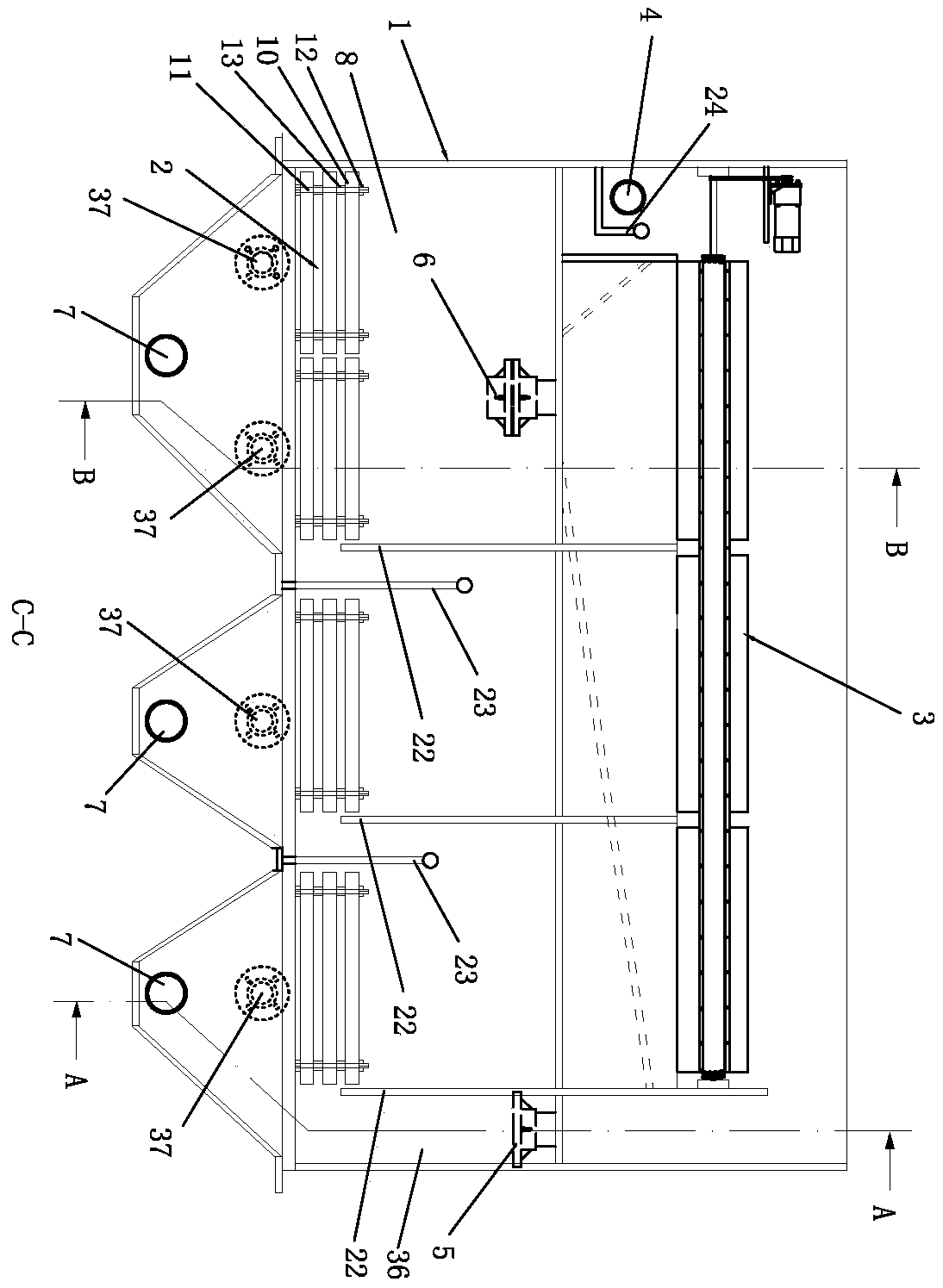

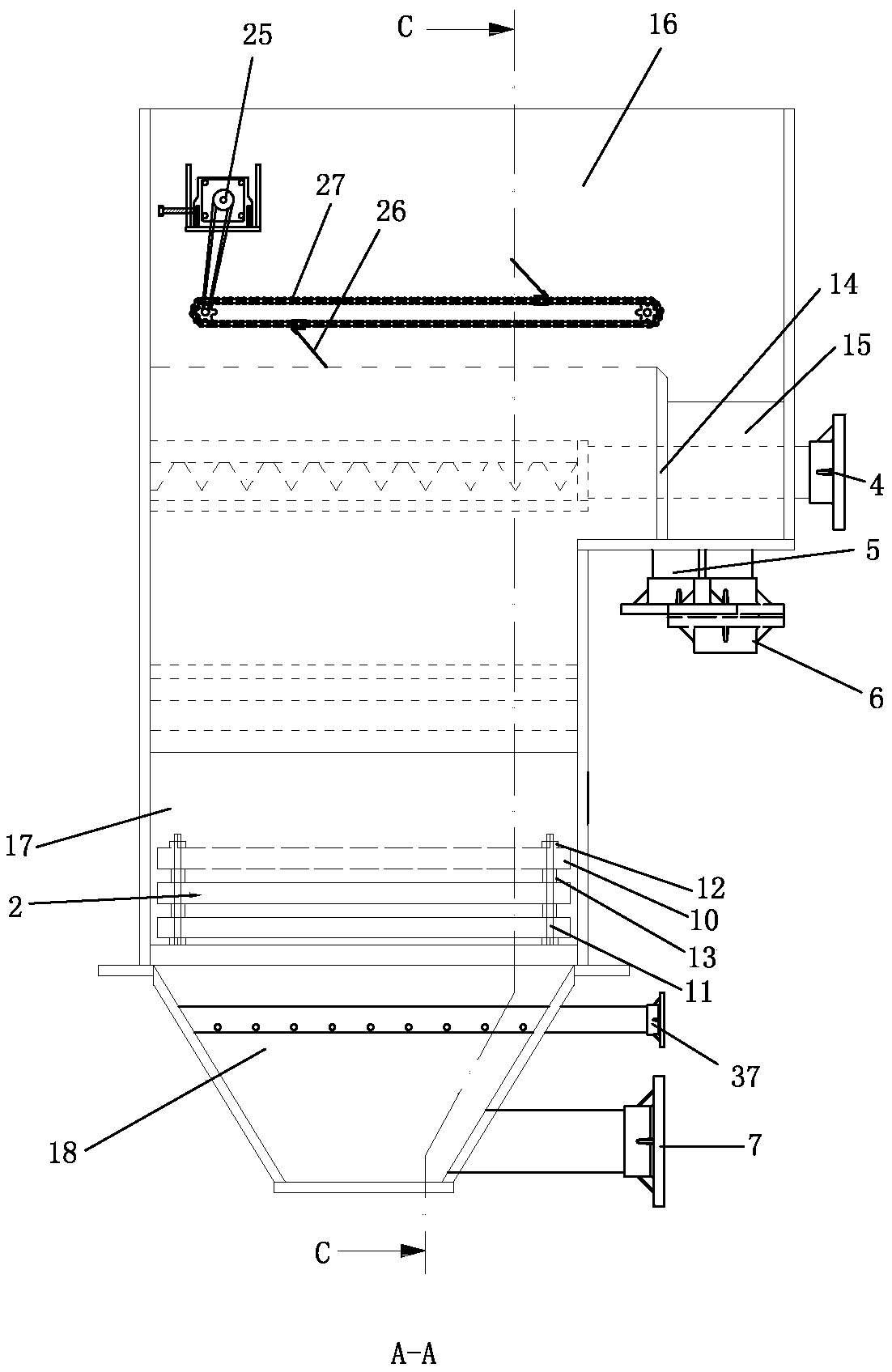

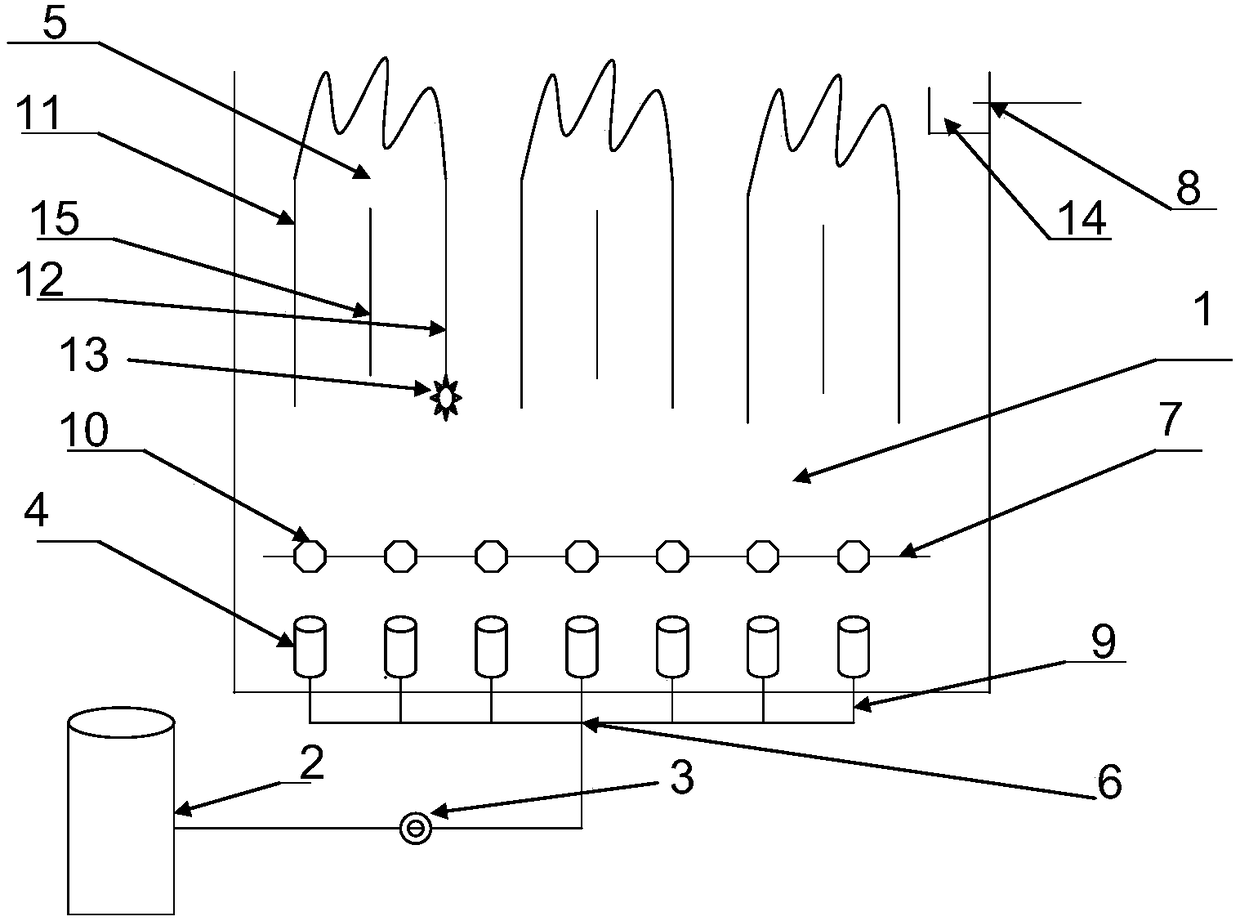

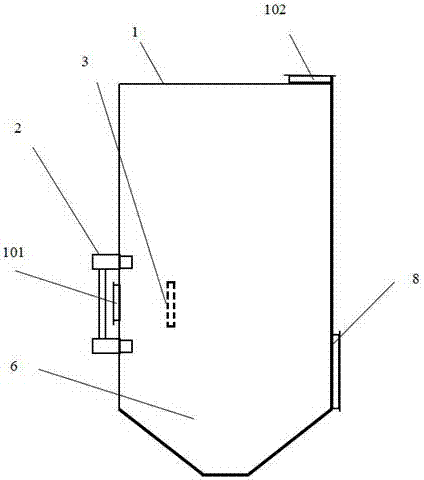

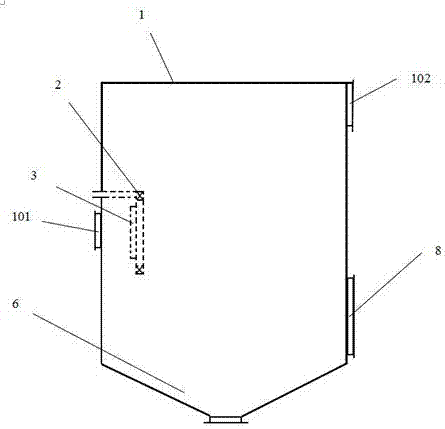

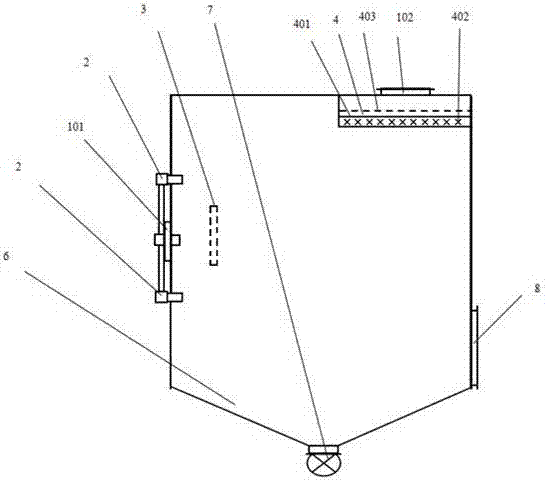

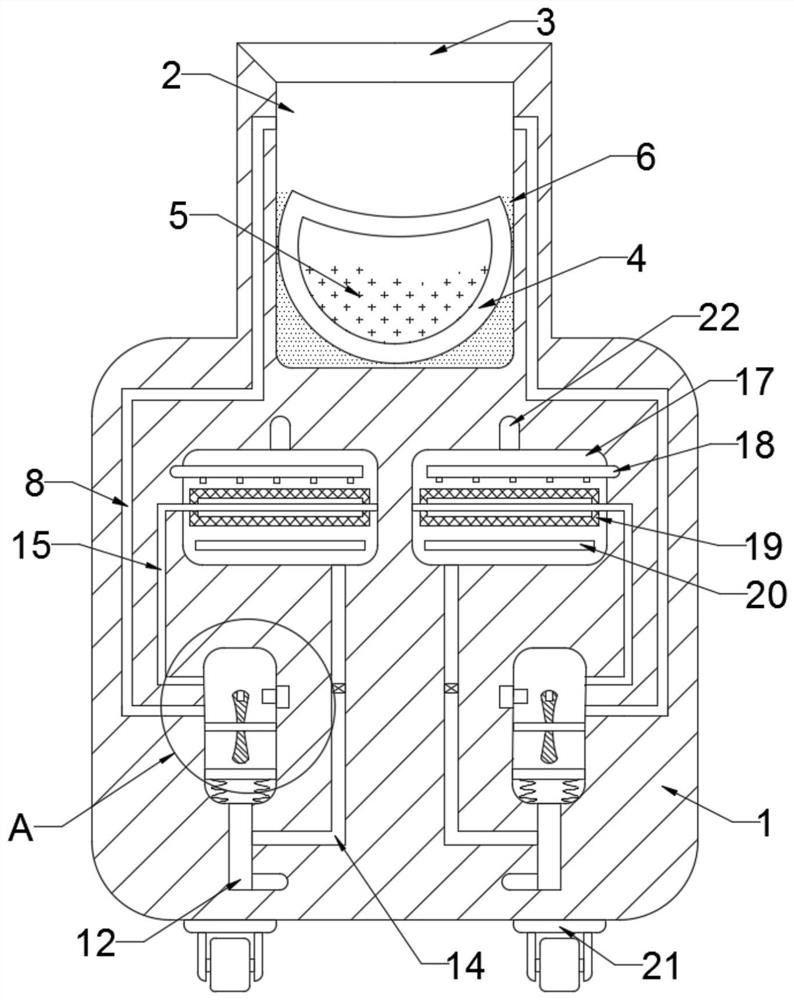

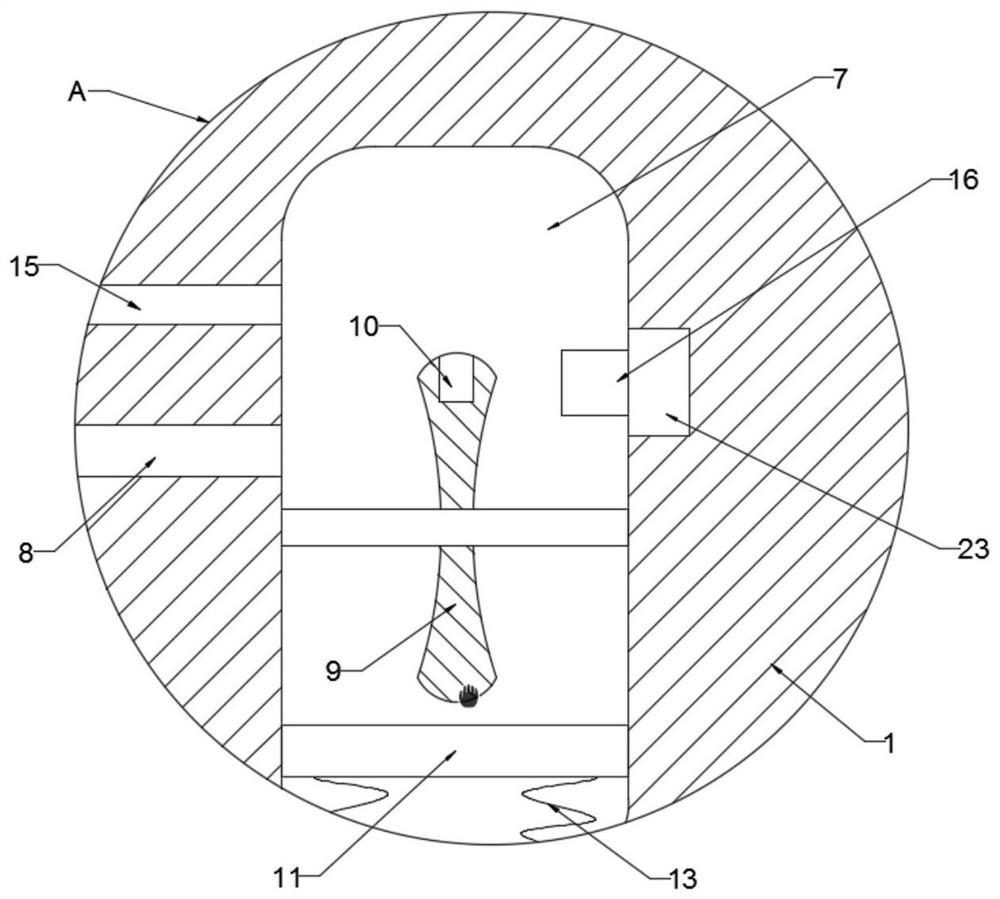

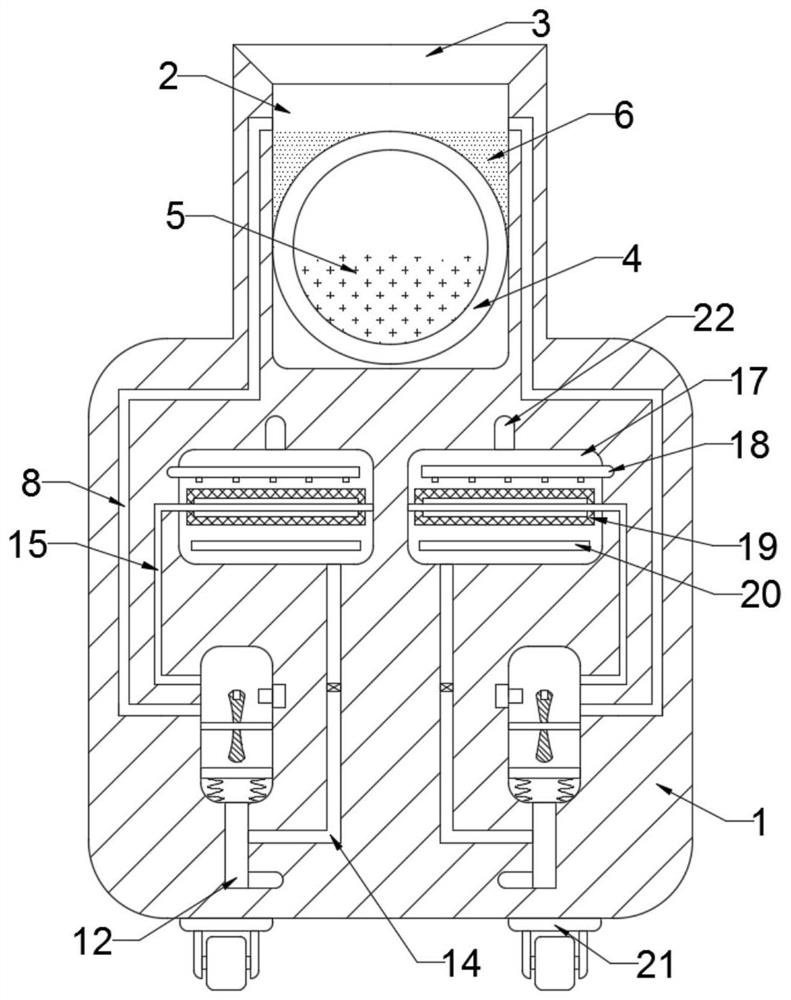

A cavitation-microbial fuel cell reactor and its method for treating wastewater

ActiveCN106145247BIncrease contact reaction areaEasy to replaceWater/sewage treatment with mechanical oscillationsBiochemical fuel cellsMicrobial fuel cellCavitation

The invention relates to a cavitation-microbiological fuel cell reactor and a method thereof for processing wastewater. The reactor comprises a reactor body (1), a raw water tank (2), a water inlet pump (3), cavitation generators (4), a microbiological fuel cell assembly (5), a water inlet (6), a water distribution clapboard (7) and a water outlet (8), wherein wastewater to be processed enters the bottom of the cavitation-microbiological fuel cell reactor from the raw water tank through the water inlet pump, the transferring of electrons in the wastewater is increased through the action of multiple groups of cavitation generators arranged on the bottom, then, the wastewater is subjected to the action of the upper microbiological fuel cell to remove organic matters in sewage, the COD (Chemical Oxygen Demand) removal rate of the processed wastewater is higher than 94.5%, and the removal rate of total nitrogen is higher than 95.3%.

Owner:扬州市泽惠环境工程有限公司

Preparation method of battery zinc negative electrode material

ActiveCN112713273AConducive to loadHigh purityNegative electrodesNickel accumulatorsElectrical batteryNano zinc oxide

The invention relates to the field of batteries, particularly to a preparation method of a battery zinc negative electrode material. The method comprises the following steps: (1) loading carbon and silicon on the surface of nano-zinc oxide, (2) shaping the nano-zinc oxide, (3) cementing a zinc material at normal temperature, (4) carrying out surface modification to aggregate metal ions, and (5) molding the material. According to the invention, generation of dendrites in electrode work can be slowed down, dendrites on the surface of the zinc negative electrode can fall off easily, aggregation of the dendrites is prevented from reducing the electric energy conversion efficiency of the battery, and the battery made of the zinc negative electrode material is stable in discharge and high in current conversion efficiency.

Owner:ZHEJIANG WELLY ENERGY CORP

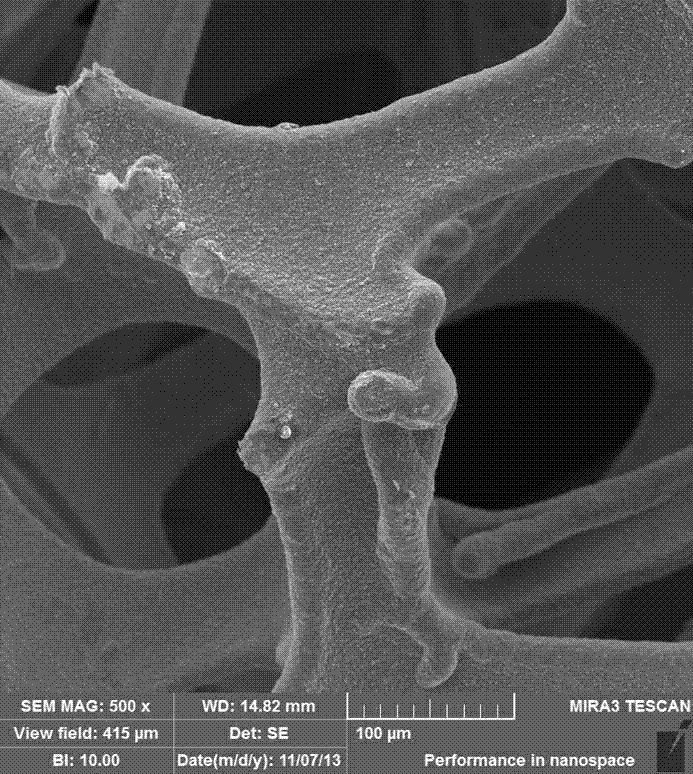

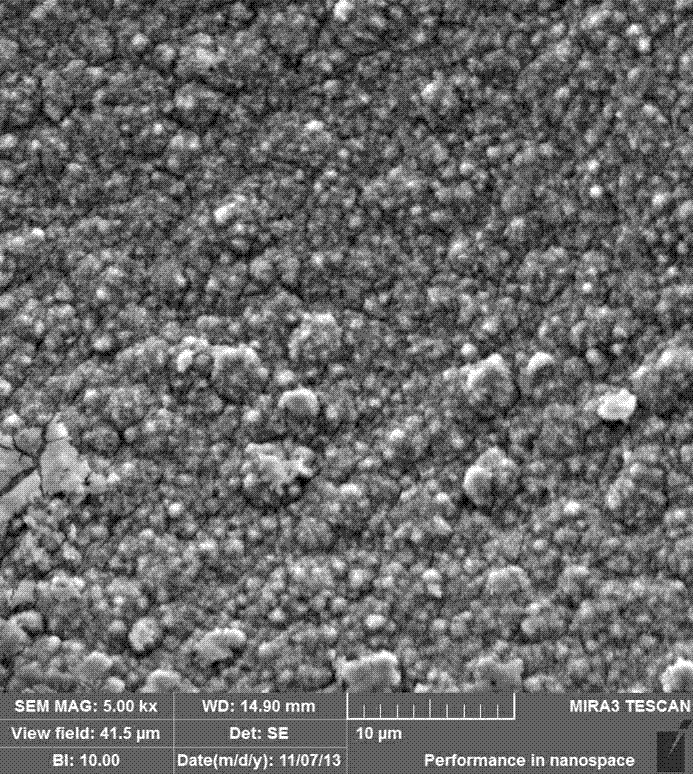

A kind of composite hydrogen evolution electrode with copper and cobalt loaded on three-dimensional nickel foam and its preparation method

ActiveCN103924260BIncrease contact reaction areaReduce hydrogen evolution overpotentialElectrode shape/formsCopperCobalt

The invention relates to a hydrogen evolution electrode with copper and cobalt loaded on three-dimensional foamed nickel, which can be used for an electro-catalysis hydrogen evolution reaction in alkaline solution and is capable of simultaneously loading base metals and a preparation method thereof, and belongs to the technical fields of material science and hydrogen production by electro-catalysis. The technical problem to be solved is to provide the composite hydrogen evolution electrode with copper and cobalt loaded on three-dimensional foamed nickel and a preparation method thereof. A method of plating a composite coating on an electro-mechanical surface is adopted, and copper and cobalt are electro-plated on the three-dimensional foamed nickel in sequence, so that the composite hydrogen evolution electrode is prepared. The prepared electrode has high catalytic activity, is non-toxic, and can keep stable structure and chemical activity under an alkaline condition. In addition, the preparation process of the composite hydrogen evolution electrode is simple, and is suitable for large-scale production.

Owner:TAIYUAN UNIV OF TECH

An industrial flue gas membrane dust collector

ActiveCN105107370BIncrease contact reaction areaEfficient removalCombination devicesElectrode constructionsMembrane methodFlue gas

Owner:湖南省小尹无忌环境能源科技开发有限公司

A method for dedusting, desulfurizing and denitrating boiler flue gas and removing dioxins

ActiveCN110252051BAchieve ultra-clean emissionsImprove desulfurization efficiencyHuman health protectionGas treatmentPtru catalystFlue gas

The invention discloses a method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas. The method comprises the following steps: extracting flue gas having a temperature of 250-350 DEG C from a boiler, injecting bicarbonate with a size of 600-700 meshes into the flue gas, and carrying out a reaction; and adding a reducing agent into the reacted flue gas, and allowing the flue gas to enter a denitration-dedusting composite device for denitration, dioxin removal and dust removal. The denitration-dedusting composite device comprises a shell, a partition plate and a plurality of basalt fiber filter cartridges, wherein the partition plate is arranged on a cross section of the shell and divides the shell into a first chamber and a second chamber; the sidewall of the shell of the first chamber is provided with a flue gas inlet; the sidewall of the shell of the second chamber is provided with a flue gas outlet; each basalt fiber filter cartridge is a hollow tube body, and basalt fiber cotton is bonded with a catalyst; each basalt fiber filter cartridge is mounted on the partition plate, and the basalt fiber filter cartridges are all located in the first chamber; and the opening of each basalt fiber filter cartridge is in communication with the second chamber.

Owner:山东中琦环保设备制造有限公司

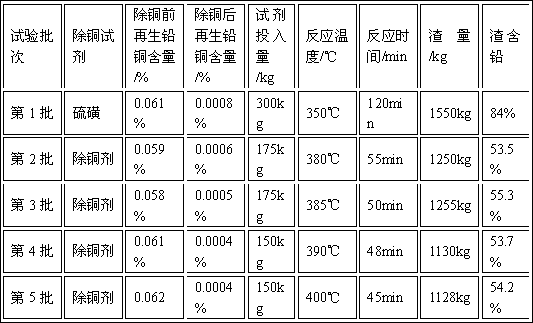

Regenerated lead copper removal agent and preparation method thereof

The invention discloses a regenerated lead copper removal agent and a preparation method thereof. The regenerated lead copper removal agent comprises the following components of, in parts by mass, 60%-80% of pyrite, 1%-20% of fluorite, 5%-30% of sulfur and 1%-10% of sodium carbonate. The method comprises the following steps that the pyrite and fluorite are mixed, then the mixture is subjected to crushing, sieving, sorting, drying and cooling to meet the requirements of the particle size and the water content, wherein the drying temperature is 90-150 DEG C, and the drying time is 30-90 minutes;and the pyrite and the fluorite powder are mixed together with sulfur and sodium carbonate according to a formula to obtain a regenerated lead copper removal agent. According to the regenerated leadcopper removal agent, the specific surface area is large, the copper removal reaction efficiency can be improved, the slag amount and the slag lead content can be reduced, the lead direct yield is improved, meanwhile, SO2 is basically not generated in the reaction process, so that the problem of environmental pollution caused by SO2 emission is solved.

Owner:骆驼集团蓄电池研究院有限公司

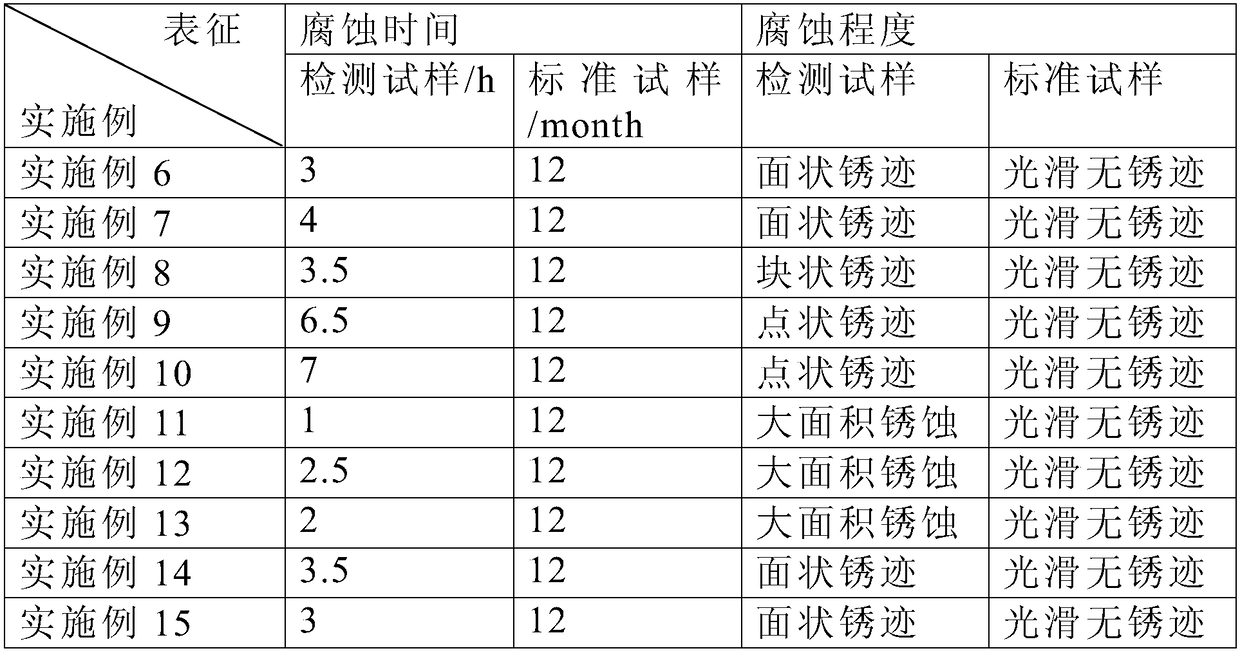

Rapid detection reagent, and detection methods thereof

InactiveCN108169113AIncrease contact reaction areaShorten detection timeWeather/light/corrosion resistancePotassiumSodium hydroxide

The invention belongs to the technical field of metal protective layer detection, and more specifically relates to a rapid detection reagent, and detection methods thereof. The rapid detection reagentcomprises one or a plurality of ingredients selected from deionized water, a cupric chloride solution, acetic acid, hydrochloric acid, a sodium hydroxide solution, an iron chloride solution, a potassium chloride solution, and a mercuric chloride solution, and the concentration of the above ingredients are controlled. According to the detection method, an acidic environment or an alkali environment is adopted so as to realize accelerated corrosion of an aluminium alloy protective layer; the raw materials of the rapid detection reagent are easily available; the invention provides two rapid detection methods using the rapid detection reagent at the same time, including an immersion method and a fumigation method. Requirements of the two methods on equipments are low; corrosion on the alloy protective layer can be realized in 0.5 to 24h; detection period is shortened; feedback can be realized quickly in site; reference is provided; and guidance on production is realized.

Owner:JIANGSU HEXING AUTOMOTIVE TECH

Red mud reduction device and red mud reduction method using same

InactiveCN113913215ATake advantage ofImprove recovery rateEnergy inputChemical/physical/physico-chemical processesThermodynamicsRed mud

A red mud reduction device and a red mud reduction method using the same relate to the field of chemical engineering. The invention aims to solve the problem that red mud is difficult to be put into industrialization due to low utilization rate, low treatment efficiency or too high economic cost at present. Fe2O3 in the red mud is reduced, and a large amount of Fe3O4 is obtained through magnetic separation and is used as a raw material for production in the iron and steel industry. Meanwhile, waste heat in the treatment process is recycled to produce steam, and large economic benefits are generated. According to the red mud reduction technology using the red mud reduction device, red mud can enter a reaction kettle without complex treatment, the equipment investment is saved, and the production efficiency is guaranteed. The device and the method are applied to the field of red mud treatment.

Owner:庞瑞朋 +1

An efficient photocatalytic reactor

ActiveCN107376799BImprove flow characteristicsImprove transmission characteristicsChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesPhoto catalyticPhotocatalytic reaction

The invention discloses an efficient photo-catalytic reactor which comprises an upper cover plate and a base. The upper cover plate is arranged on the base, the efficient photo-catalytic reactor is characterized in that a first rectangular concave plane is formed in the upper end surface of the base, conducting glass is placed in the first rectangular concave plane, and a photocatalyst is arranged on the upper surface of the conducting glass; the photocatalyst is a nanorod array thin film photocatalyst; a second rectangular concave plane is formed in the lower end surface of the upper cover plate and corresponds to the first rectangular concave plane in position; an inverted micro boss array is arranged in the second rectangular concave plane; the upper cover plate is provided with a fluid inlet and a fluid outlet, and the fluid inlet and the fluid outlet communicate with the second rectangular concave plane through micro fluid input channels and micro fluid output channels correspondingly; and the micro fluid input channels and the micro fluid output channels are formed in the upper cover plate. The efficient photo-catalytic reactor provided by the invention is simple in structure, easy to mount, low in cost, high in reaction efficiency and capable of being widely applied to the fields of energy, environment protection and the like.

Owner:CHONGQING UNIV

Bubble cover and bubble cover tower

PendingCN108212071AHigh densityImprove cutting effectUsing liquid separation agentChemical/physical/physico-chemical processesContact reactionsVolumetric Mass Density

The invention provides a bubble cover and a bubble cover tower, which relates to the technical field of purifying apparatuses. The bubble cover comprises a cover body, wherein the cover body is provided with a plurality of ventilation caps projecting outwardly in the peripheral direction, a ventilation grove is formed in the ventilation cap, the ventilation groove is communicated with the interiorof the cover body, and a notch of the ventilation groove is in a same direction with an air inlet of the cover body; a plurality of vent holes are arranged on the position, close to the notch, of a side wall of the ventilation groove in the peripheral direction of the notch; and the bubble cover tower comprises a tower body and the bubble cover, wherein a plurality of tower plates are arranged inthe tower body in the height direction, each tower plate is provided with a clamping groove, the end portion of a free end of an air ascending pipe of the bubble cover is provided with a clamping arm, and the clamping arm is matched with the clamping groove. By arranging a plurality of ventilation caps, the density of the vent holes in the bubble cover is greatly increased, the cutting effect forsmoke is improved, a contact reaction area between the liquid and the chopped smoke bubbles is increased, and the purifying effect is correspondingly improved.

Owner:SHANDONG TIANLI ENERGY SAVING ENG

A Method for Reducing Large Size Calcium Aluminate Inclusions in Steel

ActiveCN110293219BPlay a barrier roleIncrease contact reaction areaMelt-holding vesselsAluminateSteelmaking

The invention discloses a method for reducing large-scale calcium-aluminate inclusions in steel. The method is to control Al 2 o 3 ‑Decarburization depth of C-quality submerged nozzle refractory material, to achieve the purpose of reducing large-scale calcium-aluminate inclusions; the continuous casting refractory involved is a tundish submerged nozzle, and the main component of the submerged nozzle refractory material is oxidation Aluminum and carbon; in steelmaking production, by controlling Al 2 o 3 ‑Decarburization depth of C-quality submerged nozzle refractory materials to reduce large-scale calcium-aluminate inclusions. The steel type produced by the method of the invention can greatly reduce the quantity of large-size calcium-aluminate and improve the quality of steel products.

Owner:ZENITH STEEL GROUP CORP CO LTD

Environment-friendly light-driven formaldehyde removal equipment

InactiveCN113385031AIncrease in sizeQuick inhalationGas treatmentDispersed particle separationDrive wheelSilver bromide

The invention discloses environment-friendly light-driven formaldehyde removal equipment. The environment-friendly light-driven formaldehyde removal equipment comprises a machine body, wherein a groove is formed in the top wall of the machine body; an expansion ball is arranged in the groove; black powder is arranged in the groove; driving cavities are symmetrically formed in the inner wall of the machine body; driving wheels are arranged in and rotationally connected with the driving cavities, magnets are embedded in the inner walls of the driving wheels, the inner walls of the driving cavities fixedly communicate with a first hose; the end, away from the driving cavity, of the first hose fixedly communicates with the groove; the magnets are embedded in the inner walls of the driving cavities; a metal coils are fixedly connected to the inner walls of the driving cavities; and an aldehyde removal cavity is formed in the inner wall of the machine body. By arranging the groove, the expansion ball, a light transmitting mirror and other structures, when light rays penetrate through the light transmitting mirror and irradiate on the expansion ball, silver bromide in the expansion ball is decomposed, so the inner volume of the expansion ball is increased; and in the absence of illumination, the expansion ball recovers to its original size, so gas needing formaldehyde removal is quickly sucked into the equipment for purification.

Owner:ZHEJIANG SHENGNA INTELLIGENT TECH CO LTD

A kind of silicon@carbon/mxene ternary composite material for lithium ion battery and its preparation method

ActiveCN111384381BImprove conductivityImproved high current rate performanceNegative electrodesSecondary cellsCarbon coatingElectrical battery

The invention relates to the field of negative electrode materials for lithium-ion batteries, and discloses a silicon@carbon / MXene ternary composite material for lithium-ion batteries and a preparation method thereof. The silicon@carbon / MXene ternary composite material is a ternary composite material obtained by performing a self-polymerization reaction of dopamine hydrochloride on the surface of a silicon material to form a polydopamine layer, and then mixing and cross-linking with MXene in a liquid phase, followed by high-temperature treatment. In this method, the secondary amine group of polydopamine on the surface of the silicon material can undergo a crosslinking reaction with the hydroxyl group on the surface of the MXene to form a covalent bond or a hydrogen bond, thereby inhibiting the agglomeration of the silicon material and MXene and improving the electrochemical performance of the silicon material. Among them, the size of the silicon material is 20-500nm, the thickness of the carbon coating layer is 3-10nm, and the mass ratio of silicon to MXene is (0.5-4):1. The resulting silicon@carbon / MXene ternary composite has a pore volume of 0.05‑0.3 cm 3 / g, the specific surface area is 60‑120m 2 / g. The silicon@carbon / MXene ternary composite material is used as the anode material of lithium-ion batteries, showing excellent cycle performance and rate performance.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com