Preparation method of battery zinc negative electrode material

A zinc negative electrode and battery technology, which is applied to battery electrodes, negative electrodes, nickel storage batteries, etc., can solve the problems of unsatisfactory battery discharge effect, no targeted design, easy crystallization of zinc negative electrodes, etc., to improve the anti-electron corrosion effect, Reduce the integrity and enhance the effect of microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

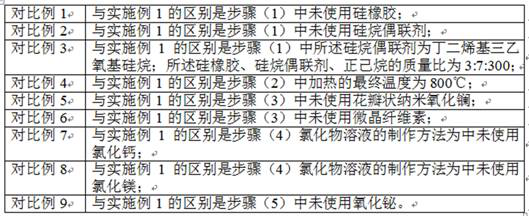

Examples

Embodiment 1

[0027] A preparation method for battery zinc negative electrode material, comprising the steps of:

[0028] (1) Carbon silicon supported on the surface of nano-zinc oxide

[0029] Mix and seal silicone rubber, silane coupling agent, and n-hexane, soak at 40°C for 20 minutes, lower the temperature to 15°C, and stir at a speed of 30r / min for 5 minutes to obtain a mixed solution, and add nano-zinc oxide to the mixed solution, After 300W ultrasonic dispersion for 20min, the mixture was dried at 50°C and 0.3 standard atmospheric pressure for 10h, and n-hexane was recovered, and the dried product was collected for later use; the silicone rubber was raw rubber powder with a fineness of 200 mesh; The coupling agent is butadienyl triethoxysilane; the mass ratio of the silicone rubber, silane coupling agent, and n-hexane is 1:0.1:300; the mass ratio of the mixed solution and nano zinc oxide is 10:3 ;

[0030] (2) Nano zinc oxide finalization

[0031] Heat the product dried in the pre...

Embodiment 2

[0039] A preparation method for battery zinc negative electrode material, comprising the steps of:

[0040](1) Carbon silicon supported on the surface of nano-zinc oxide

[0041] Mix and seal silicone rubber, silane coupling agent, and n-hexane, soak at 50°C for 30 minutes, lower the temperature to 20°C, and stir at a speed of 50r / min for 8 minutes to obtain a mixed solution, and add nanometer zinc oxide to the mixed solution, After 500W ultrasonic dispersion for 30min, dry the mixture at 55°C and 0.4 standard atmospheric pressure for 12h, recover n-hexane, and collect the dried product for later use;

[0042] Described silicone rubber is raw rubber powder of fineness 300 objects; Described silane coupling agent is vinyl triperoxy tert-butyl silane; The mass ratio of described silicone rubber, silane coupling agent, normal hexane is 3:0.5: 320; The mass ratio of the mixed solution and nano zinc oxide is 2:1;

[0043] (2) Nano zinc oxide finalization

[0044] Heat the produc...

Embodiment 3

[0052] A preparation method for battery zinc negative electrode material, comprising the steps of:

[0053] (1) Carbon silicon supported on the surface of nano-zinc oxide

[0054] Mix and seal silicone rubber, silane coupling agent, and n-hexane, soak at 45°C for 25 minutes, lower the temperature to 18°C, and stir at a speed of 50r / min for 5 minutes to obtain a mixed solution, and add nano-zinc oxide to the mixed solution, After 500W ultrasonic dispersion for 20min, the mixture was dried at 55°C and 0.3 standard atmospheric pressure for 12h, and n-hexane was recovered, and the dried product was collected for later use;

[0055] The silicone rubber is raw rubber powder with a fineness of 300 objects; the silane coupling agent is any one of butadienyl triethoxysilane, vinyl triperoxy tert-butyl silane; the silicone rubber, The mass ratio of silane coupling agent and n-hexane is 3:0.1:300; the mass ratio of the mixed solution and nano zinc oxide is 10:4.6;

[0056] (2) Nano zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com