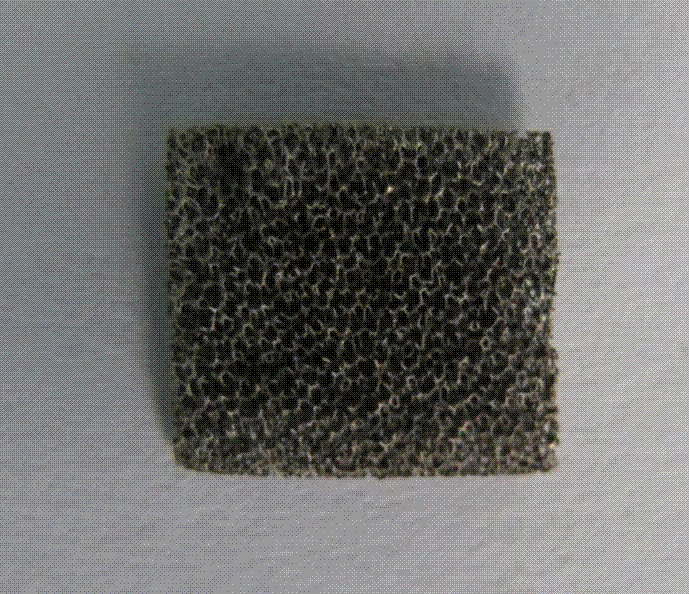

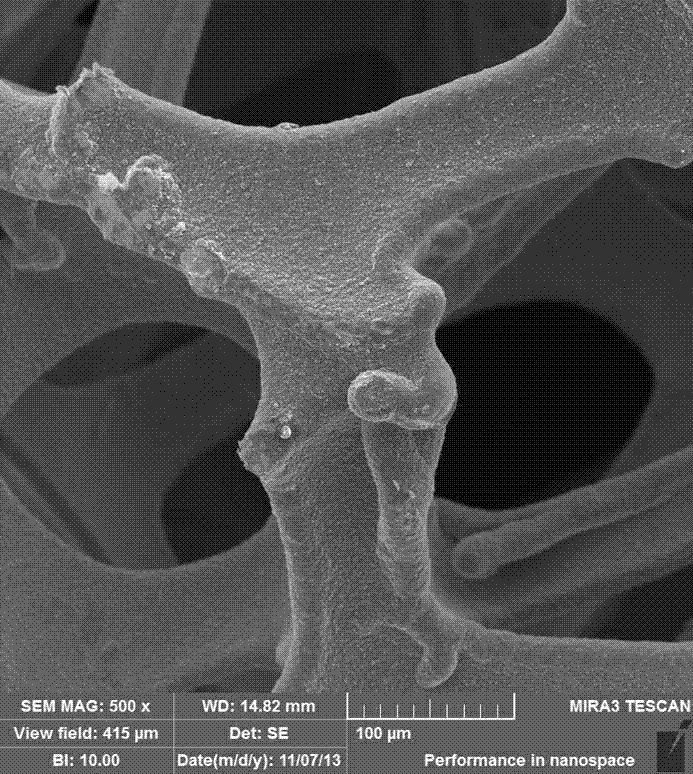

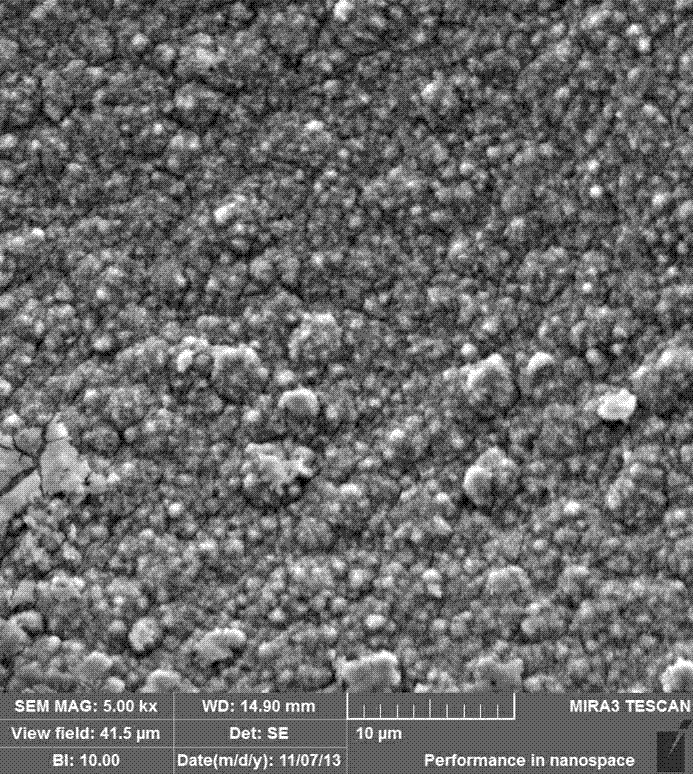

Composite hydrogen evolution electrode with copper and cobalt loaded on three-dimensional foamed nickel and preparation method thereof

A technology of hydrogen evolution electrode and nickel foam, which is applied in the fields of electrocatalytic hydrogen production and material science, can solve the problems of expensive precious metals, etc., and achieve the effects of simple operation, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a composite hydrogen evolution electrode supported by copper and cobalt on three-dimensional nickel foam is carried out according to the following steps,

[0034] a. Degrease and degrease the three-dimensional nickel foam in acetone for 1 minute, wash with ultrapure water, then acidify and activate it in 18wt.% hydrochloric acid solution, and finally place it in ultrapure water for 4 minutes;

[0035] b. Put the three-dimensional nickel foam treated in step a into the copper pyrophosphate solution, or the copper pyrophosphate solution, potassium pyrophosphate solution, and ammonium citrate solution, or a mixed solution of one or both of them, with the copper sheet as the anode , three-dimensional nickel foam as the cathode, at a current density of 0.01A / cm 2 Electrodeposition for 500s using a multifunctional pulse plating power supply under a high current;

[0036] c, cleaning the three-dimensional nickel foam with copper electrochemically depos...

Embodiment 2

[0041] A preparation method of a composite hydrogen evolution electrode supported by copper and cobalt on three-dimensional nickel foam is carried out according to the following steps,

[0042] a. Degrease and degrease the three-dimensional nickel foam in acetone for 1 minute, wash it with ultrapure water, then acidify and activate it in 18wt.% hydrochloric acid solution, and finally place it in ultrapure water for 5 minutes;

[0043] b. Put the three-dimensional nickel foam treated in step a into copper sulfate pentahydrate solution, or one or more mixed solutions of copper sulfate pentahydrate solution, biuret solution, sodium hydroxide solution, and glycerin, With copper sheet as anode and three-dimensional nickel foam as cathode, the current density is 0.03A / cm 2 Use a multi-functional pulse electroplating power supply for electrodeposition for 600s under a certain current;

[0044] c, cleaning the three-dimensional nickel foam with copper electrochemically deposited in s...

Embodiment 3

[0049] A preparation method of a composite hydrogen evolution electrode supported by copper and cobalt on three-dimensional nickel foam is carried out according to the following steps,

[0050] a. Degrease and degrease the three-dimensional nickel foam in acetone for 1 minute, wash with ultrapure water, then acidify and activate it in 18wt.% hydrochloric acid solution, and finally place it in ultrapure water for 7 minutes;

[0051] b. Put the three-dimensional nickel foam treated in step a into the mixed solution of copper sulfate pentahydrate and boric acid, take the copper sheet as the anode, and the three-dimensional nickel foam as the cathode, at a current density of 0.05A / cm 2 Electrodeposit for 700s using a multifunctional pulse electroplating power supply under high current;

[0052] c, cleaning the three-dimensional nickel foam with copper electrochemically deposited in step b with ultrapure water, and then ultrasonicating in ultrapure water for 7 minutes;

[0053] d....

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com