A kind of silicon@carbon/mxene ternary composite material for lithium ion battery and its preparation method

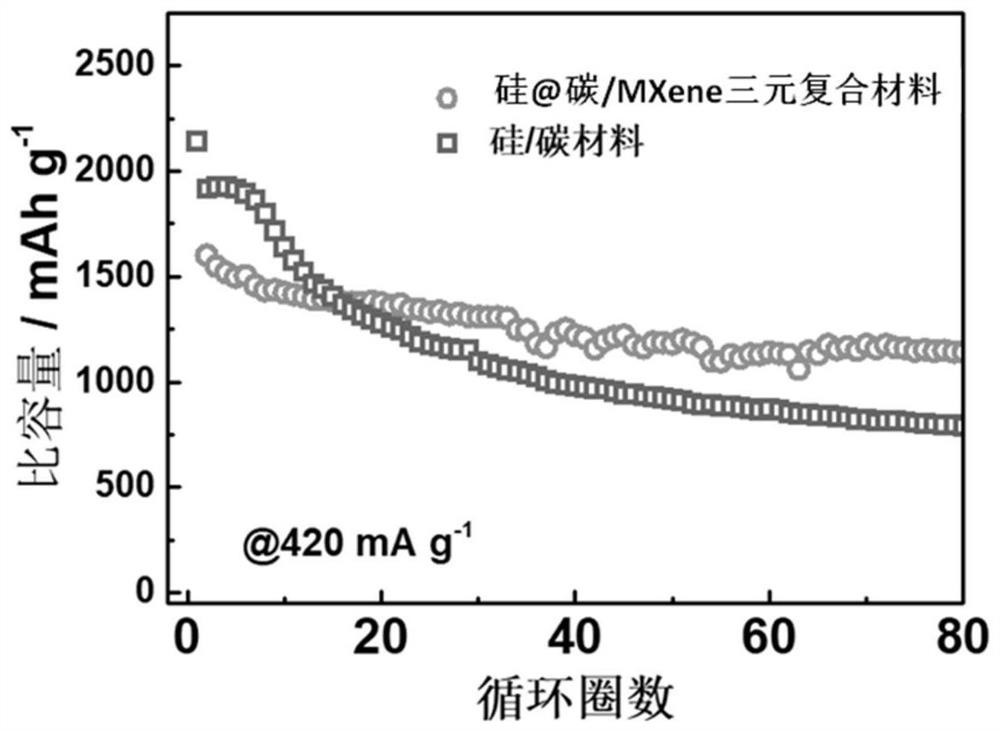

A technology for lithium-ion batteries and composite materials, applied in the field of silicon@carbon/MXene ternary composite materials for lithium-ion batteries and its preparation, can solve problems such as poor preparation effect, difficulty in forming a uniformly dispersed composite structure, and severe MXene agglomeration , to achieve the effect of increasing the contact reaction area, improving the high current rate performance, and stabilizing the cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

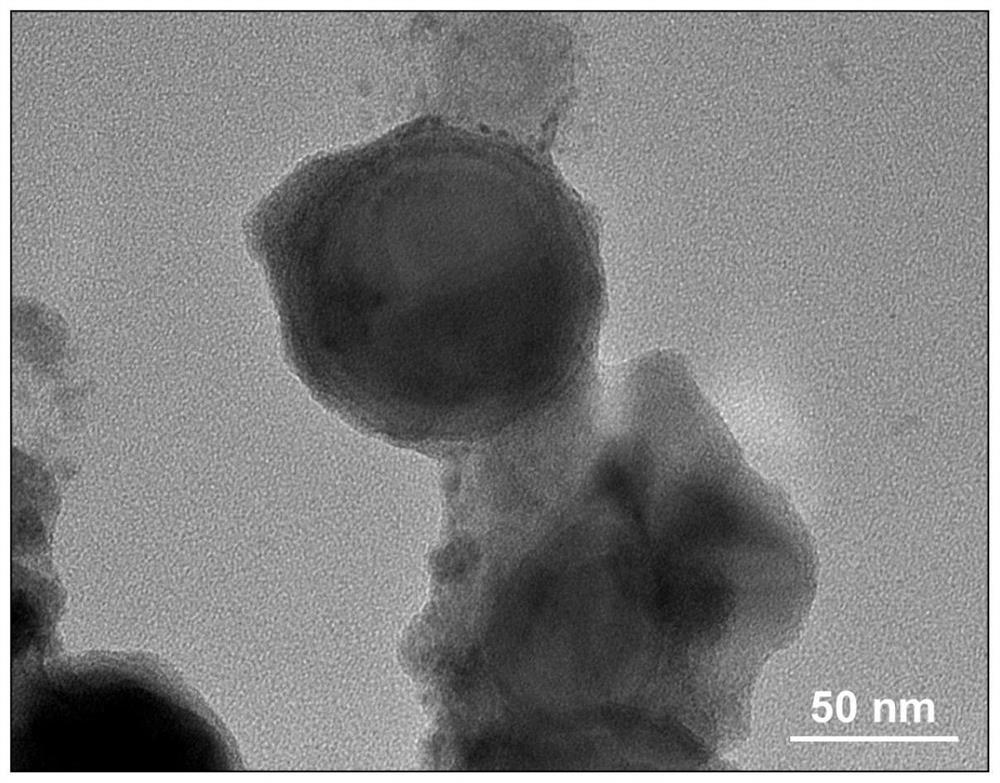

[0031] (1) Weigh 0.2423g C 4 h 11 NO 3 Dissolve in 200ml deionized water to make 0.01mol / L Tris buffer. Weigh 100 mg of nano-silicon material with a size of about 90 nm and ultrasonically disperse it in Tris buffer, add 100 mg of dopamine hydrochloride, stir for 24 hours, and collect it by centrifugation to obtain Si@polydopamine material, that is, polydopamine-coated silicon material, such as figure 1 shown;

[0032] (2) Re-disperse the Si@polydopamine material in 100ml deionized water, add 25ml MXene dispersion (2mg / ml), stir for 1h and then vacuum filter to obtain the Si@polydopamine / MXene material (mass ratio, Si:MXene =2:1);

[0033] (3) Transfer Si@polydopamine / MXene to a vacuum oven, and vacuum treatment at 60°C for 6 hours, so that the secondary amine groups of polydopamine and the hydroxyl groups on the surface of MXene undergo a crosslinking reaction to form covalent bonds or hydrogen bonds;

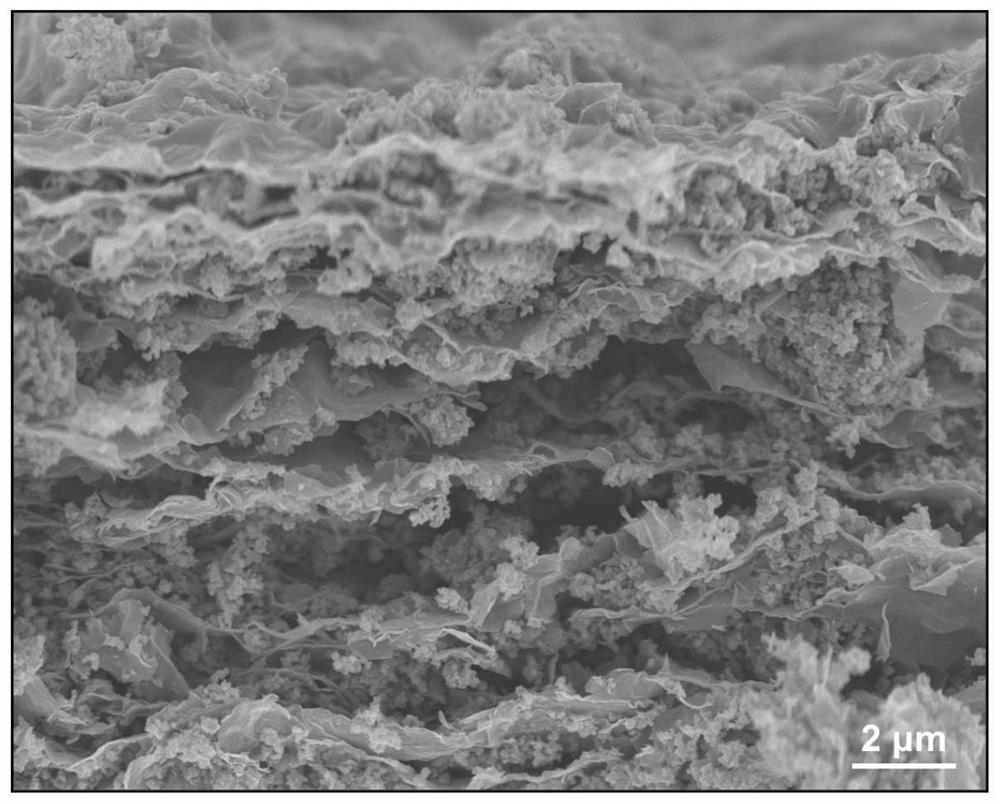

[0034] (4) The cross-linked Si@polydopamine / MXene was placed in a tub...

Embodiment 2

[0041] (1) Weigh 0.2423g C 4 h 11 NO 3 Dissolve in 200ml deionized water to make 0.01mol / L Tris buffer. Weigh 100 mg of nano-silicon material with a size of about 90 nm and ultrasonically disperse it in Tris buffer, add 100 mg of dopamine hydrochloride, stir for 24 hours, and collect by centrifugation to obtain Si@polydopamine material;

[0042] (2) Redisperse the Si@polydopamine material in 100ml deionized water, add 100ml MXene dispersion (2mg / ml), stir for 1h and then vacuum filter to obtain the Si@polydopamine / MXene material (mass ratio, Si:MXene =0.5:1);

[0043] (3) Transfer Si@polydopamine / MXene to a vacuum oven, and vacuum treatment at 60°C for 6 hours, so that the secondary amine groups of polydopamine and the hydroxyl groups on the surface of MXene undergo a crosslinking reaction to form covalent bonds or hydrogen bonds;

[0044] (4) The cross-linked Si@polydopamine / MXene was placed in a tube furnace and treated at 600 °C for 2 h under an argon atmosphere to obta...

Embodiment 3

[0048] (1) Weigh 0.2423g C 4 h 11 NO 3 Dissolve in 200ml deionized water to make 0.01mol / L Tris buffer. Weigh 100 mg of nano-silicon material with a size of about 90 nm and ultrasonically disperse it in Tris buffer, add 100 mg of dopamine hydrochloride, stir for 24 hours, and collect by centrifugation to obtain Si@polydopamine material;

[0049] (2) Redisperse the Si@polydopamine material in 100ml of deionized water, add 12.5ml of MXene dispersion (2mg / ml), stir for 1h and then vacuum filter to obtain the Si@polydopamine / MXene material (mass ratio, Si: MXene=4:1);

[0050] (3) Transfer Si@polydopamine / MXene to a vacuum oven, and vacuum treatment at 60°C for 6 hours, so that the secondary amine groups of polydopamine and the hydroxyl groups on the surface of MXene undergo a crosslinking reaction to form covalent bonds or hydrogen bonds;

[0051] (4) The cross-linked Si@polydopamine / MXene was placed in a tube furnace and treated at 600 °C for 2 h under an argon atmosphere to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com