Regenerated lead copper removal agent and preparation method thereof

A technology of copper removal agent and regenerated lead, which is applied in the field of regenerated lead, can solve problems such as poor separation effect of slag and lead, environmental pollution, and reduced lead yield, so as to improve the separation effect of slag and lead, solve environmental pollution problems, and improve contact The effect of the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

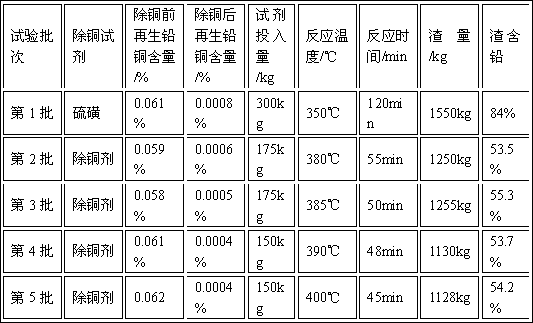

Examples

Embodiment 1

[0021] A regenerated lead copper remover comprises the following components by mass fraction: 70% of pyrite, 10% of fluorite, 15% of sulfur and 5% of sodium carbonate.

[0022] The copper removal agent is prepared through the following steps:

[0023] 1) Mix pyrite and fluorite according to the formula ratio, then crush, sieve, sort, dry at 105°C for 60 minutes, and then cool naturally to obtain semi-finished raw materials with a particle size of 0.5-30 μm;

[0024] 2) Mix the pyrite and fluorite powder produced in step 1 with flaky sulfur and sodium carbonate according to the formula ratio, and stir at a speed of 60r / min for 60min to obtain a copper removing agent.

Embodiment 2

[0026] A regenerated lead copper remover comprises the following components by mass fraction: 65% of pyrite, 15% of fluorite, 10% of sulfur, and 10% of sodium carbonate.

[0027] The copper removal agent is prepared through the following steps:

[0028] 1) Mix pyrite and fluorite according to the formula ratio, then crush, sieve, sort, dry at 110°C for 65 minutes, and then cool naturally to obtain semi-finished raw materials with a particle size of 0.5-30 μm;

[0029] 2) Mix the pyrite and fluorite powder produced in step 1 with flaky sulfur and sodium carbonate according to the formula ratio, and stir at a speed of 60r / min for 60min to obtain a copper removing agent.

Embodiment 3

[0031] A regenerated copper remover for lead comprises the following components by mass fraction: 75% of pyrite, 10% of fluorite, 10% of sulfur, and 5% of sodium carbonate.

[0032] The copper removal agent is prepared through the following steps:

[0033] 1) Mix pyrite and fluorite according to the formula ratio, then crush, sieve, sort, bake at 115°C for 70 minutes, and then cool naturally to obtain semi-finished raw materials with a particle size of 0.5-30 μm;

[0034] 2) Mix the pyrite and fluorite powder produced in step 1 with flaky sulfur and sodium carbonate according to the formula ratio, and stir at a speed of 60r / min for 60min to obtain a copper removing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com