Method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas

A technology for desulfurization and denitrification and boiler flue gas, which is applied in the field of flue gas dedusting, desulfurization and denitrification, can solve the problem of not being able to adapt to the high temperature and acid-base corrosion environment of biomass power plants, affecting the normal operation status and working performance of equipment, and the removal efficiency being affected by the fluctuation of feeding work impact and other issues, to achieve the effect of improved denitrification efficiency, long reaction time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

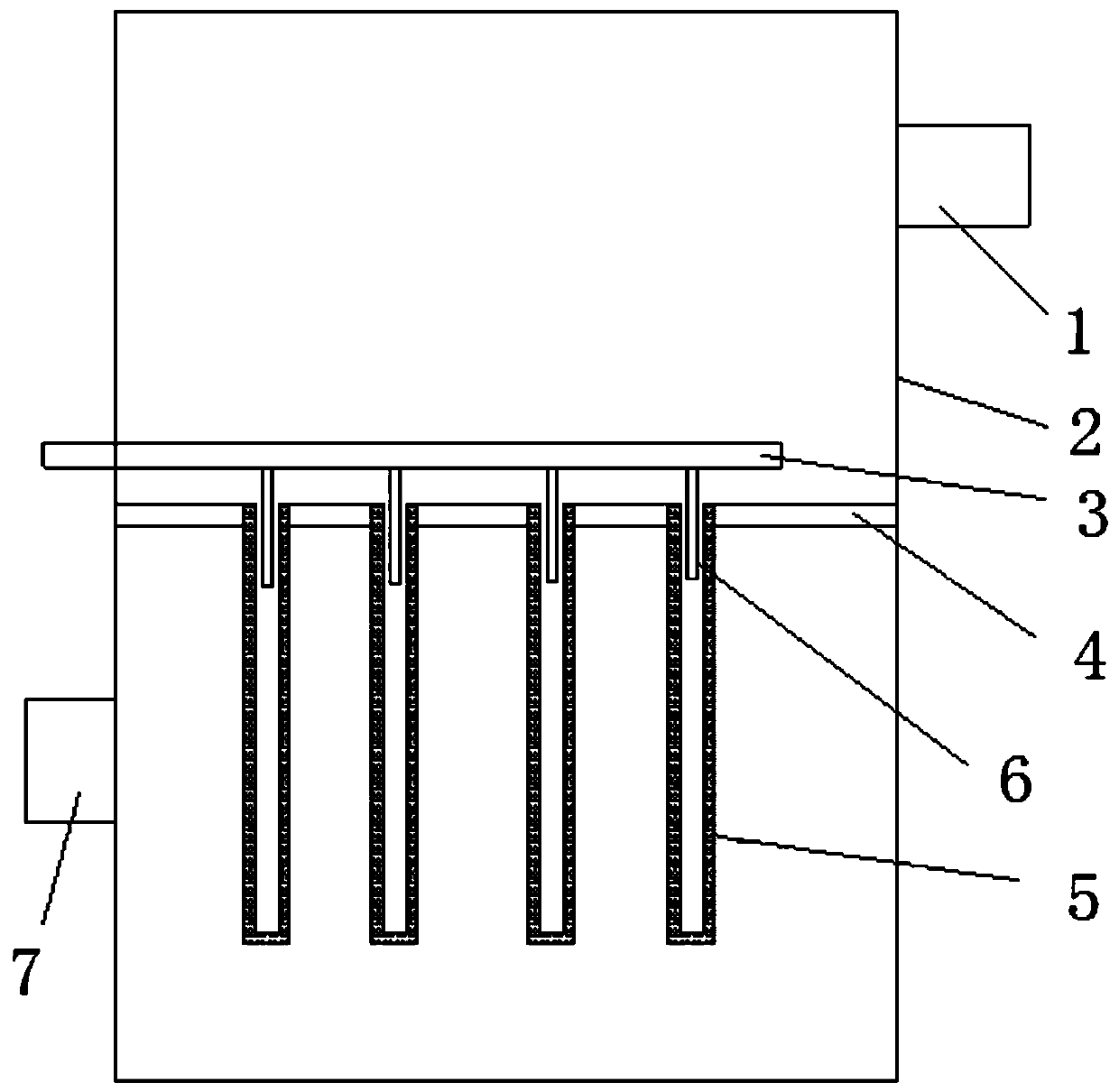

Image

Examples

Embodiment 1

[0064] This embodiment is implemented in a certain biomass power generation boiler, the main raw material is biomass, and the waste gas mainly contains soot, sulfur oxides, nitrogen oxides and the like. According to the biomass test report, it can be known that the biomass used in this embodiment has a sulfur content of 0.32% and an ash content of 7.11%. According to the calculation: SO 2 The production capacity is 458.88t / a (129.6kg / h), and the production concentration is 466.4mg / m 3 ; In order to meet the standard limit requirements of the "Boiler Air Pollutant Emission Standard", the amount of alkali consumed for desulfurization is 287t / a, and the amount of lime is 202t / a. According to the biomass test report, it can be known that the nitrogen content of the biomass used in this project is 0.22%. According to the calculation, NO X The production capacity is 281.06t / a (79.4kg / h), and the production concentration is 285.7mg / m 3 . In order to meet the standard limit requi...

Embodiment 2

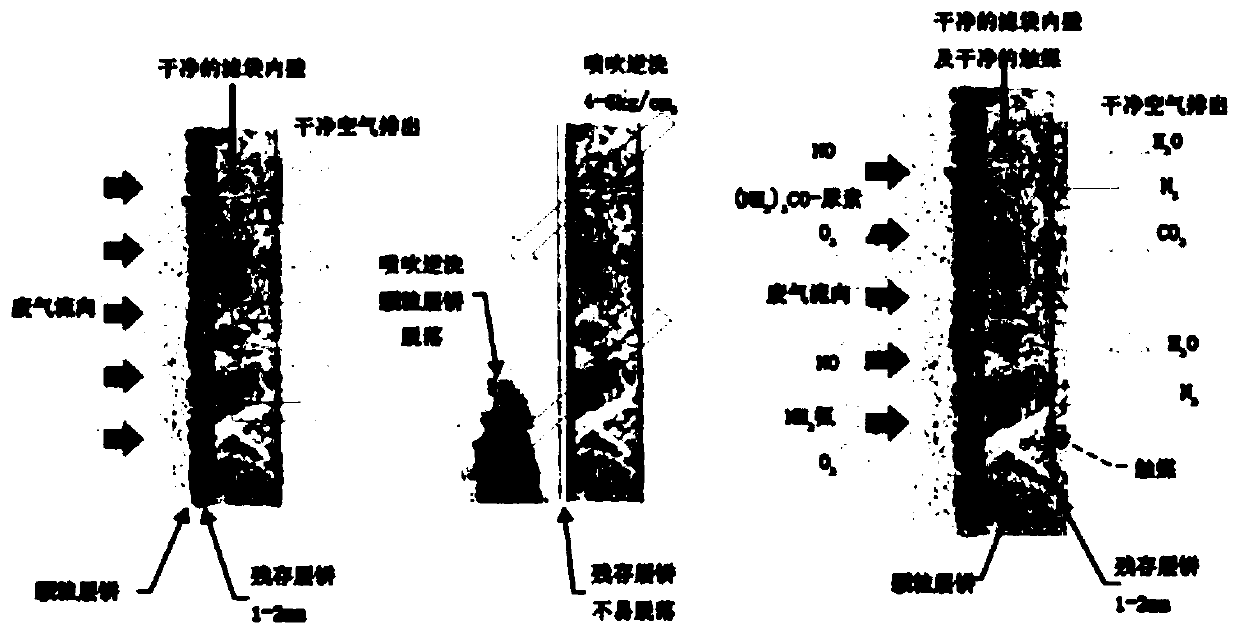

[0081] Both the inlet and outlet of the flue gas system are equipped with an online continuous detection system for flue gas, and the inlet and outlet are monitored separately: SO 2, O 2 , temperature, pressure, flow, dust. The desulfurization reactor is designed with high-efficiency sodium-based dry powder injection and uniform distribution device. After the flue gas discharged from the boiler is adjusted by hot flue gas, the temperature of the flue gas is 300°C. 3 , baking soda) ultrafine particle (600-650 mesh) powder, the ultrafine powder baking soda particle has a huge specific surface area, and at a reasonable flue gas temperature, it is rapidly decomposed into fresh sodium carbonate when heated. Sodium carbonate, with high surface activity, has a strong ability to react with acidic substances, and it quickly reacts with acidic substances in flue gas such as SO 2 , SO 3 , HF, HCl and other reactions. Such as reacting with SOx in flue gas to generate sodium sulfite an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com