Patents

Literature

58results about How to "Achieve ultra-clean emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for integrating ultra-clean emission, desulfurization, denitrification and dedusting of flue gas and process of device

InactiveCN106237814AOvercome the serious problem of escapingPromote oxidationDispersed particle separationFlue gasEmission standard

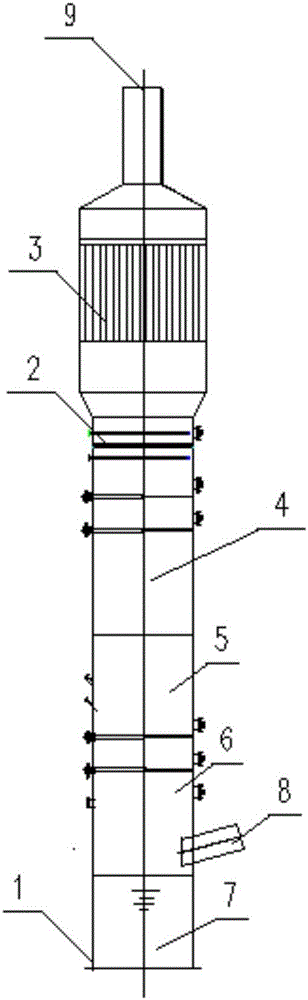

The invention discloses a device for integrating ultra-clean emission, desulfurization, denitrification and dedusting of flue gas, and a process of the device. The device comprises a tower body, wherein a flue gas inlet and a flue gas outlet are formed in the tower body; the flue gas inlet is formed in a lower side wall of the tower body; the flue gas outlet is formed in the top of the tower body; the device comprises a slurry pool, a desulfurization layer, an oxidation layer, a denitrification layer and a wet electrostatic precipitator from the tower bottom to top sequentially; the flue gas enters the tower body from the flue gas inlet, and is subjected to the desulfurization of a lower spraying layer, the oxidation of a middle oxidation layer, the denitrification of an upper spraying layer and the dedusting of the wet electrostatic precipitator sequentially, so that the flue gas at the outlet reaches ultra-clean emission standards of the flue gas. In the invention, ClO2 is used as an oxidant for oxidizing NO, and MgOH is used as a desulfurization and denitrification agent, to overcome the shortcomings of complicated structure and poor removal effect of a traditional desulfurization and denitrification device; fine particles in the flue gas can be removed in the same device in order by adopting a mode of mounting the wet electrostatic precipitator at the tower top, so as to effectively prevent the formation of 'gypsum rain' and improve the purification efficiency of the flue gas.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

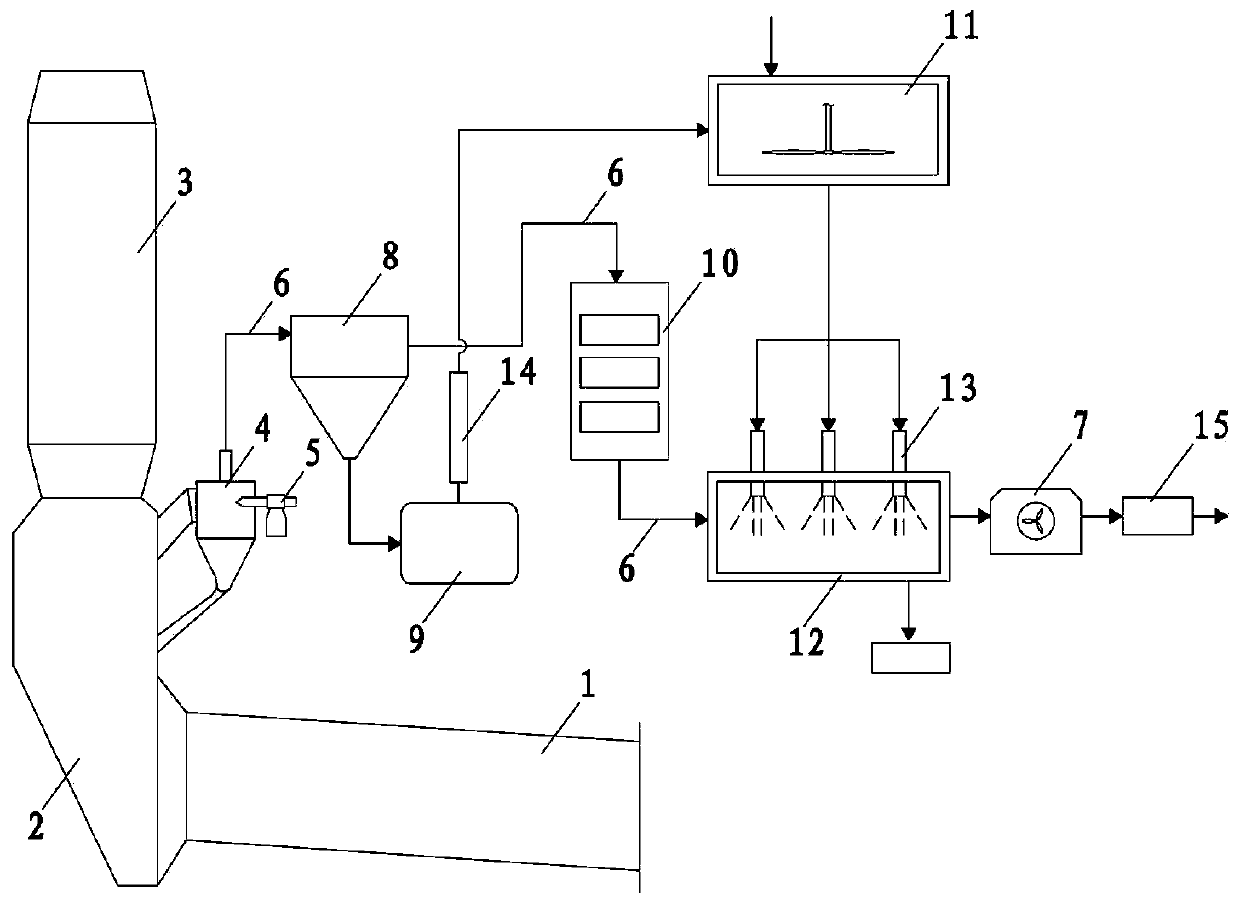

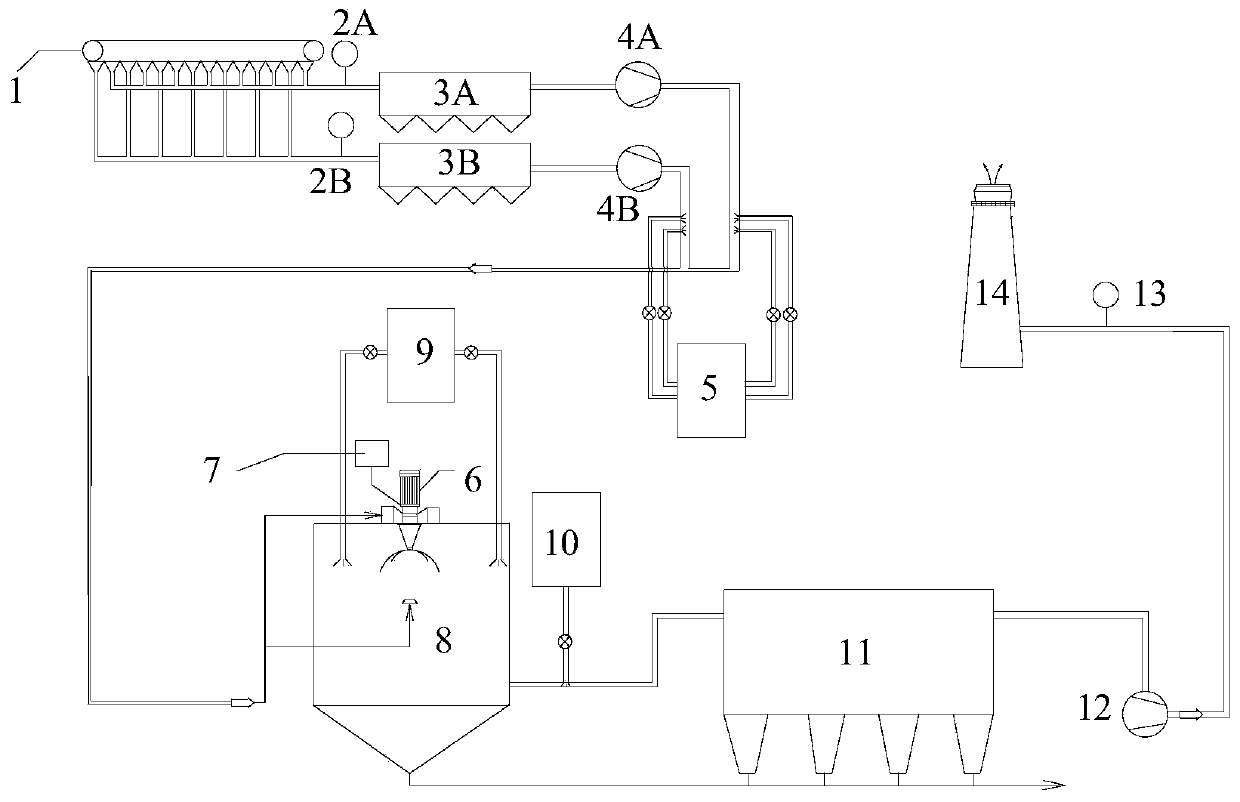

Boiler flue gas denitration purification system and boiler flue gas denitration purification method

ActiveCN104888591ANo secondary pollutionWill not cause secondary pollutionUsing liquid separation agentOzone generatorFlue gas

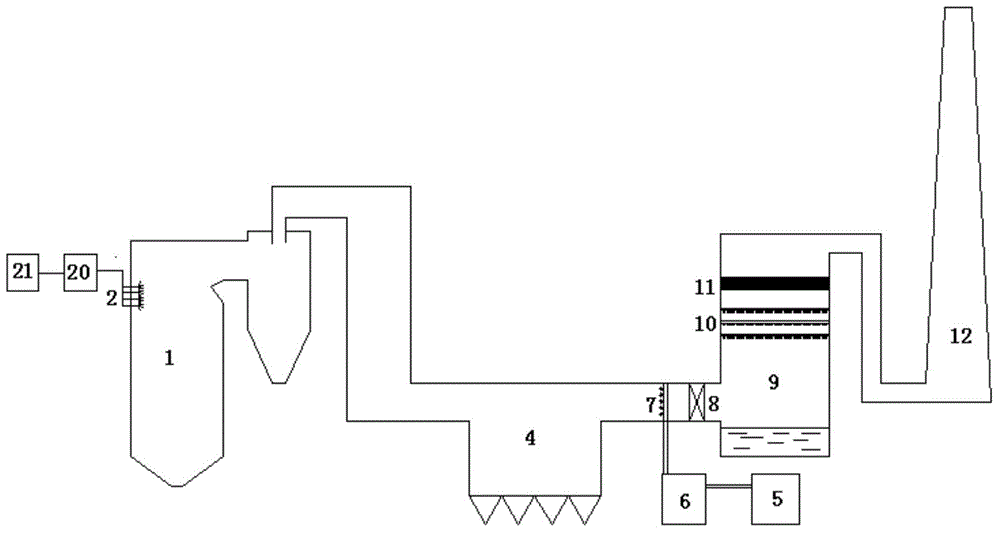

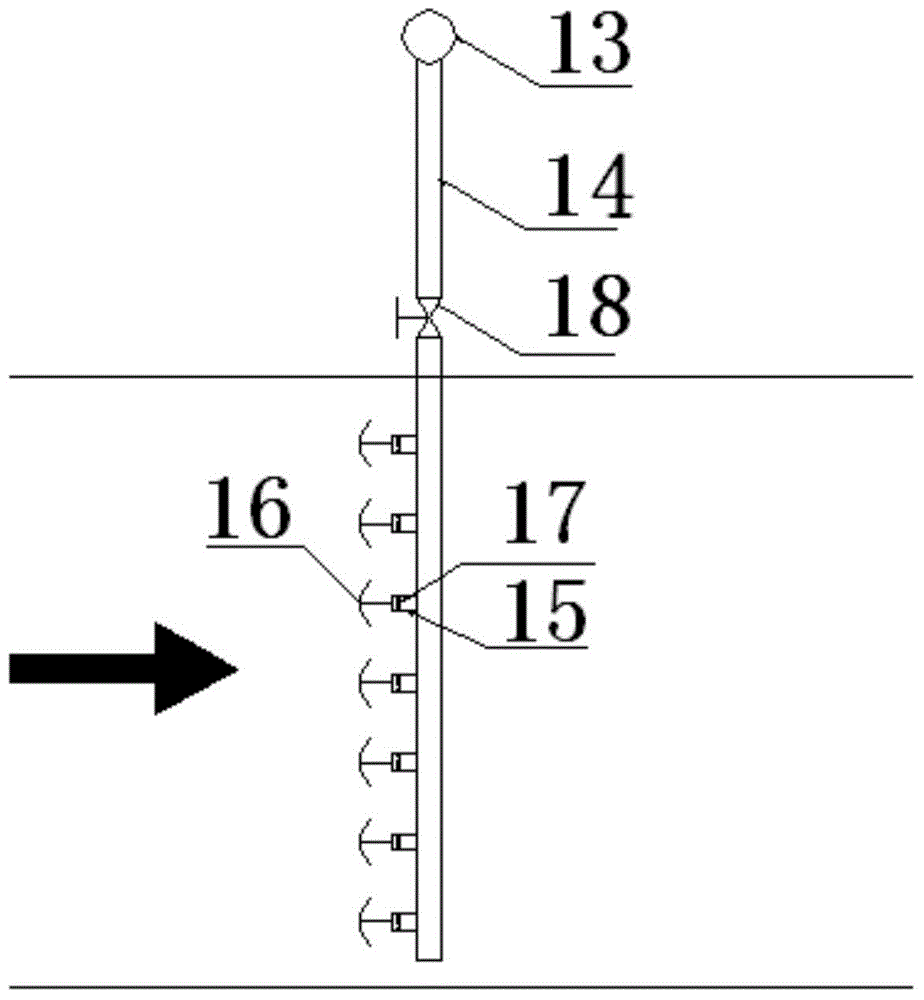

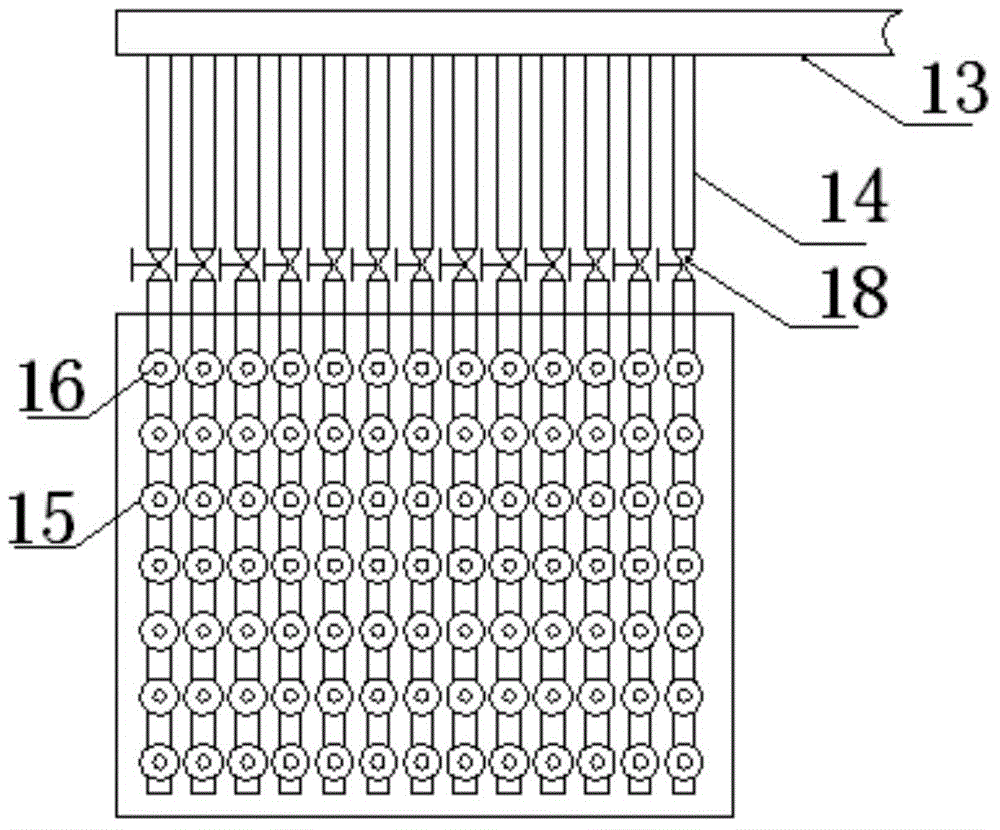

The invention discloses a boiler flue gas denitration purification system which comprises a boiler, a dust collector, a desulfurization tower and a chimney which are connected in sequence, wherein the hearth of the boiler is connected with a denitration reductant jet module, the dust collector is connected with the desulfurization two through an inlet flue of the desulfurization tower; the purification system further comprises an ozone jet device and a static mixer which are arranged in the inlet flue of the desulfurization tower in sequence along the flowing direction of the flue gas, an ozone generator connected with the ozone jet device and an air separation device connected with the ozone generator. The invention further provides a method for performing flue gas denitration by using the system. By ingeniously arranging an ozone denitration device in front of the desulfurization tower of an existing denitration system, not only is the oxynitride concentration of the final flue gas controlled to be not greater than 20mg / Nm<3>, and also no secondary environment pollution is caused; the system is convenient for modification on the basis of an original denitration system; while the resource is saved and the cost is lowered, relatively high denitration efficiency can be guaranteed.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

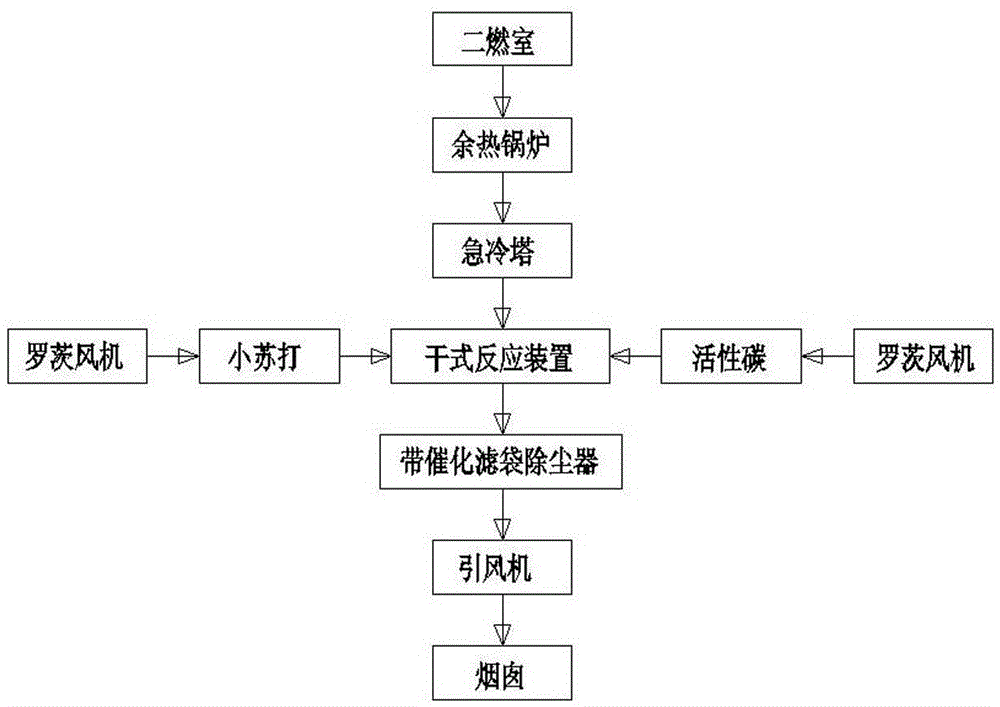

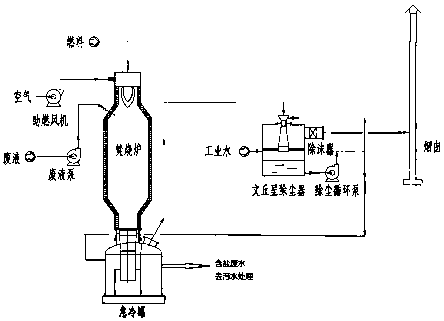

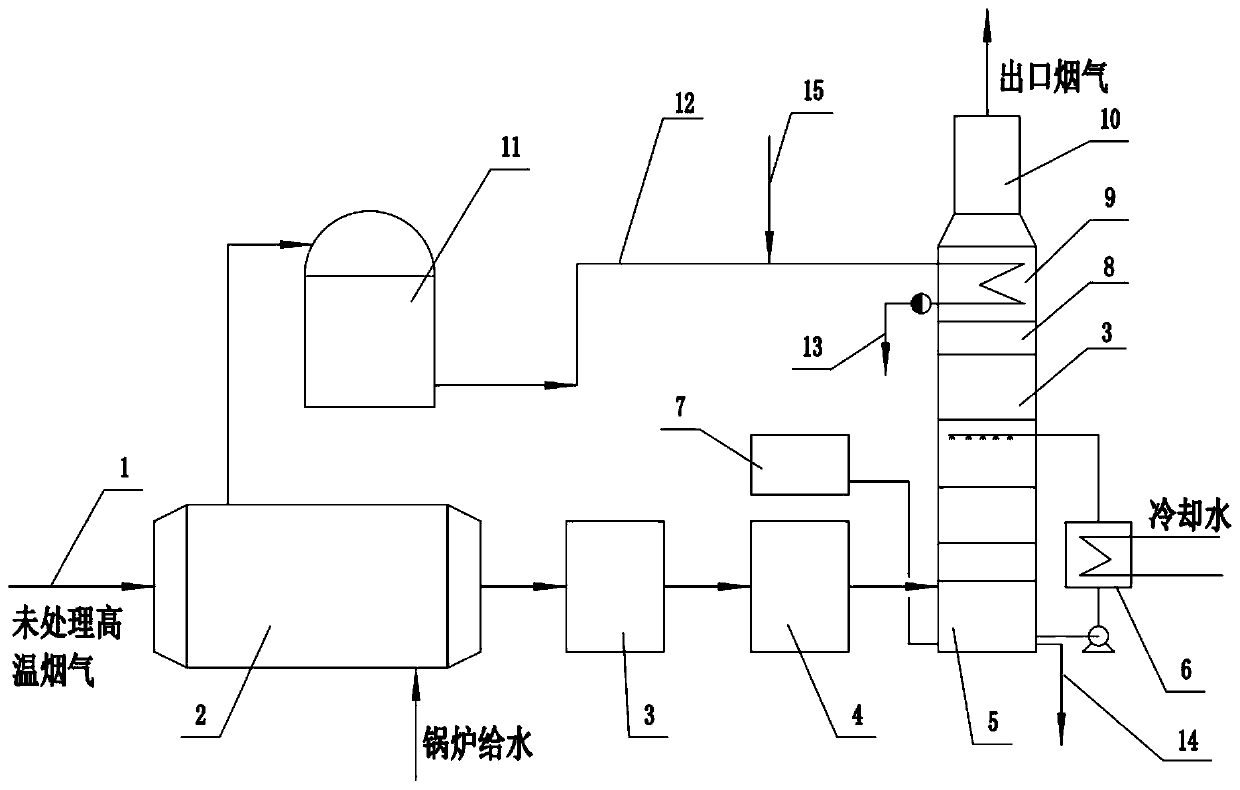

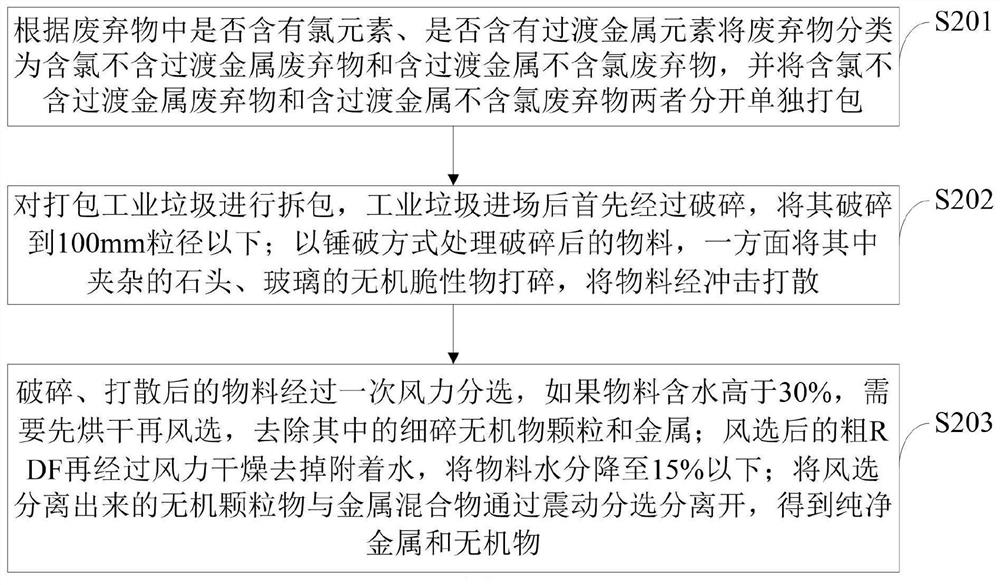

Ultra-clean treatment method for incinerated tail gas

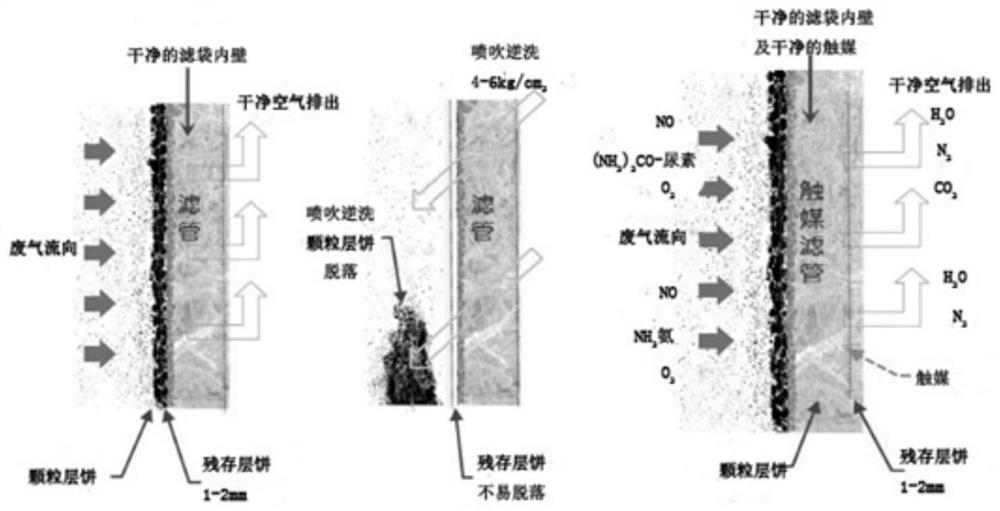

InactiveCN105627335ALow powerSmall running resistanceDispersed particle separationCombustion technology mitigationCombustion chamberAtmospheric air

The invention discloses an ultra-clean treatment method for incinerated tail gas. The ultra-clean treatment method is characterized by sequentially comprising the steps that the tail gas continues to be combusted through a secondary combustion chamber; heat recovery is conducted on the tail gas through a waste heat boiler; the tail gas is cooled through a quench tower; baking soda powder and active carbon powder are sprayed into the tail gas exhausted out of the quench tower, and the tail gas, the baking soda powder and the active carbon powder are mixed and fed into a dust remover provided with a catalytic filtering bag to remove heavy metal and dioxin in the tail gas; and the qualified tail gas with the acid gas being removed is exhausted into the atmosphere through an induced draft fan and a chimney. The ultra-clean processing method is simple in technique. By treating and incinerating the tail gas through the method, spraying, washing and smoke reheating are not needed, the effect for removing the dioxin in the tail gas is good, fire disasters can be avoided, and the operation cost is reduced; and in addition, secondary pollution such as sewage is avoided. The ultra-clean processing method is suitable for treating the tail gas exhausted from household refuse and hazardous waste combustion furnaces.

Owner:JIANGSU QUANNENG ELECTROMECHANICAL EQUIP ENG LTD BY SHARE LTD

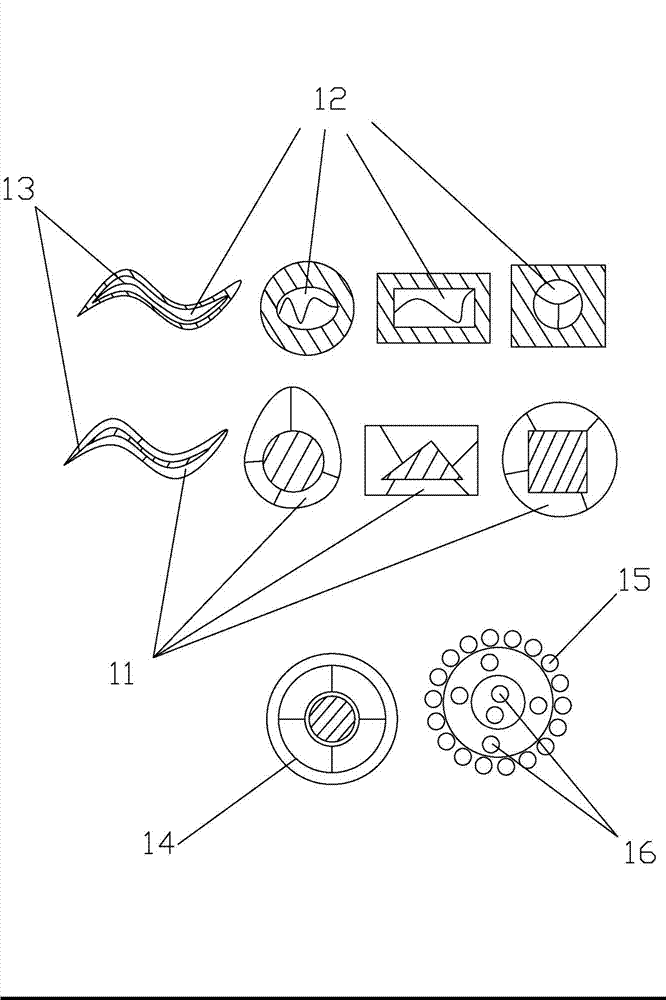

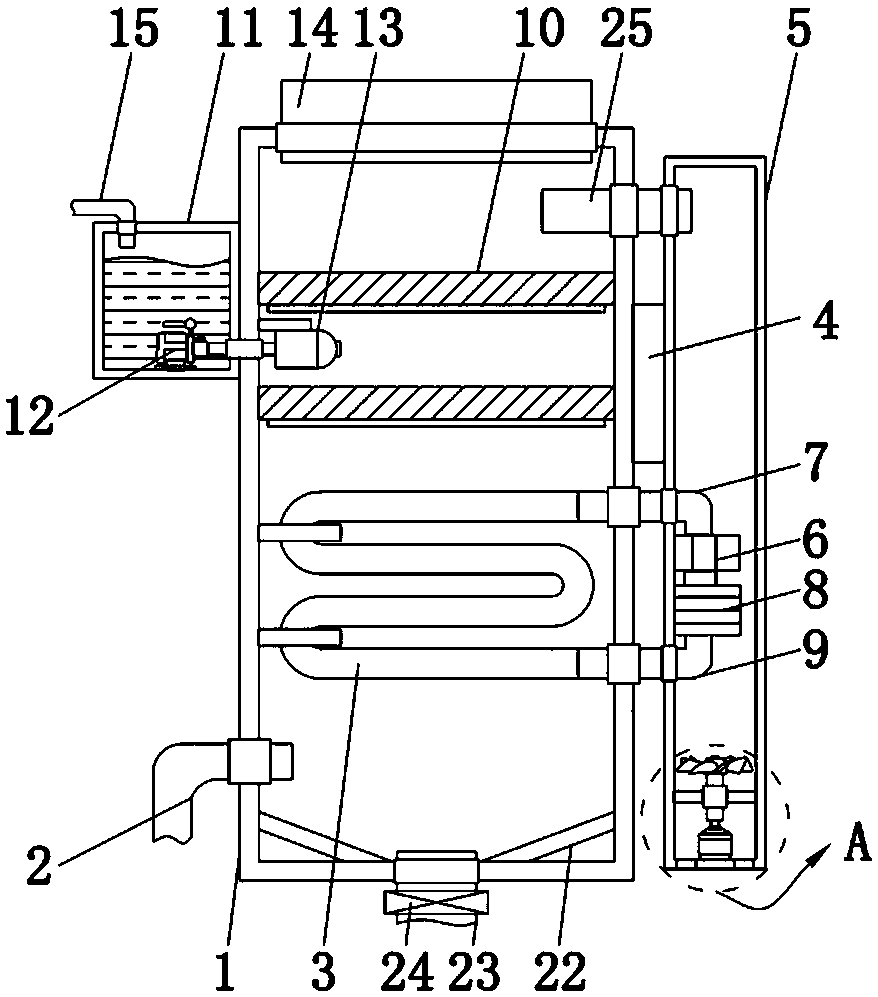

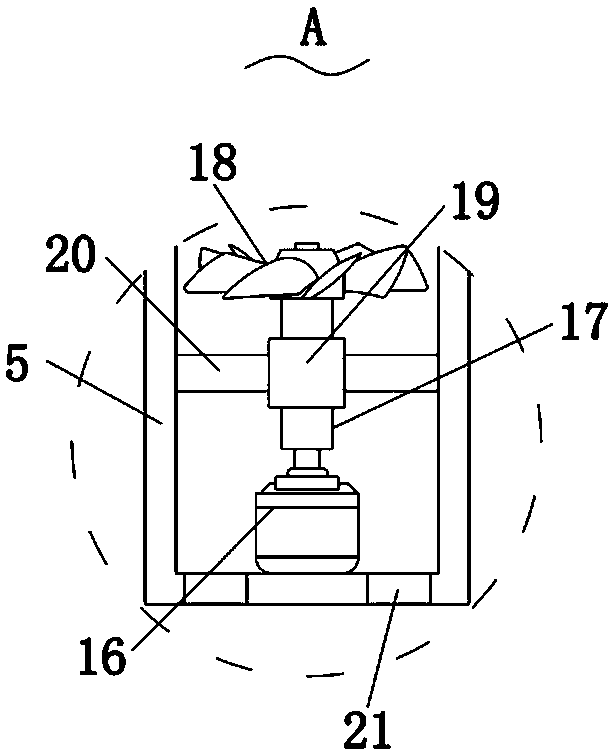

Demisting device for cooling haze and removing dust

PendingCN106975312AAchieve ultra-clean emissionsCombination devicesGas treatmentEngineeringDust emission

The invention relates to a demisting device for cooling haze and removing dust. The demisting device comprises demisters, such as, a haze cooler / condenser, a backflow plate, a big bent plate / big wave plate, a flow mixing plate and an ultra dazzle plate, wherein the haze cooler utilizes a refrigerating system with a shell / chamber type tunnel to condense the dust into fog, haze, or a cooling system, such as, use, air and boiler airing, is used as a first-level tubular demister, so that most dust and fog drop can be effectively removed; the demisters, such as, the backflow plate, can further gather, centrifuge at ultrahigh speed and remove the haze formed by the condenser; the professional instruments, such as, a liquid collecting wall and a drainage ditch, can realize the systematizing and streamlining of the demisting haze-removing operation and can eliminate the dust carrying; the dust emission is below 5mg / Nm<3> and the water mist is below 10mg / Nm<3>; the multi-level haze cooler is arranged for realizing zero emission at the rate of feeding dust of 30mg / Nm<3> and ultra-clean emission at the rate of 30-60mg / Nm<3>; and the device can simultaneously and efficiently remove SO3 aerosol and heavy metals, such as, Hg0 particles.

Owner:孙厚杰

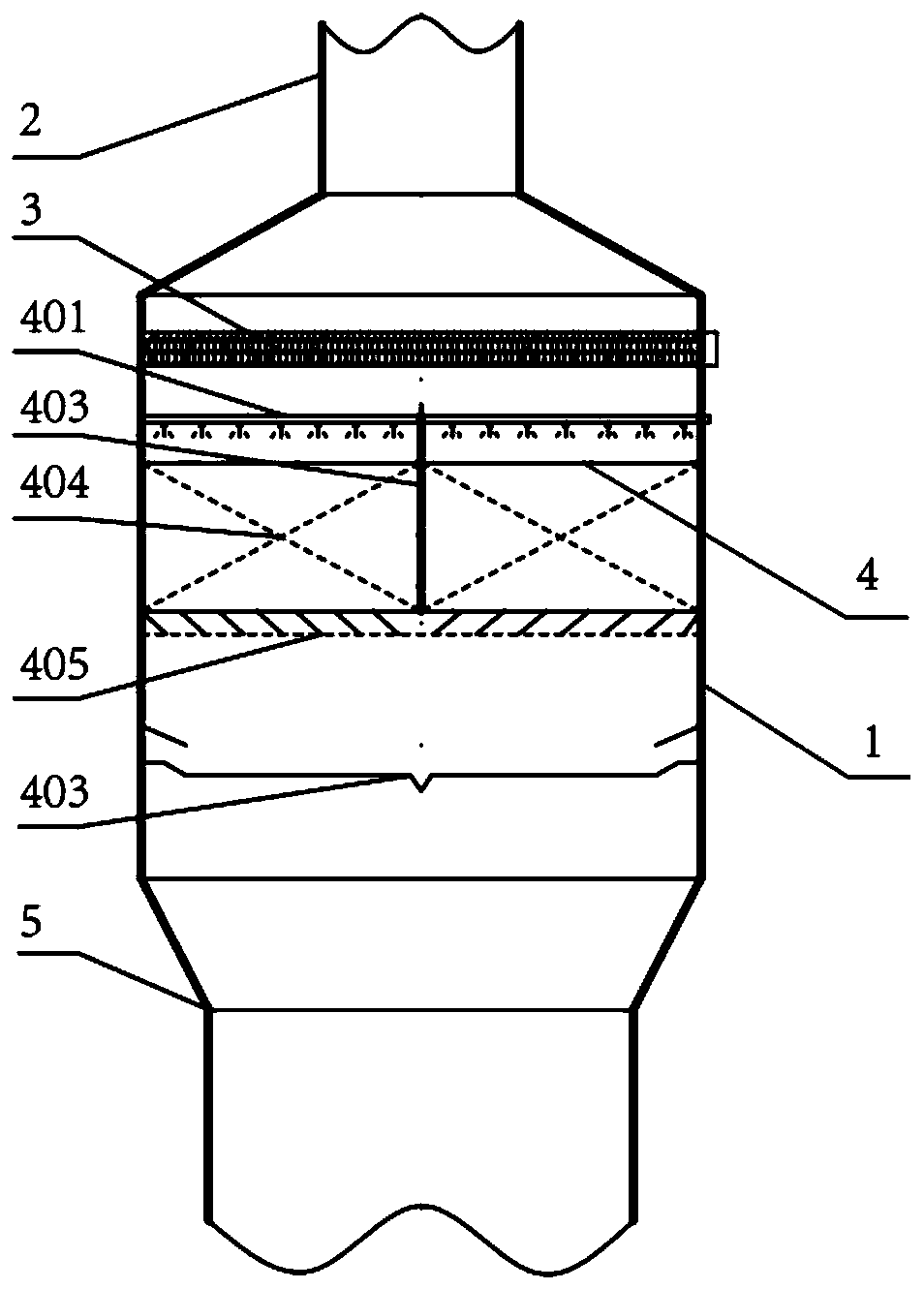

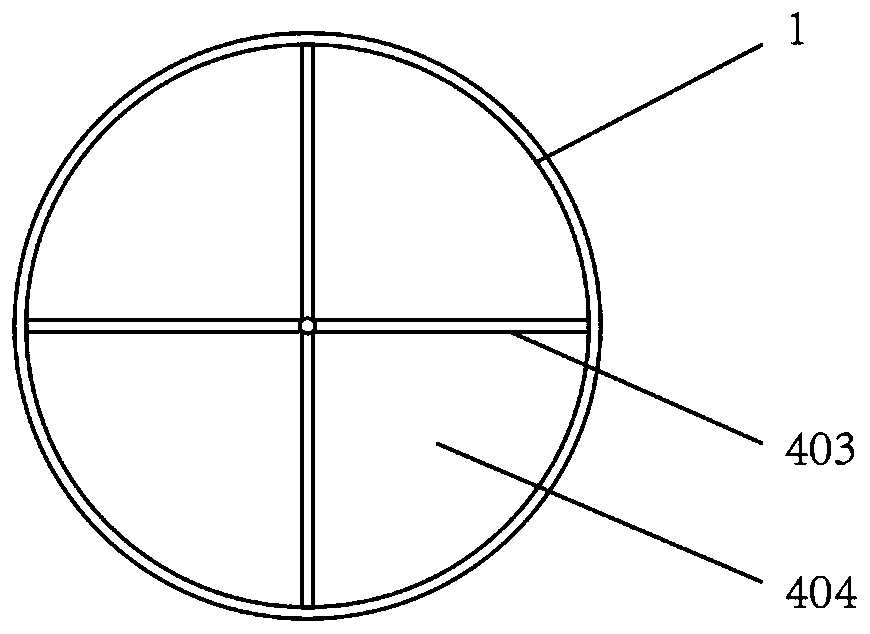

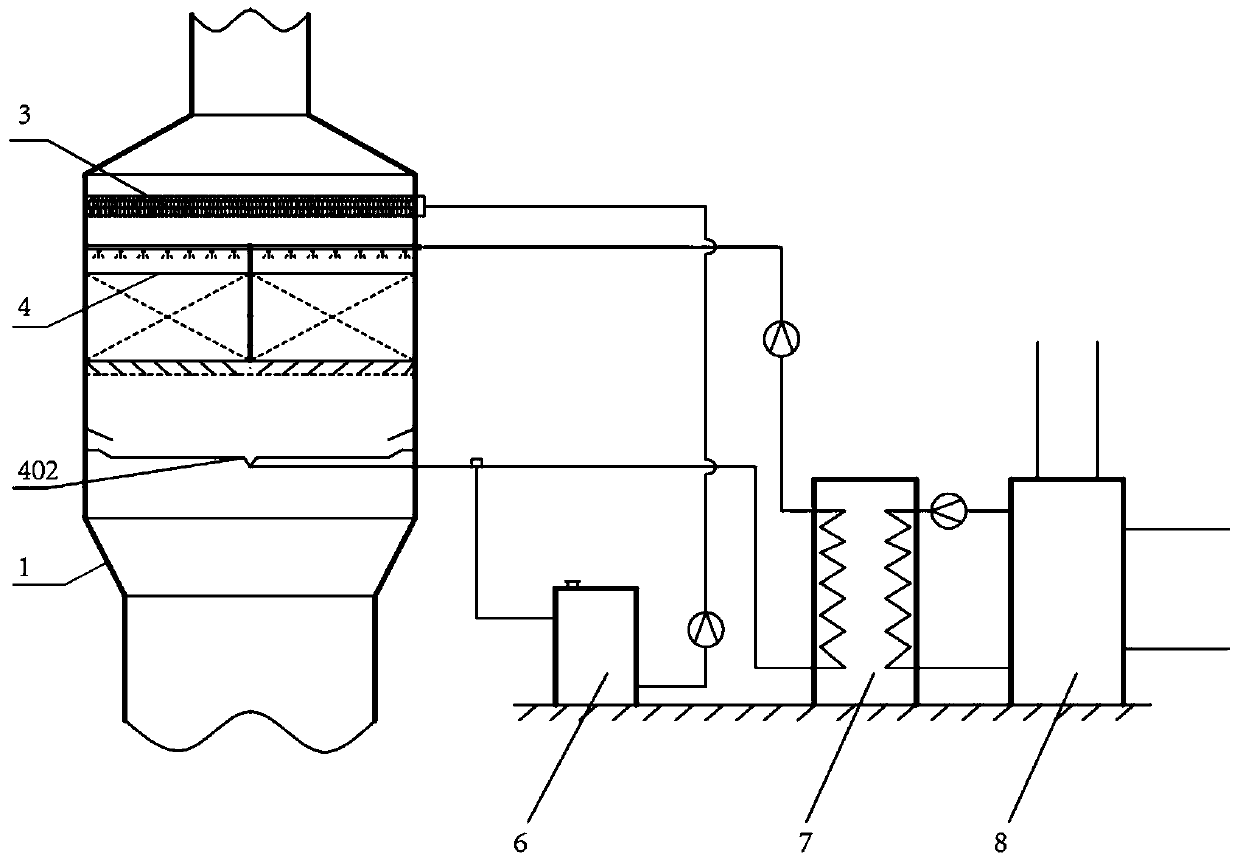

Integrated treatment method and device for flue gas wet-type phase-change ultraclean dust removal and rime fog removal

PendingCN109794133ASolve the problem of dust removal, whitening and fog removalSolve the smearing visual senseCombination devicesFlue gasWater resources

The invention discloses an integrated treatment method and device for flue gas wet-type phase-change ultraclean dust removal and rime fog removal. The method comprises the following steps of 1, cooling, wherein to-be-treated flue gas is cooled, so that saturated wet flue gas is subjected to phase change and liquefied into liquid drops; 2, liquid drop agglomeration and dust removal, wherein flue gas containing the liquid drops continues to be collided and agglomerated under the function of a rotational flow plate, and formed water drops adsorb flue gas dust in the falling process; 3, rime fog removal, wherein the flue gas treated in step 2 and the gas subjected to rime fog removal are sufficiently mixed before flue gas is discharged, unsaturated flue gas is formed, and then the treated fluegas is directly discharged. By means of the integrated treatment method and device, the purpose of dust removal and rime fog removal of wet-type desulfurized flue gas is effectively achieved, the moisture in the discharged flue gas is recycled while the problem of tailing of visual organs is solved, the water resource is saved, and the purposes of environmental protection, standard reaching, andultralow near-zero discharge are achieved.

Owner:YUNNAN HUAYUN TIANLANG ENVIRONMENTAL PROTECTION

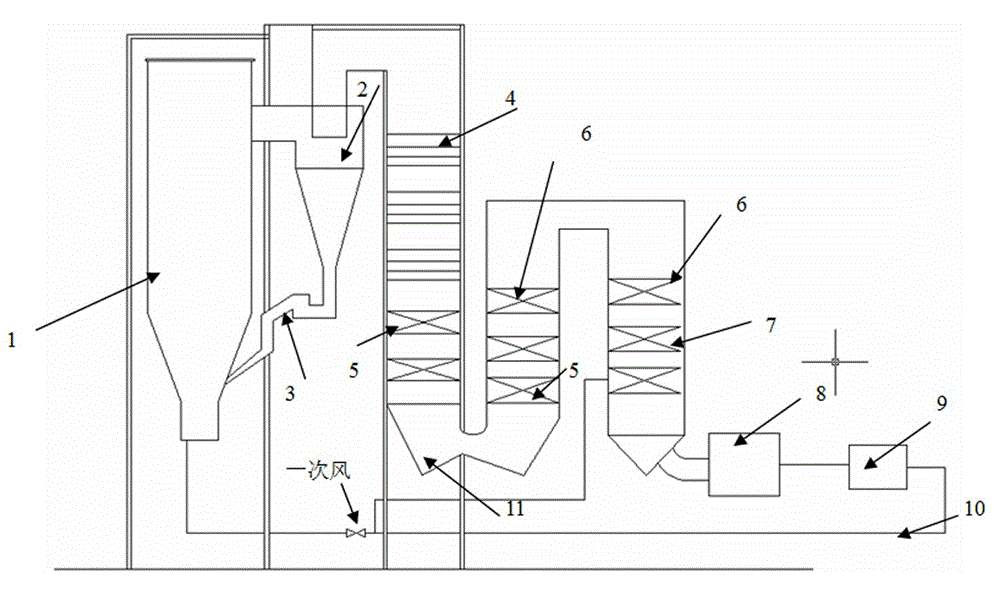

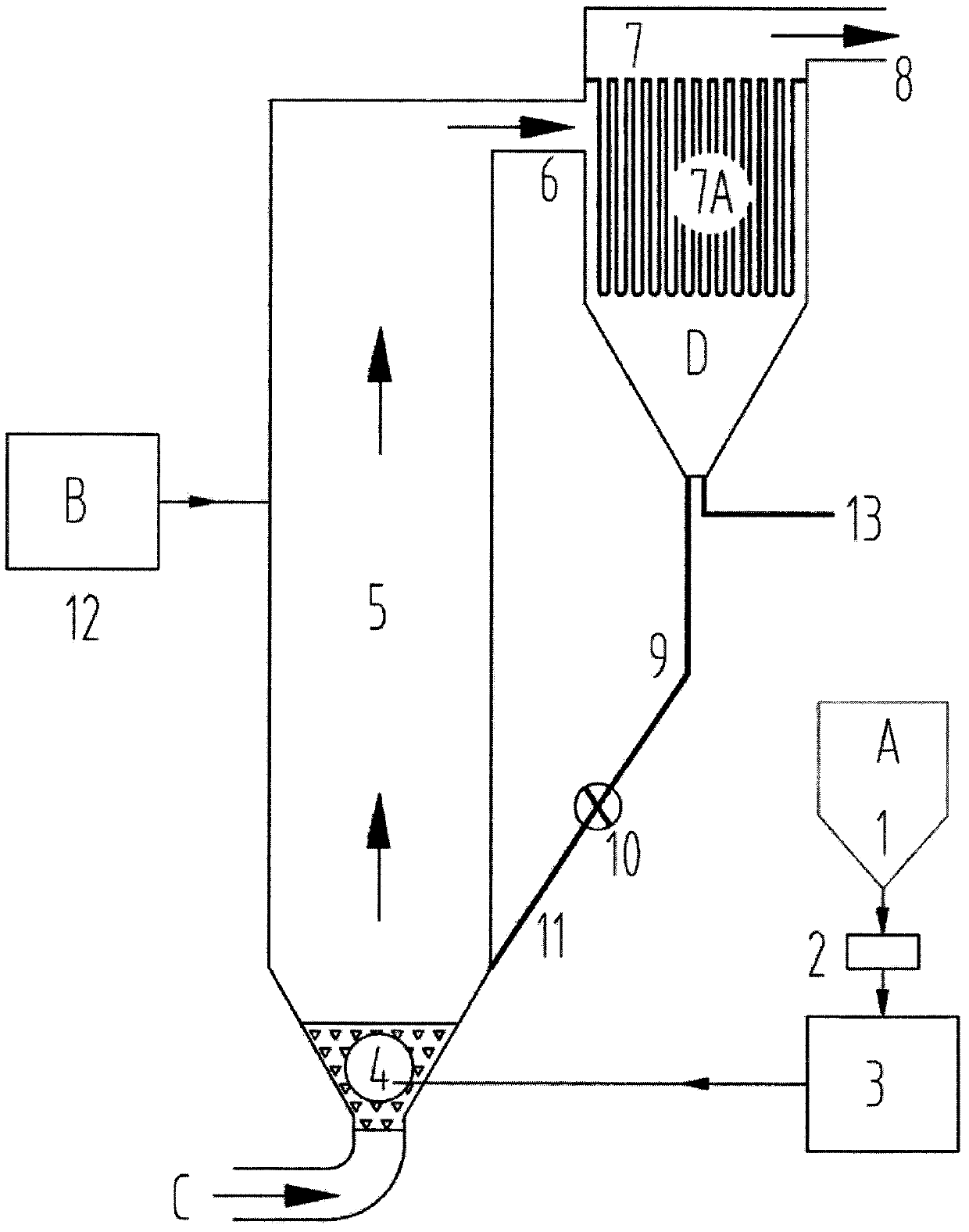

Special circulating fluidized bed boiler with flue gas recirculation

InactiveCN104456545AInhibitionAdjustable bed temperatureFluidized bed combustionStaged combustionFlue gasFluidized bed

The invention discloses a special circulating fluidized bed boiler with flue gas recirculation, which belongs to the technical field of an industrial boiler, relates to a circulating fluidized boiler and solves the problems of the existing circulating fluidized bed boiler that the bed temperature is instable, the heated surface is easily worn, scaling and corrosion exist, NOX emission concentration is high. The special circulating fluidized bed boiler with flue gas recirculation comprises a separator communicated with a hearth, the top of the separator is communicated with three tail vertical flues, the bottom of the separator is communicated with the hearth through a return plate, the tail ends of the vertical flues are sequentially connected with a dust collector and an induced draft fan, and an outlet of the induced draft fan is communicated with the bottom of the hearth through a flue gas recirculation pipe. The balance of overall boiler temperature can be realized by adopting flue gas recirculation technology, the generation of NOX can be inhibited, the fuel adaptability is wide, and the combustion stability is high.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

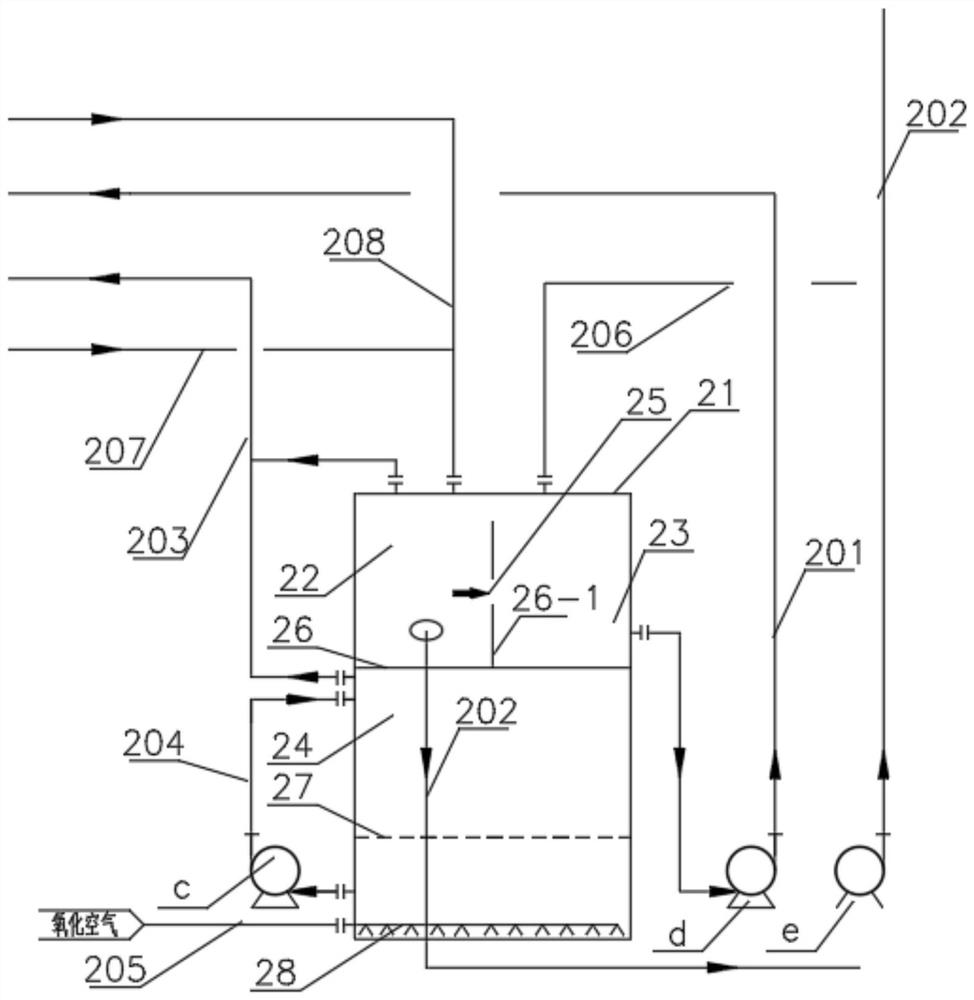

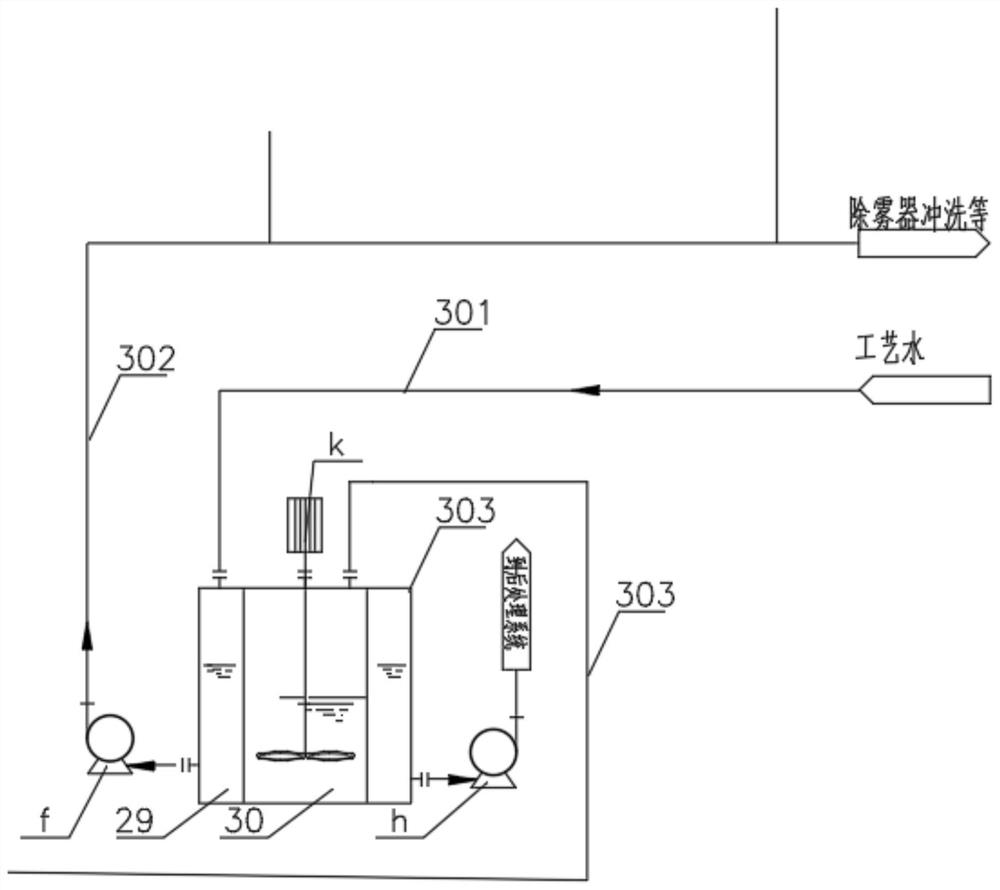

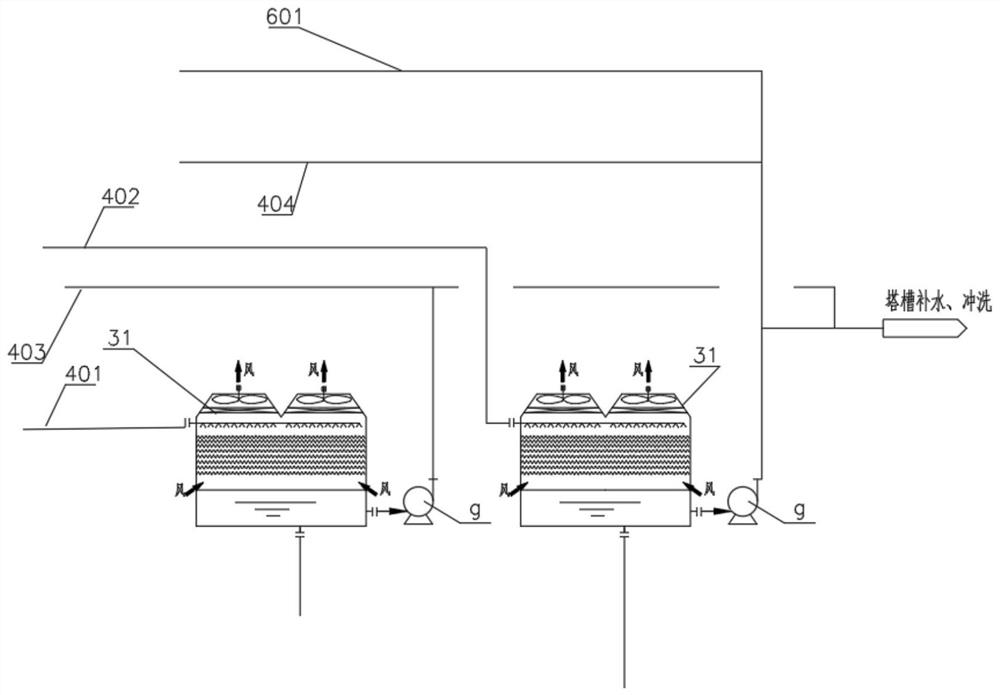

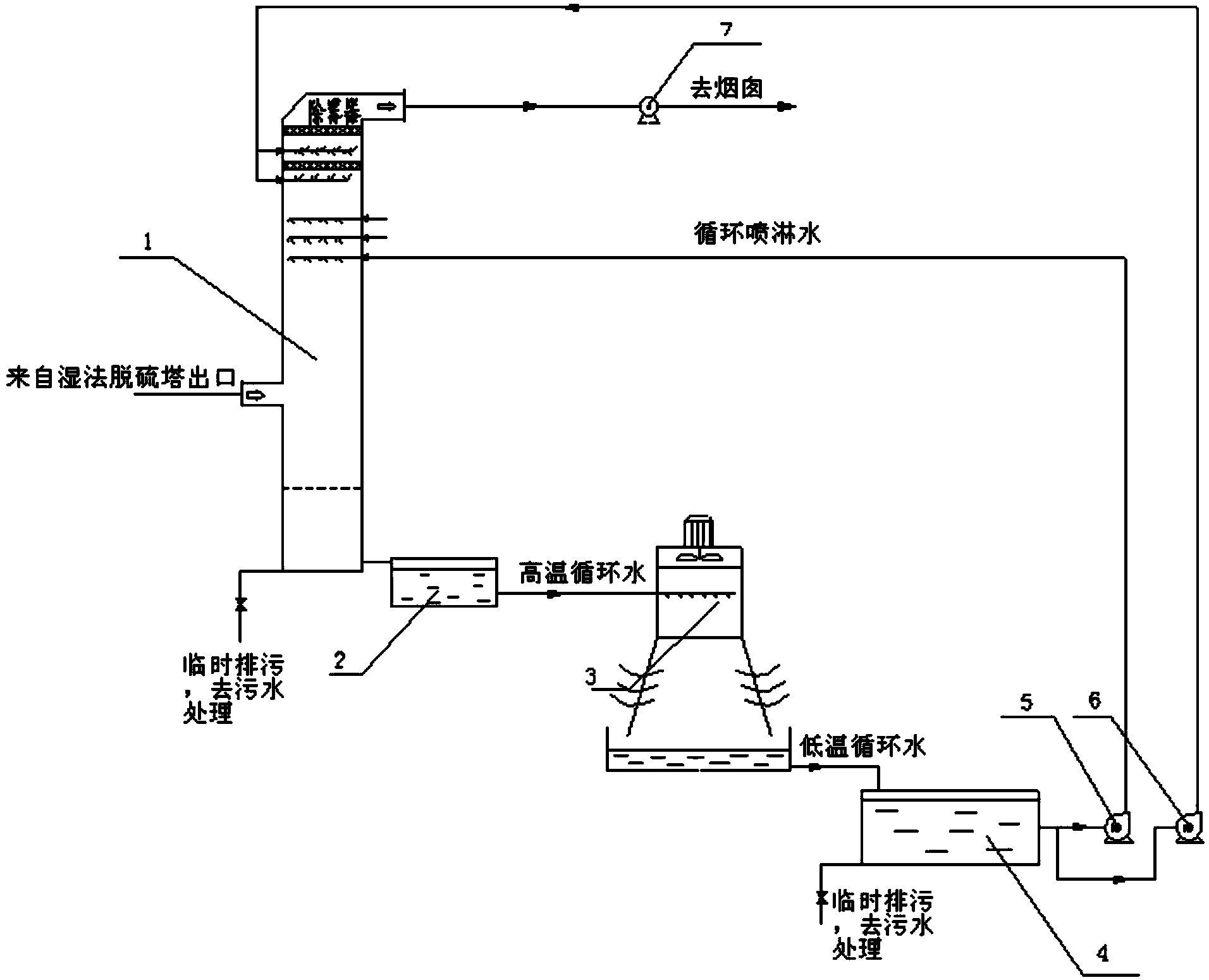

Water-saving and energy-saving ammonia desulphurization discharge process and system capable of preventing ammonia from escaping from aerosol

InactiveCN111841272APrevent escapeAvoid synergistic removalCombination devicesGas treatmentCooling towerSlurry

The invention discloses a water-saving and energy-saving ammonia desulphurization ultra-clean discharge system and process capable of preventing ammonia from escaping from aerosol. The system comprises a slurry disturbance system, a cooling concentration crystallization system, a sulfur oxide absorption system, an ammonia capture system, a washing purification system and a crystal particle enlarging system, circulating spray liquid of the desulfurizing tower from bottom to top adopts solutions with different components, and the concentration gradient is decreased progressively so that the desulfurizing efficiency is effectively improved, escape of aerosol and ammonia is avoided, and the phenomena of trailing and falling of ammonia-process desulfurized flue gas are eliminated. Different technologies such as multi-stage cyclone coupling, packing, a demister, an efficient cyclone water film dust collector and a wire mesh demister are combined, optimization of the distribution condition offlue gas in the tower is achieved, the retention reaction time of the flue gas is prolonged, further coagulation of fine particles and trapping of slurry droplets are promoted, the flue gas is washedthrough low-temperature washing liquid of the external cooling tower, cooperative removal of the fine particles is achieved, and ultra-clean emission is achieved.

Owner:江苏昆仑互联科技有限公司

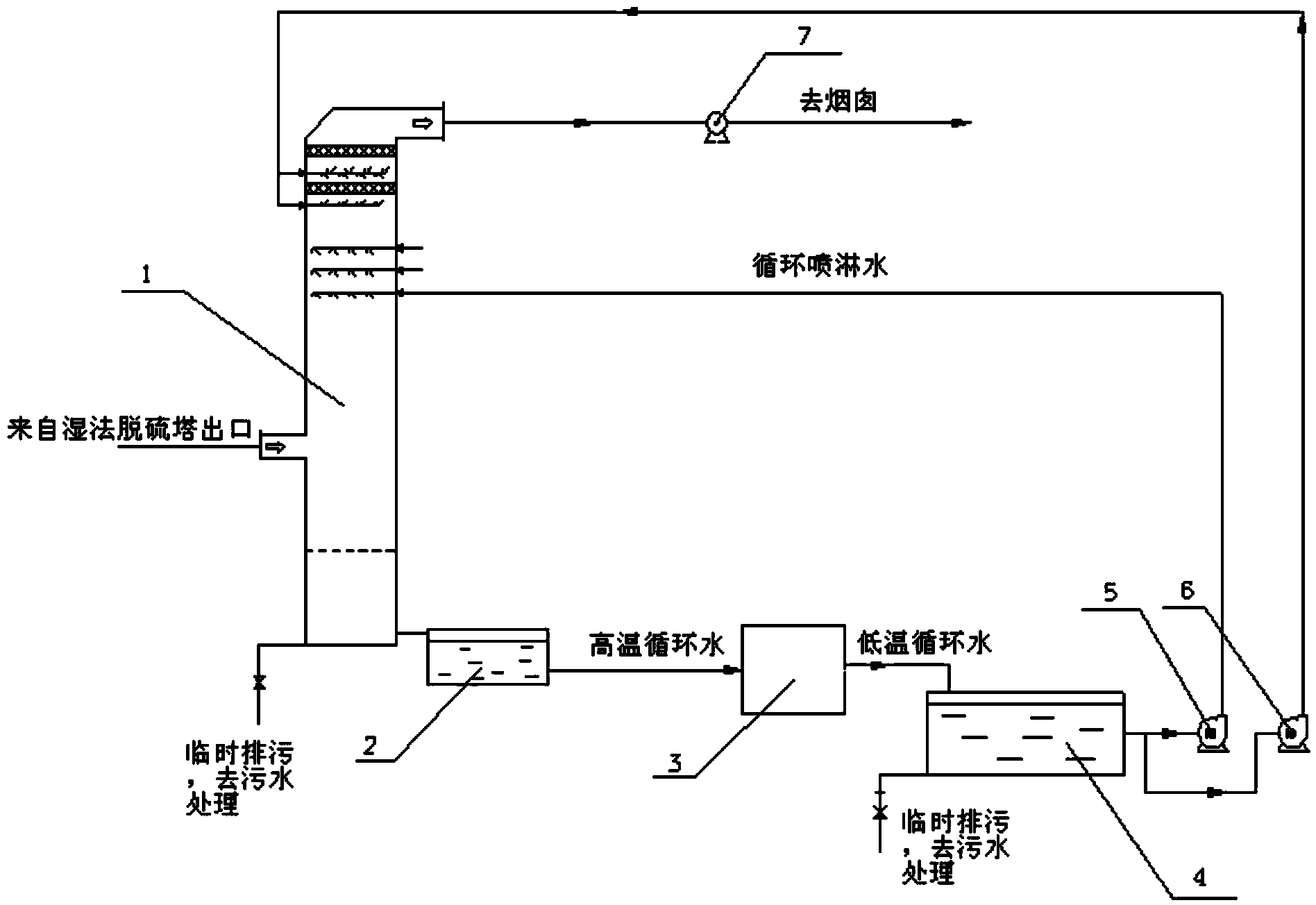

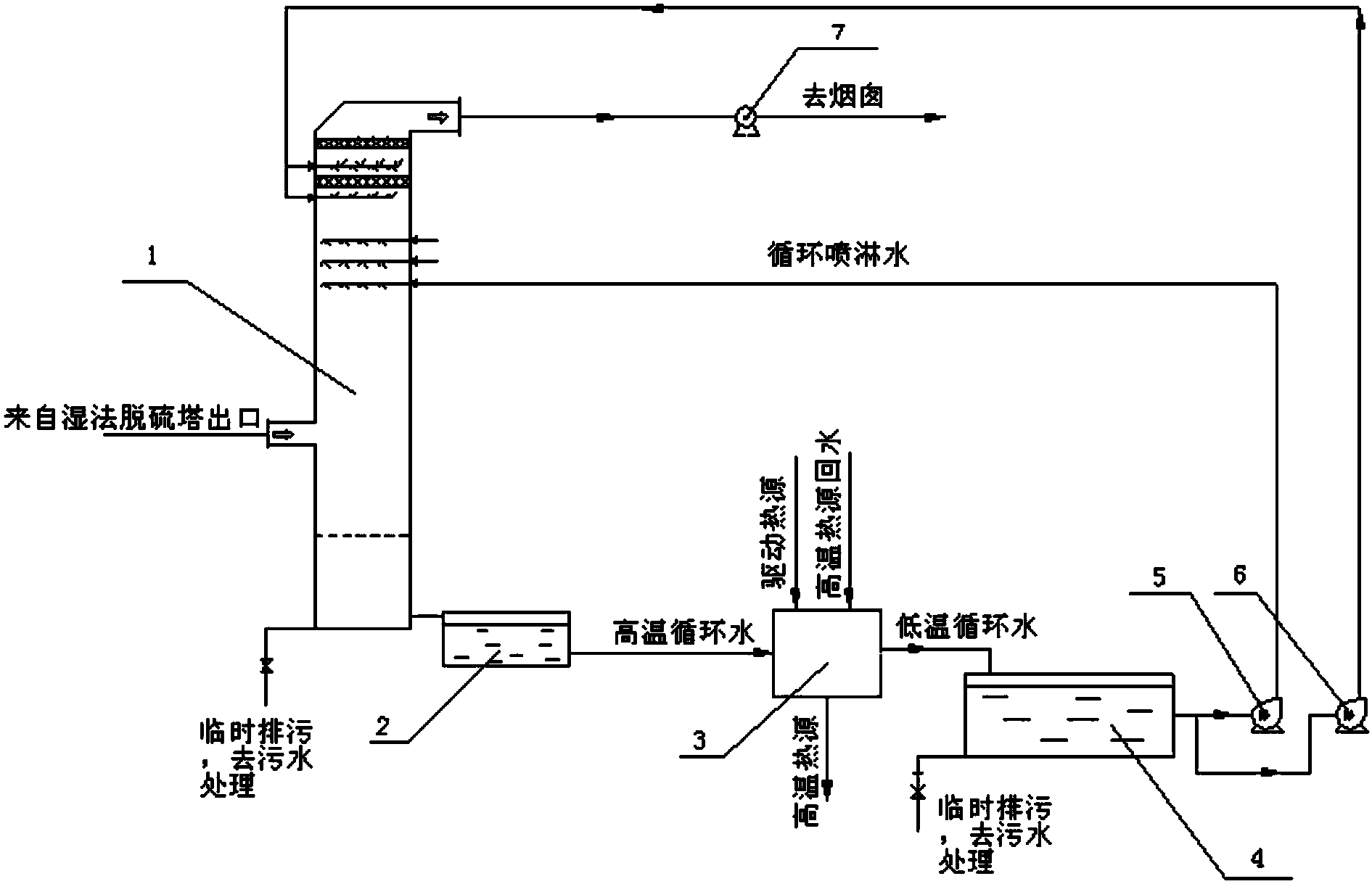

Ultralow-temperature ultra-clean flue gas exhausting system and method for thermal power plant

InactiveCN104226088AAchieve ultra-clean emissionsAlleviate the phenomenon of white smokeUsing liquid separation agentChemical treatmentHandling system

The invention relates to an ultralow-temperature ultra-clean flue gas exhausting system and method for a thermal power plant. Flue gas from a wet desulphurization outlet enters from the lower part of a heat exchange scrubbing tower and flows from bottom to top, circulating cooling water flows from top to bottom in the heat exchange scrubbing tower after being atomized by a multi-layer nozzle by a circulating water pump, the flue gas and the atomized circulating cooling water are subjected to strong heat and mass transfer, a great amount of moisture is separated out in the reduction process of flue gas temperature, and a great amount of heat is released; and besides, pollutants in the flue gas are captured by the circulating cooling water, the circulating cooling water is drained through the lower part of the heat exchange scrubbing tower after absorbing the moisture and the heat in the flue gas, enters a circulating water treatment system to be subjected to sedimentation, filtering and chemicals treatment, then enters a heat exchange system to be cooled and is recycled. The system is simple and convenient to operate, can effectively alleviate the phenomenon that a chimney exhausts white smoke after wet desulphurization, can achieve the ultra-clean emission of flue gas of the thermal power plant, can recycle moisture and low-grade heat in the flue gas and has the good environment protection property and the high economical efficiency.

Owner:HUANENG CLEAN ENERGY RES INST

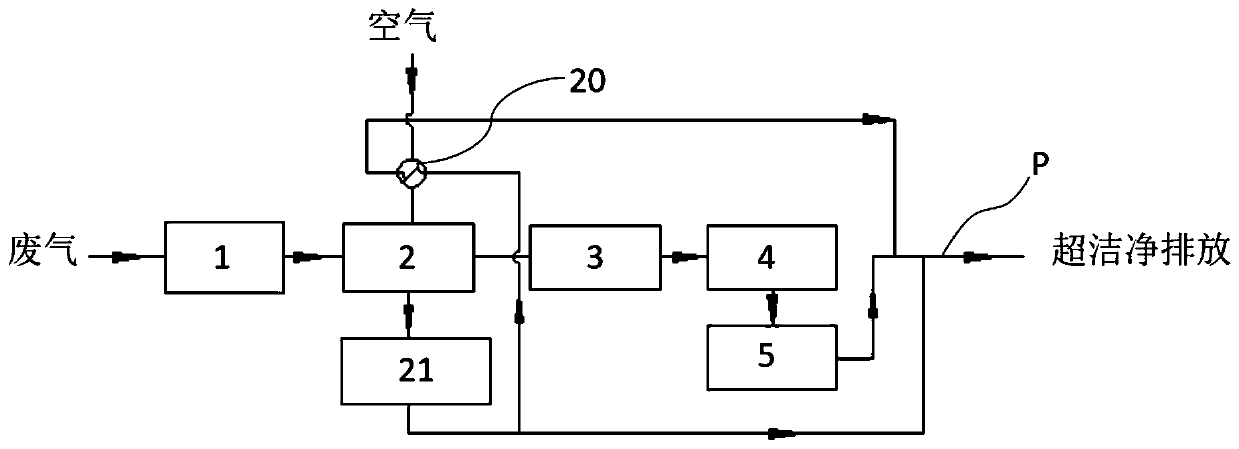

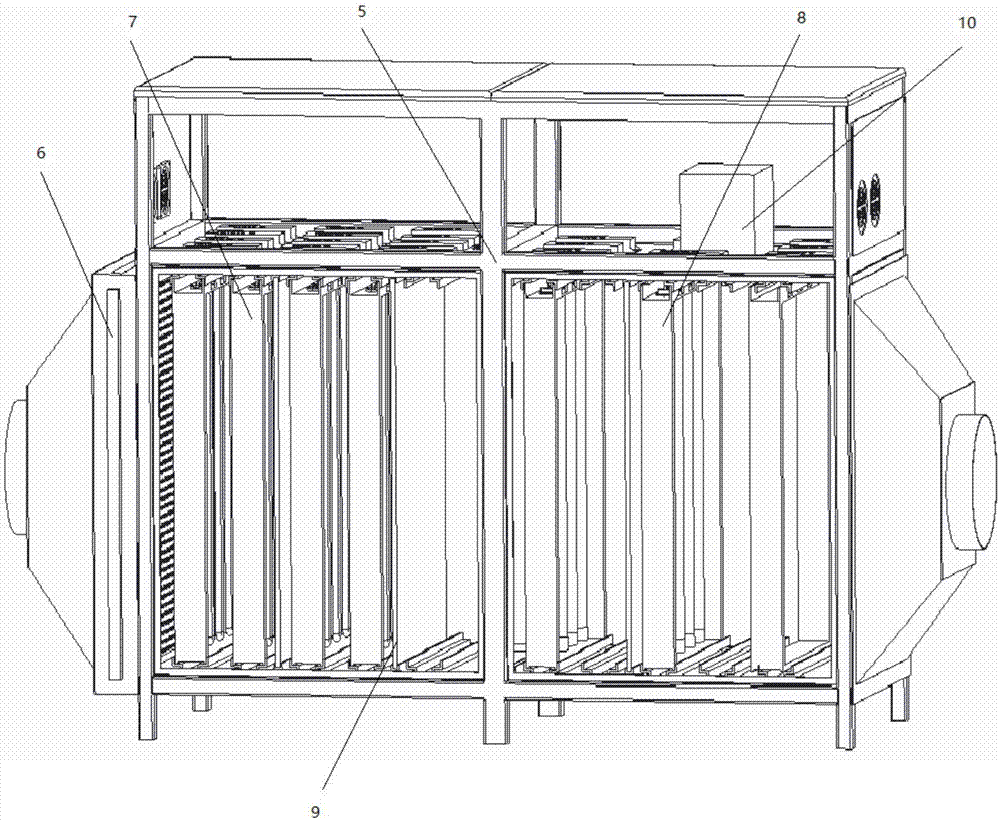

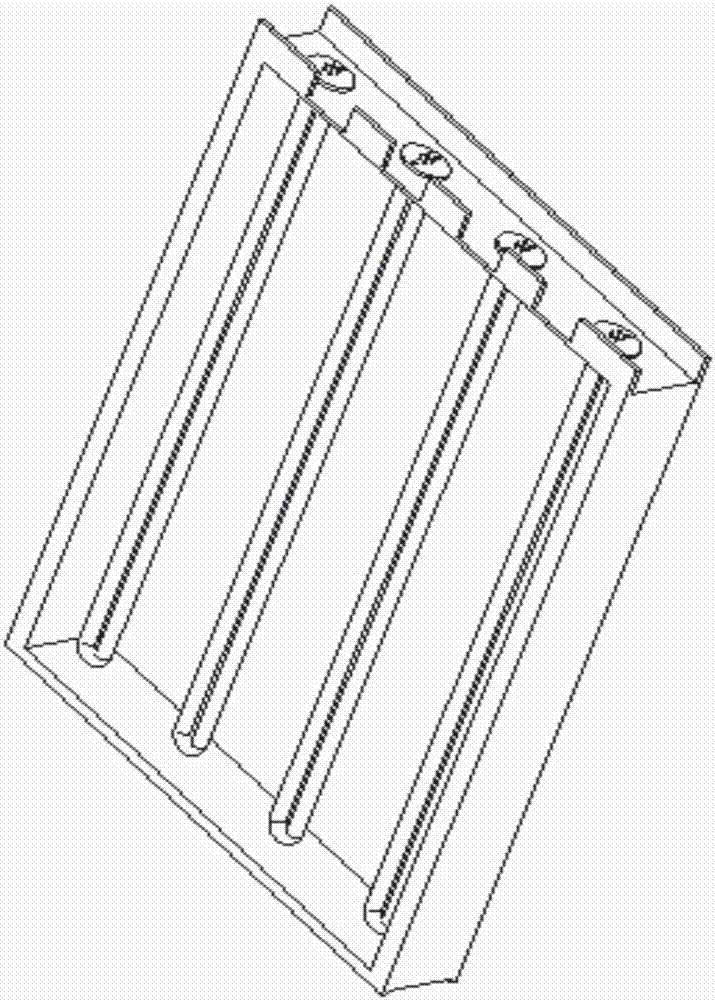

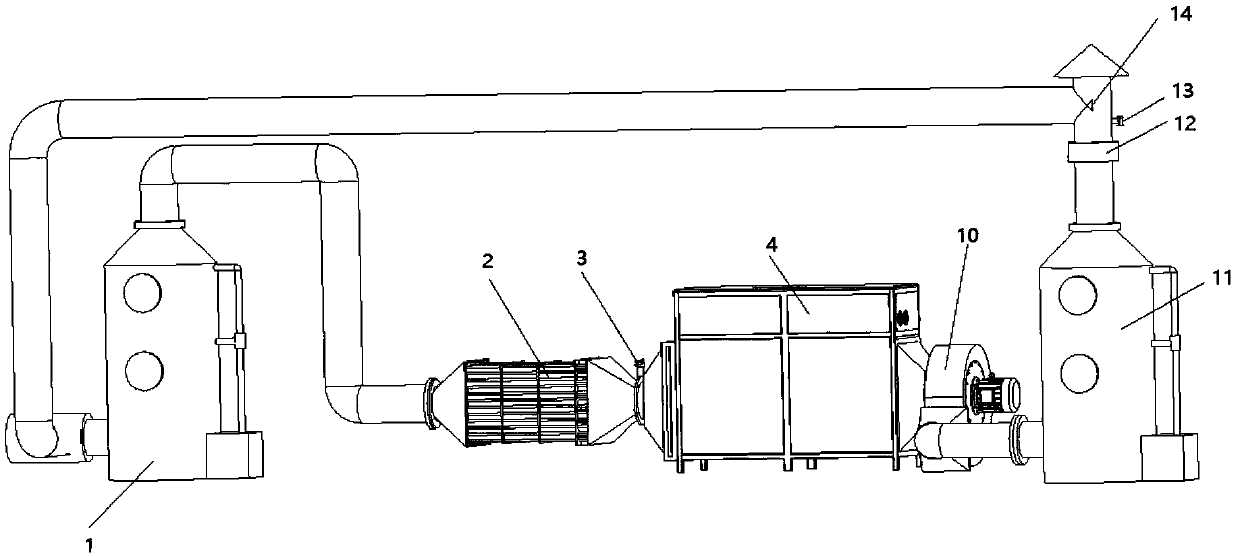

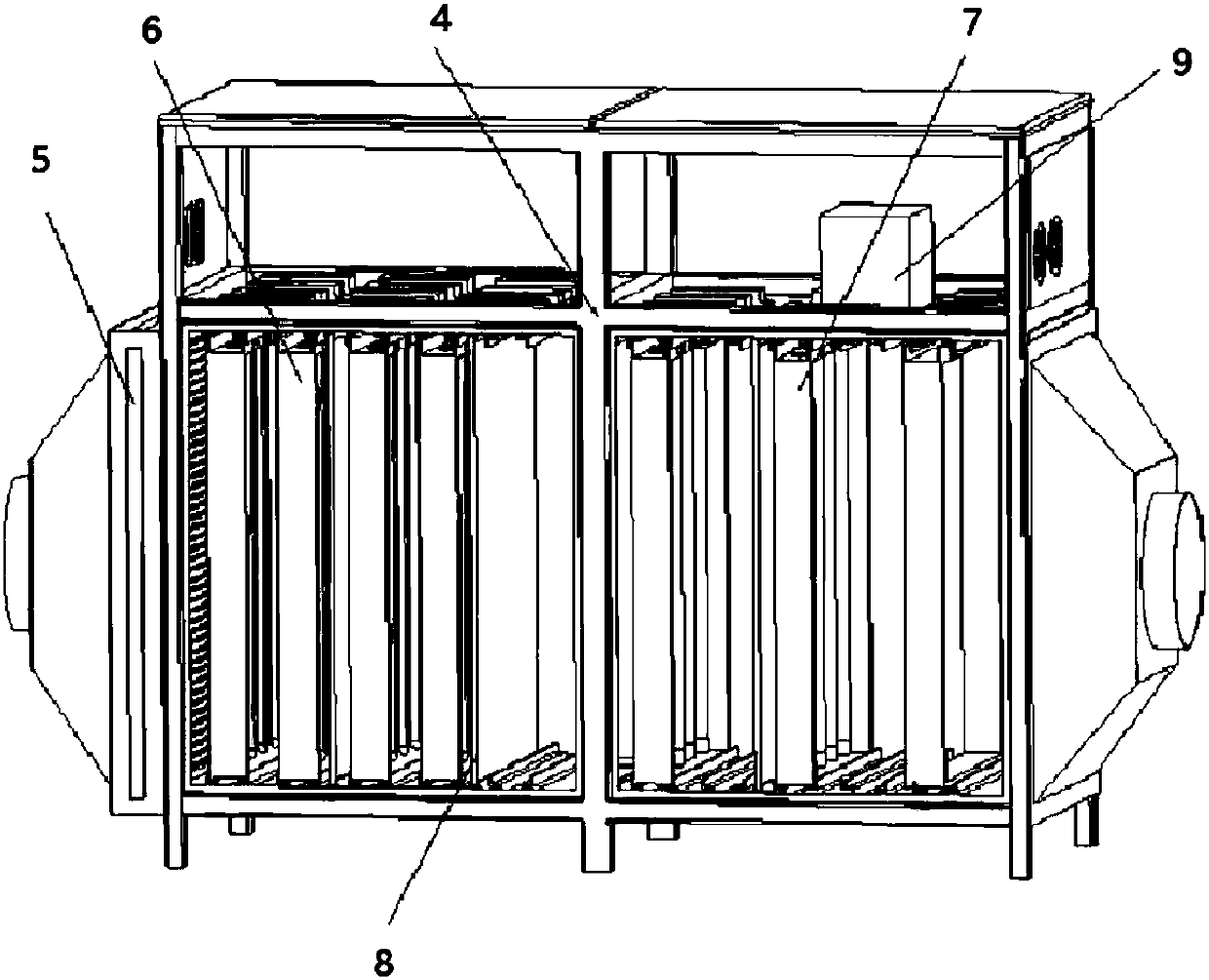

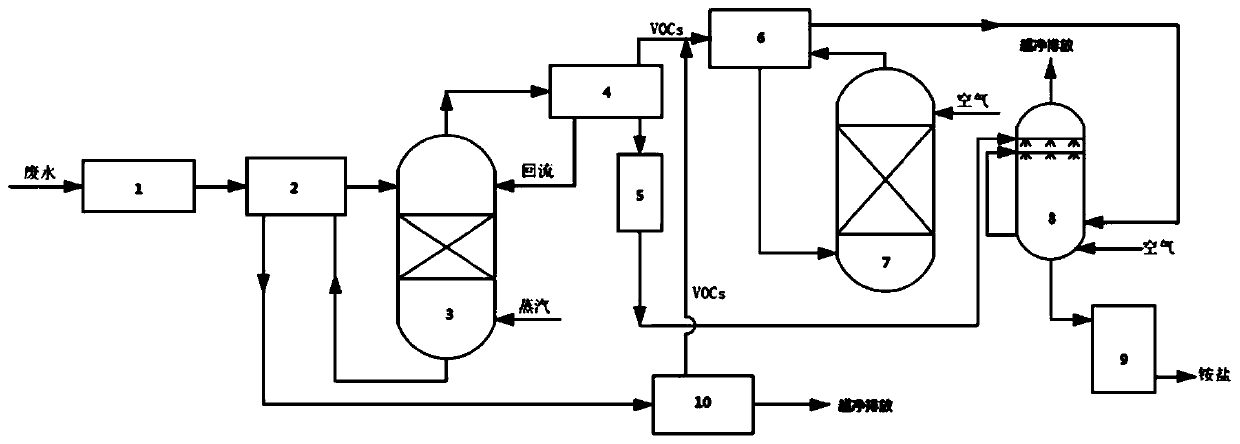

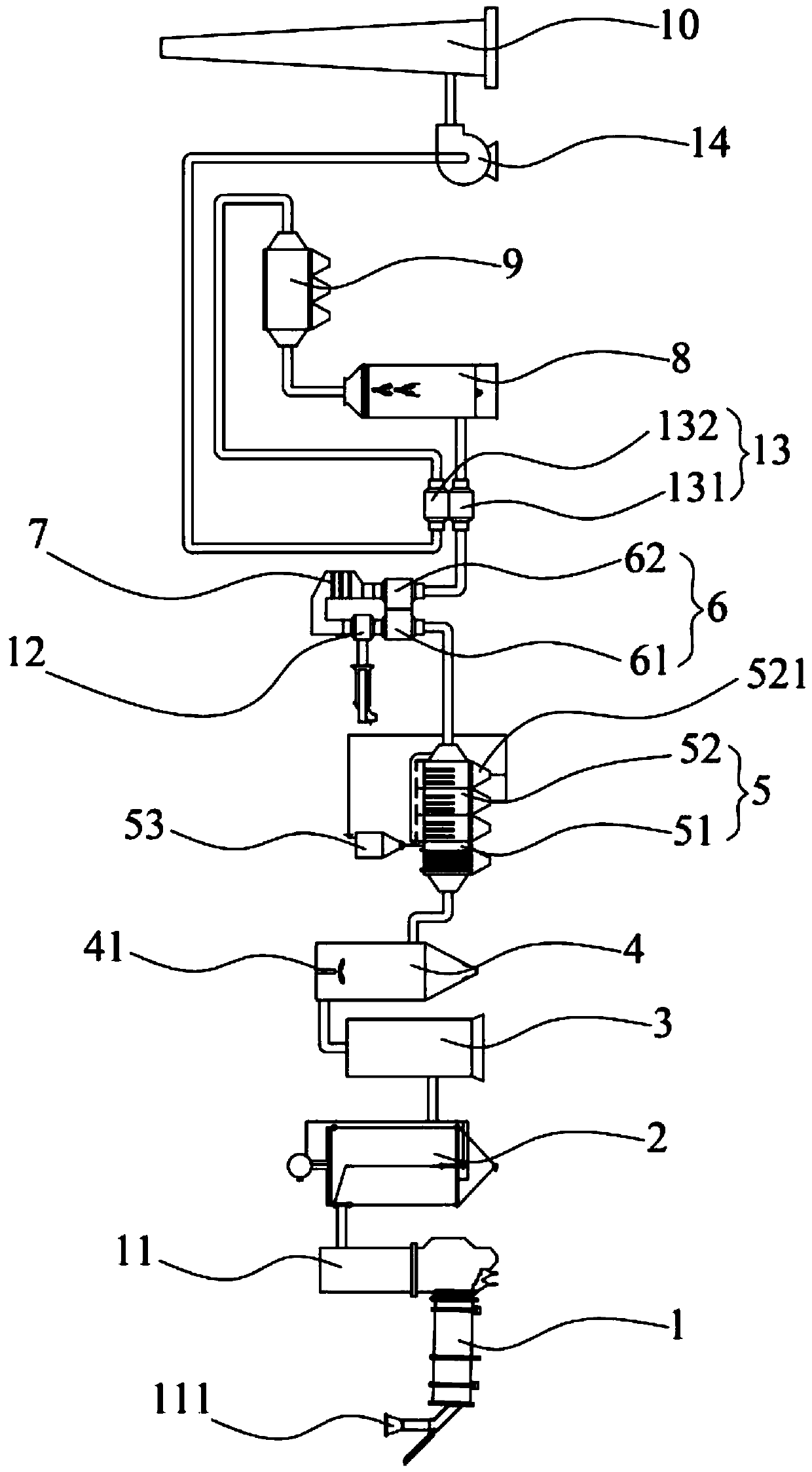

System and technology for treating unstable large-volume VOCs waste gas

PendingCN110772987AReduce volatilityStable and uniform purification effectGas treatmentDispersed particle separationTreatment systemWaste gas

The invention discloses a system for treating unstable large-volume VOCs waste gas. The system comprises: a preprocessing device used for preprocessing the waste gas to filter out dusts in the waste gas and removing non-VOCs in the waste gas; an adsorbing and concentrating connected to the outlet of the preprocessing device and used for adsorbing and concentrating the preprocessed waste gas; and ahigh-energy-level photooxidation device communicated with the outlet of the adsorbing and concentrating device through a homogenizing connection device, wherein the outlet end of the high-energy-level photooxidation device is further connected with a discharge pipeline through washing device, the adsorbing and concentrating device is provided with a hot purified gas inlet and a desorbed gas outlet, and the desorbed gas outlet is connected with an oxidation device, the oxidation device is provided with a purified gas outlet, and the purified gas outlet is connected with the discharge pipeline.The invention further provides a corresponding treatment technology of the system. A combined device or process of preprocessing, adsorption concentration, homogenization connection, high-energy-level photooxidation and washing absorption is adopted to make any unstable large-volume VOCs waste gas discharged in an ultra-clean manner.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

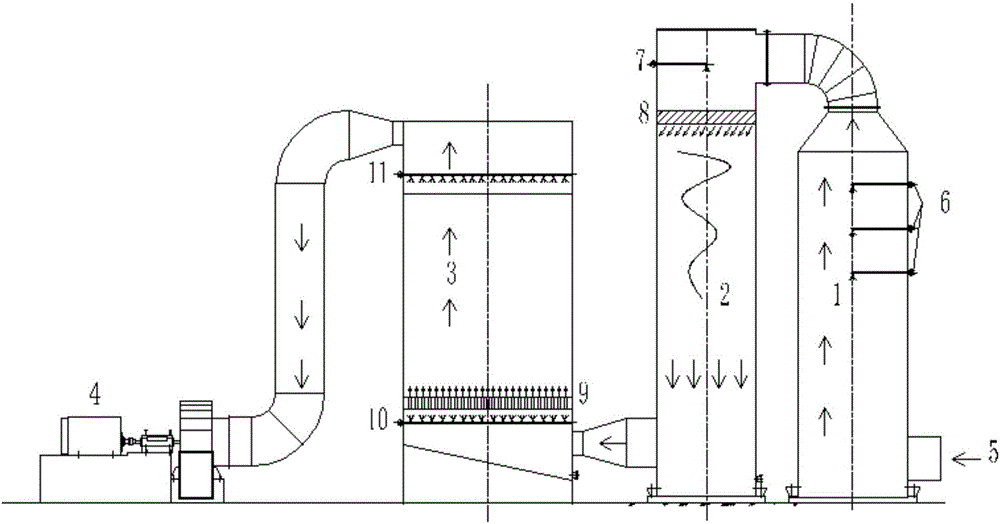

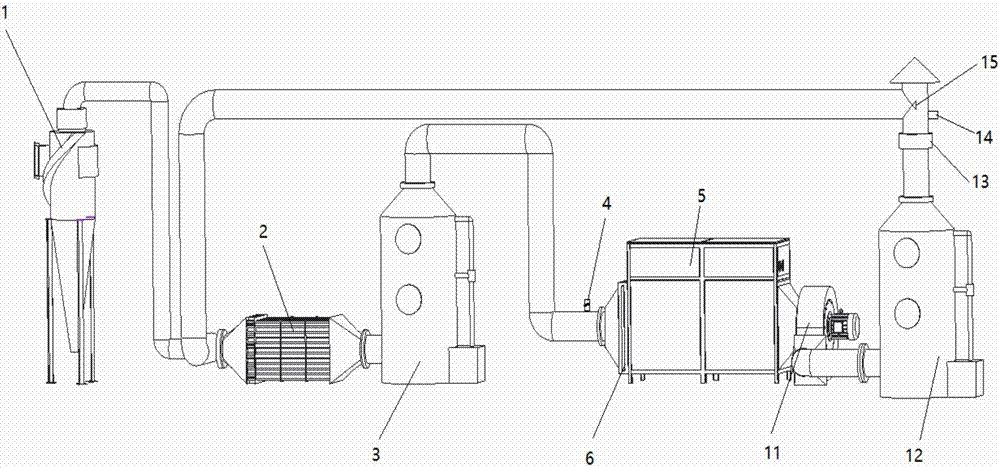

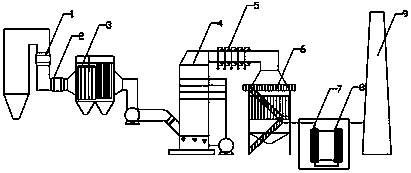

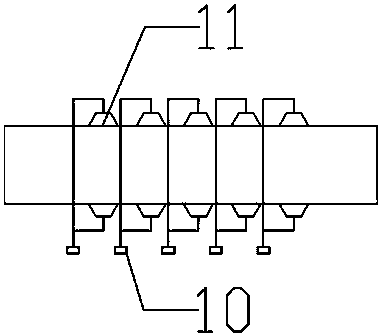

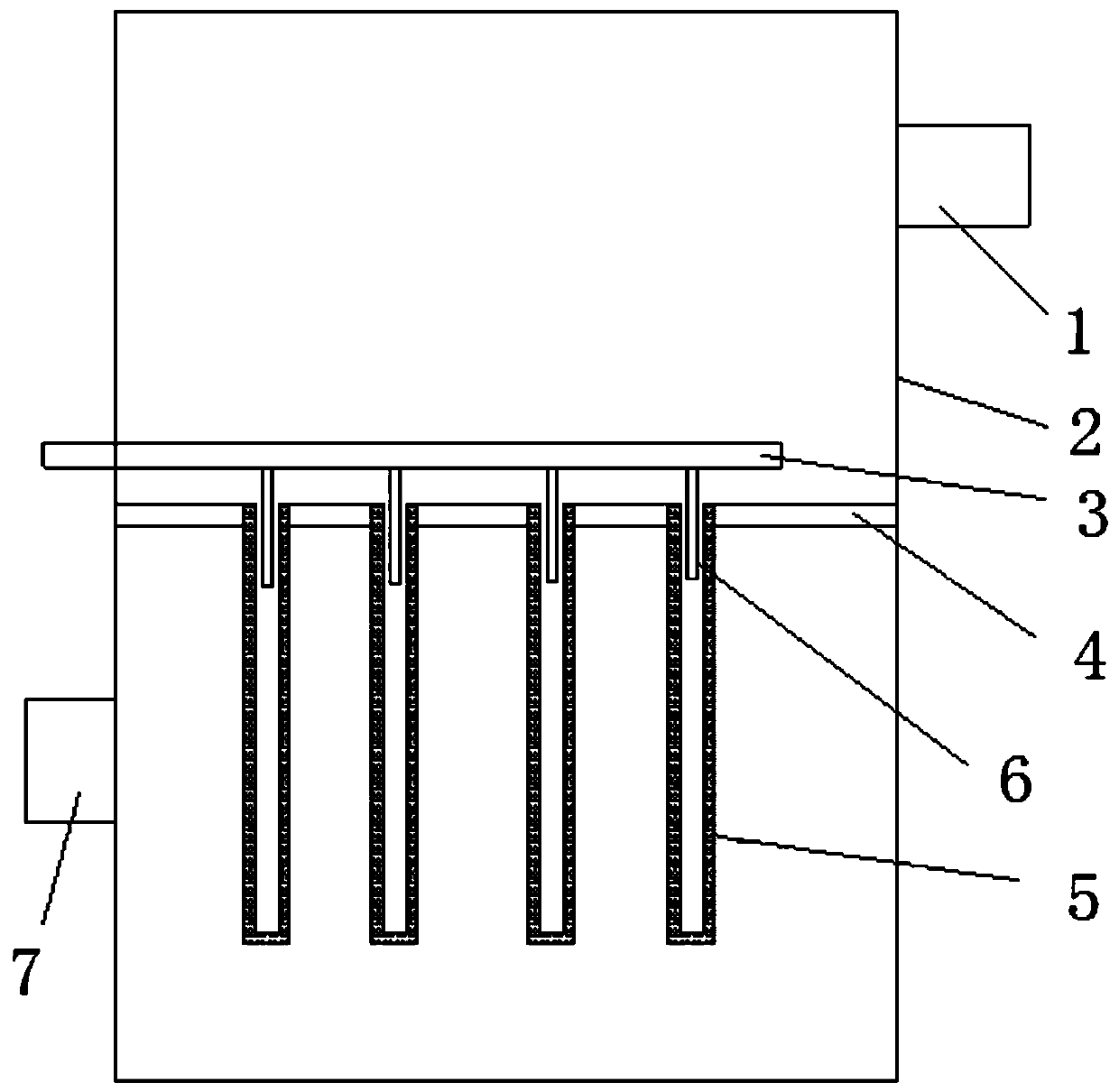

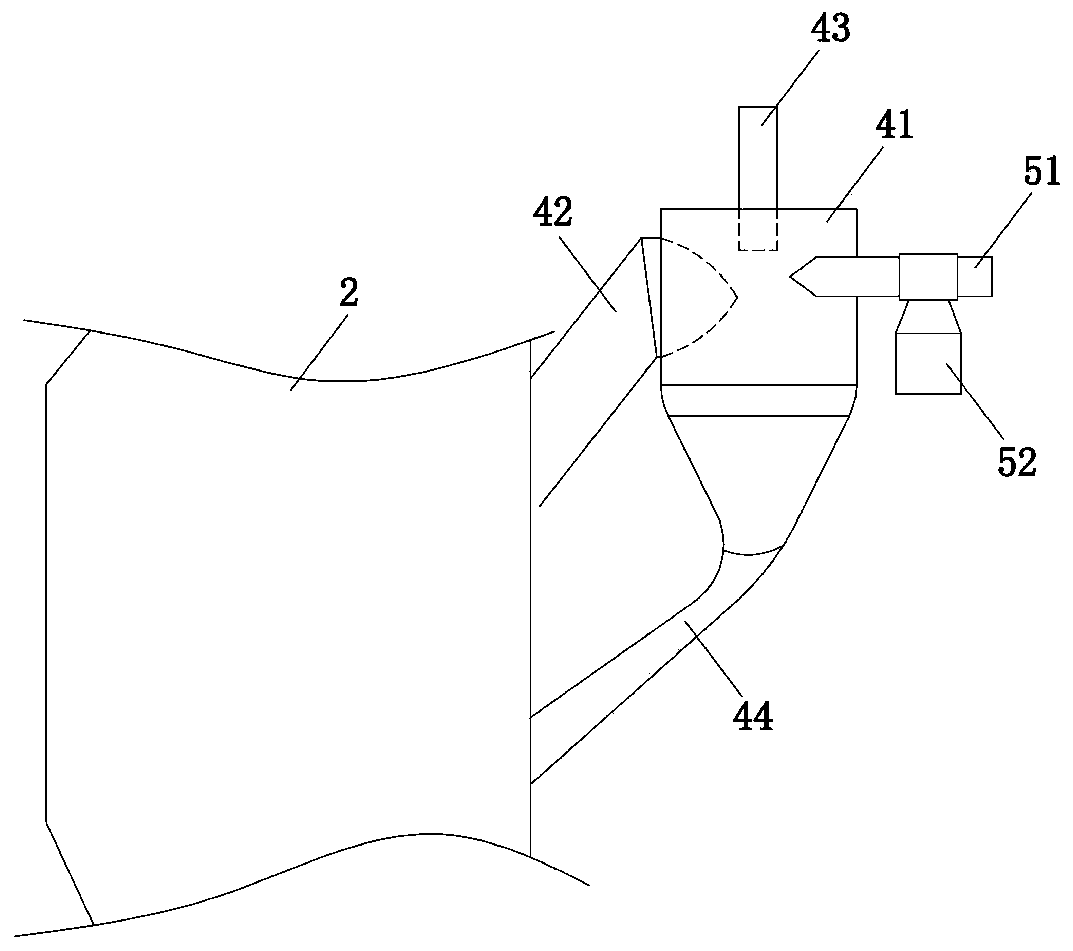

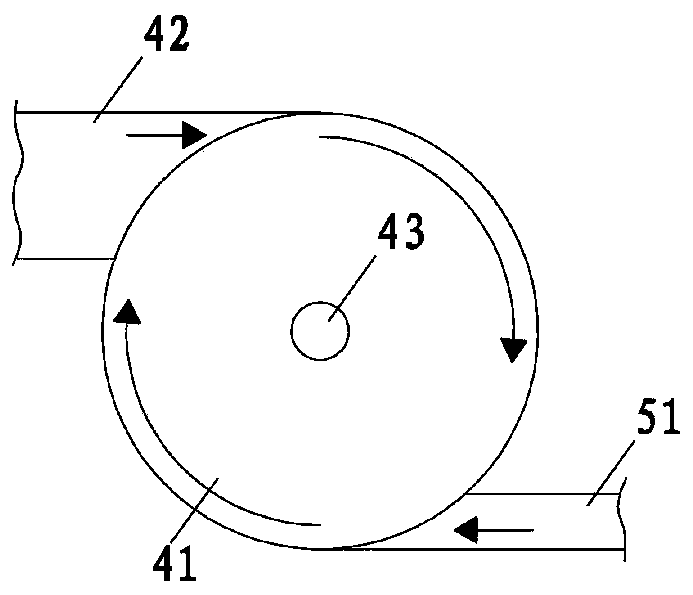

Process method and device for ultra-clean discharge treatment of dust-containing steam in steel slag rolling region

The invention relates to a process method and a device for ultra-clean discharge treatment of dust-containing steam in a steel slag rolling region. The device comprises a washing tower (1), a cyclone tower (2), a static dedustor (3), an induced draft fan (4) and a middle connecting pipeline and a chimney thereof. The system path of the process method is as follows: dust-containing steam (5) in a steel slag treatment rolling region enters the washing tower (1) and the cyclone tower (2) successively through a dust collecting hood for spraying and cyclone separating treatment, and enters through a gas uniform distributing device (9) at the inlet of the static dedustor (3), so that the dust-containing steam uniformly enters an inner electric field region of the static dedustor (3), and a spraying device (10) which is arranged at the inlet sprays online. The dust-containing steam treated by the static dedustor (3) enters the chimney along the pipeline through the induced draft fan to be discharged. Meanwhile, a washing device is arranged at an outlet of the static dedustor (3) so as to wash the inner electric field region in production intermittence. The dedusting efficiency is improved, so that the dust-containing concentration of flue gas at the outlet of the dedusting system reaches an ultra-clean discharge standard.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

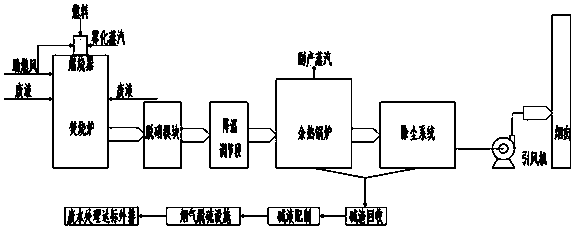

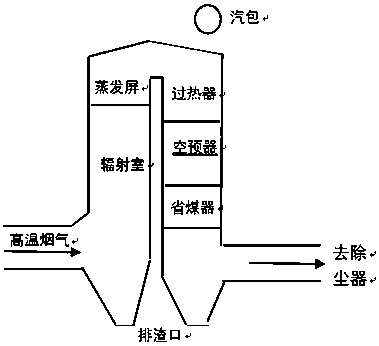

High-salinity wastewater treatment method of epoxypropane/styrene co-production device

InactiveCN109974014AReduce processing costsReduce consumptionGas treatmentDispersed particle separationLiquid wasteSlag

The invention discloses a high-salinity wastewater treatment method of epoxypropane / styrene co-production device. The method adopts a novel process scheme featuring incineration, waste heat boiler andsoda slag comprehensive utilization. The method mainly comprises the steps including liquid waste incineration; denitration treatment; cooling regulating; waste heat recovering; dedusting treatment;and soda slag recycling. According to the method, high-temperature flue gas entering a waste heat boiler is cooled firstly, molten inorganic salt can be precipitated in the solid form and is preventedfrom entering the waste heat boiler, then high-temperature flue gas enters the waste heat boiler to produce steam of the required grade as a by-product, soda slag produced by a system can be collected from the bottom of a vertical incinerator, the lower portion of the waste heat boiler and the interior of a dust remover, is pretreated and is then used for wet method alkali washing desulfurizationfacility comprehensive utilization, and accordingly, the purposes of treatment of wastes with processes of wastes against one another, energy-saving, cost-reducing and turning waste into valuable areachieved.

Owner:SINOCHEM QUANZHOU PETROCHEM CO LTD

Intelligent tail gas photo-oxygen pyrolysis treatment device by adopting oil-gas purification technology

PendingCN107983120AEnergy-saving and efficient processingEasy to handleCombination devicesGas treatmentCycloneMicrocontroller

The invention discloses an intelligent tail gas photo-oxygen pyrolysis treatment device by adopting an oil-gas purification technology. The device comprises a cyclone demisting and dust falling cooler, oil-gas purification electric field equipment, a front-end spraying tower, a photo-oxygen pyrolysis cabinet, an induced draft fan, a dry-process flue gas comprehensive treatment tank and an ozone filtering net, wherein the cyclone demisting and dust falling cooler is connected with an organic waste gas pipeline of a factory; the photo-oxygen pyrolysis cabinet is connected with the front-end spraying tower by virtue of an air pipe; a lamp bank module is arranged inside the photo-oxygen pyrolysis cabinet; the induced draft fan is mounted at an air outlet of the photo-oxygen pyrolysis cabinet;the dry-process flue gas comprehensive treatment tank is connected with an air outlet of the induced draft fan; a waste gas concentration detection sensor is arranged at an inlet of the photo-oxygen pyrolysis cabinet; an intelligent control cabinet used for mounting a single-chip system is arranged in the photo-oxygen pyrolysis cabinet; and the single-chip system controls an on-off combination ofthe lamp bank module according to information fed back by the waste gas concentration detection sensor. The treatment device disclosed by the invention has the beneficial effects that energy-saving and high-efficiency operations of the whole set of system can be realized, the service life of the lamp bank module is prolonged, the organic waste gas treatment effect is improved, secondary pollutioncaused by the traditional wet process is solved, and super-clean emission is realized.

Owner:QINGDAO UNIV OF SCI & TECH

Ultra-clean environment-friendly treatment island for tail gas of coal-fired boiler

PendingCN107617319AAchieve ultra-clean emissionsReasonable structural designCombination devicesStationary tubular conduit assembliesDesalinationCoupling system

The invention discloses an ultra-clean environment-friendly treatment island for tail gas of a coal-fired boiler. A denitrification device is connected and arranged in front of a boiler preheater, anda waste heat absorption device, a dry type dust collector, a desulfurization device, an ultrasonic wave condensation device, a wet-type electric precipitator, a cooling MGGH and a heating MGGH are sequentially connected and arranged behind the boiler preheater, so that one dehumidification, desalination and desulfurization smoke treatment integrated mutual coupling system which completely and efficiently traps fine particles PM2.5 and aerosol is formed. The ultra-clean environment-friendly treatment island for the tail gas of the coal-fired boiler is reasonable in structure design and outstanding in using effect, especially special setting of the ultrasonic wave condensation device, the cooling MGGH and the heating MGGH respectively realize ultrasonic coagulation, agglomeration and growthas well as the dehumidification, desalination and desulfurization on the fine particles PM2.5 in smoke, and ultra-clean discharge of the smoke is realized while environmental protection cost is reduced.

Owner:SUQIAN LONGKING ECOTECH

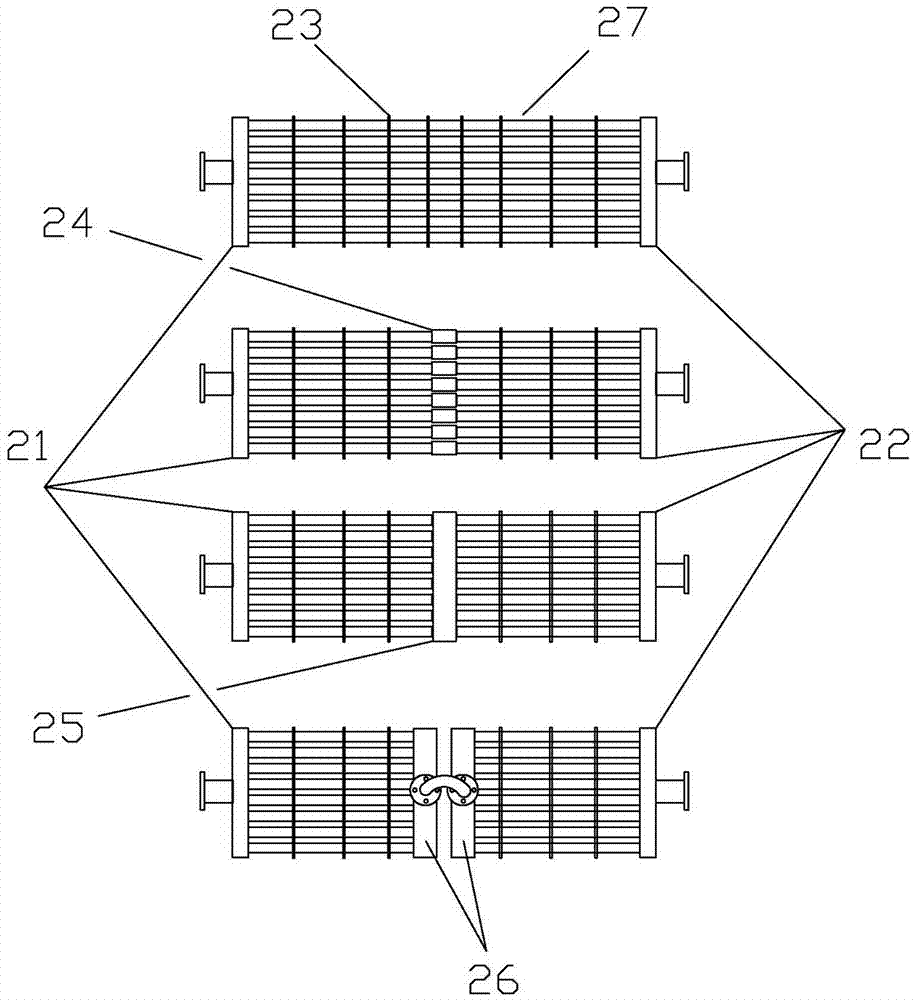

Method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas

ActiveCN110252051AAvoid wastingImprove working conditionsHuman health protectionGas treatmentFlue gasBasalt fiber

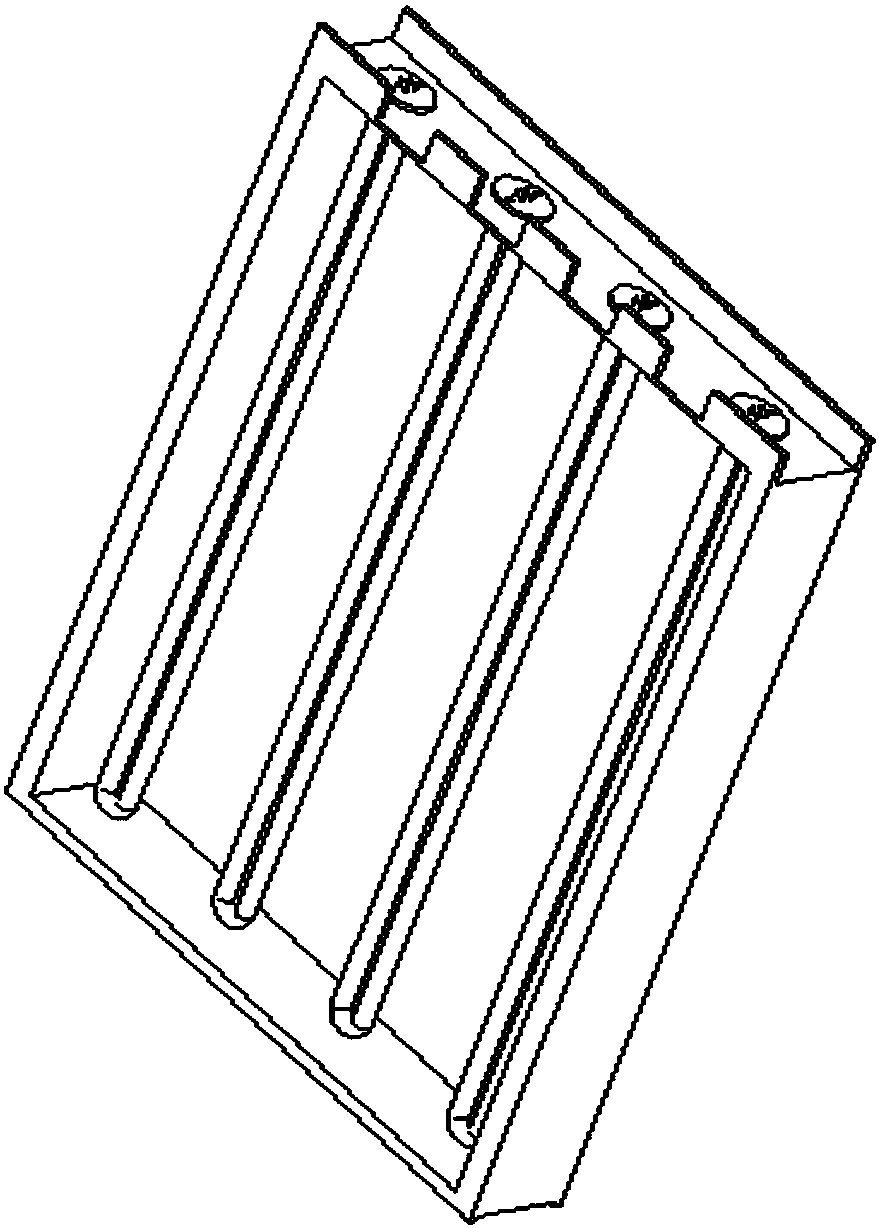

The invention discloses a method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas. The method comprises the following steps: extracting flue gas having a temperature of 250-350 DEG C from a boiler, injecting bicarbonate with a size of 600-700 meshes into the flue gas, and carrying out a reaction; and adding a reducing agent into the reacted flue gas, and allowing the flue gas to enter a denitration-dedusting composite device for denitration, dioxin removal and dust removal. The denitration-dedusting composite device comprises a shell, a partition plate and a plurality of basalt fiber filter cartridges, wherein the partition plate is arranged on a cross section of the shell and divides the shell into a first chamber and a second chamber; the sidewall of the shell of the first chamber is provided with a flue gas inlet; the sidewall of the shell of the second chamber is provided with a flue gas outlet; each basalt fiber filter cartridge is a hollow tube body, and basalt fiber cotton is bonded with a catalyst; each basalt fiber filter cartridge is mounted on the partition plate, and the basalt fiber filter cartridges are all located in the first chamber; and the opening of each basalt fiber filter cartridge is in communication with the second chamber.

Owner:山东中琦环保设备制造有限公司

Flue gas treatment system and method for cement kiln

PendingCN111111404AReduce the temperaturePromote decompositionGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to the technical field of flue gas treatment, and discloses a flue gas treatment system and method for a cement kiln; the flue gas treatment system comprises a flue gas extraction device, an air cooling device, a nitrogen reduction device, a desulfurization device and an induced draft device; the gas inlet end of the flue gas extraction device is used for being communicated with the cement kiln; the air cooling device is communicated with the flue gas extraction device and is used for carrying out shock cooling treatment on flue gas extracted by the flue gas extraction device; the gas outlet end of the flue gas extraction device is sequentially communicated with the nitrogen reduction device and the desulfurization device through a flue or sequentially communicated with the desulfurization device and the nitrogen reduction device through a flue, and the induced draft device is mounted on the flue; during flue gas treatment of the cement kiln, chlorine removal, alkali removal, desulfurization, denitrification and dioxin removal can be considered at the same time, the flue gas treatment efficiency is high, normal operation of the cement kiln is guaranteed, and ultra-clean emission of flue gas is achieved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Intelligent tail gas photooxygenation pyrolysis device using cavitation liquid technology

PendingCN108014595AEasy to handleImprove processing efficiencyGas treatmentDispersed particle filtrationLiquid wasteMicrocontroller

The invention discloses an intelligent tail gas photooxygenation pyrolysis device using a cavitation liquid technology. A cavitation liquid waste gas washing device is connected with an oil gas purifying electric field device through an air pipe. The oil gas purifying electric field device is connected with a photooxygenation pyrolysis cabinet through an air pipe. A waste gas concentration detecting sensor is installed at the inlet of the photooxygenation pyrolysis cabinet. A certain number of high-energy ultraviolet lamp group modules are installed in the photooxygenation pyrolysis cabinet atcertain intervals. A single-chip microcomputer control system is installed in an intelligent control cabinet. An induced draft fan is installed at the air outlet of the photooxygenation pyrolysis cabinet, and the air outlet of the negative pressure type induced draft fan is connected into a dry method smoke comprehensive processing tank. The single-chip microcomputer control system can control the combined switching on and switching off of the lamp group modules according to information fed back by the waste gas concentration detecting sensor. Energy-saving efficient running of the whole system can be achieved, the service life of the lamp group modules is prolonged, the organic waste gas processing effect is improved, a secondary pollution problem caused by a traditional wet method process is avoided, and super-clean emission is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

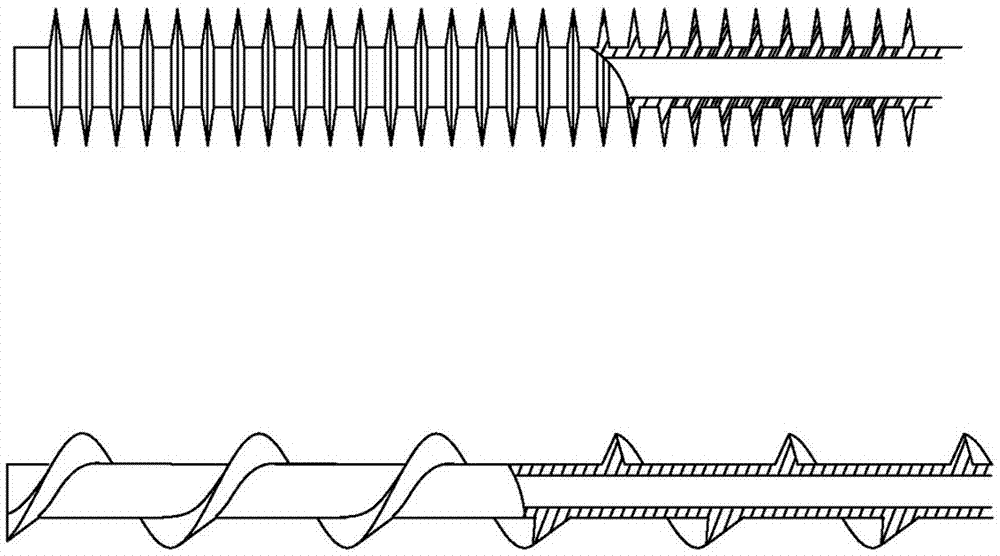

Method and equipment for preventing dioxin generation and achieving ultra-clean emission of flue gas

InactiveCN110354663AAchieve ultra-clean emissionsGas treatmentDispersed particle filtrationFiberEngineering

The invention discloses a method and equipment for preventing dioxin generation and achieving ultra-clean emission of flue gas. The equipment comprises: a deacidification agent, a denitration agent, adeacidification agent bin, a metering feeder, a pneumatic powder injector, a gas-solid mixer, a dry type reaction tower, a flue channel, a ceramic fiber filtering pipe dust removing device, a flue gas outlet, a material return pipe 1, a high-temperature mill, a material return pipe 2, a denitration ammonia spraying system and an ash discharge valve. According to the method, flue gas produced by the combustion of an incinerator stays for more than 2 s at a high temperature of 850 DEG C, and then is gradually cooled to a temperature of 350-400 DEG C; the cooled flue gas enters the gas-solid mixer through a flue gas inlet, and is instantaneously mixed with the deacidification agent, and the denitration agent is sprayed by the denitration ammonia spraying system, such that the HCL, the Cl, the Cl2 and the SO2 in the soot are neutralized with the deacidification agent, and the chlorination reaction necessary in a dioxin synthesis reaction is terminated; and the obtained material enters thehigh-temperature ceramic fiber filtering pipe dust removing device, and contacts vanadium pentoxide so as to be subjected to a selective catalysis reaction, such that the NOx is decomposed into harmless N2 and H2O, and the dioxin is decomposed into CO2, H2O and HCl so as to achieve the ultra-clean emission.

Owner:杨晓袆

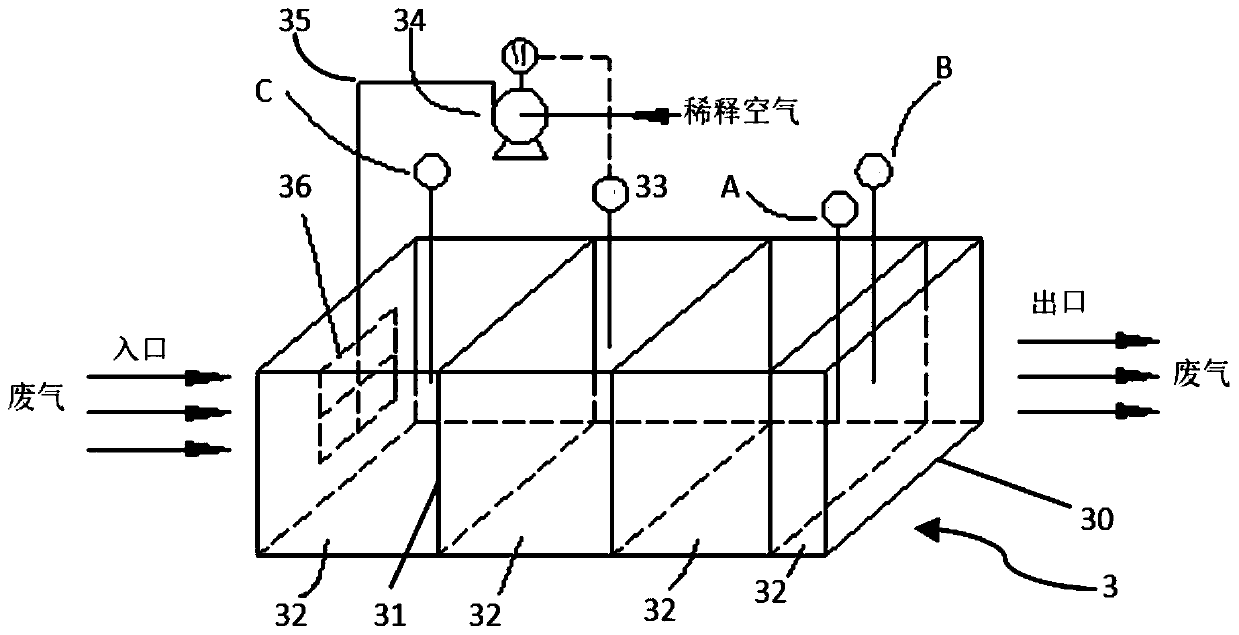

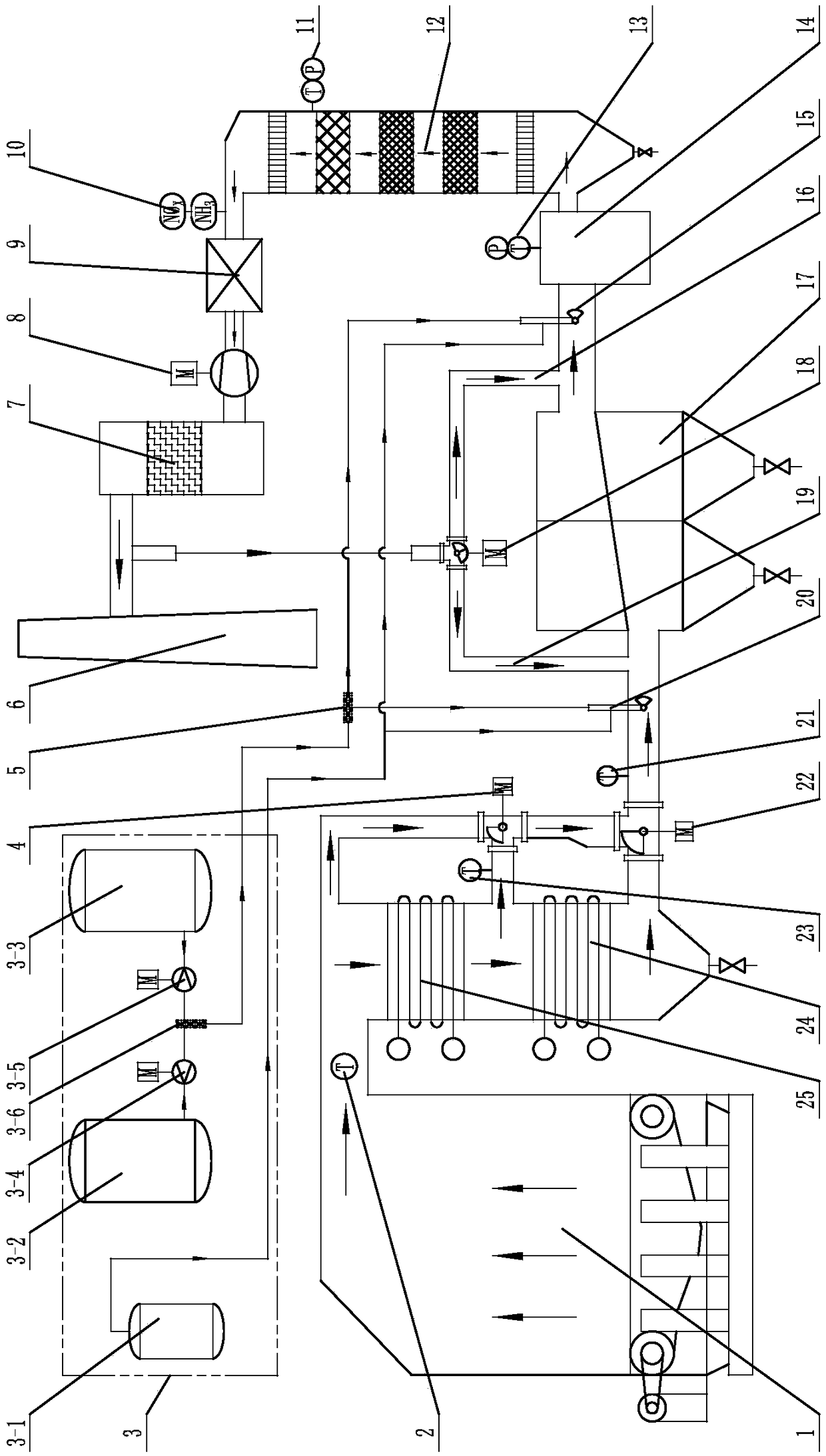

Super-clean treatment process system for flue gas

PendingCN108654374ADoes not affect operationReduce resistanceGas treatmentDispersed particle filtrationProcess systemsFlue gas

The invention discloses a super-clean treatment process system for flue gas, relates to the field of super-clean emission treatment of flue gas from industrial boilers and kilns and solves the problems that performance of the existing SCR denitration system is greatly affected by load fluctuation, resistance is higher, dust removal efficiency of a pre-dedusting device is low, and secondary dust removal equipment needs to be added in front of an induced draft fan to realize super-clean emission. The super-clean treatment process system comprises a smoke temperature regulating system, a dust remover, an SCR reactor, a waste heat recovery system, an induced draft fan and super-clean desulfurization dust removal equipment which are sequentially connected from front to back, one end of a reducing agent system is communicated with an inlet of the dust remover, the other end of the reducing agent system is communicated with an inlet of a disturber, the disturber is arranged at an inlet of theSCR reactor, a first thermocouple is arranged at an inlet of a high-temperature heat exchange surface, a second thermocouple is arranged at an outlet of the high-temperature heat exchange surface, and a third thermocouple is mounted between an outlet of a medium-temperature three-way valve and the dust remover. The process system is used for realizing super-clean flue gas emission denitration treatment of first dust removal and later smoke removal treatment.

Owner:宁波国电龙高科环境工程技术有限公司

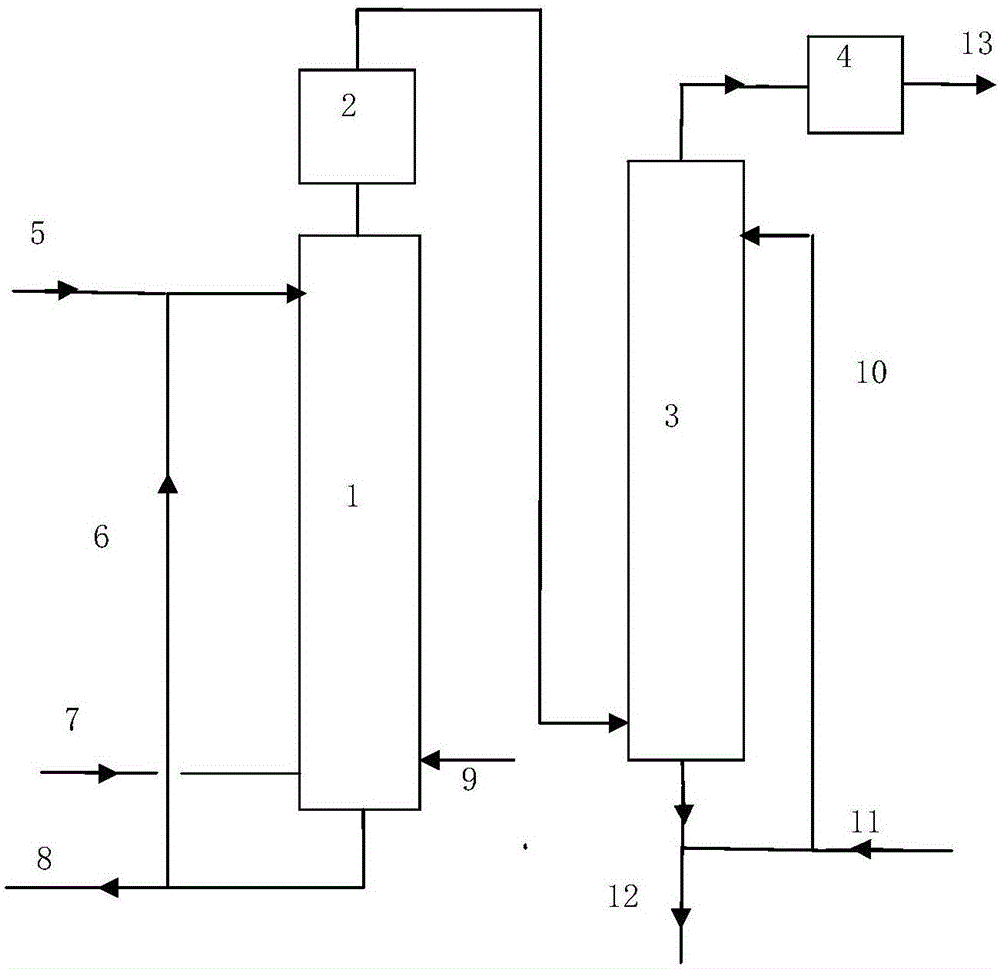

Flame-free torch type ultra-clean discharge process for high-ammonia-nitrogen wastewater containing VOCs

PendingCN111115933AAchieve ultra-clean emissionsTreatment involving filtrationWater/sewage treatment by neutralisationAmmoniacal nitrogenPtru catalyst

The invention discloses a flame-free torch type ultra-clean discharge process for high-ammonia-nitrogen wastewater containing VOCs. The process comprises the following steps that: wastewater is pretreated by a pretreatment unit and then enters a stripping tower to recover ammonia nitrogen, VOCs in the wastewater are separated out at the same time, and ammonia nitrogen is recovered into an ammoniawater tank in the form of ammonia water under the action of a condenser; the VOCs existing in a gas phase are heated by a second preheater and then enter an oxidation tower, decomposition and oxidation reactions are carried out under the action of a catalyst, and exhaust gas products containing carbon dioxide, sulfur dioxide, water and the like are generated; a high-temperature exhaust gas productheats the tower-entering VOCs in the second preheater, and after heat exchange, ultra-clean discharge of tail gas is realized after spraying and washing by the ammonia water from the ammonia water tank in an absorption tower, and spraying and washing liquid enters a crystallizer for evaporative crystallization to obtain ammonium salt; waste liquid discharged from the bottom of a stripping tower passes through a first preheater for preheating of feed wastewater and then passes through a post-treatment unit, so ultra-clean discharge of the wastewater is realized.

Owner:JIANGSU SUNPOWER TECH

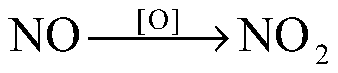

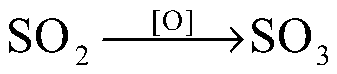

Ultralow emission process for catalytic cracking smoke

InactiveCN106345250AReduce generationReduce effluxGas treatmentDispersed particle separationFlue gasSlurry

The invention provides an ultralow emission process for catalytic cracking smoke, comprising the following steps of: introducing an addition agent in a catalytic cracking catalyst, reducing Sox and NOx content in the catalytic smoke in a lower cost maximally, wherein the maximum concentration of NOx in the smoke does not exceed 400mg / m3; high temperature flue gas from a heat recovery boiler of a catalytic cracking device contacts with a circulation slurry in an urgent cooling desulfurizing tower to cool, dedust and desulfurize; the maximum concentration of the desulfurized smoke Sox does not exceed 150mg / m3; the desulfurized smoke enters the bottom ofa denitrating tower by a dustproof defroster to be in reverse contact with a denitrating solution; the denitrated smoke is evacuated after being removal of the fog; Soxin the smoke basically realizes zero emission; and when NOx content is below 30mg / Nm3, the purpose of ultralow emission is realized.

Owner:SINOPEC ENG GRP CO LTD

Deep purification equipment for dangerous waste incineration flue gas and purification treatment method of deep purification equipment

PendingCN111550797AAchieve ultra-clean emissionsMeet ultra-low emission standardsCombination devicesIncinerator apparatusSprayerAcid gas

The invention puts forward deep purification equipment for dangerous waste incineration flue gas. The deep purification equipment comprises a rotary kiln, a boiler, a quenching tower, a spraying tower, a composite dust remover, a first flue gas heat exchanger, a reactor, a deacidification tower, a dust remover and a chimney; the rotary kiln, the boiler, the quenching tower, the spraying tower, thecomposite dust remover, the first flue gas heat exchanger, the deacidification tower, the dust remover and the chimney are sequentially connected through pipelines; the reactor is connected onto thefirst flue gas heat exchanger; a water sprayer is arranged on the boiler; an atomizer is arranged on the spraying tower; and a powder sprayer is arranged on the composite dust remover. Heat exchange is performed on the flue gas, denitration of the glue gas is realized, nitric oxide in the flue gas is removed, activated carbon powder is sprayed into the composite dust remover, dioxin in the flue gas can be removed, baking soda powder is sprayed by the powder sprayer, and acid gas in the flue gas can be removed by the aid of the deacidification tower, so that ultra-clean emission of the organicdangerous waste incineration flue gas can be realized.

Owner:武汉东衍环境工程技术有限公司

Coal-fired flue gas surplus energy recovery spray tower with load adaptability

PendingCN110237682AImprove heat transfer efficiencyReduce spray water flowDispersed particle separationFlue gasWater flow

The invention belongs to the technical field of flue gas heat recovery and purification, and particularly relates to a coal-fired flue gas surplus energy recovery spray tower with load adaptability. The coal-fired flue gas surplus energy recovery spray tower comprises a tower body, wherein a gas outlet is formed in the top of the tower body; a gas inlet is formed in the bottom of the tower body; a demister is arranged below the gas outlet in the tower body; a spray layer is arranged below the demister and comprises a liquid distribution device; a spray area is arranged below the liquid distribution device; a water pan is arranged below the spray area; a plurality of partition plates are arranged in the spray area, parallel to the flow direction of the flue gas; the partition plates divide the spray area into a plurality of independent spray areas; a turnable flue gas baffle is arranged below each independent spray area. According to the spray tower, the opening / closing of independent spray areas in the spray layer is controlled according to the flue gas flow so as to control the partitions with the liquid distribution device turned on; thus, the spray water flow is reduced, and the heat exchange efficiency in the centralized area is higher.

Owner:GUOHUI ENVIRONMENTAL PROTECTION NEW ENERGY

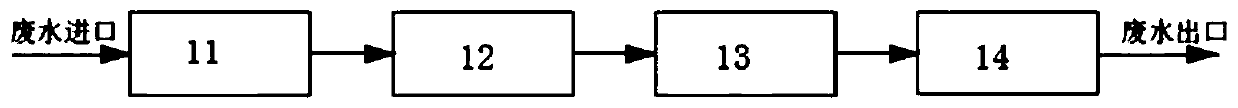

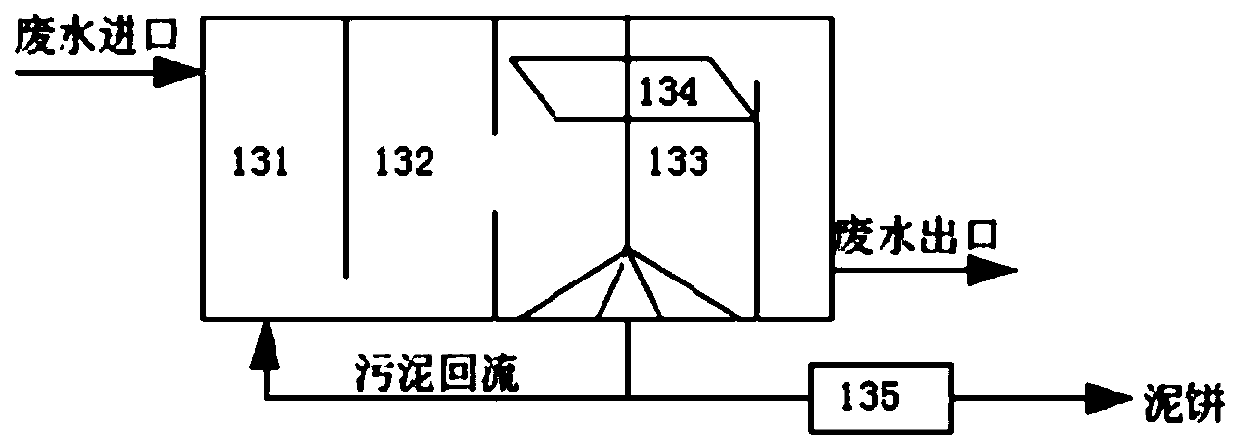

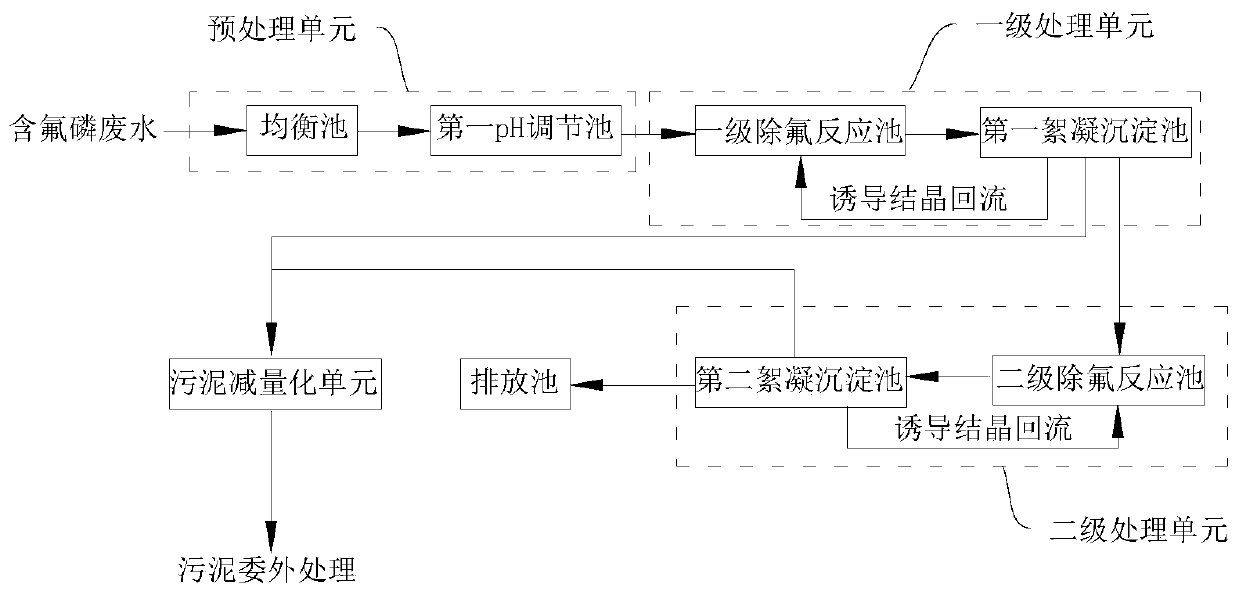

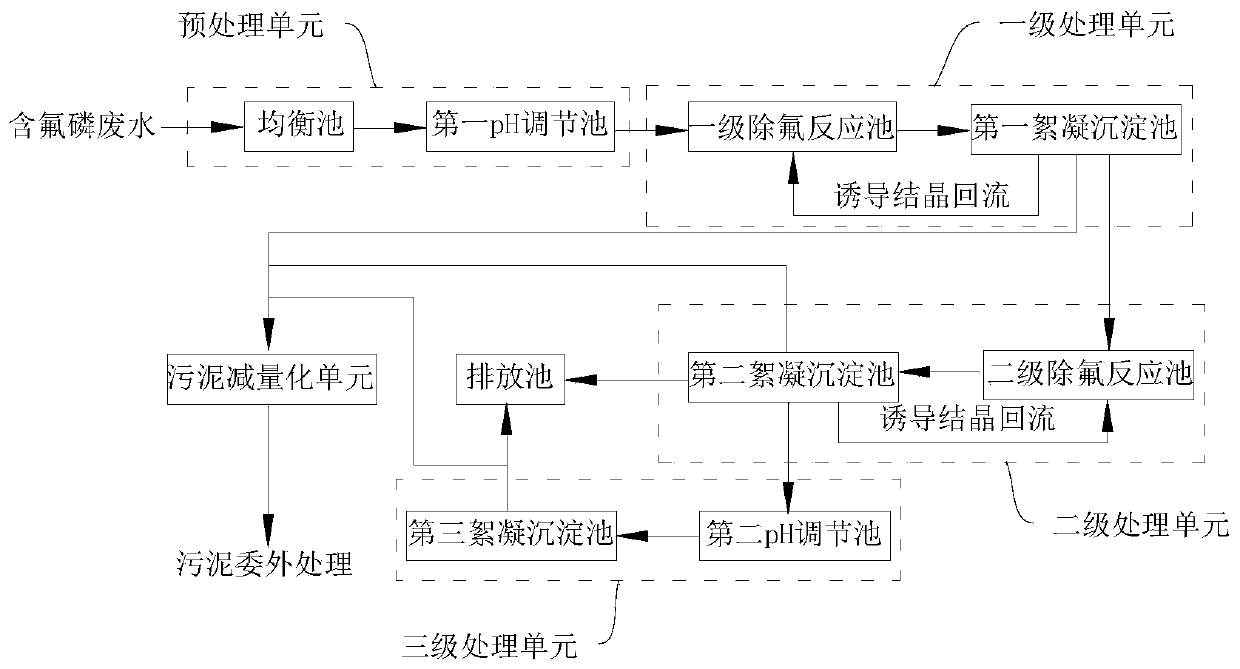

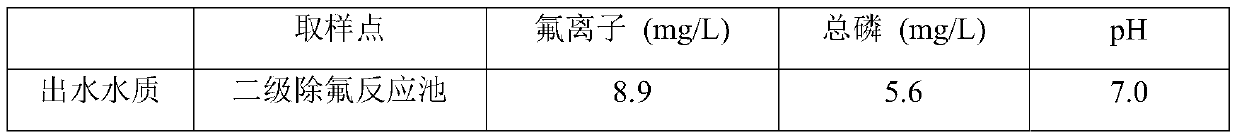

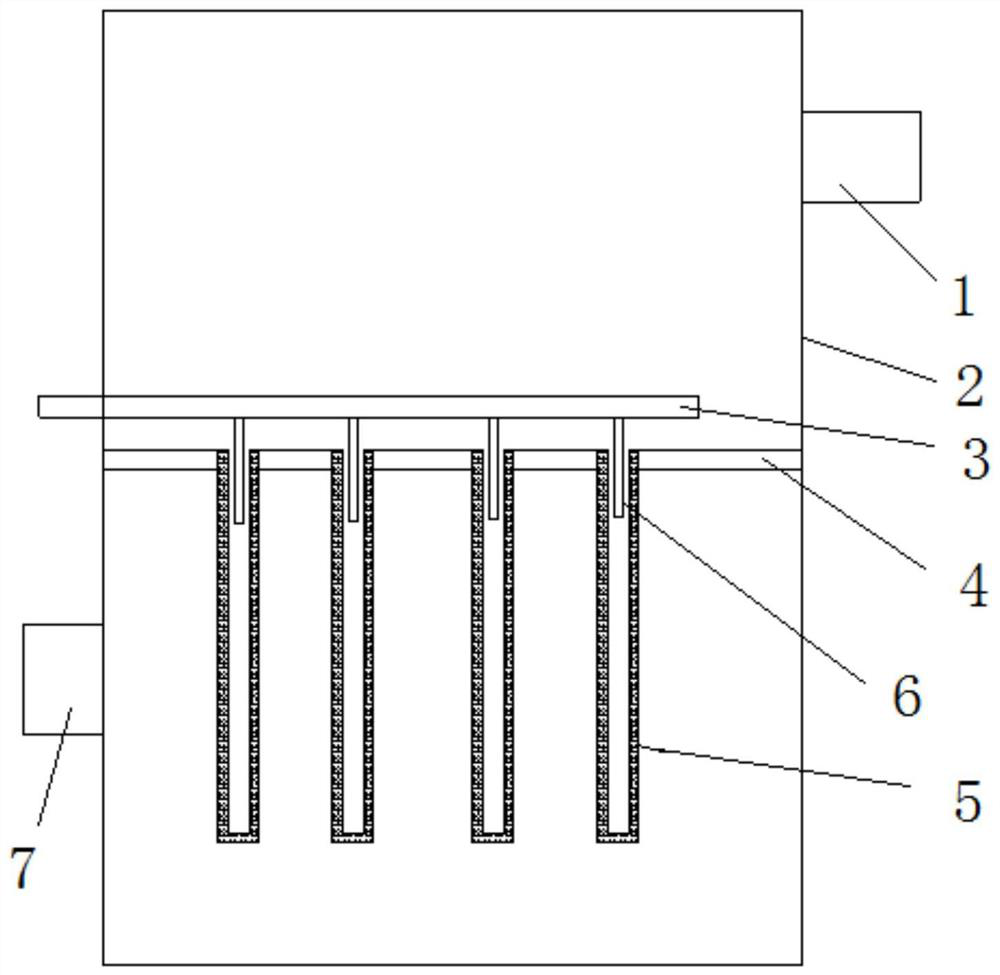

Treatment system and treatment process for wastewater containing fluorine and phosphorus

InactiveCN111302536AReduce productionLow running costSpecific water treatment objectivesWater contaminantsIndustrial waste waterSludge

The invention discloses a treatment system and a treatment process for wastewater containing fluorine and phosphorus, and belongs to the technical field of industrial wastewater treatment. The treatment system comprises a pretreatment unit, a primary treatment unit, a secondary treatment unit, a discharge tank and a sludge reduction unit. According to the treatment system and the treatment processprovided by the invention, ultra-clean discharge of wastewater containing fluorine and phosphorus can be realized, and after the wastewater is subjected to deep fluorine and phosphorus removal treatment, at least the fluorine content in the wastewater can be reduced to 1.0 mg / L or below, the total phosphorus content in the wastewater can be reduced to 2.0 mg / L or below, and for some special areas, the total phosphorus content can be further reduced to 0.5 mg / L or below; the system and the process are suitable for purifying fluorine and phosphorus wastewater related to the fields of coal chemical industry, solar energy, semiconductors and the like, wherein the treatment process is simple, corresponding reaction units can be increased or decreased according to the actual situation of project emission standards, all reaction tanks are compactly arranged, the land is saved, and the operation and maintenance cost is low.

Owner:四川恒泰环境技术有限责任公司

A method for dedusting, desulfurizing and denitrating boiler flue gas and removing dioxins

ActiveCN110252051BAchieve ultra-clean emissionsImprove desulfurization efficiencyHuman health protectionGas treatmentPtru catalystFlue gas

The invention discloses a method for dedusting, desulfurization, denitration and dioxin removal of boiler flue gas. The method comprises the following steps: extracting flue gas having a temperature of 250-350 DEG C from a boiler, injecting bicarbonate with a size of 600-700 meshes into the flue gas, and carrying out a reaction; and adding a reducing agent into the reacted flue gas, and allowing the flue gas to enter a denitration-dedusting composite device for denitration, dioxin removal and dust removal. The denitration-dedusting composite device comprises a shell, a partition plate and a plurality of basalt fiber filter cartridges, wherein the partition plate is arranged on a cross section of the shell and divides the shell into a first chamber and a second chamber; the sidewall of the shell of the first chamber is provided with a flue gas inlet; the sidewall of the shell of the second chamber is provided with a flue gas outlet; each basalt fiber filter cartridge is a hollow tube body, and basalt fiber cotton is bonded with a catalyst; each basalt fiber filter cartridge is mounted on the partition plate, and the basalt fiber filter cartridges are all located in the first chamber; and the opening of each basalt fiber filter cartridge is in communication with the second chamber.

Owner:山东中琦环保设备制造有限公司

Coal-fired boiler flue gas whiteness-removing system with low energy consumption

ActiveCN109806751AReduce heat transfer areaIncrease tube wall temperatureDispersed particle separationCombustion technology mitigationFlue gasLower grade

The invention discloses a coal-fired boiler flue gas whiteness-removing system with low energy consumption. The flue gas whiteness-removing system comprises a boiler water-supply preheater, a sprayingand condensing system, a duster, a desulfurization tower, a flue gas heater and a chimney. The spraying and condensing system comprises a spraying tower, a spraying water cooler, a dosing device, theduster, and a defogger; a spraying device is arranged in the middle of the spraying tower; the spraying device is communicated with the bottom of the spraying tower through the spraying water cooler;the dosing device is communicated with the bottom of the spraying tower; the top of the spraying tower is sequentially provided with the duster and the defogger. Condensed flue gas is heated throughsteam saved or produced to remove whiteness from the flue gas, and a heating source of the flue gas heater is transferred into steam, so that the heat exchanging area of the flue gas heater is reduced, and the temperature of the wall of the flue gas heater is increased to prevent dew point corrosion from appearing on the flue gas heater. Ordinary materials can be used to ensure the long service life of the equipment, used steel materials are reduced, project construction price is lowered, and after heat resources is transferred from low grade to high grade to be utilized.

Owner:周岩

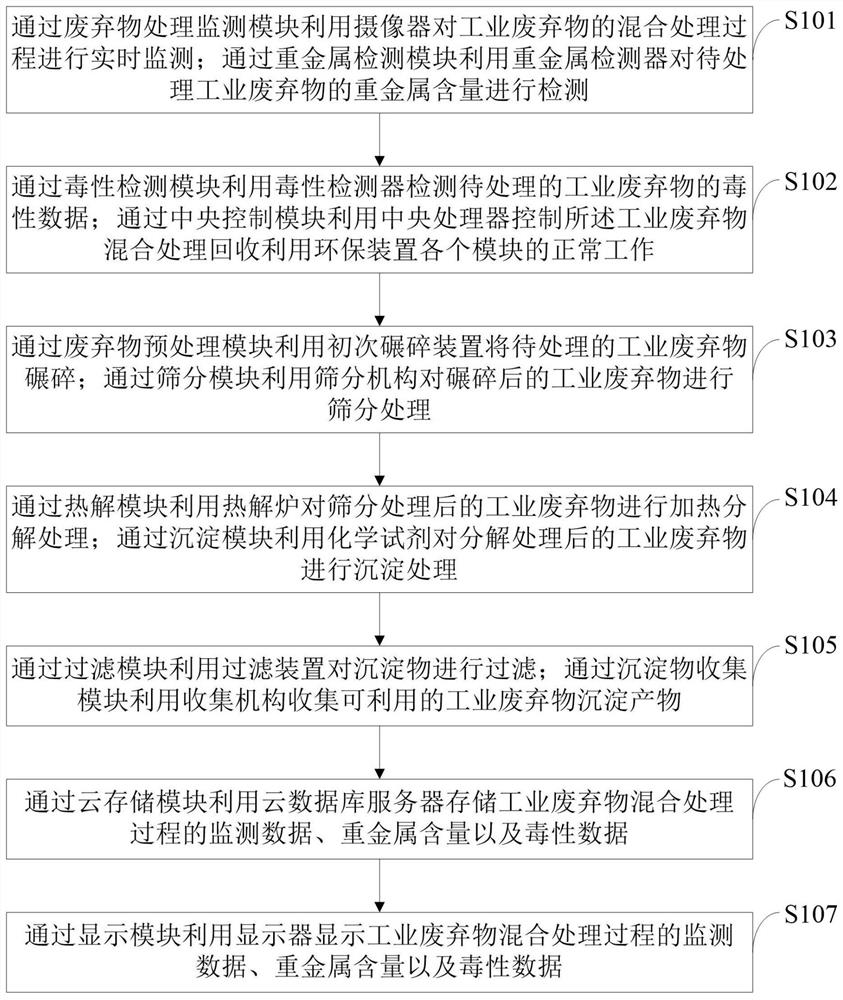

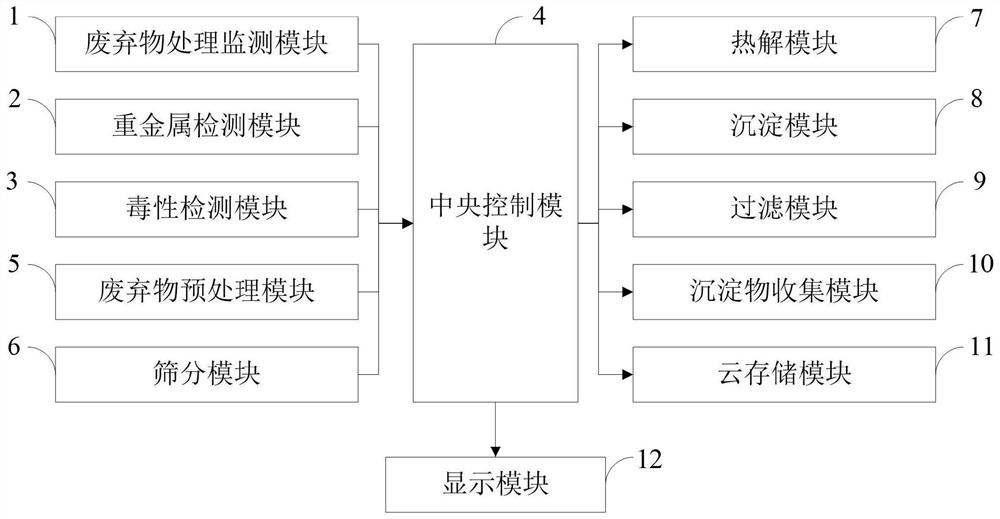

Environmental protection device for mixed treatment, recycling and utilization of industrial waste and control method thereof

InactiveCN111842425AImprove the fineness of sievingImprove work efficiencySolid waste disposalTransportation and packagingFiltrationWaste treatment

The invention belongs to the technical field of environmental protection, and discloses an environmental protection device for mixed treatment, recycling and utilization of industrial waste and a control method thereof. The environmental protection device for mixed treatment, recycling and utilization of industrial waste comprises a waste treatment monitoring module, a heavy metal detection module, a toxicity detection module, a central control module, a waste pretreatment module, a screening module, a pyrolysis module, a precipitation module, a filtration module, a sediment collection module,a cloud storage module and a display module. The environmental protection device provided by the invention creates conditions for the comprehensive utilization of organic industrial solid waste by crushing and sorting the organic industrial solid waste into standardized derivative fuels through the screening module; through the crushing, scattering, sorting, drying and other processes, the fineness of waste screening is improved; and organic pollution factors contained in the organic solid waste are eliminated through the pyrolysis module, and the material reaction environment is reduced, thereby avoiding the generation of dioxin and avoiding the secondary pollution on the environment during the disposal process, and the environmental benefits are significant.

Owner:唐山聚人环保科技有限公司

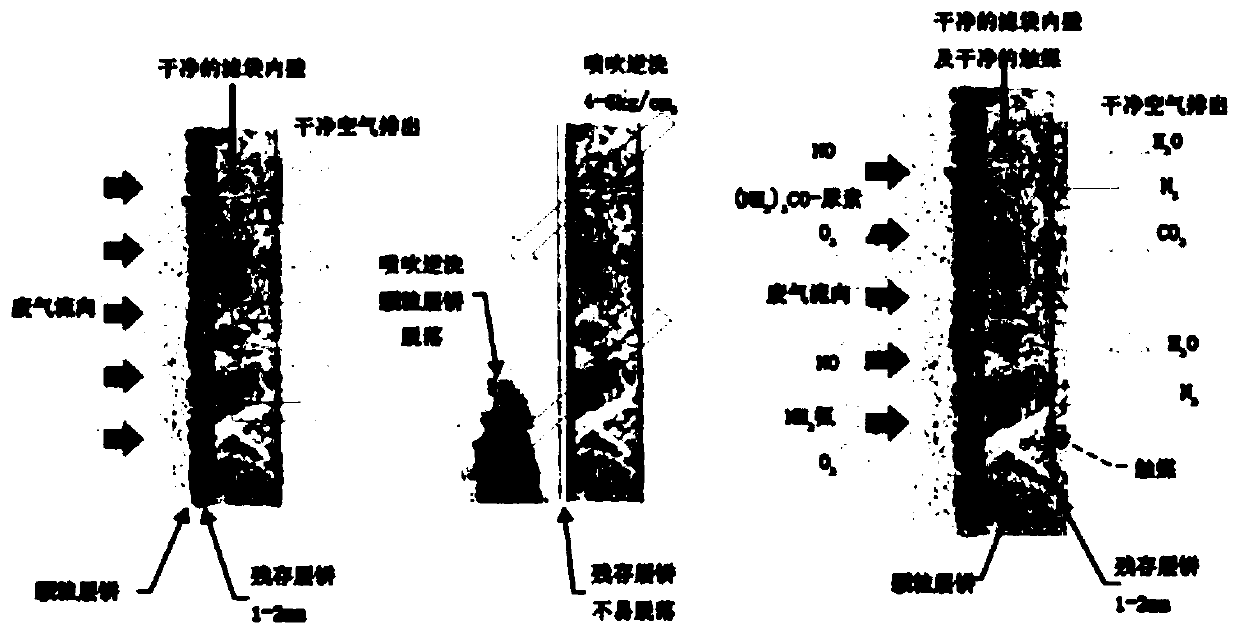

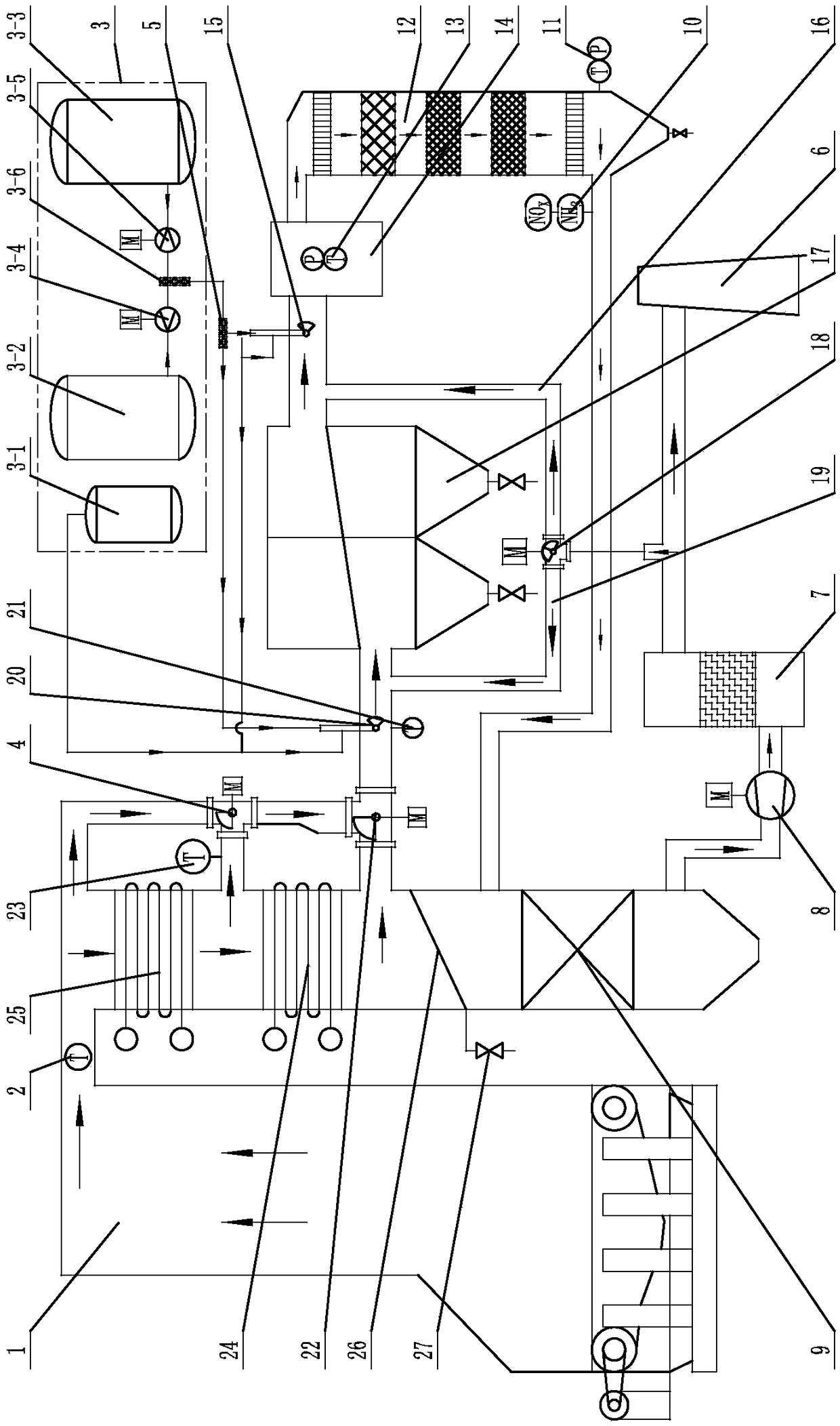

Semi-dry desulfurization-denitrification integrated device and method for sintering flue gas

The invention discloses a semi-dry desulfurization-denitrification integrated device and method for sintering flue gas, belonging to the technical field of desulfurization and denitrification. The device comprises a sintering machine, an electric precipitator, a main exhaust fan, an oxidizing agent tank, a rotary atomizer, an SDA desulfurizing tower, a reductant absorption tank, a supplementary absorbent tank, a bag-type dust collector, a booster fan and a flue gas monitoring device. The method comprises the following steps: firstly, dedusting flue gas by virtue of the electric precipitator, then feeding the flue gas into a flue, spraying a denitration oxidant component A into the flue, feeding the treated flue gas into the SDA desulfurization tower, spraying flue gas with slaked lime slurry, and spraying a denitration reduction absorbent component B into the SDA desulfurization tower by virtue of a high-pressure spray gun; and spraying the denitration supplementary absorbent componentC into a pipeline located between the exhaust outlet of the SDA desulfurization tower and the bag-type dust collector, and discharging the purified flue gas through a chimney after the flue gas is dedusted by the bag-type dust collector. The method disclosed by the invention is simple and low in operation cost, and has remarkable environment-friendly benefits.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

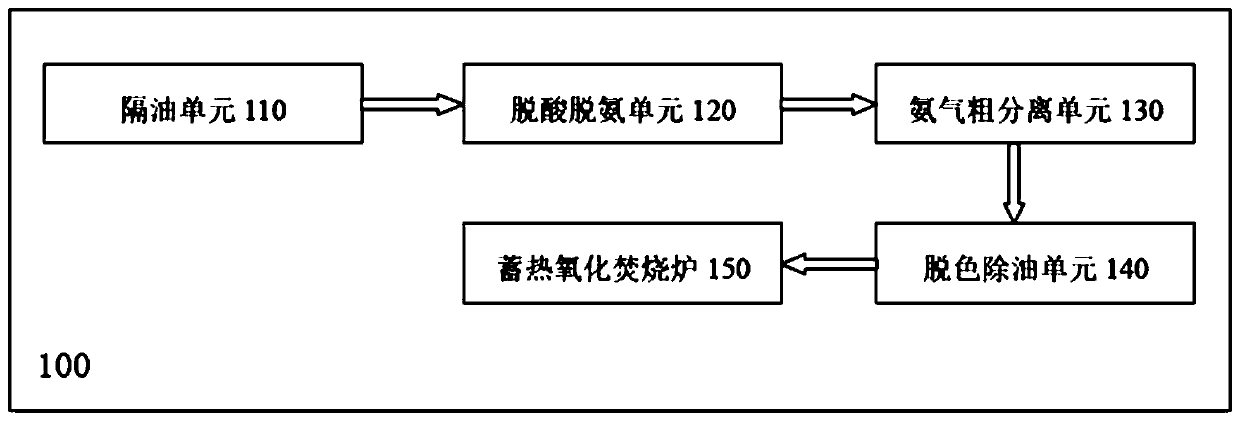

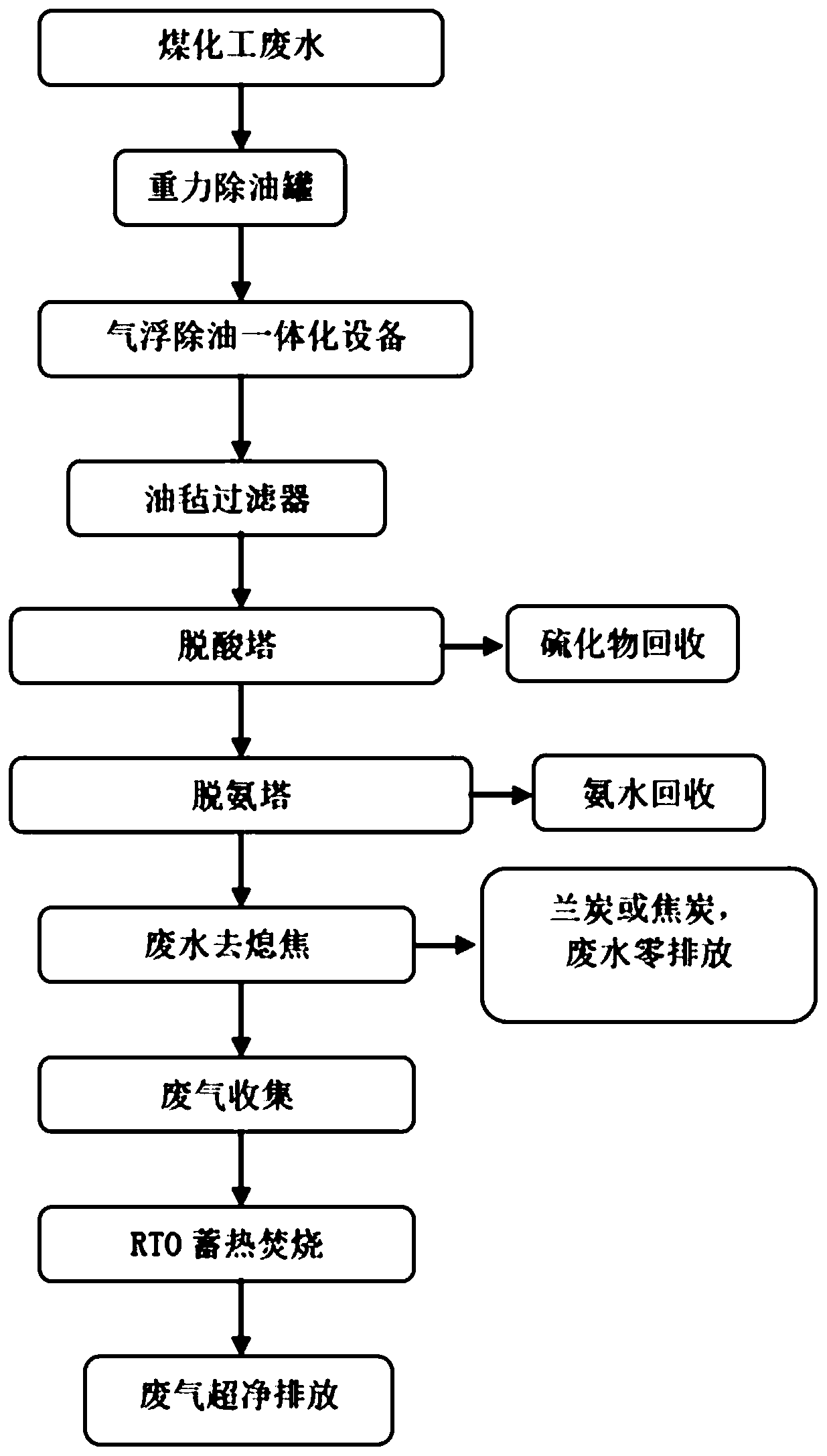

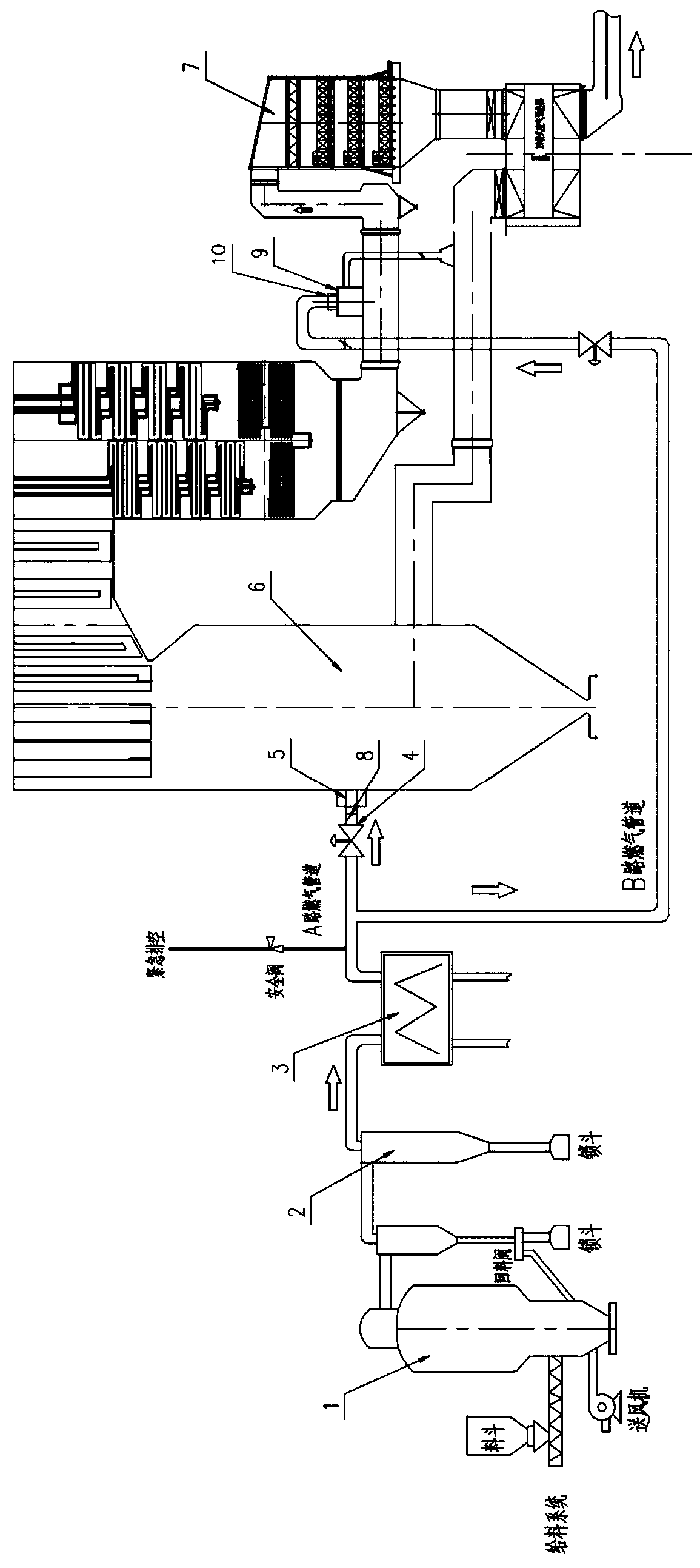

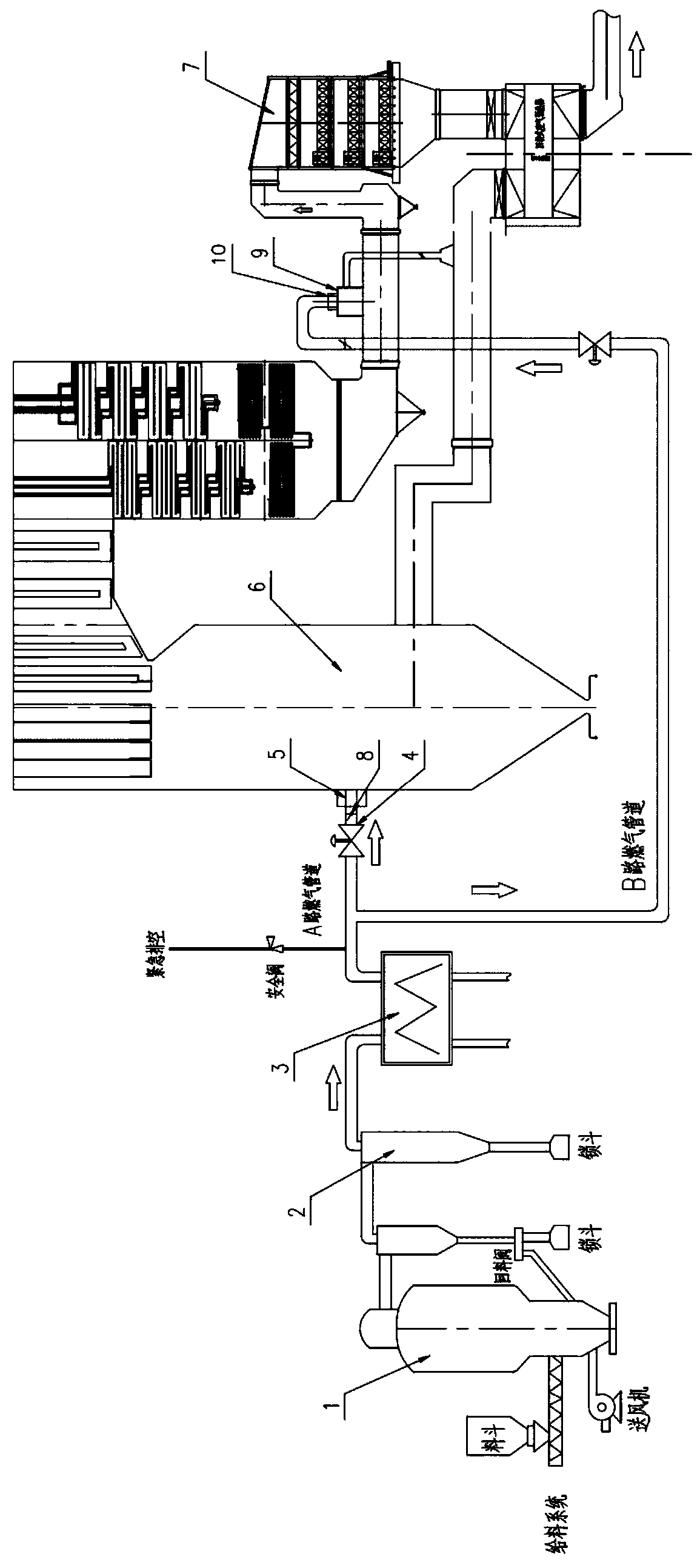

Coal chemical industry wastewater and waste gas co-treatment system and method

PendingCN111087113AAchieving zero emissionsLow investment costFatty/oily/floating substances removal devicesWater contaminantsExhaust fumesWastewater

The invention discloses coal chemical industry wastewater and waste gas synergistic treatment system and method, wherein the method comprises the steps: firstly carrying out the pretreatment of coal chemical industry wastewater, and enabling the sulfide content in the wastewater to be less than 20 mg / l and the ammonia content to be less than 100 mg / l; then quenching the pretreated coal chemical industry wastewater; then, waste gas generated after coke quenching is pretreated, and wastewater generated after waste gas pretreatment is fed into coal chemical industry wastewater for pretreatment; and finally, the pretreated waste gas is subjected to heat storage oxidation incineration. According to the scheme, after the coal chemical industry wastewater is pretreated and quenched, volatile organic compounds are purified through oxidative incineration, and closed-cycle cooperative treatment is carried out on the coal chemical industry wastewater and waste gas, so that zero emission of the wastewater and ultra-clean emission of the waste gas are achieved.

Owner:上海安居乐环保科技股份有限公司

Biomass gas coupled coal-fired unit power generation device

PendingCN109705920AEfficient use ofIncrease power generation timeEnergy inputGranular/pulverulent flues gasificationAir preheaterOne pass

The invention provides a biomass gas coupled coal-fired unit power generation device, which mainly solves the problems that under an ultralow load situation, SCR inlet temperature is lower than effective working temperature of a catalyst, which causes that denitration cannot be put in use. A circulating fluidized bed gasifier, a cyclone dust collector, a fuel gas heat exchanger are successively connected via pipelines. The outlet of the fuel gas heat exchanger is divided into two paths: one passes through a fuel gas combustor A via a path-A fuel gas pipeline and is connected to the hearth of aboiler furnace, the other passes through a fuel gas combustor B via a path-B fuel gas pipeline and is connected to a horizontal flue in the front of a SCR denitration device. The SCR denitration device is connected to the outlet of a coal-firing boiler economizer through the horizontal flue. The fuel gas combustion chamber of the fuel gas combustor B is connected to a tail secondary air duct of the coal-firing boiler. The tail secondary air duct of the coal-firing boiler and the outlet flue of the SCR denitration device are respectively to a revolving air preheater. The device achieves coupled power generation of the biomass flue gas and the coal-fired unit under an ultralow load situation of the coal-fired unit.

Owner:HARBIN BOILER

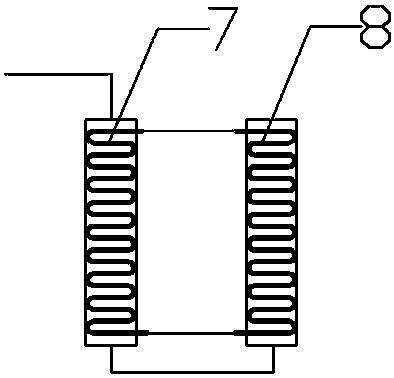

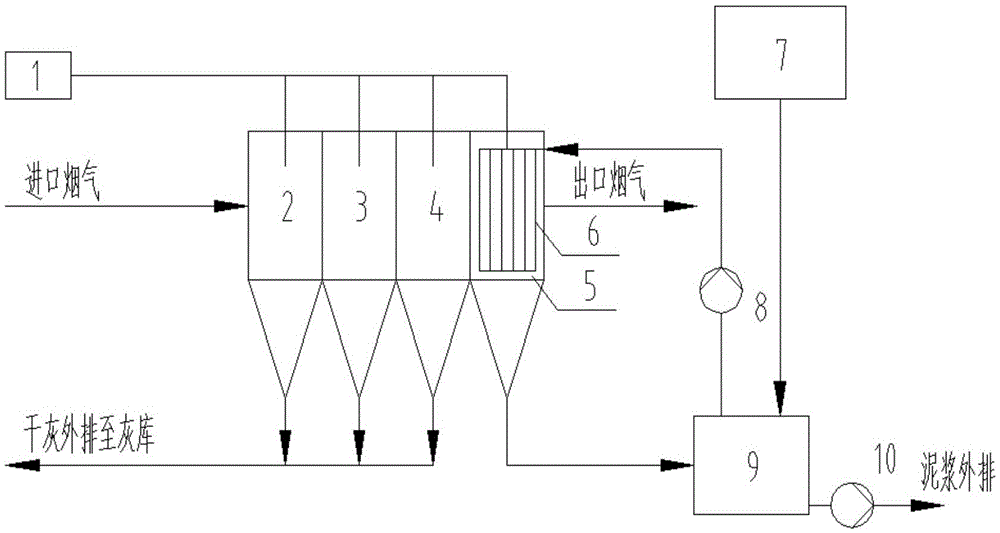

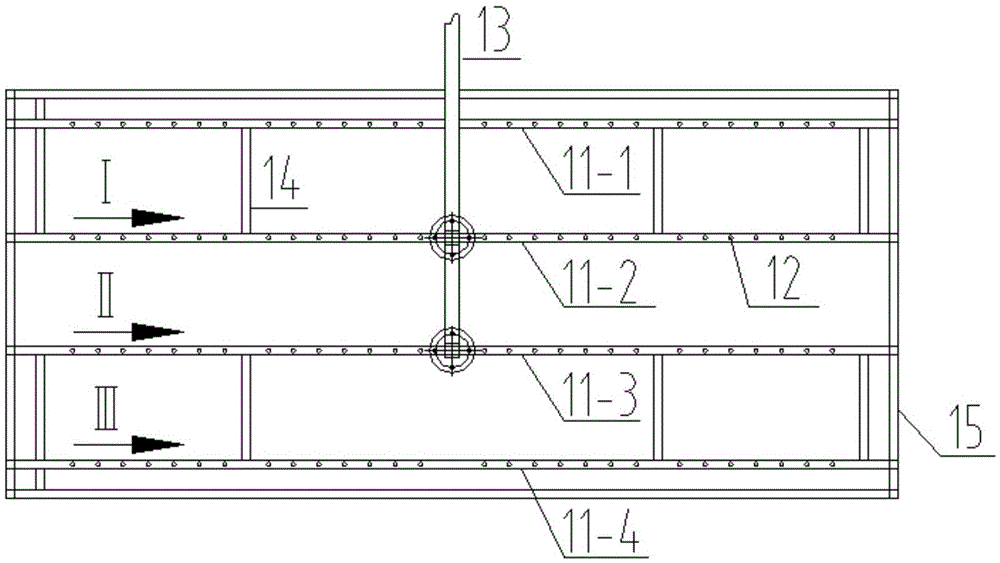

Dry and wet coupling electrostatic dust collection system and dust collection technology

InactiveCN105583076AUltra clean emissionsThe amount of renovation work is smallElectrode constructionsElectrostatic precipitatorVoltage

The invention discloses a dry and wet coupling electrostatic dust collection system and a dust collection technology. Multiple stages of electric fields are arranged in the dry and wet coupling electrostatic dust collection system. A dust collection plate in the last stage of electric field is a wet type pole plate. A plurality of rows of transverse water distributing pipes which are perpendicular to the wet type pole plate or inclined relative to the wet type pole plate are arranged above the wet type pole plate. A plurality of water distributing micro-holes are formed in each row of transverse water distributing pipe. The bottom of the last stage of electric field is connected with an ash sluicing water treatment recycling system through a water collection device. A centrifugal machine or a flocculent precipitating tank is connected with the transverse water distributing pipes through a water inlet pipe to achieve water resource recycling. The dry and wet coupling electrostatic dust collection system and the dust collection technology have the beneficial effects that the requirements for the smoke temperature, the flow speed, the operation voltage and the like of the electric field where the wet type pole plate is located are matched with those of the electric field at the front end of the wet type pole plate, so that in the practical transformation process, a shell of an original electrostatic dust collector can be reserved, transformation can be completed under the assistance of a flushing water system, the transformation project amount is small, and cost is low. A water distributing system is designed and matched with the flexible pole plate, so that water does not make direct contact with smoke, the influence on temperature reduction of the smoke is very low, smoke condensation is avoided, and meanwhile damage to subsequent equipment is avoided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com