Ultralow emission process for catalytic cracking smoke

A catalytic cracking and flue gas technology, applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve problems such as low sulfur resistance, poor adaptability of raw materials, instability, etc., to reduce the generation of pollutants, reduce Effects of purification cost and denitrification cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

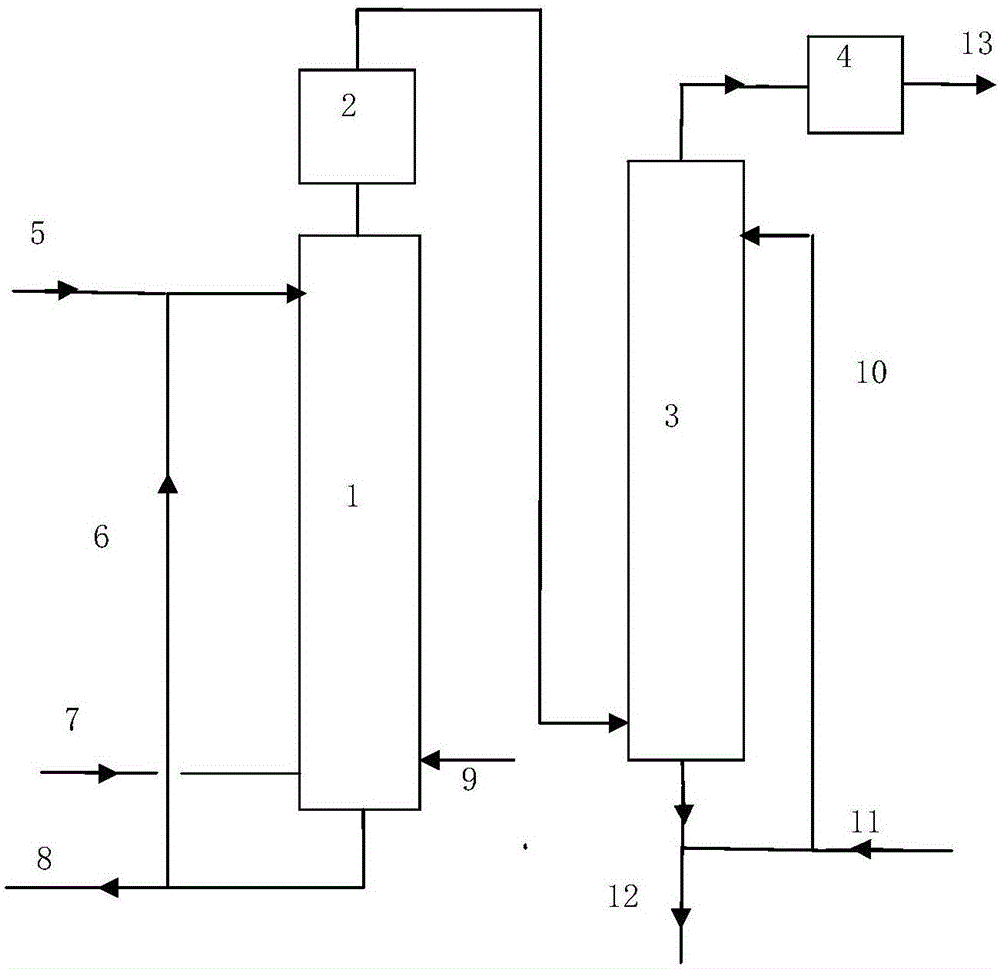

Image

Examples

Embodiment 1

[0040] The first step: auxiliary desulfurization and denitrification

[0041] The content of NOx and SOx in the flue gas of a refinery catalytic cracking flue gas before adding additives is 1360mg / m 3 , 200mg / m 3 , adding a denitrification additive (LDN-1 denitrification additive) accounting for 1.5% of the total storage capacity of the catalytic cracking catalyst, and after the operation is stable, it is calibrated, and the NOx and SOx contents in the catalytic cracking flue gas are respectively 340mg / m 3 , 180mg / m 3 , The denitrification rate is 75%.

[0042] The second step: desulfurization

[0043] The flue gas from the waste heat boiler of the FCC unit is in full contact with the circulating slurry in the quenching scrubber, and the pH of the circulating slurry is controlled to be 5-9 by adding fresh sodium lye. The quenching scrubber is an empty tower. The concentration of sulfur dioxide in the purified flue gas is 30mg / m 3 , The desulfurization rate is 83.3%.

[...

Embodiment 2

[0047] The first step: auxiliary desulfurization and denitrification

[0048] The content of NOx and SOx in the flue gas of a refinery catalytic cracking flue gas before adding additives is 100mg / m 3 、1115mg / m 3 , adding a desulfurization aid (LST-1 desulfurization aid) accounting for 4% of the total storage capacity of the catalytic cracking catalyst, and then calibrated after the operation is stable. The NOx and SOx contents in the flue gas from catalytic cracking are respectively 95mg / m 3 , 245mg / m 3 , the desulfurization rate is 78%.

[0049] The second step: desulfurization

[0050] The high-temperature flue gas from the waste heat boiler of the FCC unit is in full contact with the circulating slurry in the quenching scrubber, and the pH of the circulating slurry is controlled to be 5-9 by adding fresh sodium lye. The quenching scrubber is an empty tower. The concentration of sulfur dioxide in the purified flue gas is 29.5mg / m 3 , The desulfurization rate is 88%.

...

Embodiment 3

[0054] The first step: auxiliary desulfurization and denitrification

[0055] The content of NOx and SOx in the flue gas of a refinery catalytic cracking flue gas before adding additives is 260mg / m 3 、935mg / m 3 , adding a multi-effect additive (LTA-1 multi-effect additive) accounting for 2.5% of the total storage capacity of the catalytic cracking catalyst, calibrated after the operation was stable, and the NOx and SOx contents in the catalytic cracking flue gas were 158mg / m 3 , 290mg / m 3 , The denitrification rate is 39.2%, and the desulfurization rate is 68.9%.

[0056] The second step: desulfurization

[0057] The flue gas from the waste heat boiler of the FCC unit is in full contact with the circulating slurry in the quenching scrubber, and the pH of the circulating slurry is controlled to be 5-9 by adding fresh sodium lye. The quenching scrubber is an empty tower. The concentration of sulfur dioxide in the purified flue gas is 42mg / m 3 , The desulfurization rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com