Process method and device for ultra-clean discharge treatment of dust-containing steam in steel slag rolling region

A technology of steam and steel slag, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of inability to achieve ultra-clean emission indicators, few dust removal methods, etc., achieve simple operation and maintenance, improve dust removal efficiency, and run The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

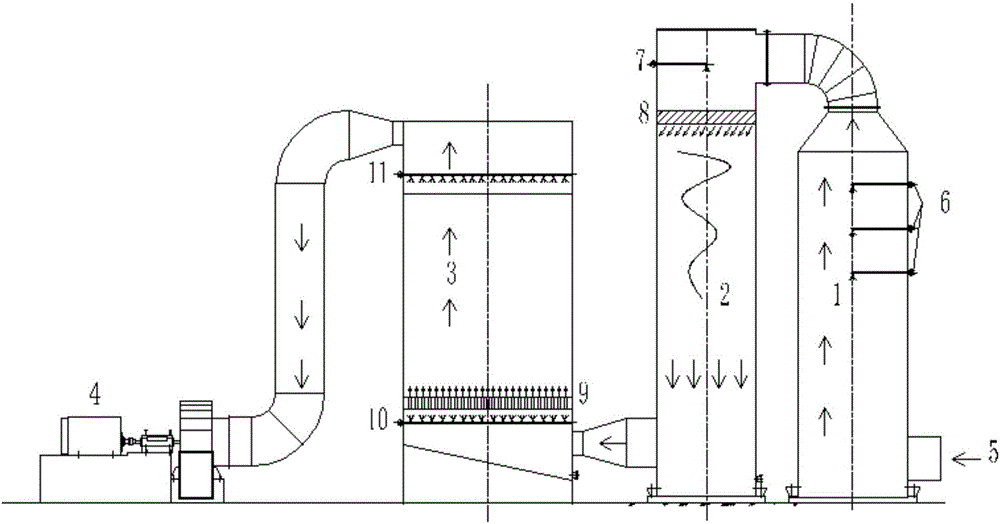

[0020] Such as figure 1 As shown, a device for dedusting the dust-laden steam in the rolling area of steel slag treatment to achieve ultra-clean discharge, which includes a washing tower 1, a swirl tower 2, an electrostatic precipitator 3, a first pipeline, a second pipeline, and a third pipeline. pipeline, the fourth pipeline and the induced draft fan 4; the bottom of the washing tower 1 is provided with a first opening, and the first opening is connected with the rolling zone space through the first pipeline, and is used to introduce the dust-containing steam 5 generated in the rolling zone into the washing tower 1 for spraying treatment, the second pipeline connecting the washing tower 1 and the cyclone tower 2 is arranged on the top of the washing tower 1 and the cyclone tower 2, and is used to introduce the dust-laden steam treated by the washing tower 1 into the cyclone tower 2 The cyclone separation process is carried out in the cyclone tower 2, the bottom of the cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com