Special circulating fluidized bed boiler with flue gas recirculation

A flue gas recirculation and circulating fluidized bed technology, which is applied in the field of circulating fluidized bed boilers and special circulating fluidized bed boilers, can solve the problems of high emission concentration of chemicals, easy wear of the heating surface, unstable bed temperature, etc., and achieve The effects of stable combustion, guaranteed reducing atmosphere, and effective bed temperature balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

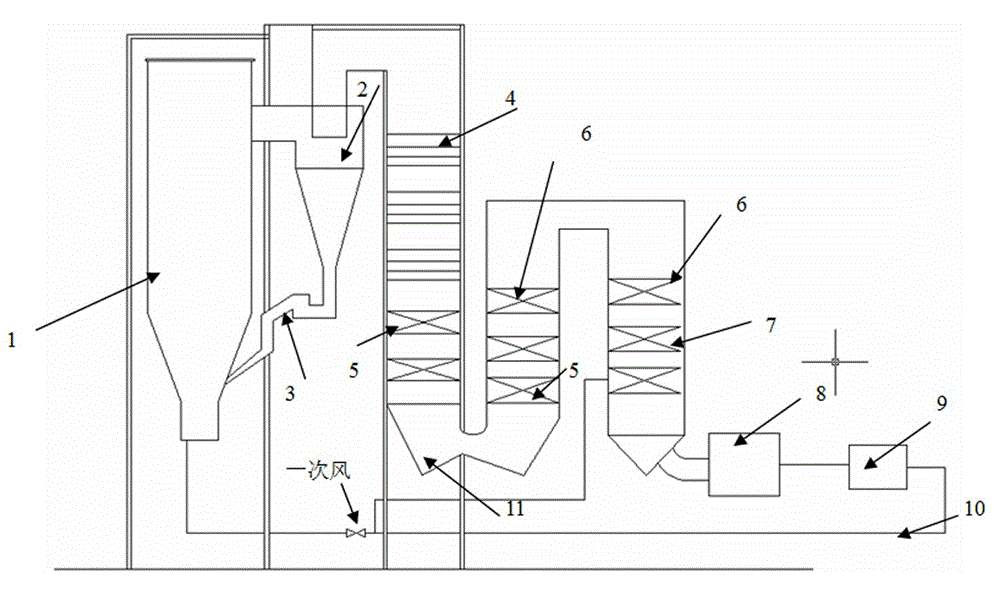

[0024] Such as figure 1 A special circulating fluidized bed boiler with flue gas recirculation is shown, including a separator 2 communicated with the furnace 1, the top of the separator 2 communicates with three tail vertical flues, and the bottom of the separator 2 communicates with the boiler through the return plate 3 The furnace 1 is connected, and the end of the vertical flue is connected to the dust collector 8 and the induced draft fan 9 in turn, and the outlet of the induced draft fan 9 is connected to the bottom of the furnace 1 through the flue gas recirculation pipe 10 .

[0025] The separator 2 is an eccentric volute type high-efficiency fly ash circulation separator; in the first vertical flue of the three tail vertical flues, a water-cooled evaporator 4 and a superheater 5 are fixed from top to bottom, and in the second vertical flue A superheater 5 and an economizer 6 are fixed from bottom to top, and an economizer 6 and an air preheater 7 are fixed in the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com