High-salinity wastewater treatment method of epoxypropane/styrene co-production device

A propylene oxide and treatment method technology, which is applied in the field of high-salt waste liquid treatment of propylene oxide/styrene co-production equipment, can solve the problems of short continuous operation period of the system, increased project investment, energy consumption, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for treating high-salt waste liquid of a propylene oxide / styrene cogeneration unit, comprising the following steps:

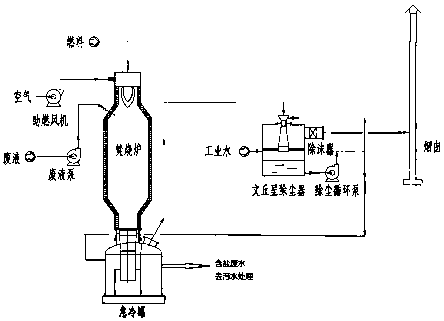

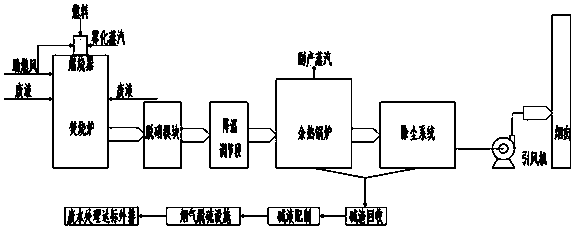

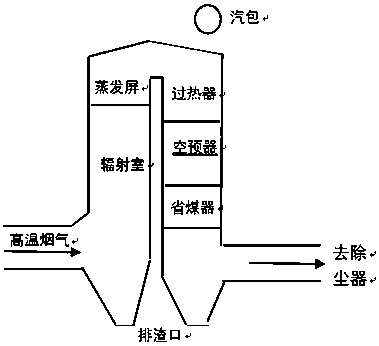

[0022](1) Waste liquid incineration: the high-salt waste liquid from the propylene oxide / styrene co-production unit atomized by compressed air is passed into a vertical incinerator for incineration, and the organic matter in the waste liquid is converted into CO 2 and water, the alkaline substances and organic salts in the waste liquid are converted into molten inorganic salts, and the system produces high-temperature flue gas after incineration; the vertical incinerator is composed of a main burner and an incineration chamber, and the main burner adopts multiple The fuel burner is used to process the fuel atomized by compressed air, and the burner is a low NOx burner. The outlet temperature of the incineration chamber is 1200°C. The total residence time of the high-temperature flue gas generated by the incineration of waste liquid in the inciner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com