Demisting device for cooling haze and removing dust

A technology of demisting device and demister, which is applied in the direction of combined device, steam/steam condenser, auxiliary pretreatment, etc., and can solve the problems of high cost and unsatisfactory ultra-clean technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

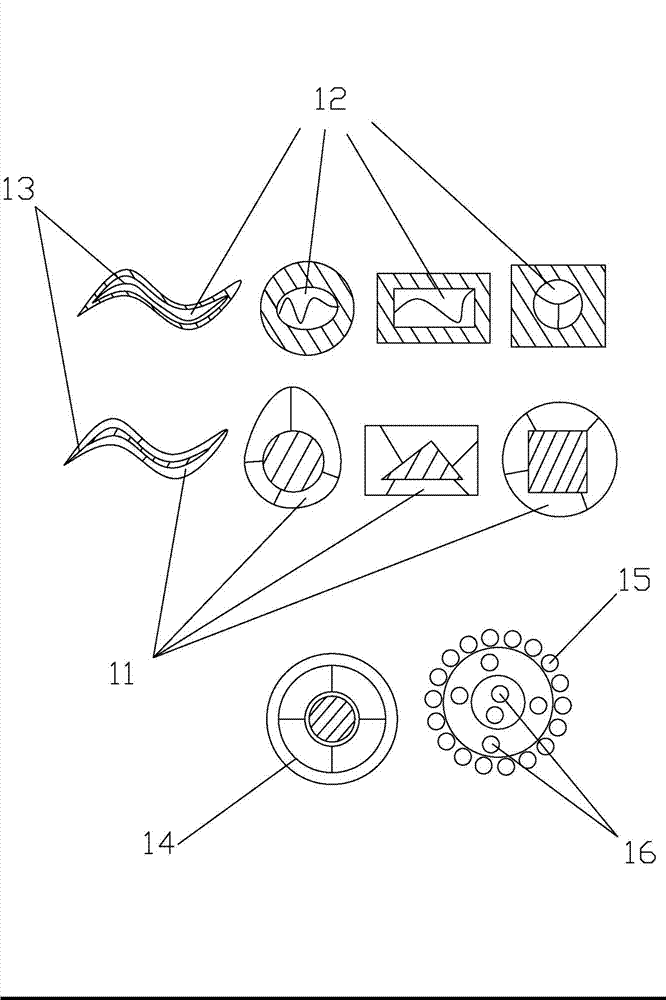

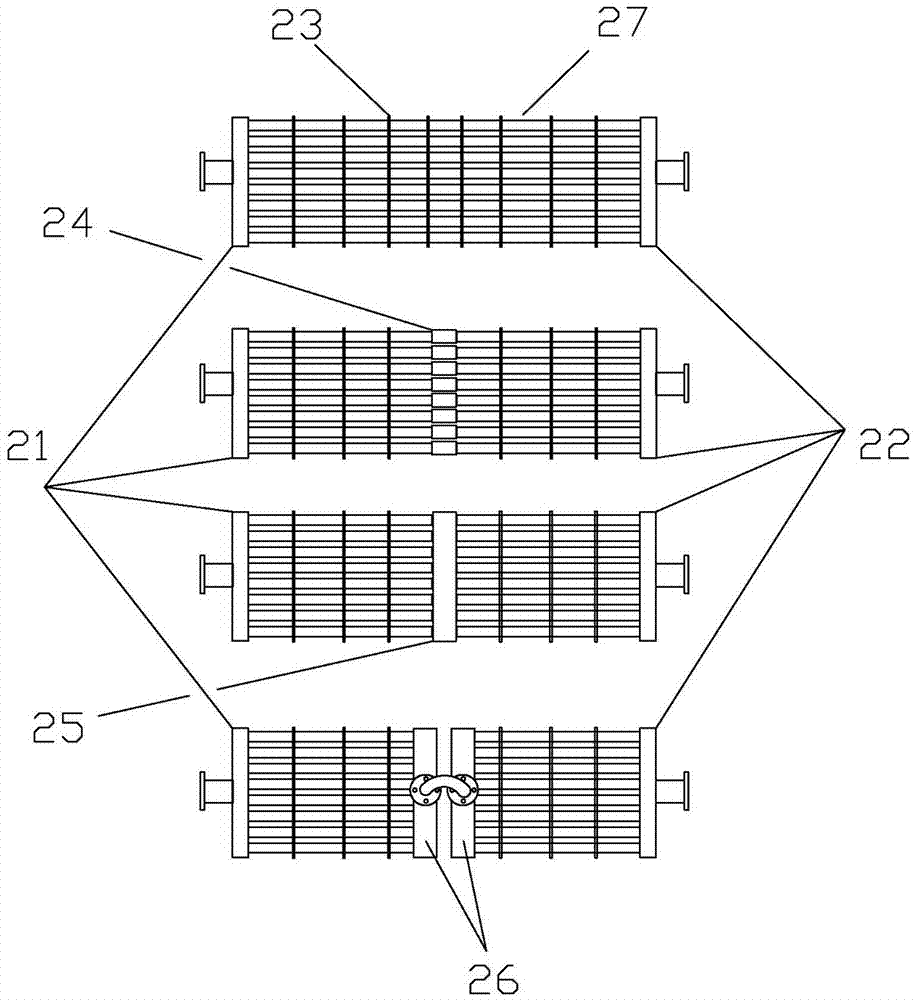

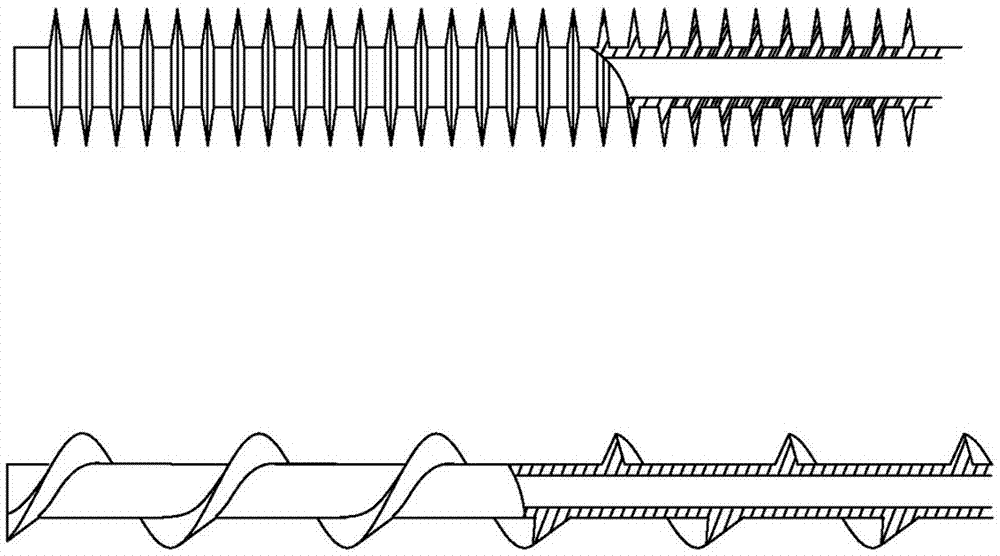

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] The principle of fine dust

[0042] At present, the main problem of ultra-clean emission is the removal of fine dust. After wet spraying, dust with a particle size of 0-15 μm can be 100% carried by the flue gas. 50% of the dust with a particle size of 250 µm can be carried by the flue gas, while the dust with a particle size of more than 500 µm is hardly carried by the flue gas. The main reason is the surface tension phenomenon of liquid droplets (water droplets). The surface tension of liquids is different, and some are very large, such as the surface tension of mercury, and the surface tension of water is also very large, such as capillary effect, steel needles can float on On the surface of the water, some aquatic insects do not live underwater but on the water, walking like flying, such as water striders, etc. Some small land insects such as spiders can w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com