Biomass gas coupled coal-fired unit power generation device

A technology for coal-fired units and power generation devices, applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry, etc., which can solve the problems of low catalyst effective working temperature, denitrification that cannot be put into use, and low smoke temperature at the SCR inlet. , to achieve the effects of promoting stable combustion, increasing power generation time, and increasing inlet smoke temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

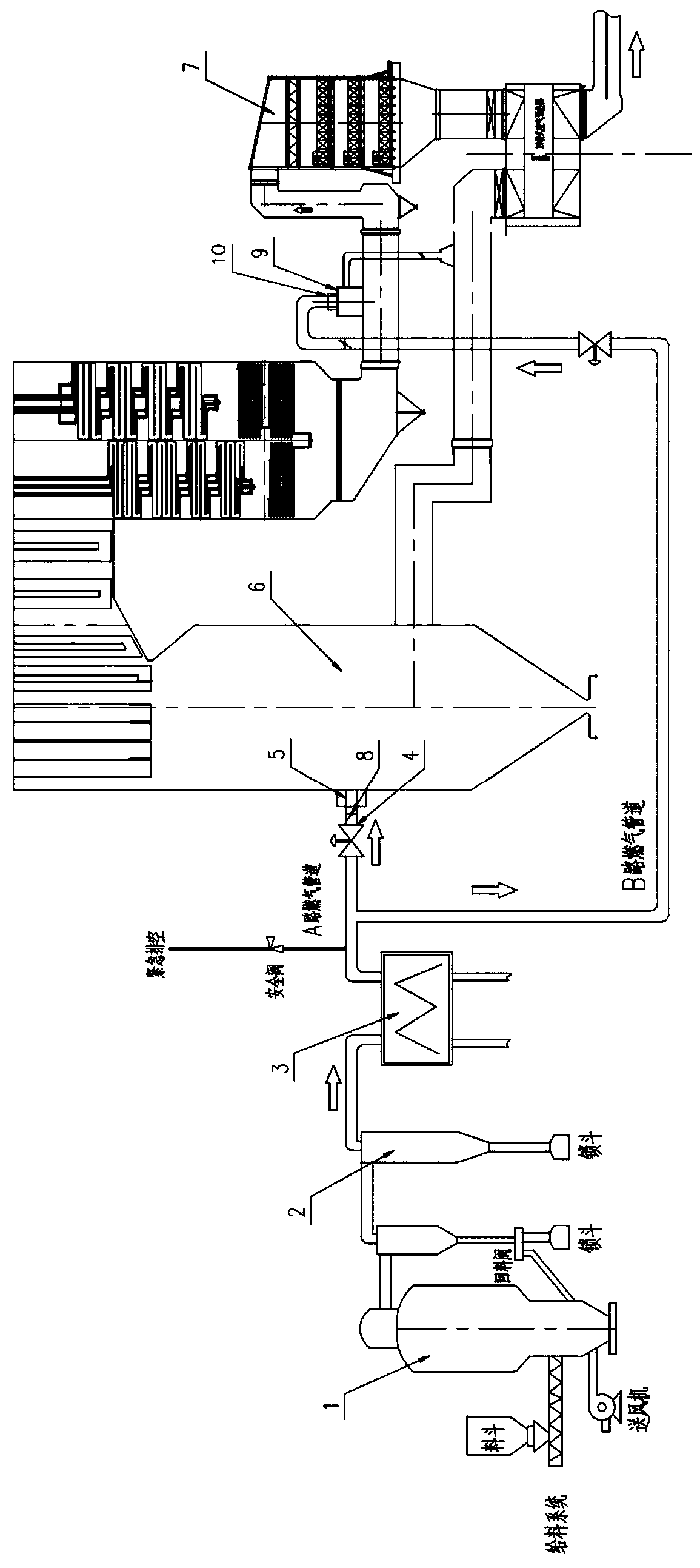

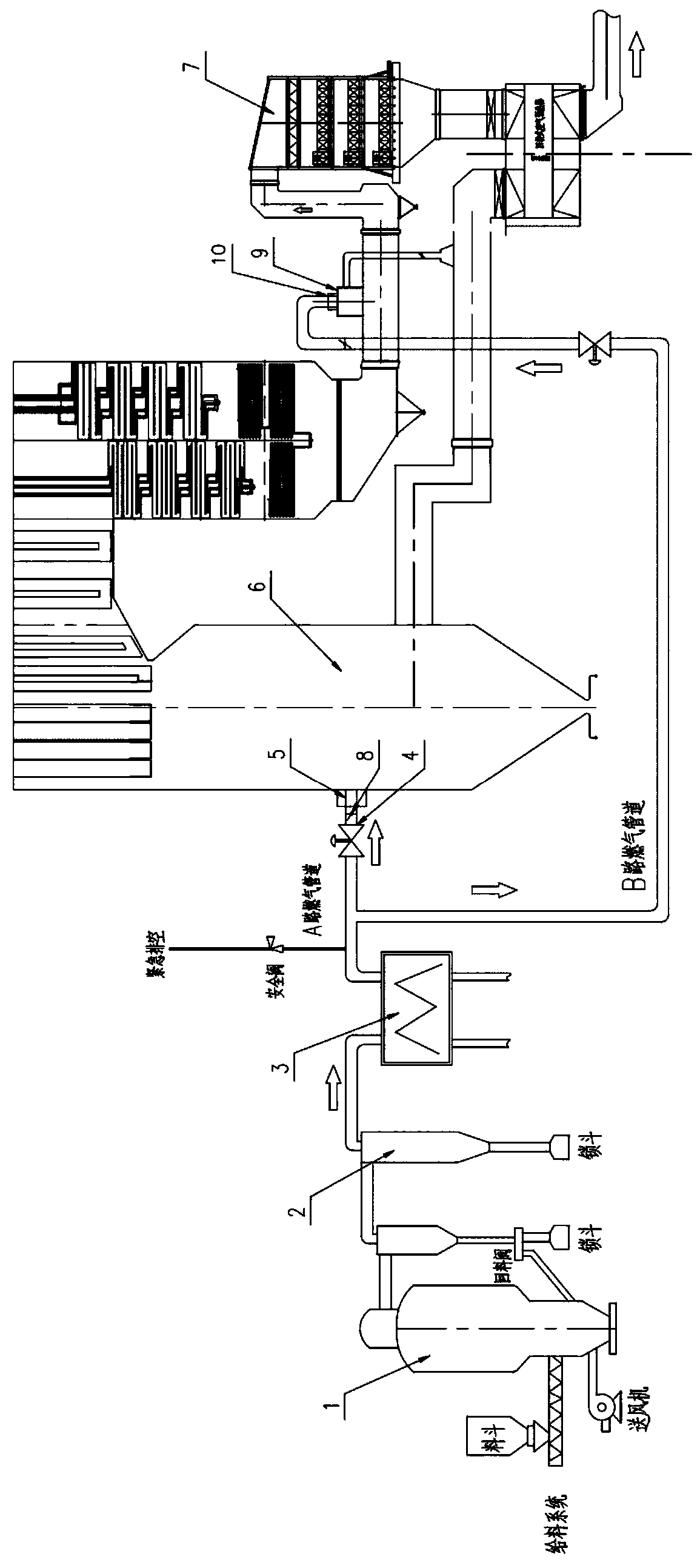

[0018] Such as figure 1 As shown, a biomass gasification coupling coal-fired unit power generation device involved in this embodiment includes a circulating fluidized bed gasifier 1, a cyclone dust collector 2, a gas heat exchanger 3, a valve 4, and a gas burner A5 , coal-fired boiler 6, SCR denitrification device 7, baffle plate 8, gas combustion chamber 9, gas burner B10, characterized in that the circulating fluidized bed gasifier 1, cyclone dust collector 2, gas heat exchanger 3 are connected sequentially through pipelines. One of the outlets of the gas heat exchanger 3 is connected to the furnace of the coal-fired boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com