Coal chemical industry wastewater and waste gas co-treatment system and method

A technology for the co-processing of wastewater from coal chemical industry, applied in the field of coal chemical industry, can solve the problems of complex process, low treatment efficiency, peculiar smell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0043] Since the coal chemical wastewater and waste gas are treated separately in the existing scheme, and each treatment scheme has many problems, it is impossible to realize zero discharge of waste water and waste gas.

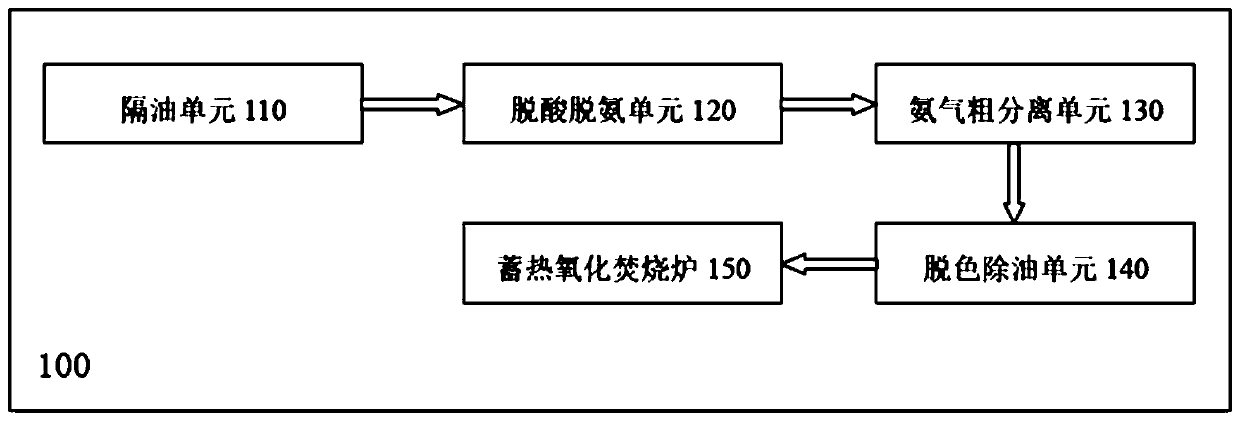

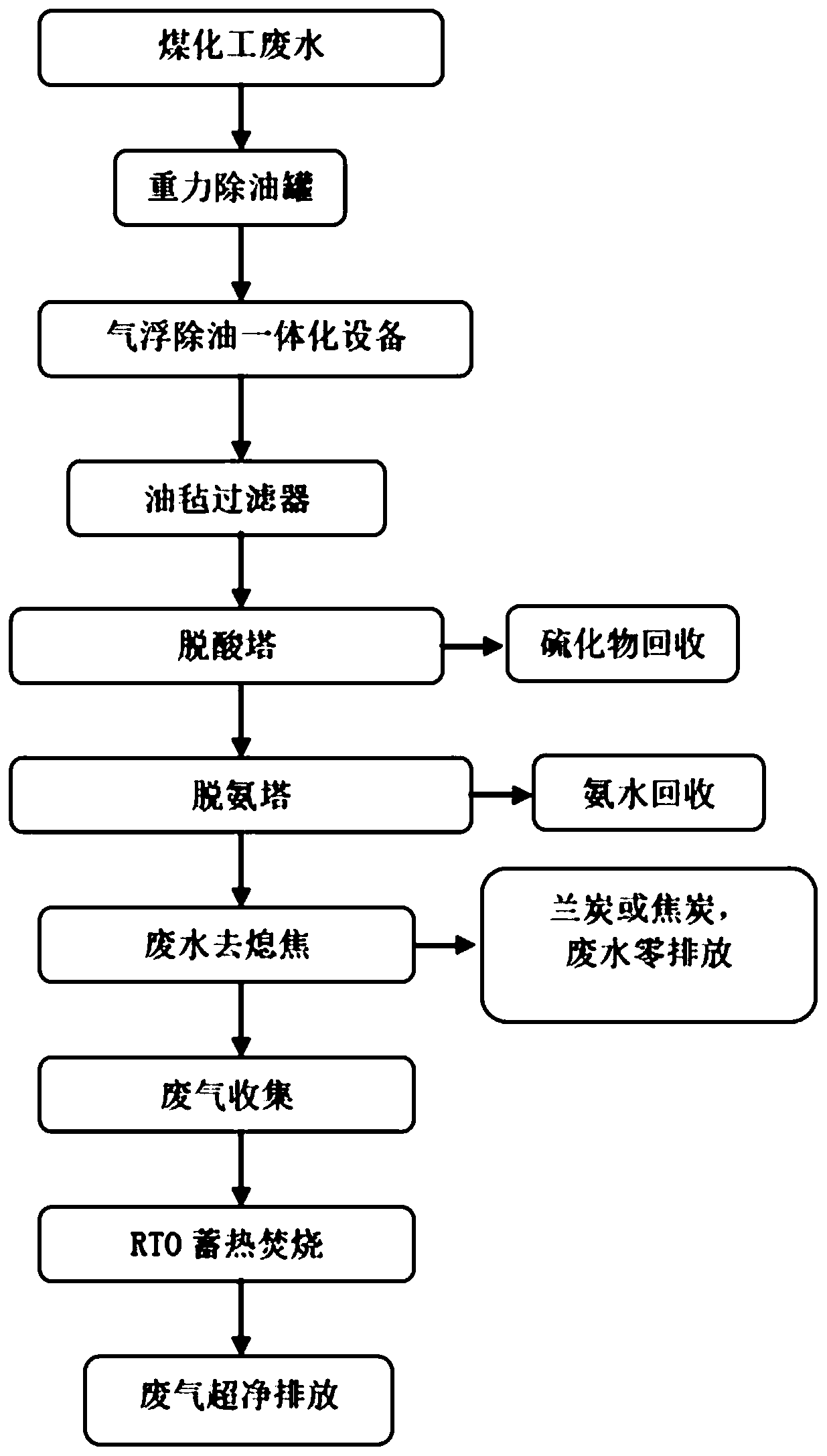

[0044] To this end, this plan through a large number of studies on the pollution status, treatment technology and compliance requirements of coal chemical wastewater and waste gas, and proposes a technology for the co-processing of coal chemical wastewater and waste gas, which preprocesses coal chemical wastewater to remove sulfide and ammonia nitrogen. After entering the high-temperature coke quenching of the production process, the waste water undergoes high-temperature treatment and volatilizes to form waste gas. The waste gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com