Semi-dry desulfurization-denitrification integrated device and method for sintering flue gas

A semi-dry desulfurization and sintering flue gas technology, applied in the field of desulfurization and denitrification, can solve problems such as difficult to handle nitrate and nitrite, hazardous waste of nitrite, environmental impact, etc., and achieve simple operation and low operating cost , little corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

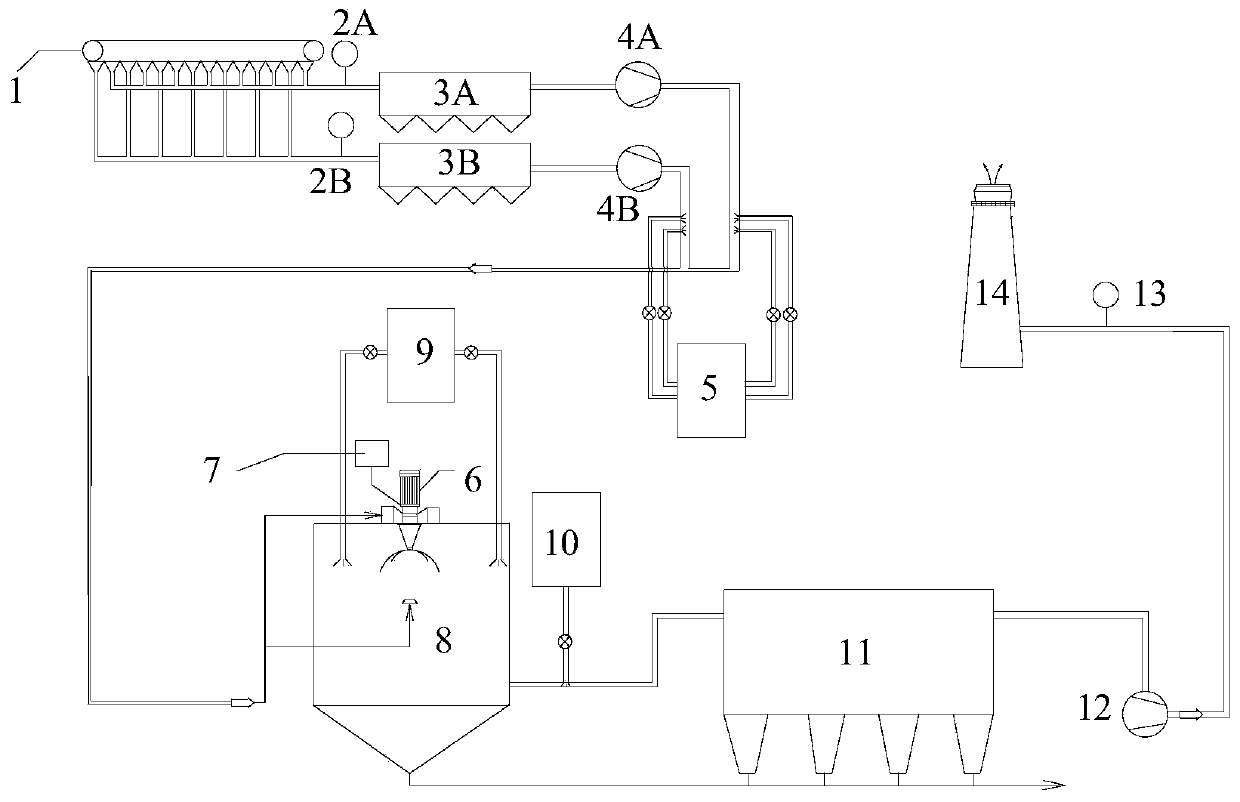

[0051] Example 1: The flue gas volume of sintering flue gas is 1.1 million Nm 3 / h. The flue gas from the sintering machine is dedusted by the electrostatic precipitator to greatly reduce the amount of dust. At this time, the flue gas is drawn into the flue by the main exhaust fan. At the same time, the denitrification oxidant component A is sprayed into the flue on the right side of the main exhaust fan through a high-pressure spray gun, and part of the NO in the flue gas is quickly oxidized by the denitrification oxidant component A into high-valence nitrogen oxides, SO 2 Oxidation to SO 3 , The approximate consumption of denitrification oxidant component A is 425-430Kg / h. Subsequently, the oxidized flue gas enters the SDA desulfurization tower, and at the same time, the slaked lime slurry is transformed into very fine droplets (less than 50 μm on average) to spray the flue gas through a rotary atomizer. At this time, the denitration and reduction absorbent components B i...

Embodiment 2

[0052] Example 2: The flue gas volume of sintering flue gas is 900,000 Nm 3 / h. The flue gas from the sintering machine is dedusted by the electrostatic precipitator to greatly reduce the amount of dust. At this time, the flue gas is drawn into the flue by the main exhaust fan. At the same time, the denitrification oxidant component A is sprayed into the flue on the right side of the main exhaust fan through a high-pressure spray gun, and part of the NO in the flue gas is quickly oxidized by the denitrification oxidant component A into high-valence nitrogen oxides, SO 2 Oxidation to SO 3 , The approximate consumption of denitrification oxidant component A is 298-305Kg / h. Subsequently, the oxidized flue gas enters the SDA desulfurization tower, and at the same time, the slaked lime slurry is transformed into very fine droplets (less than 50 μm on average) to spray the flue gas through a rotary atomizer. At this time, the denitration and reduction absorbent components B is al...

Embodiment 3

[0053] Example 3: The flue gas volume of sintering flue gas is 1 million Nm 3 / h. The flue gas from the sintering machine is dedusted by the electrostatic precipitator to greatly reduce the amount of dust. At this time, the flue gas is drawn into the flue by the main exhaust fan. At the same time, the denitrification oxidant component A is sprayed into the flue on the right side of the main exhaust fan through a high-pressure spray gun, and part of the NO in the flue gas is quickly oxidized by the denitrification oxidant component A into high-valence nitrogen oxides, SO 2 Oxidation to SO 3 , the approximate consumption of denitrification oxidant component A is 346.5-355Kg / h. Subsequently, the oxidized flue gas enters the SDA desulfurization tower, and at the same time, the slaked lime slurry is transformed into very fine droplets (less than 50 μm on average) to spray the flue gas through a rotary atomizer. At this time, the denitration and reduction absorbent components B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com