Flame-free torch type ultra-clean discharge process for high-ammonia-nitrogen wastewater containing VOCs

A high-ammonia-nitrogen, waste water technology, applied in the direction of water pollutants, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high process energy consumption, high cost of waste water treatment, and insufficient utilization efficiency of VOCs resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

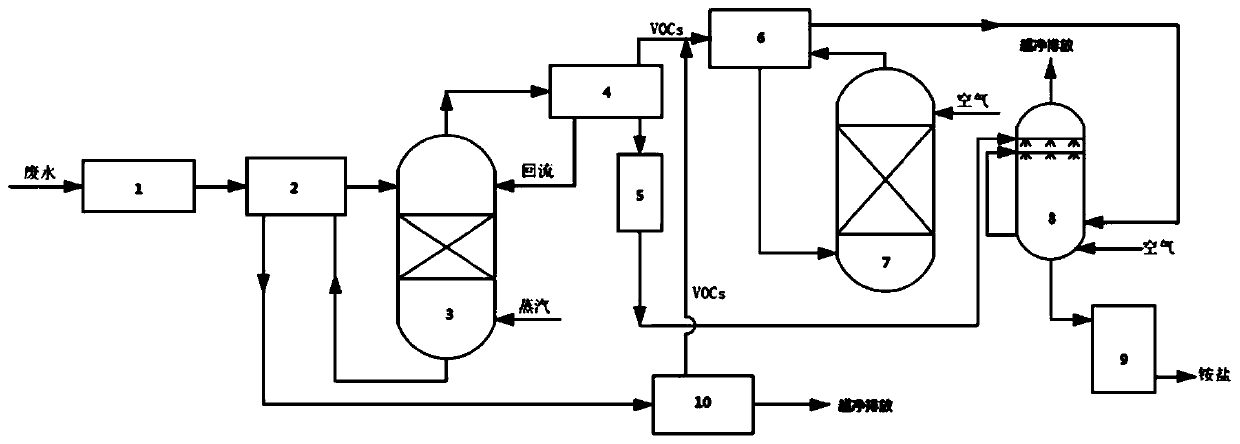

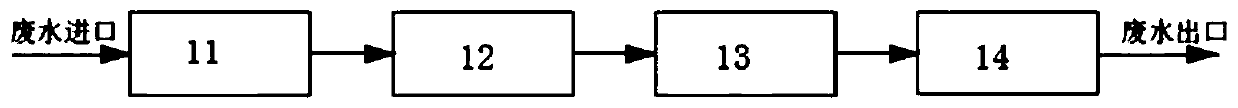

[0039] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention. See figure 1 , a flameless torch type ultra-clean discharge system for high ammonia nitrogen containing VOCs waste water, mainly including a pretreatment unit 1, a stripping unit, a flameless torch unit, an evaporation crystallization unit and a postprocessing unit 10; the pretreatment unit 1, steam The extraction unit, the flameless torch unit, and the evaporation crystallization unit are connected in sequence, and the post-treatment unit 10 is connected to the stripping unit pipeline; the pre-treatment unit 1 is used to pre-treat VOCs-containing high-ammonia-nitrogen wastewater to reduce the Heavy metal ions, suspended solids, chroma, hardness and COD; the stripping unit is used for the recovery of ammonia nitrogen and the separation of VOCs; the flameless torch unit is used for ultra-clean decomposition and oxidation of VOCs; the...

Embodiment 2

[0045] The leachate treatment capacity of a waste incineration plant is 150m 3 / d, its water quality index organic acid is 10000~20000mg / L, COD cr 20000~40000mg / L, BOD 5 10000~20000mg / L, NH 3 -N is 5000-8000mg / L, suspended matter SS is 3000-8000mg / L, total hardness is 3000-5000mg / L, and pH is 6-8. Among them, the concentration of various heavy metal ions is 20-50 mg / L for Fe, 3-5 mg / L for Zn, 3-5 mg / L for Cr, and 2-3 mg / L for Mn.

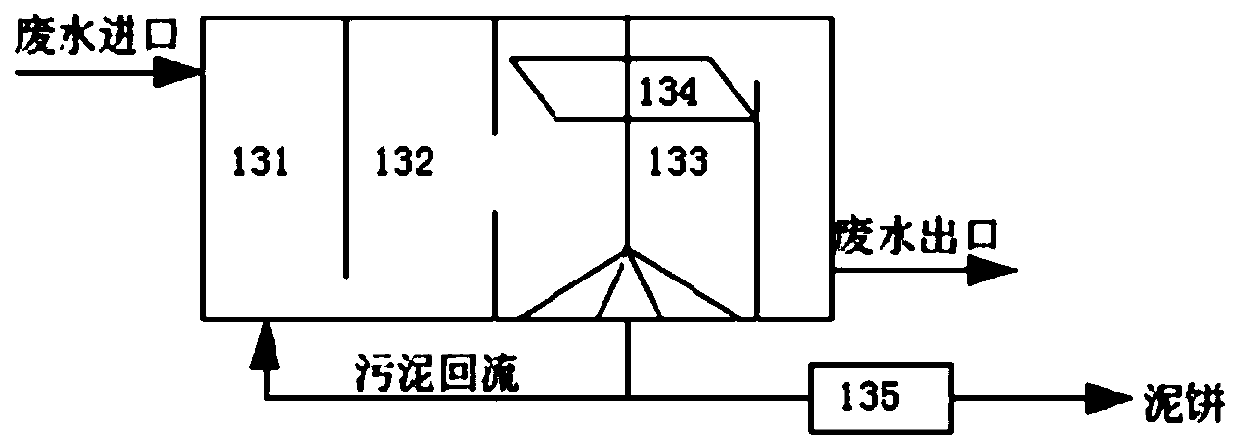

[0046] The temperature of the feed wastewater is 5-35°C, and the wastewater first enters the regulating pool 11 in the pretreatment unit 1 for homogenization to reduce the impact of water quality fluctuations; then enters the dosing pool 12, where NaOH and NaOH are added 2 CO 3 solution, the dosing tank 12 is provided with a stirrer; the waste water enters the high-density clarification tank 13 from the dosing tank 12, and adds polyferric chloride and polyacrylamide into the coagulation tank 131 and the flocculation tank 132 respectively and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com