Intelligent tail gas photo-oxygen pyrolysis treatment device by adopting oil-gas purification technology

A cracking treatment, oil and gas technology, applied in the direction of gas treatment, membrane technology, combined devices, etc., can solve the problems of secondary pollution of pollutants, energy waste, low level of intelligent control, etc., to avoid leakage, energy-saving and efficient treatment, Guarantee the effect of zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

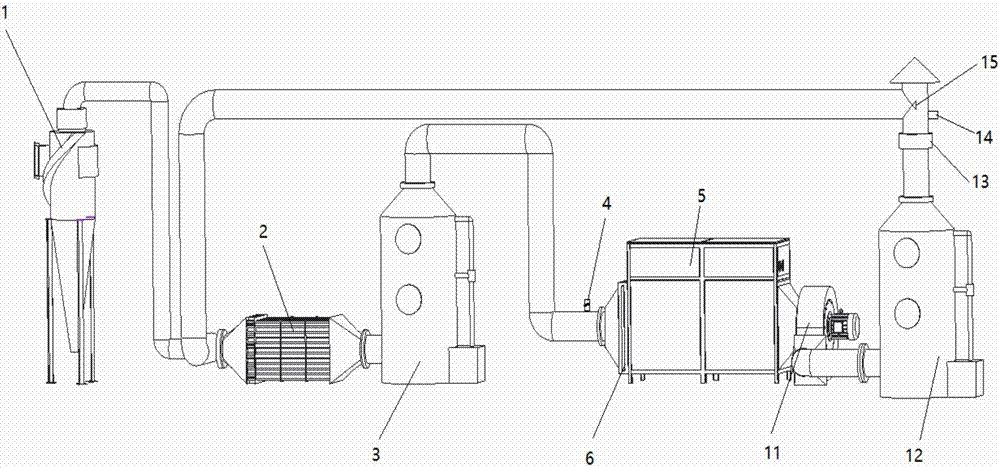

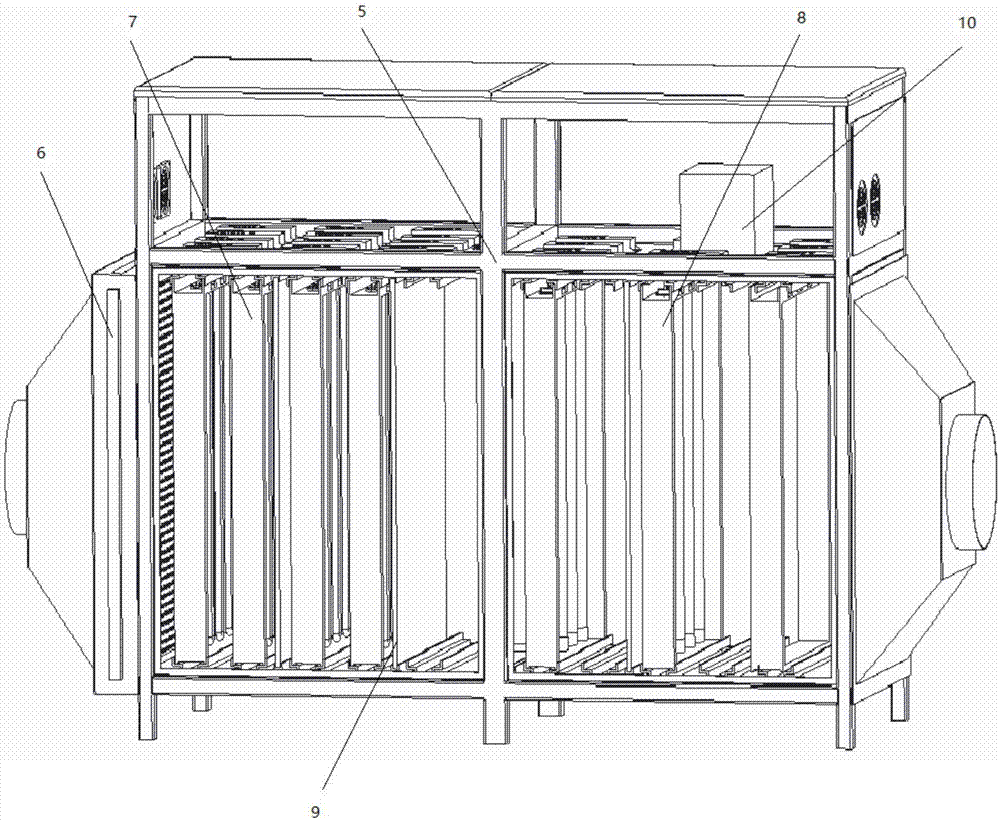

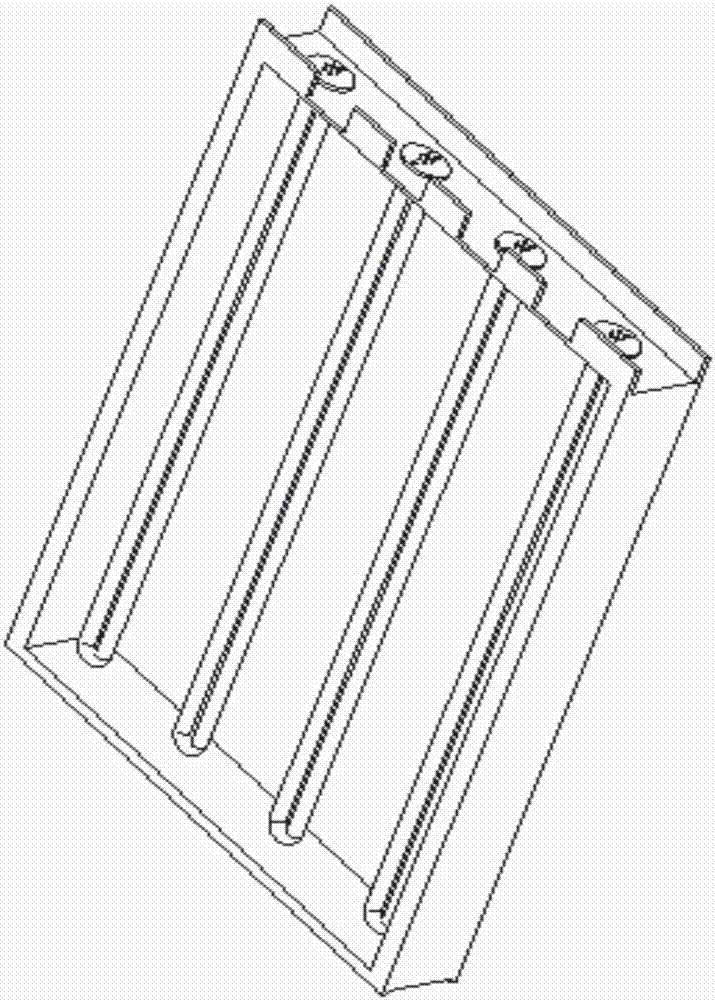

[0023] Such as figure 1 , 2 , 3 and 4, an intelligent tail gas photo-oxygen cracking treatment device using oil and gas purification technology, including cyclone demisting and dust reduction cooler 1, oil and gas purification electric field equipment 2, front-end spray tower 3, exhaust gas concentration detection sensor 4, light Oxygen cracking cabinet 5, dust-proof wet filter 6, high-energy ultraviolet lamp group module 7, ozone supply module 8, TiO2 Catalytic network 9, single-chip microcomputer control system in intelligent control cabinet 10, negative pressure induced draft fan 11, dry flue gas comprehensive treatment tank 12, ozone filter screen 13; air inlet and exhaust port of cyclone demist and dust reduction cooler 1 It is respectively connected to the exhaust port of the factory and the oil and gas purification electric field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com