Method for treating electrogalvanizing wastewater

A treatment method and electro-galvanizing technology, applied in water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. Large proportion, strong degreasing and dirt-carrying capacity, and investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

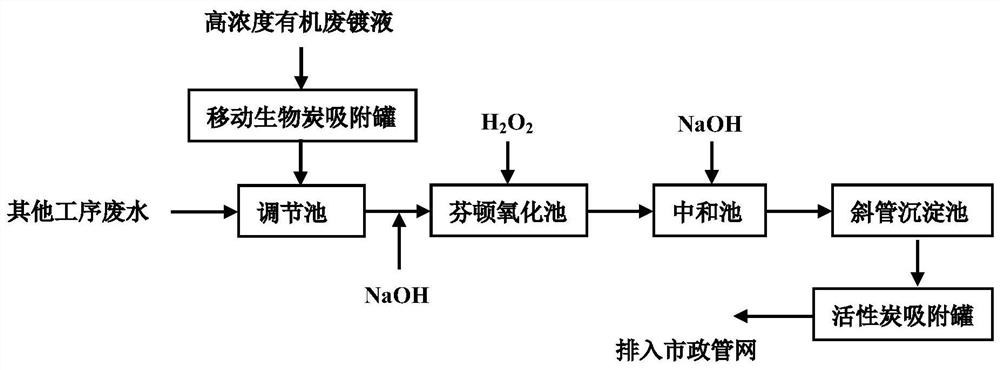

[0043] A treatment method for electro-galvanized wastewater, comprising the following steps:

[0044] Step 1, introduce the high-concentration organic waste plating solution into the mobile biochar adsorption tank, the filter material height is 1.5m, and the filtration rate is 6m / h. The biochar filter material is prepared by the following method: (1) take a certain amount of walnut shells and wash them, Dry at 105°C, crush and sieve, and take 6-12 mesh walnut shell particles; (2) Fully mix the prepared walnut shell particles, urea, and potassium bicarbonate according to the mass ratio of 4:2:1, and then insulate at 635°C Pyrolysis under the condition of oxygen for 3.0h; (3) After cooling the above materials, ultrasonically immerse them in 0.2mol / L hydrochloric acid solution for 1.5h, the ultrasonic frequency is 50kHz, the ultrasonic power is 100W, and then rinse with distilled water several times until neutral, After drying at 105°C, the biochar filter material was obtained. ...

Embodiment 2

[0053] Step 1, introduce the high-concentration organic waste plating solution into the mobile biochar adsorption tank, the filter material height is 1.5m, and the filtration rate is 6m / h. The biochar filter material is prepared by the following method: (1) take a certain amount of walnut shells and wash them, Dry at 105°C, crush and sieve, and take 6-12 mesh walnut shell particles; (2) Fully mix the prepared walnut shell particles, urea, and potassium bicarbonate according to the mass ratio of 4:2:1, and then insulate at 635°C Pyrolysis under the condition of oxygen for 3.0h; (3) After cooling the above materials, ultrasonically immerse them in 0.2mol / L hydrochloric acid solution for 1.5h, the ultrasonic frequency is 50kHz, the ultrasonic power is 100W, and then rinse with distilled water several times until neutral, After drying at 105°C, the biochar filter material was obtained. This step can adsorb and remove some high-concentration organic pollutants, and reduce the conce...

Embodiment 3

[0062] Step 1, introduce the high-concentration organic waste plating solution into the mobile biochar adsorption tank, the filter material height is 1.5m, and the filtration rate is 6m / h. The biochar filter material is prepared by the following method: (1) take a certain amount of walnut shells and wash them, Dry at 105°C, crush and sieve, and take 6-12 mesh walnut shell particles; (2) Fully mix the prepared walnut shell particles, urea, and potassium bicarbonate according to the mass ratio of 4:2:1, and then insulate at 635°C Pyrolysis under the condition of oxygen for 3.0h; (3) After cooling the above materials, ultrasonically immerse them in 0.2mol / L hydrochloric acid solution for 1.5h, the ultrasonic frequency is 50kHz, the ultrasonic power is 100W, and then rinse with distilled water several times until neutral, After drying at 105°C, the biochar filter material was obtained. This step can adsorb and remove some high-concentration organic pollutants, and reduce the conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com