Patents

Literature

33results about How to "Energy saving treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

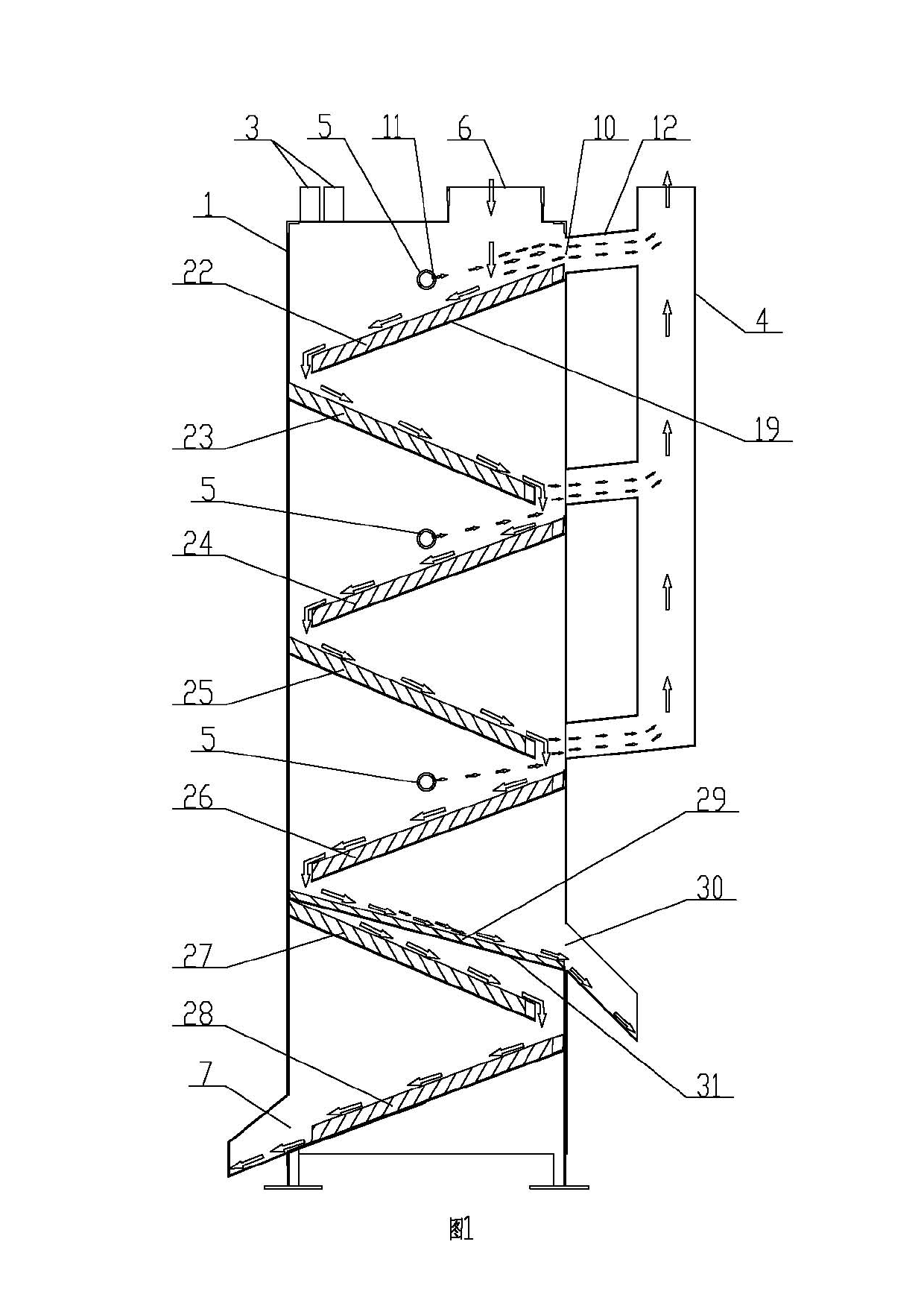

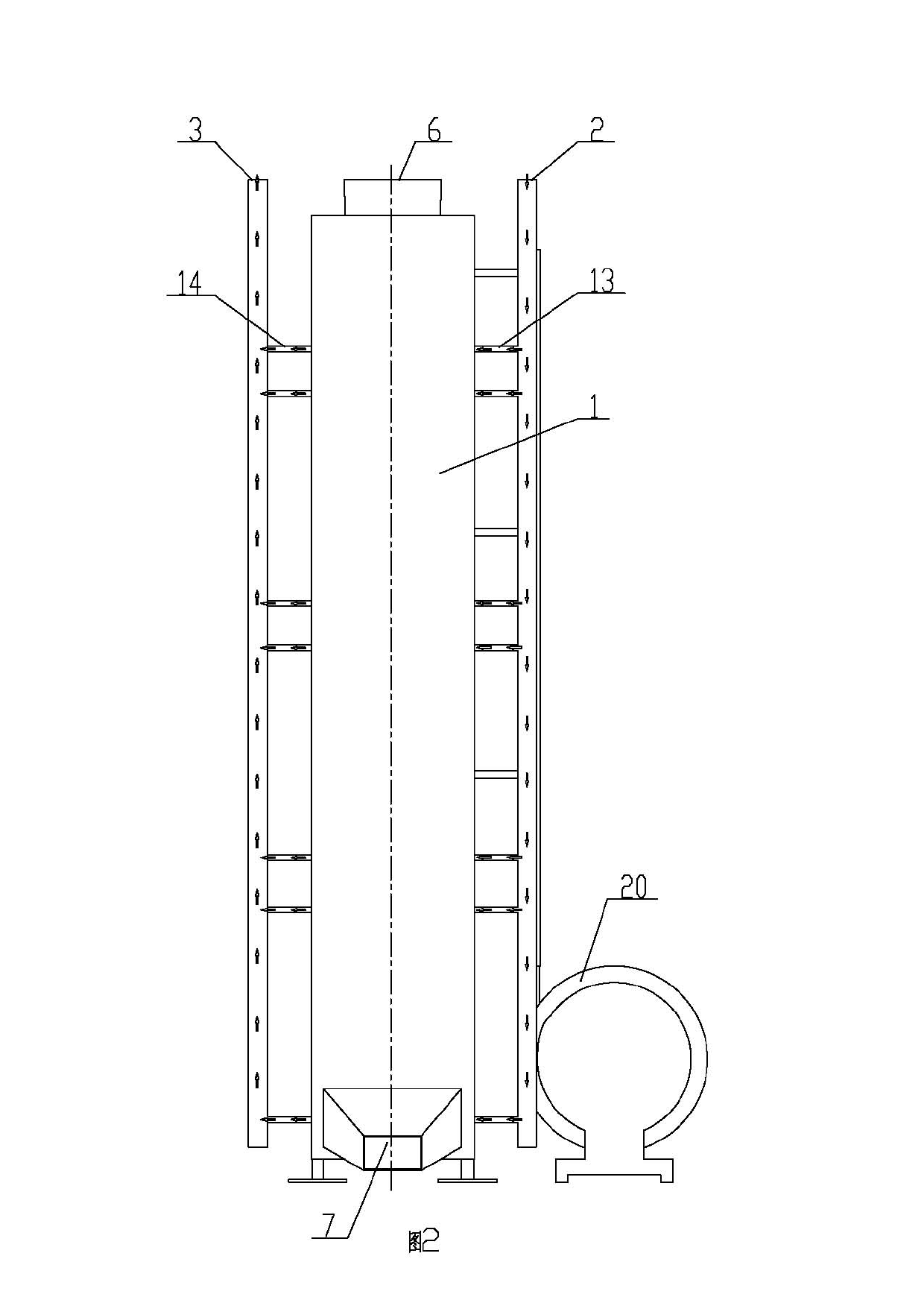

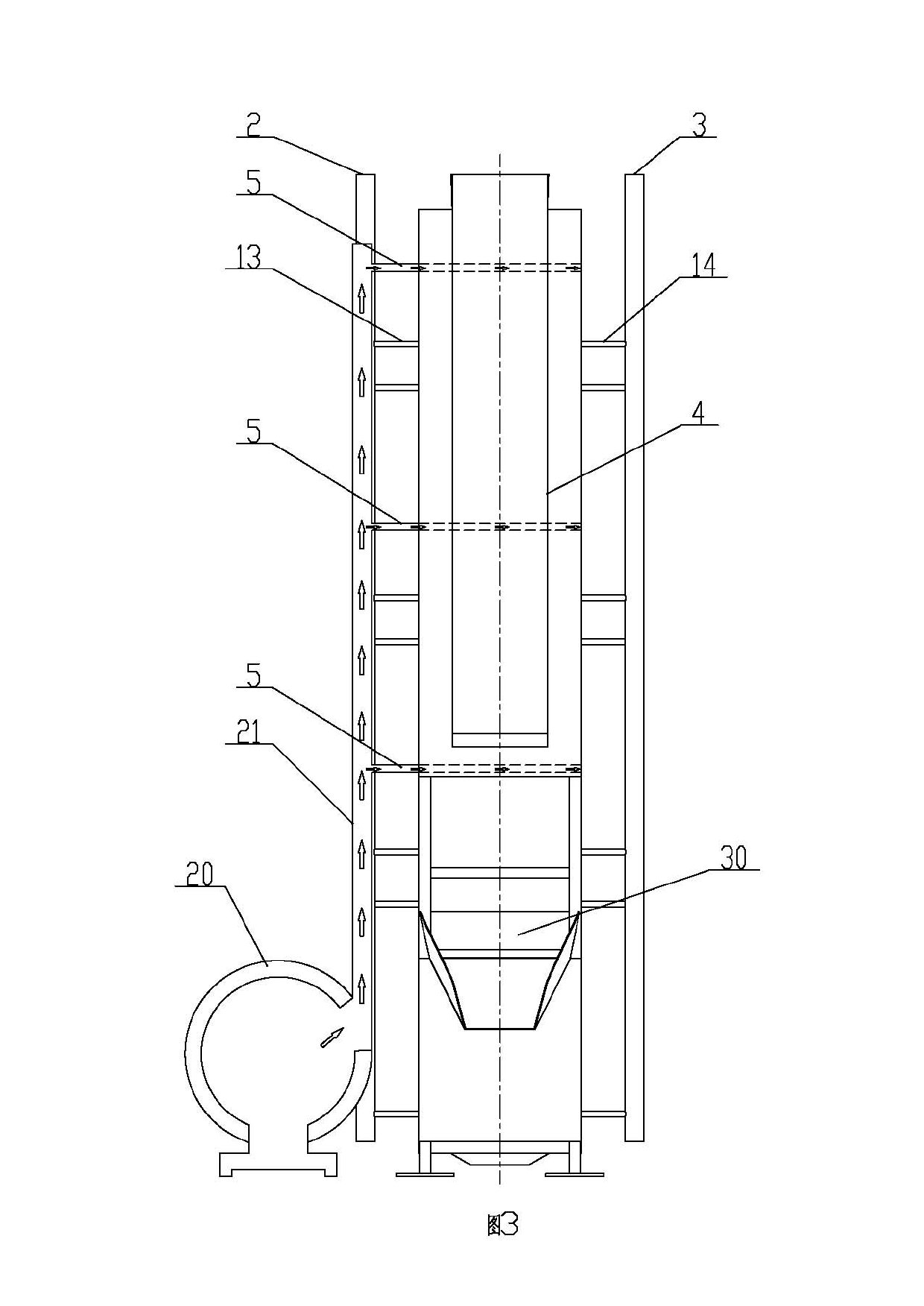

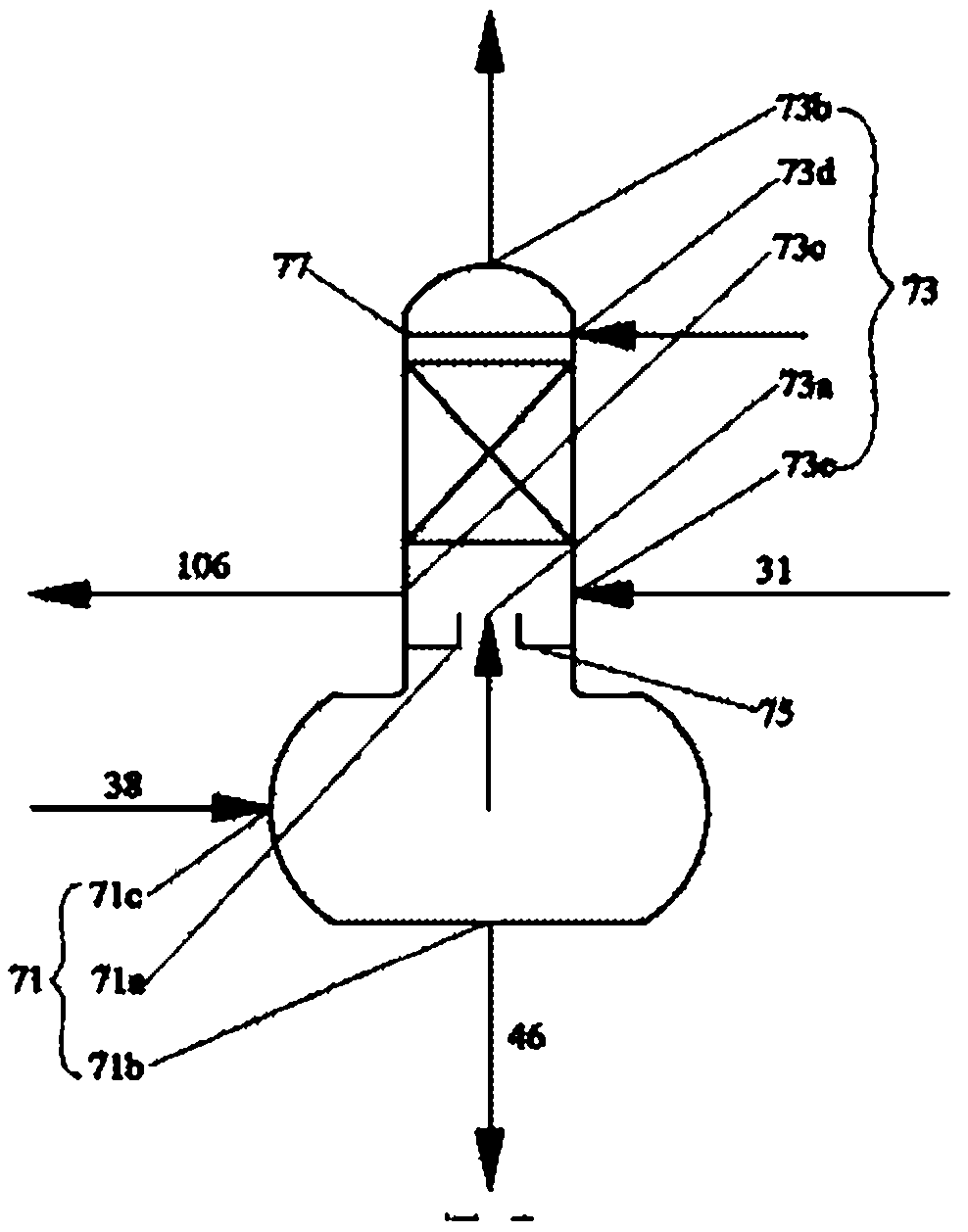

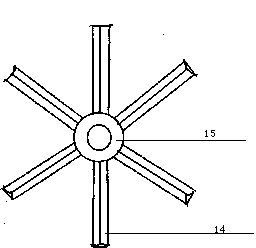

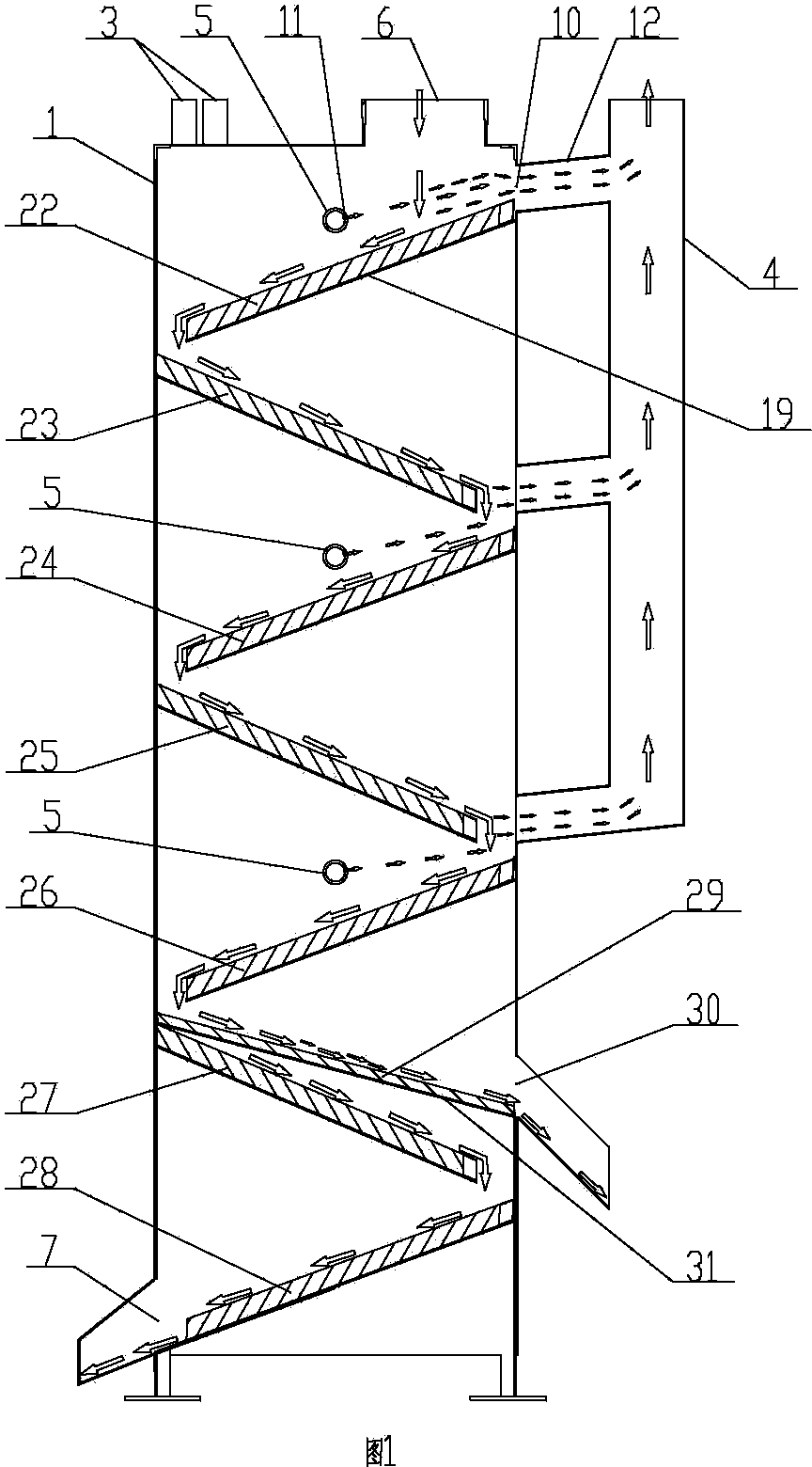

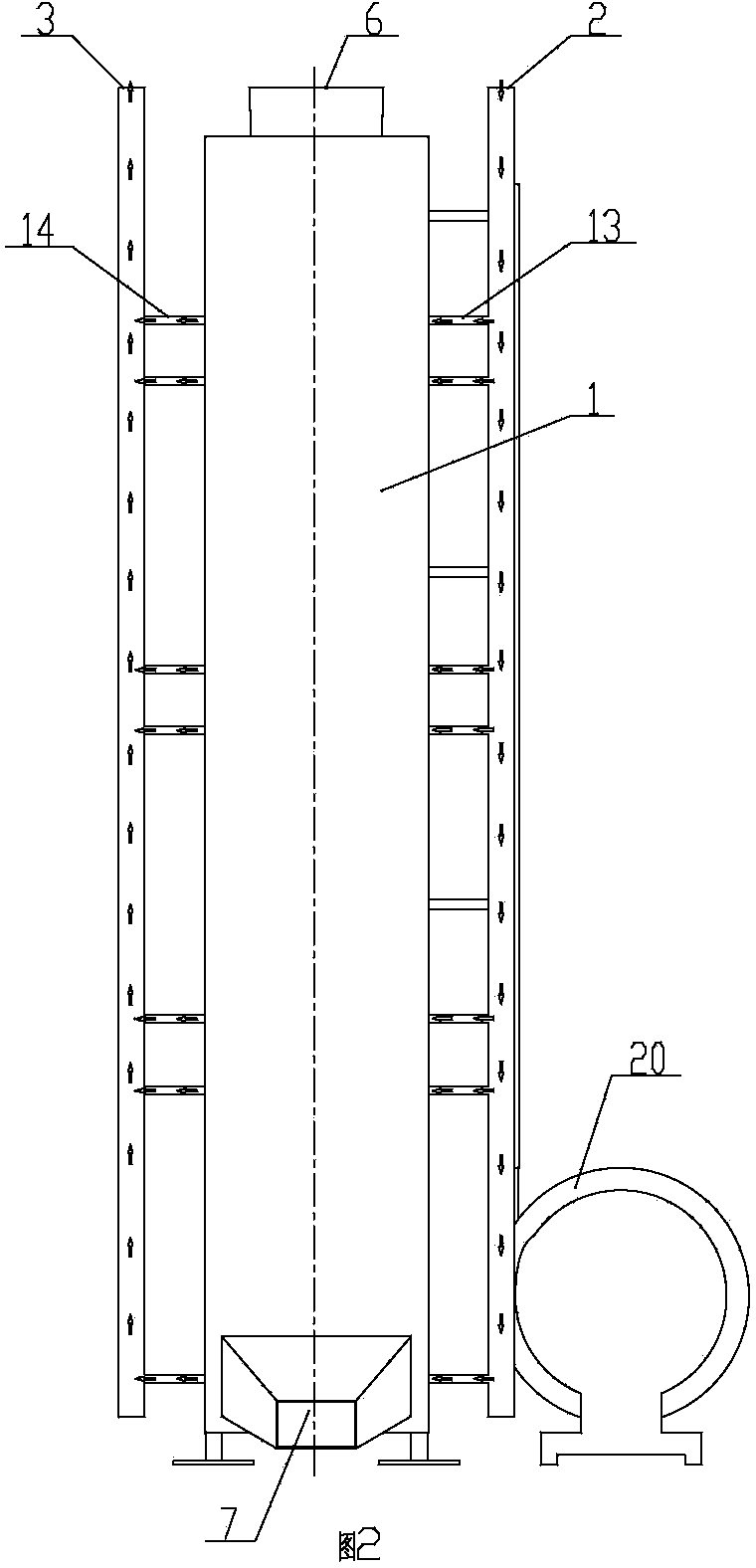

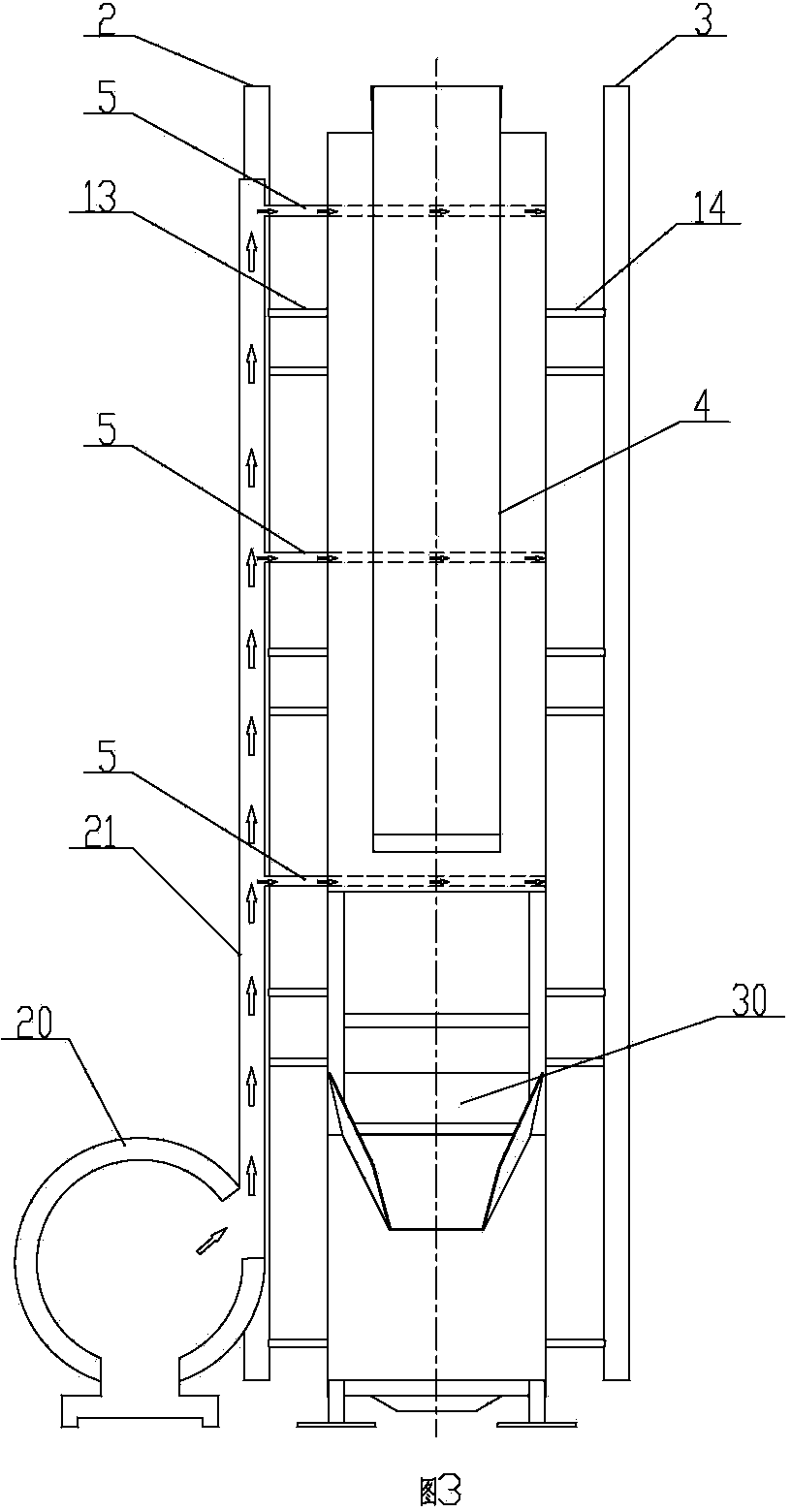

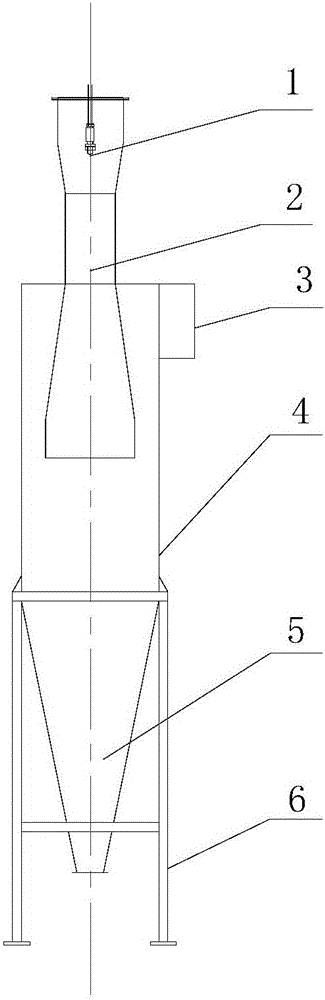

Moulding sand cooling dedusting tower as well as casting moulding sand processing device and method

ActiveCN102430708AReasonable structurePremium treatmentMould handling/dressing devicesEngineeringMolding sand

The invention relates to the technology field of processing and recycling of casting moulding sand and in particular relates to a moulding sand cooling dedusting tower as well as a casting moulding sand processing device and a using method thereof. The moulding sand cooling dedusting tower comprises a vertical box body, a cooling box, a water inlet pipe, a water outlet pipe, a dedusting pipe and an air pipe, wherein a sand inlet is arranged at the upper end of the vertical box body; the cooling box of which the upper surface is an oblique surface is fixed in the inner cavity of the vertical box body; the upper end of the cooling box is a moulding sand flow-in end and communicated with the sand inlet; the lower end of the cooling box is a moulding sand flow-out end; and a sand outlet is arranged at the exterior of the vertical box body at the lower end of the corresponding cooling box and communicated with the moulding sand flow-out end. The device provided by the invention has a reasonable and compact structure, relatively large plastic and iron particles are separated through a filtering block net, small iron impurities are separated by a magnetic separation conveyor, and fine screening and cooling dedusting of the moulding sand are realized through the moulding sand cooling dedusting tower, therefore, the moulding sand cooling dedusting tower can be used for processing the casting moulding sand in an energy-saving, efficient and high-quality mode, has high working efficiency, is economical and environmentally-friendly, and can be used for reducing the labor intensity, the potential safety hazard and the labor cost.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

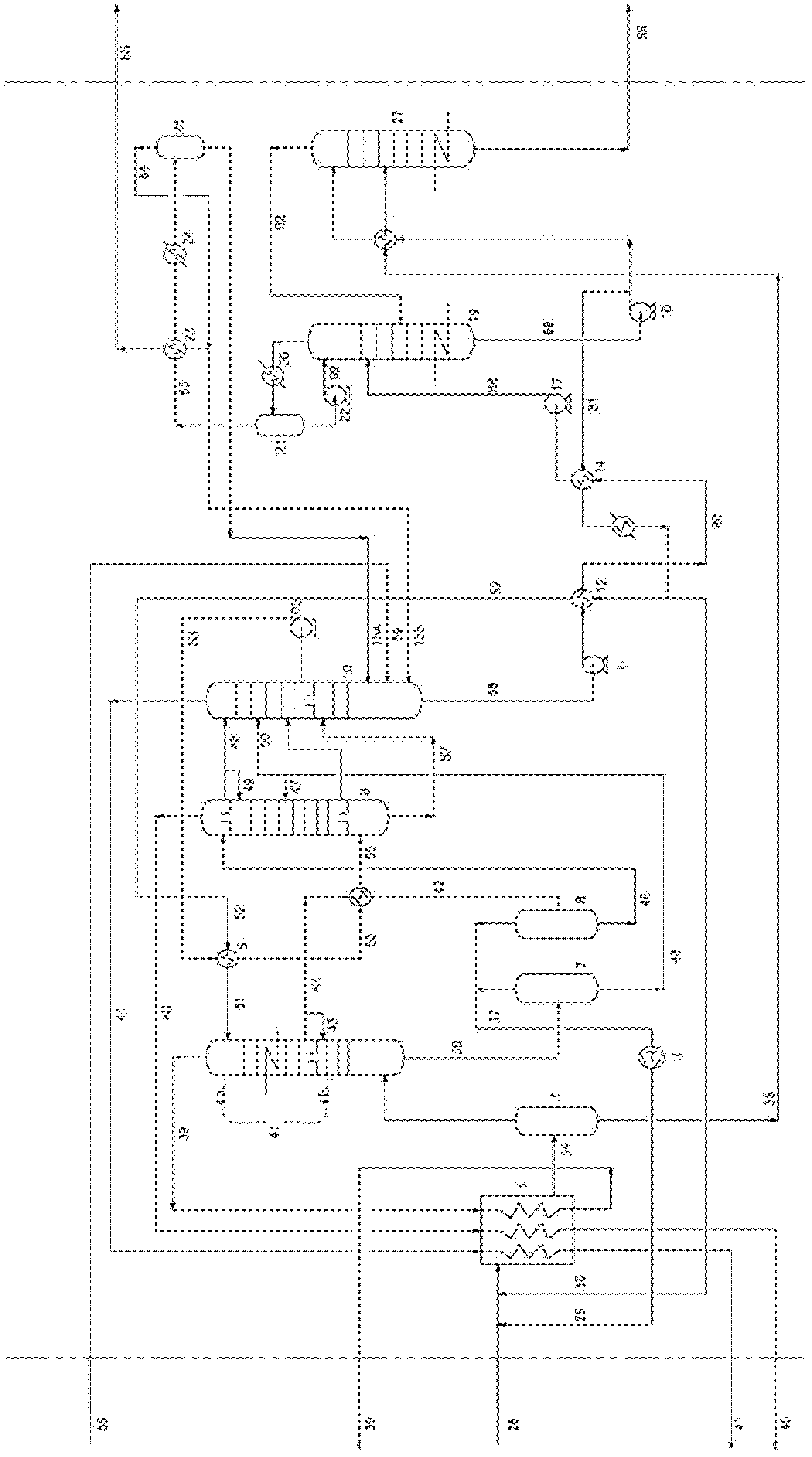

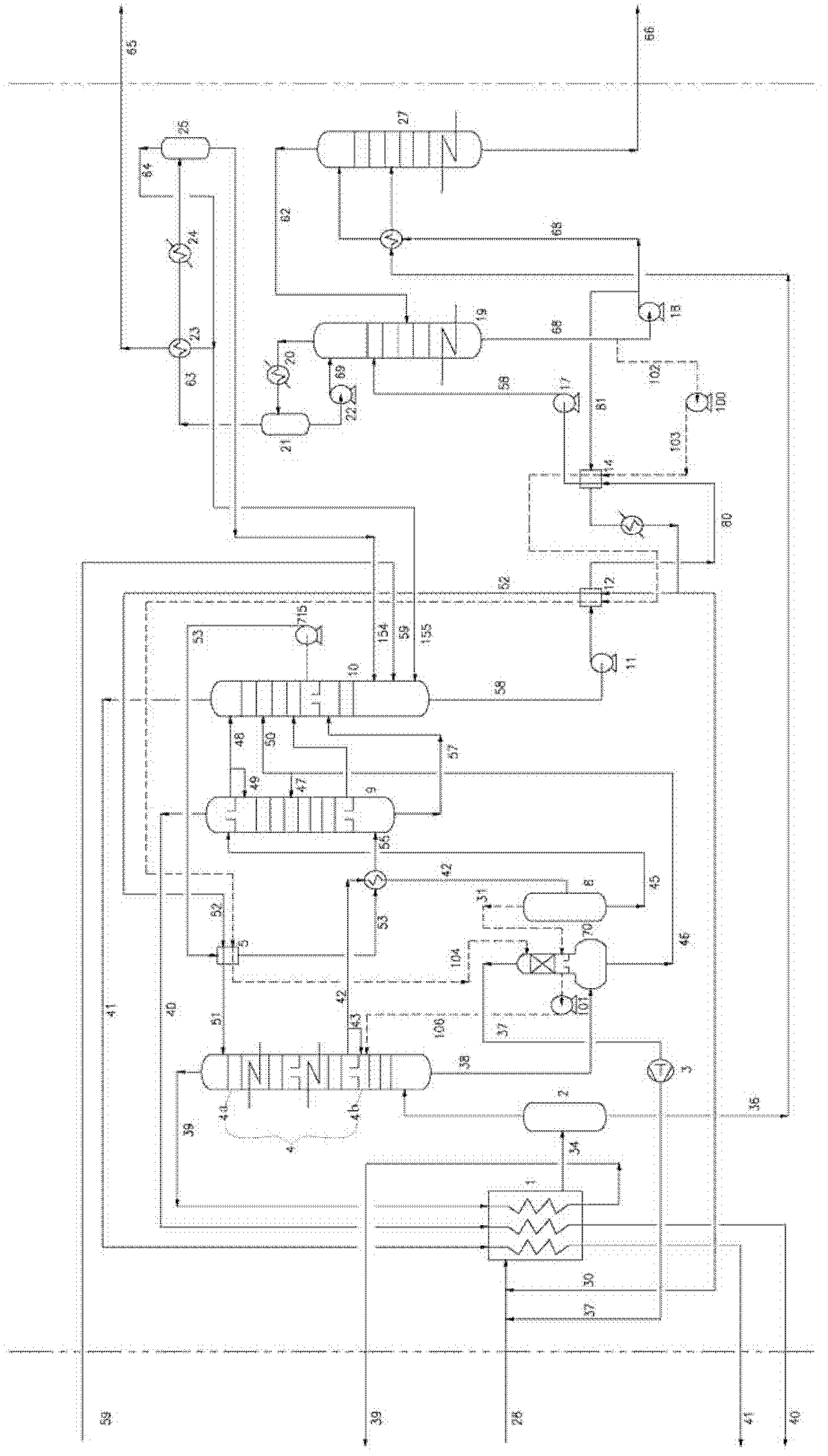

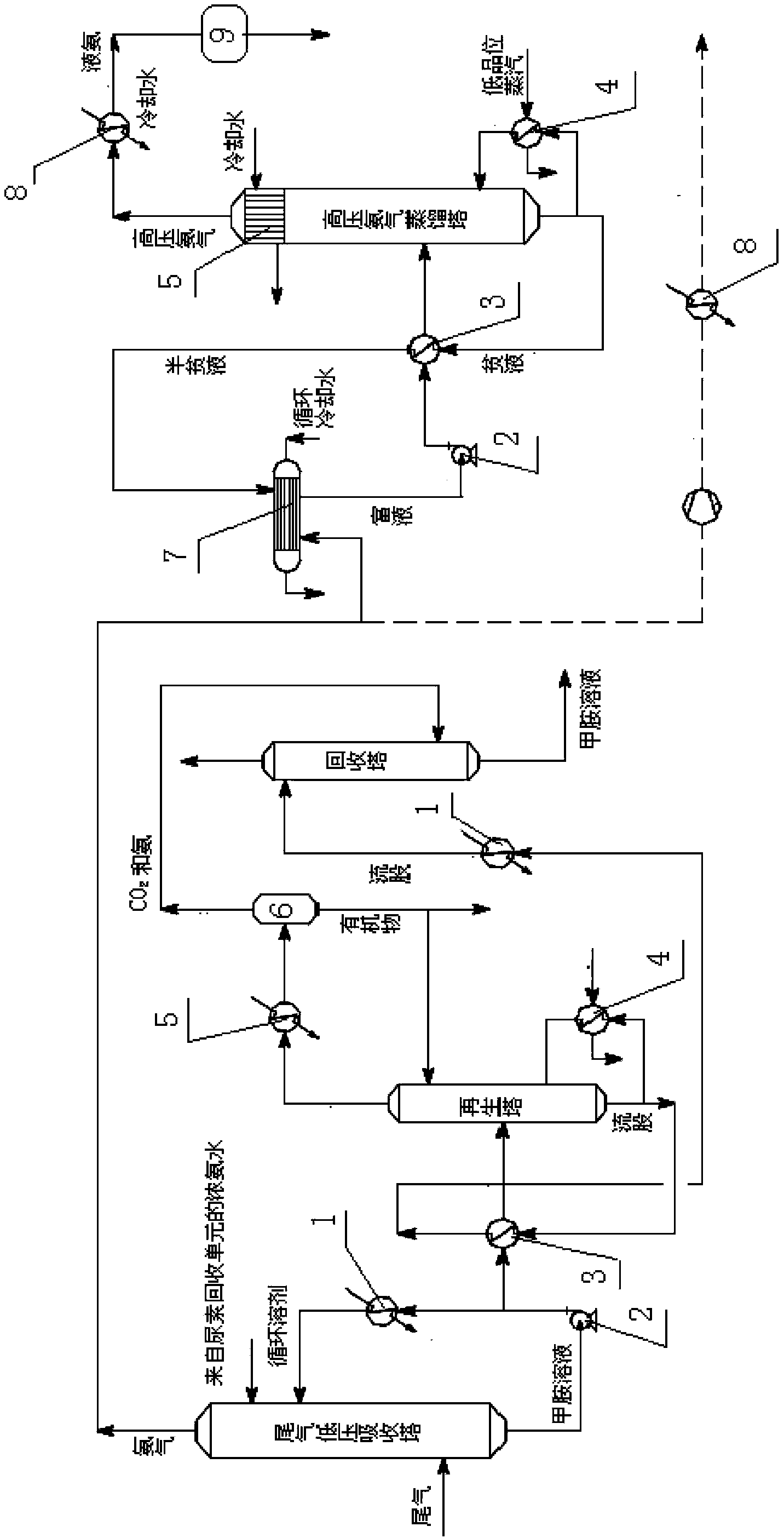

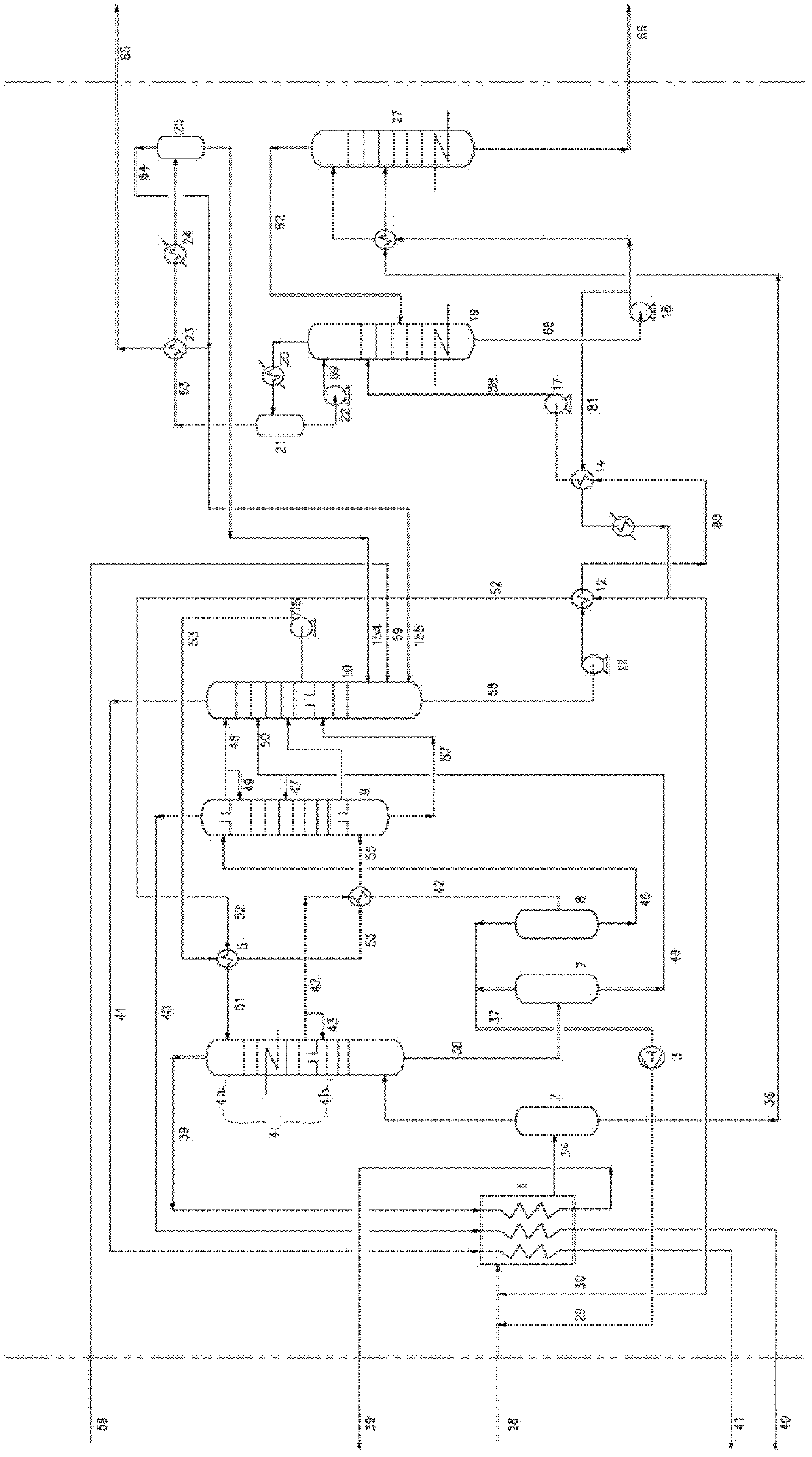

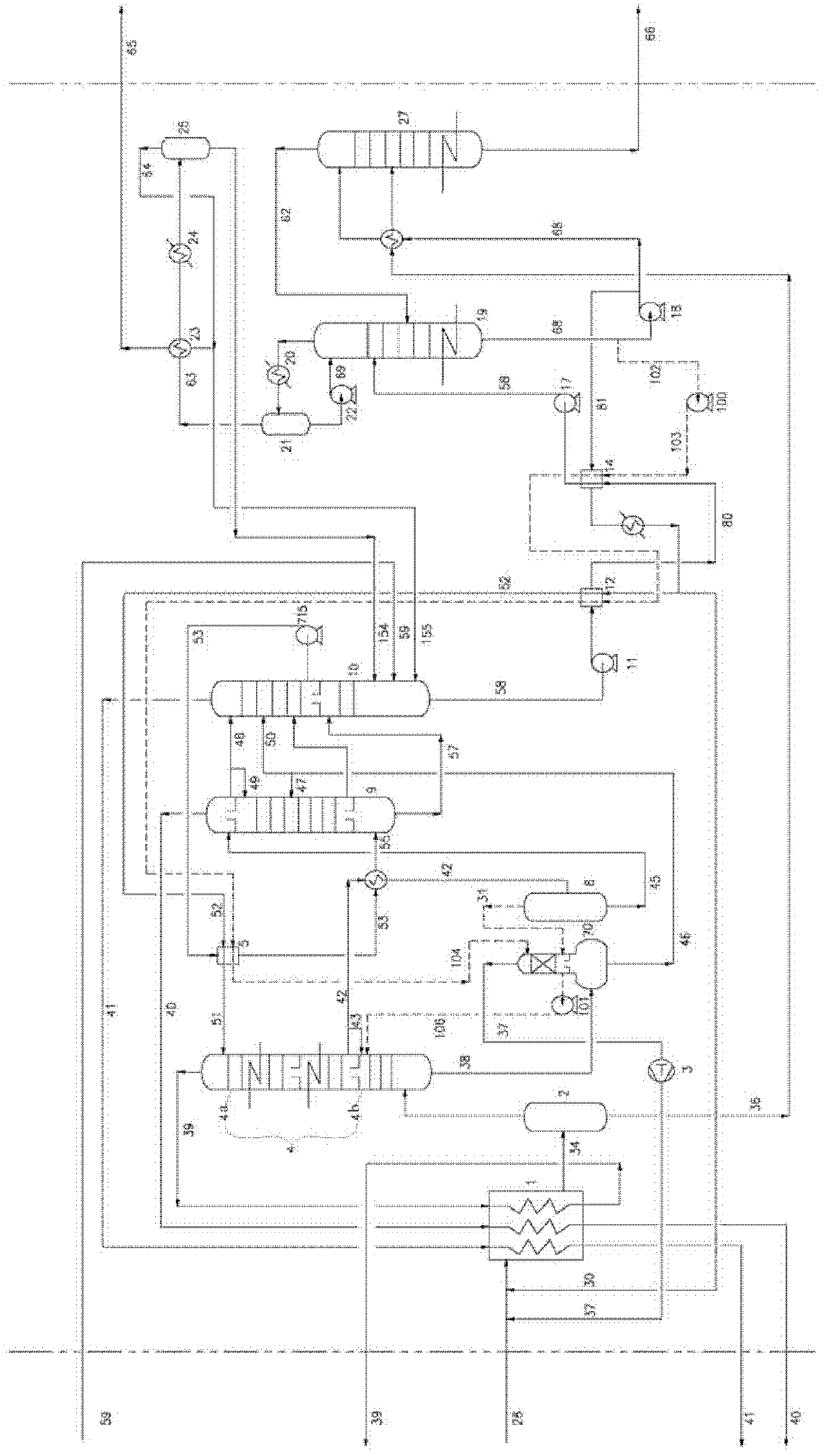

Low temperature methanol wash method and equipment

ActiveCN102489120AHigh recovery rateEasy to handleDispersed particle separationCombustible gas purificationSulfurDesorption

The invention discloses a low temperature methanol wash method and equipment, wherein the method comprises an absorption step, a desorption step and a methanol heat regeneration step. The absorption step further comprises: adopting first lean methanol solution to absorb virgin gas for the first time, and cooling to form first rich methanol solution; forming first gas and first liquid after gas-liquid separation; adopting second lean methanol solution to absorb the first gas for a second time, and forming second absorbed rich methanol solution after the second lean methanol solution is absorbed for a second time; carrying out flash distillation on the second absorbed rich methanol solution to form second gas and flash distillated rich methanol solution; and adopting third lean methanol solution to absorb the second gas for a third time, forming third gas and reflux rich methanol solution, and respectively recycling the third gas and the reflux rich methanol solution. The method can be high-efficient, flexible, safely and energy-saving to treat carbonyl gas with different pressures, temperatures, moisture contents and sulphur concentrations.

Owner:HUANENG CLEAN ENERGY RES INST

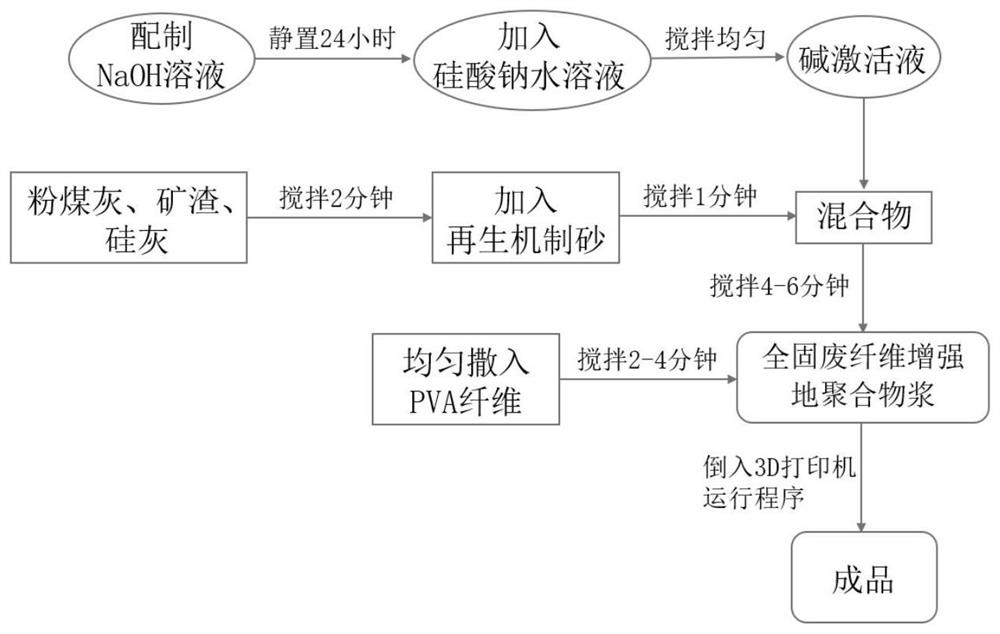

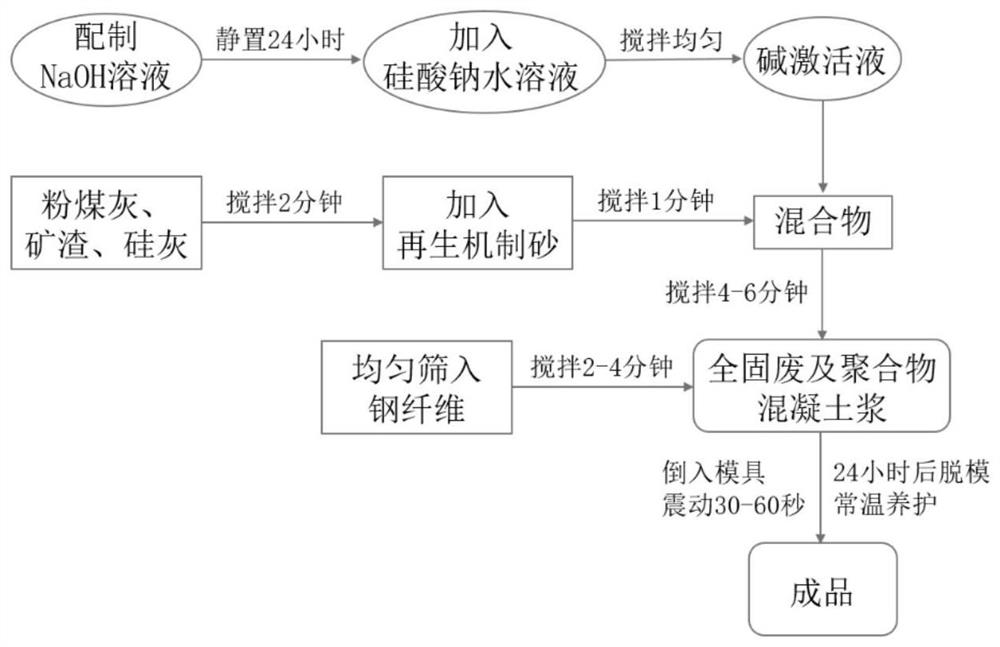

All-solid waste fiber reinforced geopolymer composite material suitable for 3D printing technology

ActiveCN113754359AImprove sustainabilityEasy to handleAdditive manufacturing apparatusCement productionIndustrial constructionAggregate (composite)

The invention relates to the technical field of solid waste resource utilization and geopolymer concrete preparation, in particular to an all-solid waste fiber reinforced geopolymer composite material suitable for a 3D printing technology. The all-solid waste fiber reinforced geopolymer composite material comprises the following raw materials in parts by mass: 20-30 parts of aggregate, 70-80 parts of a cementing material, carbon nanotubes, PVA fibers and an alkali activator, wherein the cementing material comprises the following components in percentage by mass: 15-30% of fly ash, 55-65% of slag and 10-25% of silica fume; and the aggregate is regenerated machine-made sand. The all-solid-waste ultra-high-performance geopolymer concrete provided by the invention can reach initial setting within 10-25 minutes after being discharged, and meets the 3D printing requirement. Besides, the fly ash, the slag and the regenerated machine-made sand are all derived from industrial building solid wastes, so that the waste of the solid wastes can be effectively reduced, the sustainability of the building is improved, and an efficient, environment-friendly and energy-saving solution is provided for treatment after the building is demolished.

Owner:无锡初如企业管理合伙企业(有限合伙)

Alkaline chloride galvanizing additive and preparation method thereof

The invention discloses an alkaline chloride zinking primer, wherein the primer comprises following components based on mass percent: 9.6% to 14.5% sodium hydroxide, 5.0% to 7.0% potassium chloride, 0.6% to 0.9% zinc oxide, 0.35% to 0.45% DPE-3 adjuvant, 0.35% to 0.45% ZB-80 lustre-coating agent and 76% to 84% water. The preparation method of the alkaline chloride zinking primer is provided. The invention has advantages that the plating layer has high combination ratio, high depositing speed, bright and fined plated products without brittleness, coarse skin and color change when baking temperature is at 250 deg. C, great anti-impurity capacity, without fogging and bubbling phenomena. The salt spray test uses 150 hours to 200 hours with low cost. The invention saves energy and is easy to processes waste.

Owner:唐军

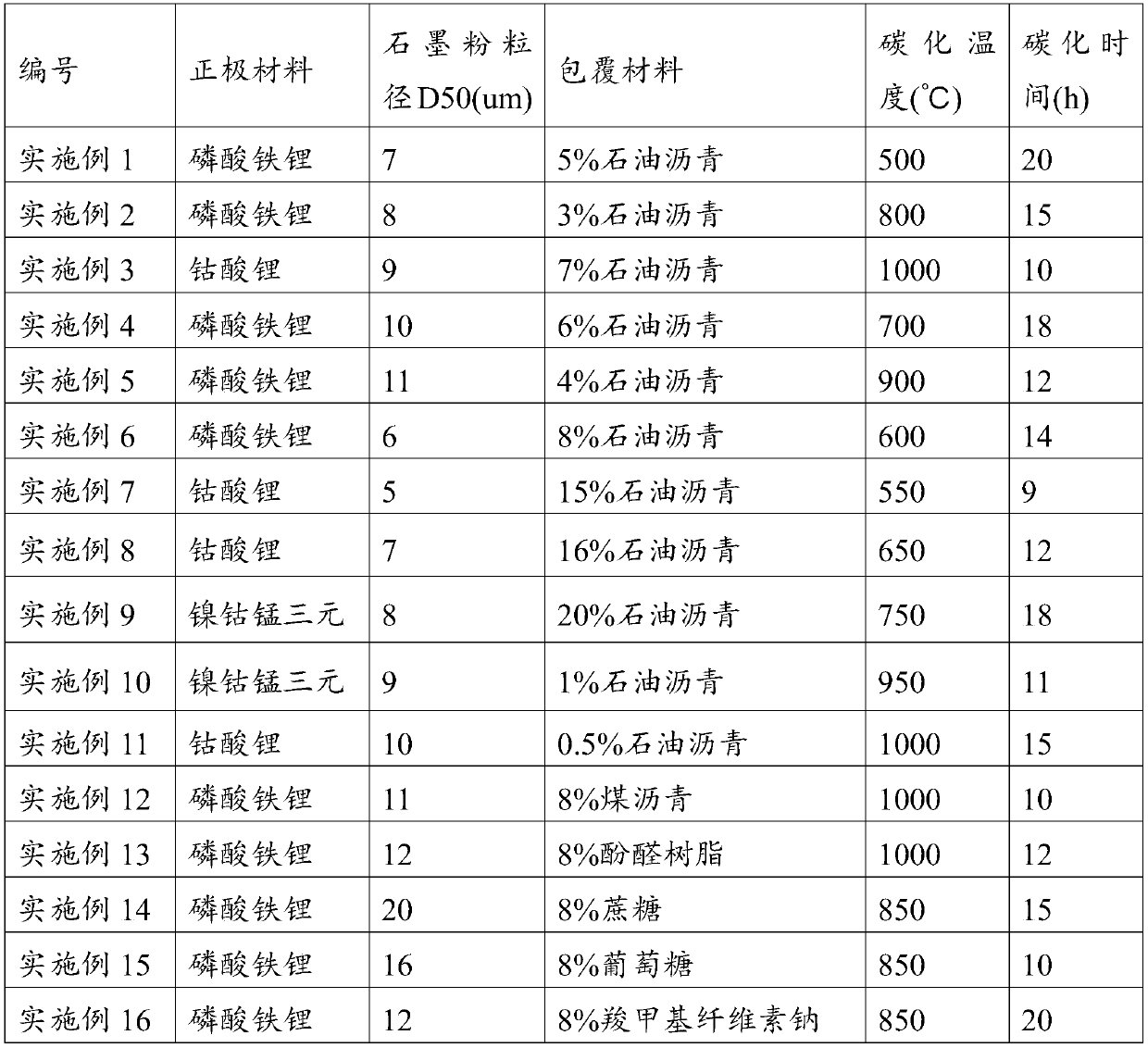

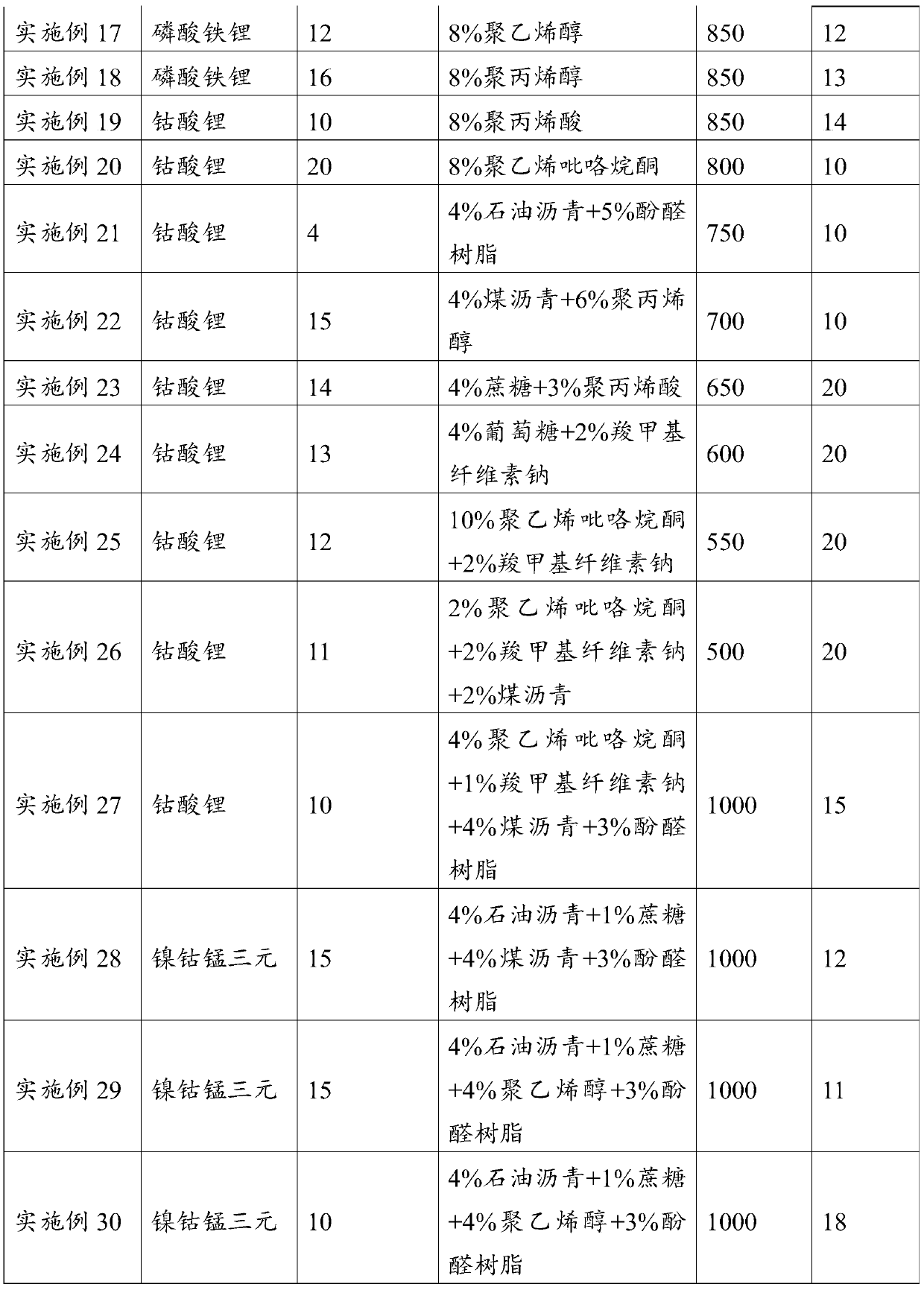

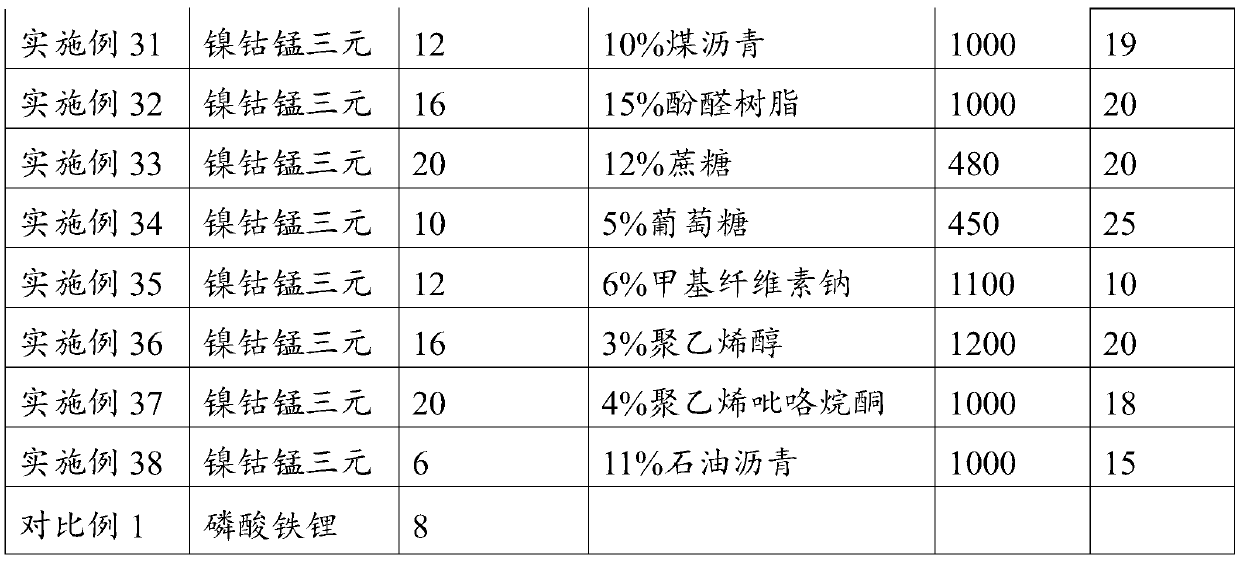

Method of recycling graphite material based on novel aluminum-graphite dual-ion battery

ActiveCN110759341ARaise the gradeIncrease profitGraphiteWaste accumulators reclaimingPolyvinyl alcoholPyrrolidinones

The invention discloses a method of recycling a graphite material based on a novel aluminum-graphite dual-ion battery and relates to the technical field of battery recovery. The method comprises the steps that S1, the waste novel aluminum-graphite dual-ion battery is recovered to obtain graphite powder; S2, the graphite powder is mixed with a coating material, coating granulation is performed after uniform mixing, and graphite particles are obtained; and S3, the graphite particles are carbonized, and the recycled graphite material is obtained, wherein in the step S2, the coating material accounts for 1-15% of the total mass of the mixture of the powder and the coating material, and the coating material is at least one of petroleum asphalt, coal pitch, phenolic resin, sucrose, glucose, carboxymethylcellulose, polyvinyl alcohol, polypropylene glycol, polyacrylic acid and polyvinylpyrrolidone. According to the scheme, the recovered graphite powder is deeply treated, the grade of the graphite powder is increased, and the application field of the graphite powder is expanded; and in the whole treatment process, energy is saved, the environment is protected, high efficiency is realized, and the material utilization rate is high.

Owner:REAL POWER IND LTD +1

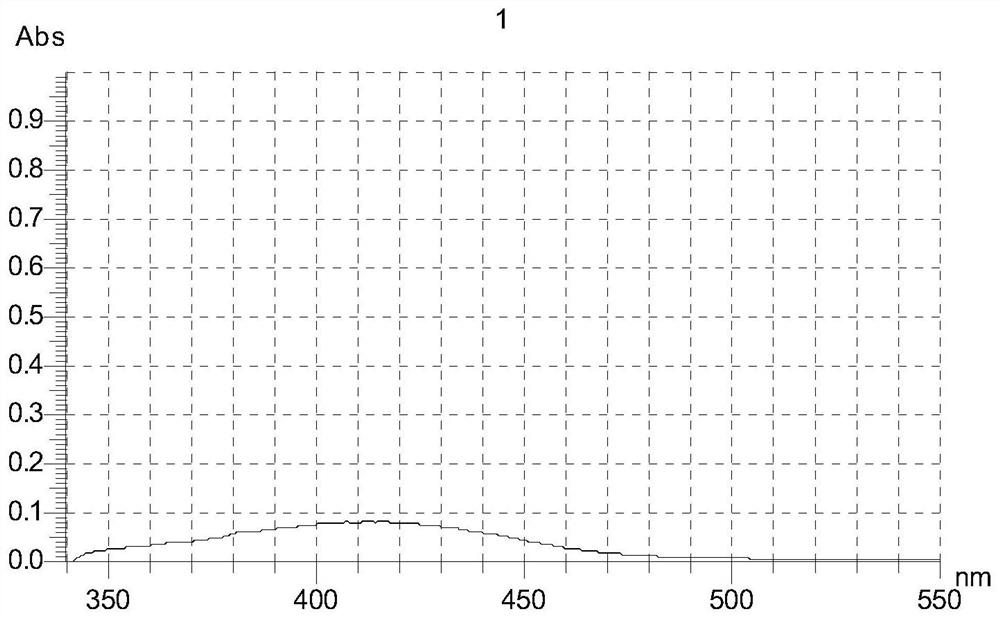

Method for treating organic pigment waste water

InactiveCN102633380AEasy to handleEnergy saving treatmentMultistage water/sewage treatmentCross-linkAbsorption column

The invention provides a method for treating organic pigment waste water, wherein the method comprises the following steps of: (1) regulating pH of waste water within 7-10.5, and adding a decoloring agent, activated carbon powder and polypropylene; (2) treating a clear liquid of the pretreated waste water after air floatation or sediment in a resin absorption column, wherein resin is selected from nonpolar macroporous adsorption resin provided with a porous framework structure and formed through the mutual cross-linking polymerization by taking styrene or acrylic ester as a monomer, divinylbenzene as a cross-linking agent, and toluene or dimethylbenzene as porogen. According to the method provided by the invention, waste water is not required to be diluted and is directly processed; the treating and reaction time of waste water is short, and the total retention time of the pretreatment and the resin absorption is less than 10 hours; the occupation area is small; biochemical bacteria are not required for the running and starting of the system; the running and starting are quick; the management is simple; the resin after absorption can be reused; the operation cost is low; and the yielding water is superior to first level discharge standard stipulated by Integrated Waste Water Discharge Standard of People's Republic of China (GB8978-1996).

Owner:SHANGHAI WINNER ENVIRONMENTAL TECH

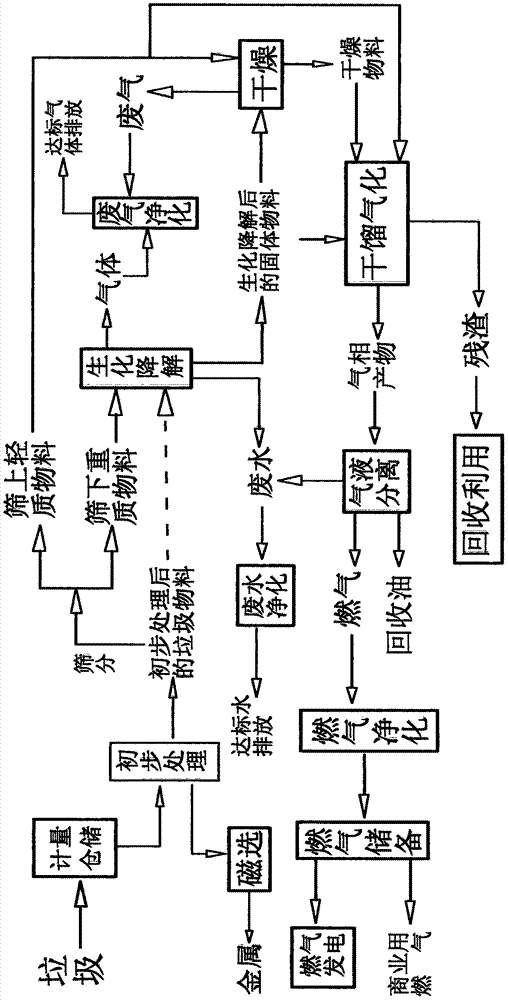

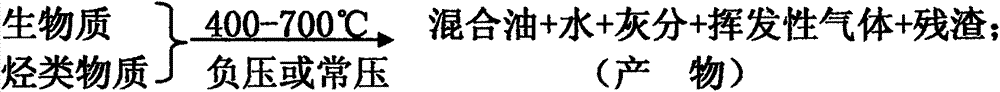

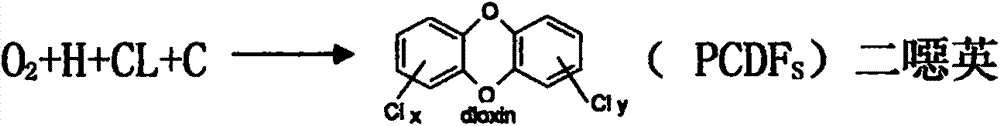

Energy-saving type garbage dry distillation gas preparation and gas power generation method

InactiveCN107225142AEnergy saving treatmentReduce energy consumptionSolid waste disposalPre treatmentChemistry

The invention belongs to an energy-saving type garbage dry distillation gas preparation and gas power generation method, in particular to a method for treating garbage to produce gas and generating power through the gas via procedures of pretreatment, biochemical degrading, dry distillation, gasification, gas-liquid separation, gas purification and gas utilization for the garbage. The method has the advantages of energy conservation, environment friendliness, efficiency and continuous treatment of the garbage, and is high in inventiveness, novelty and industrial practicability.

Owner:周鼎力

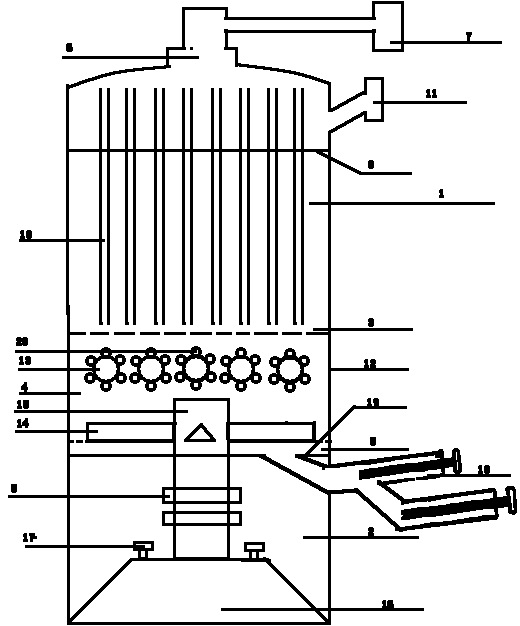

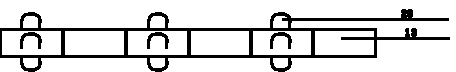

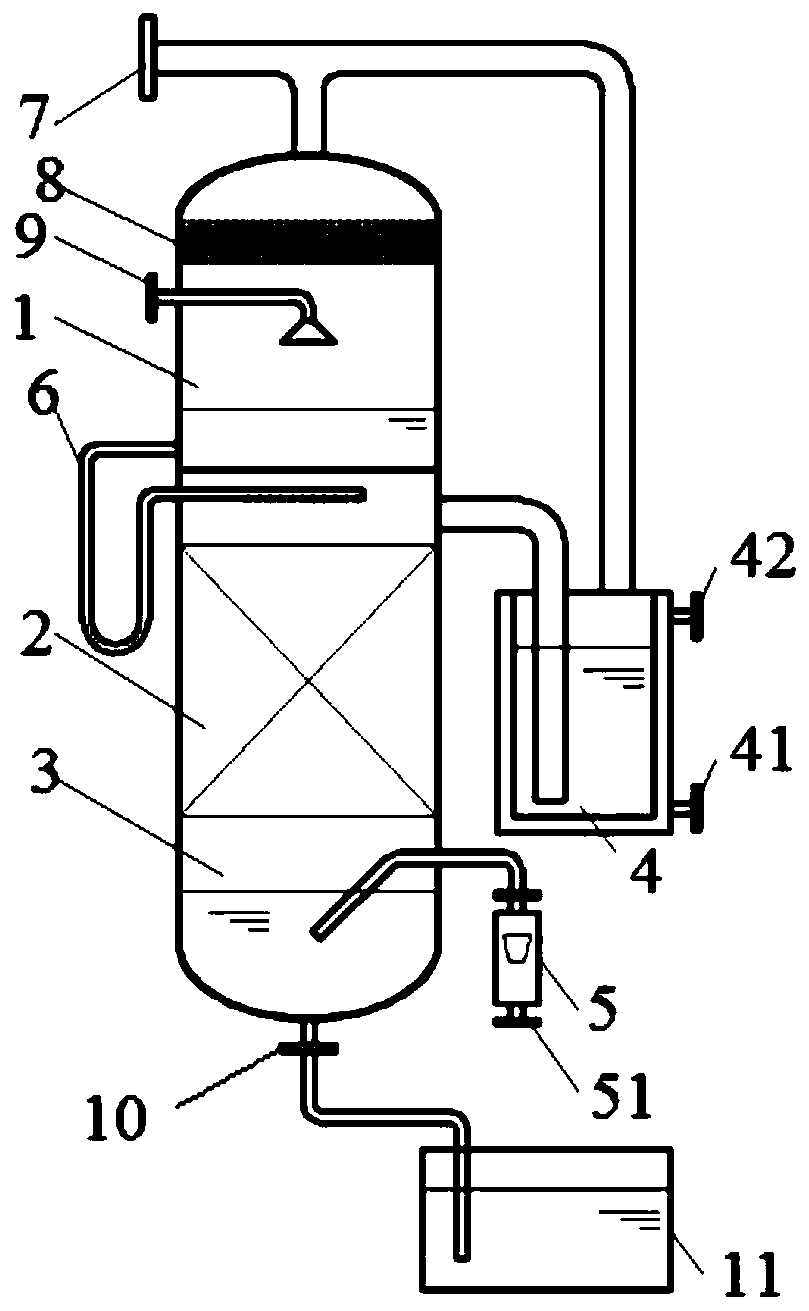

Sludge vaporizing furnace

InactiveCN102994152ASave dehydration equipment and gas cooling equipmentSimplified processing stepsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisExhaust gasFuel gas

The invention belongs to a device for converting an exhaust gas and sludge into a renewable combustion gas, and aims to provide a sludge vaporizing furnace for simultaneously solving combustion gas cooling and sludge water treatment. The vaporizing furnace is divided into an upper part which is a vaporizing room and a lower part which is a motor room through a drop bottom having a through hole, and the vaporizing room is divided into a drying zone, a vaporizing zone and a high temperature zone from top to bottom; the top of the drying zone is provided with an air exhaust hole, and is connected with an outside air exhaust system; and the upper portion of the drying zone is fixedly provided with a sludge baffle plate provided with a plurality of pores, furnace air ducts traverse the pores on the sludge baffle plate to link up the whole drying zone and are supported by the sludge baffle plate, and apertures of the pores are slightly greater than the external diameters of the furnace air ducts, so domestic sludge is reasonably and efficiently converted into the renewable combustion gas, dehydration and combustion gas cooling devices are saved, and the sludge treatment efficiency is improved. The sludge vaporizing furnace really realizes the sludge treatment having the advantages of energy saving, environmental protection and high efficiency.

Owner:南京绿展能源有限公司

Moulding sand cooling dedusting tower as well as casting moulding sand processing device and method

ActiveCN102430708BEnergy saving treatmentPremium treatmentMould handling/dressing devicesDust controlTower

The invention relates to the technology field of processing and recycling of casting moulding sand and in particular relates to a moulding sand cooling dedusting tower as well as a casting moulding sand processing device and a using method thereof. The moulding sand cooling dedusting tower comprises a vertical box body, a cooling box, a water inlet pipe, a water outlet pipe, a dedusting pipe and an air pipe, wherein a sand inlet is arranged at the upper end of the vertical box body; the cooling box of which the upper surface is an oblique surface is fixed in the inner cavity of the vertical box body; the upper end of the cooling box is a moulding sand flow-in end and communicated with the sand inlet; the lower end of the cooling box is a moulding sand flow-out end; and a sand outlet is arranged at the exterior of the vertical box body at the lower end of the corresponding cooling box and communicated with the moulding sand flow-out end. The device provided by the invention has a reasonable and compact structure, relatively large plastic and iron particles are separated through a filtering block net, small iron impurities are separated by a magnetic separation conveyor, and fine screening and cooling dedusting of the moulding sand are realized through the moulding sand cooling dedusting tower, therefore, the moulding sand cooling dedusting tower can be used for processing the casting moulding sand in an energy-saving, efficient and high-quality mode, has high working efficiency, is economical and environmentally-friendly, and can be used for reducing the labor intensity, the potential safety hazard and the labor cost.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

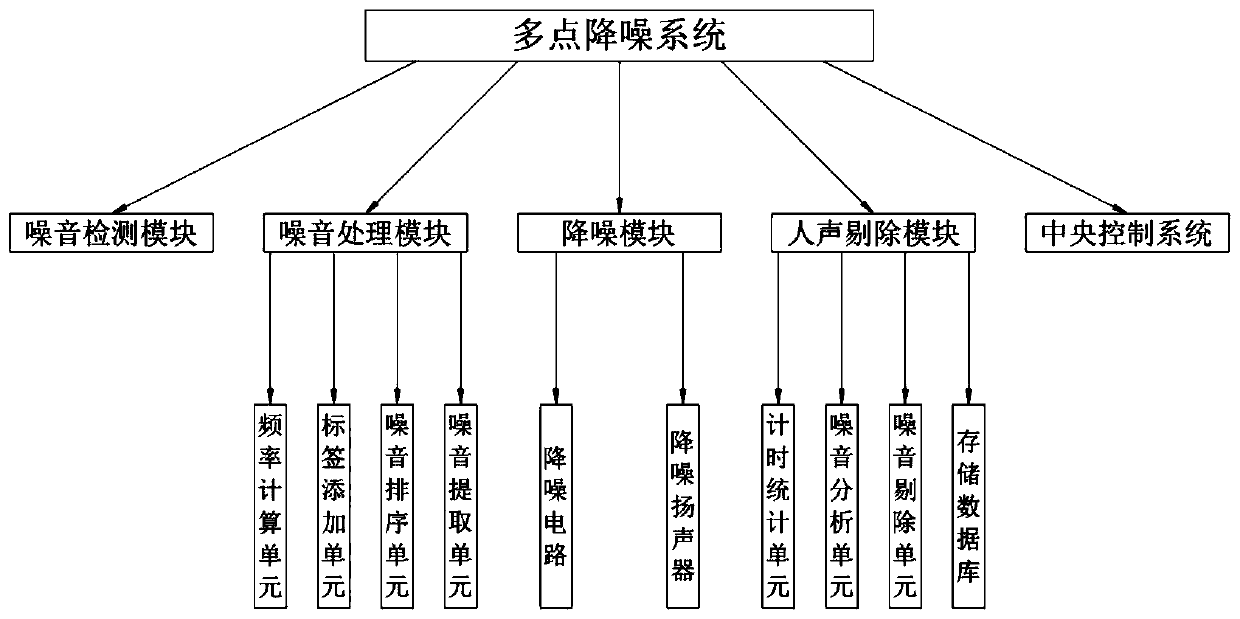

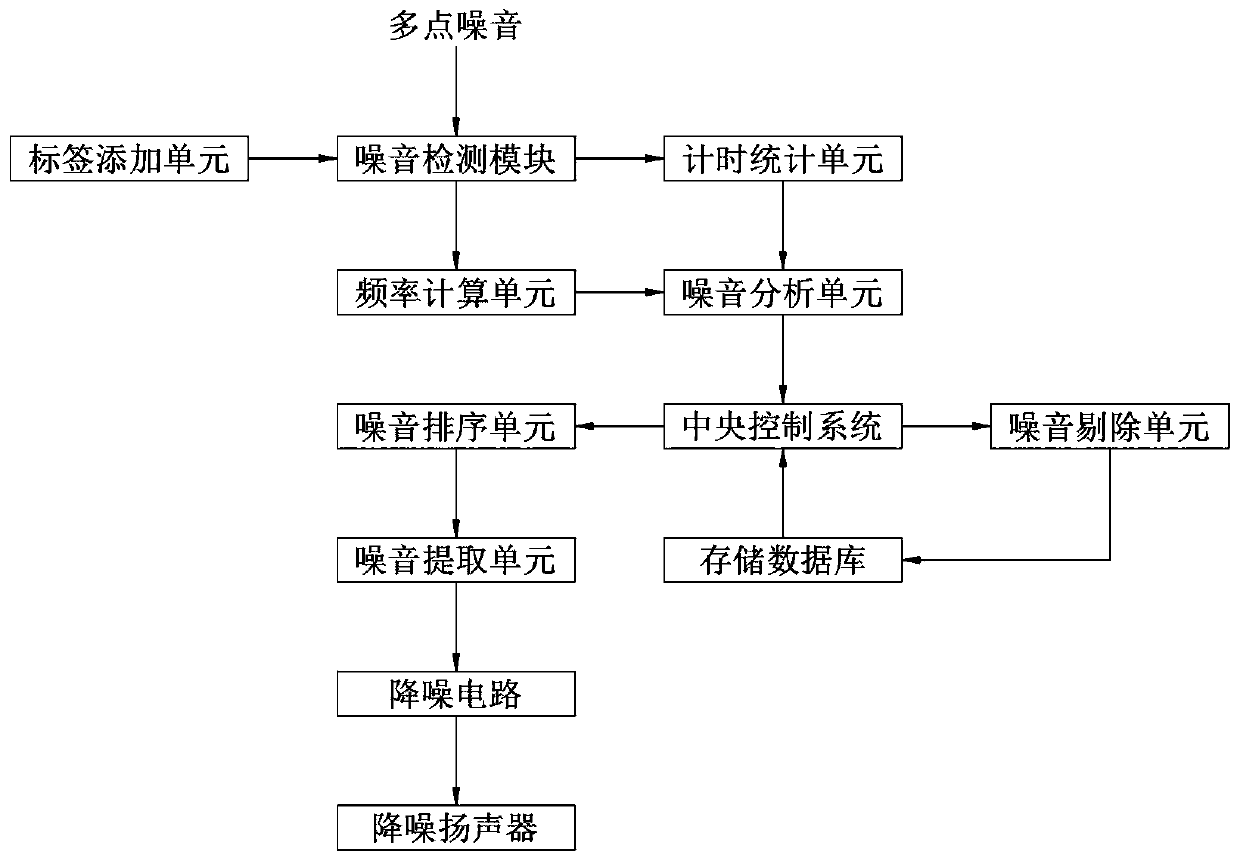

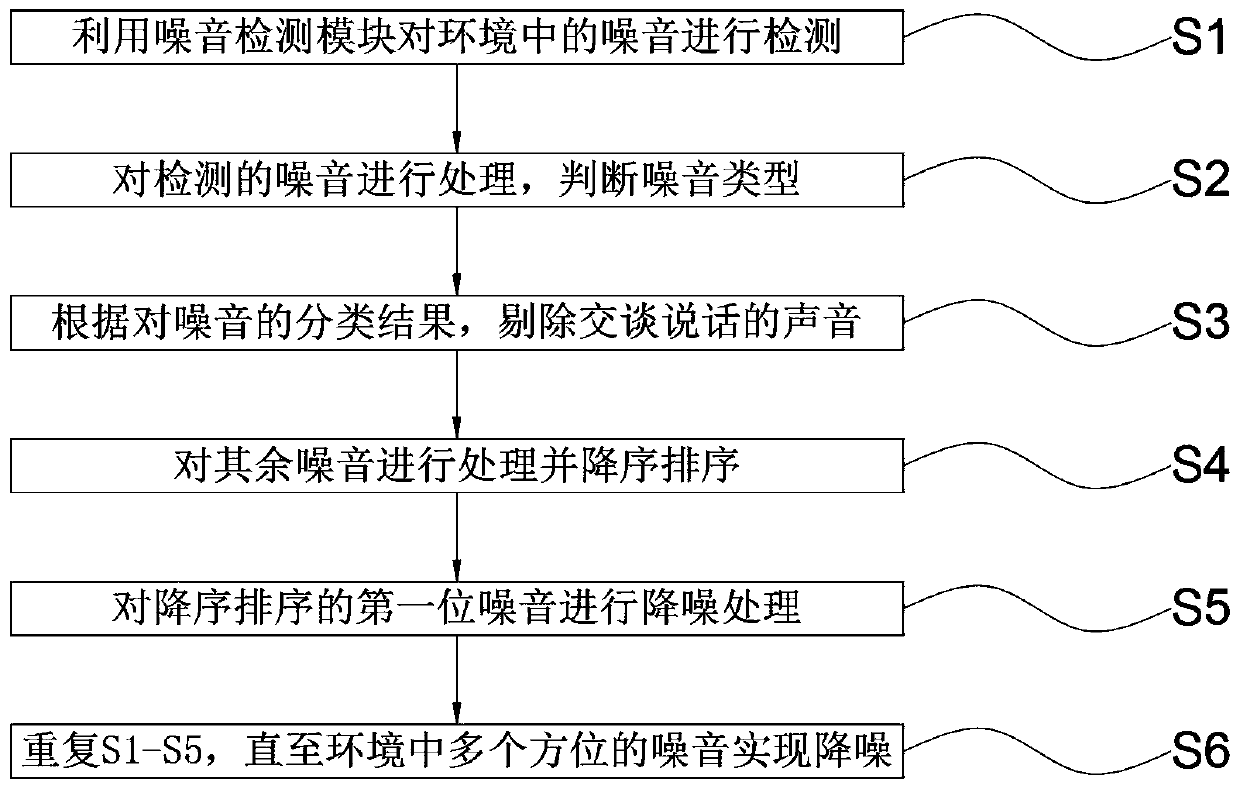

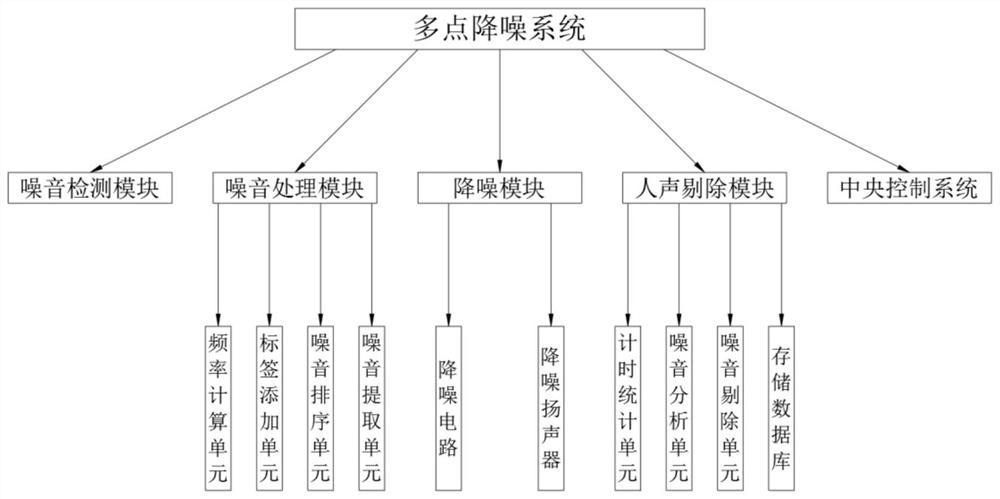

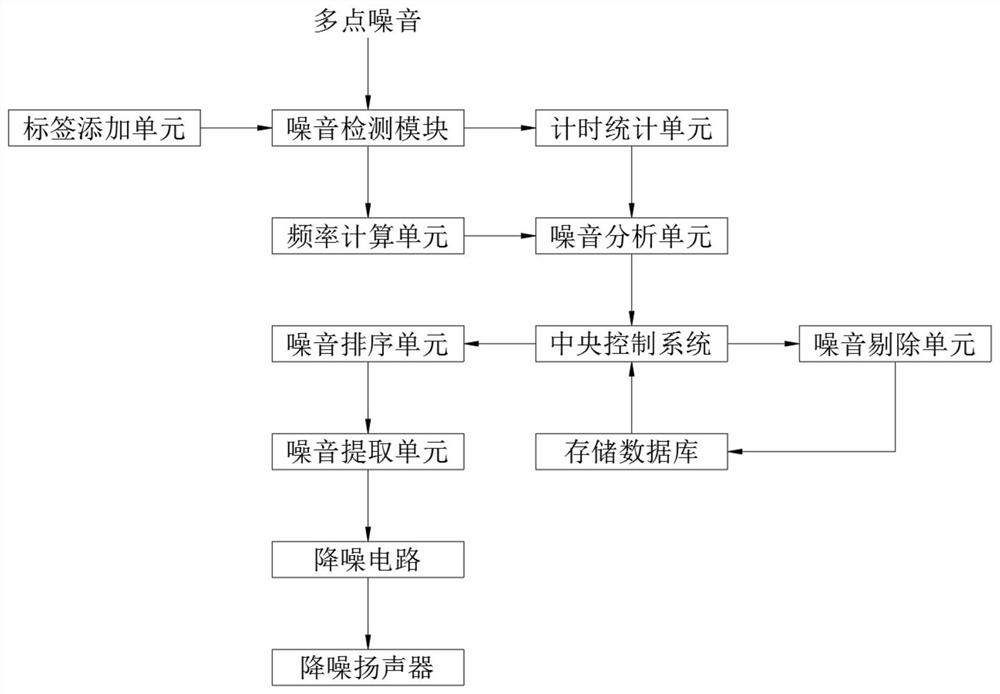

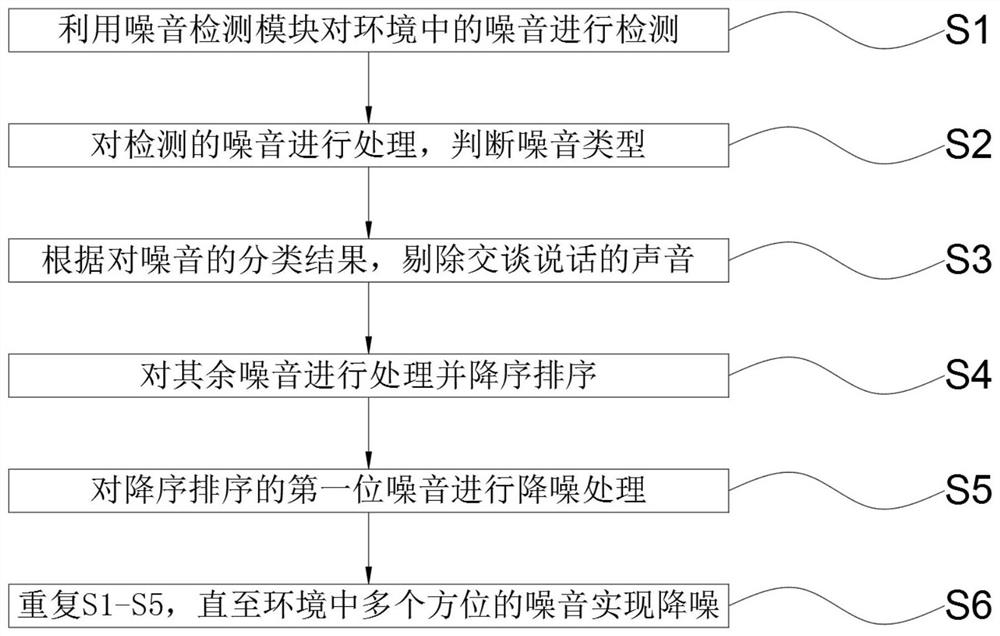

Multidirectional selective noise reduction system and method for space environment

ActiveCN111583898AReduce the steps of denoising one by oneAvoid interactionSound producing devicesNoise detectionControl system

The invention discloses a multidirectional selective noise reduction system and method for a space environment. The system comprises a noise detection module, a noise processing module, a central control system, a human voice elimination module and a noise reduction module, the noise detection module is used for detecting noise in the environment, the noise processing module is used for processingthe noise detected by the noise detection module, the central control system is used for controlling the whole multi-point noise reduction system, the human voice elimination module is used for identifying and eliminating human voice in noise detected by the noise detection module, and the noise reduction module is used for reducing the noise detected by the noise detection module. The multidirectional selective noise reduction system is scientific, reasonable and safe and convenient to use, the operation that noise reduction processing needs to be conducted on each noise signal is avoided, the step that noise reduction is conducted on the multiple noise signals one by one is omitted, differentiated noise reduction is conducted on the noise signals through the multi-point noise reductionsystem, and the multi-point noise reduction system is more intelligent and user-friendly.

Owner:苏州双福智能科技有限公司

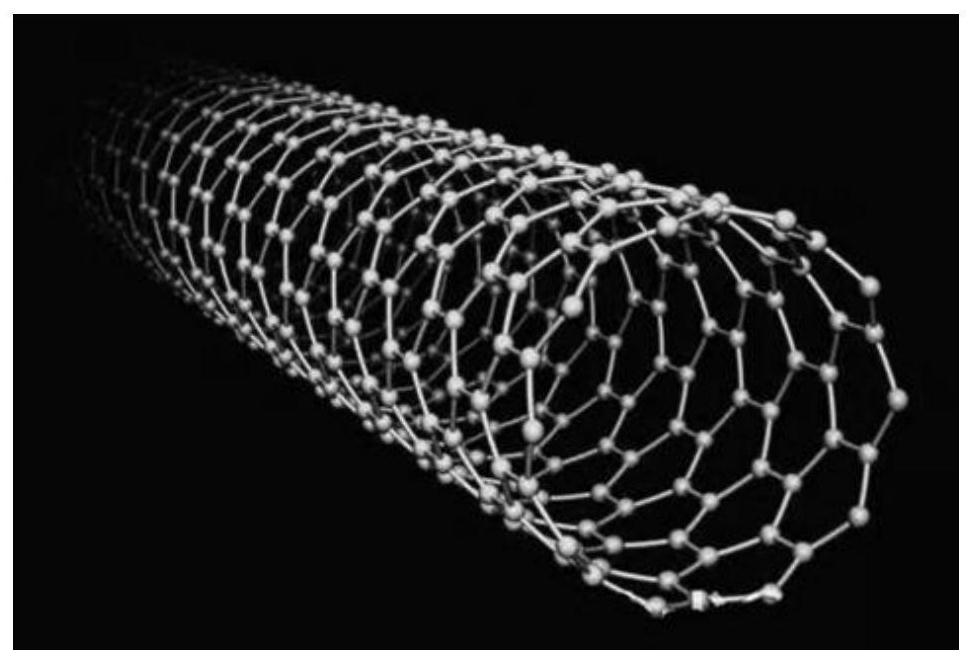

All-solid-waste ultra-high-performance geopolymer concrete and preparation method thereof

ActiveCN114014594AImprove sustainabilityEasy to handleSolid waste managementCement productionSlagCarbon nanotube

The invention relates to the technical field of geopolymer concrete, in particular to all-solid-waste ultra-high-performance geopolymer concrete and a preparation method thereof. The all-solid-waste ultra-high-performance geopolymer concrete is prepared from the following raw materials in parts by mass: 20 to 30 parts of aggregate, 70 to 80 parts of cementing material, carbon nanotubes, steel fibers and an alkali activator, wherein the cementing material comprises the following components in percentage by mass: 15-35% of fly ash, 50-70% of slag and 5-25% of silica fume; and the aggregate is regenerated matrix sand. The geopolymer concrete does not need to use a water reducing agent, and has the advantages of effective utilization of waste resources, low cost, simple preparation and excellent performance.

Owner:无锡初如企业管理合伙企业(有限合伙)

A multi-directional selective noise reduction system and method for a space environment

ActiveCN111583898BReduce the steps of denoising one by oneAvoid interactionSound producing devicesNoise detectionControl system

The invention discloses a multi-directional selective noise reduction system and method for a space environment, comprising a noise detection module, a noise processing module, a central control system, a human voice elimination module, and a noise reduction module. The noise is detected, the noise processing module is used to process the noise detected by the noise detection module, the central control system is used to control the entire multi-point noise reduction system, and the human voice elimination module is used to eliminate noise The human voice in the noise detected by the detection module is identified and eliminated, and the noise reduction module is used to reduce the noise detected by the noise detection module. The present invention is scientific and reasonable, safe and convenient to use, avoids the operation of noise reduction processing for each noise signal, reduces the steps of noise reduction for multiple noise signals one by one, and makes the multi-point noise reduction system realize effective noise signal reduction. Differential noise reduction makes the multi-point noise reduction system more intelligent and humanized.

Owner:苏州双福智能科技有限公司

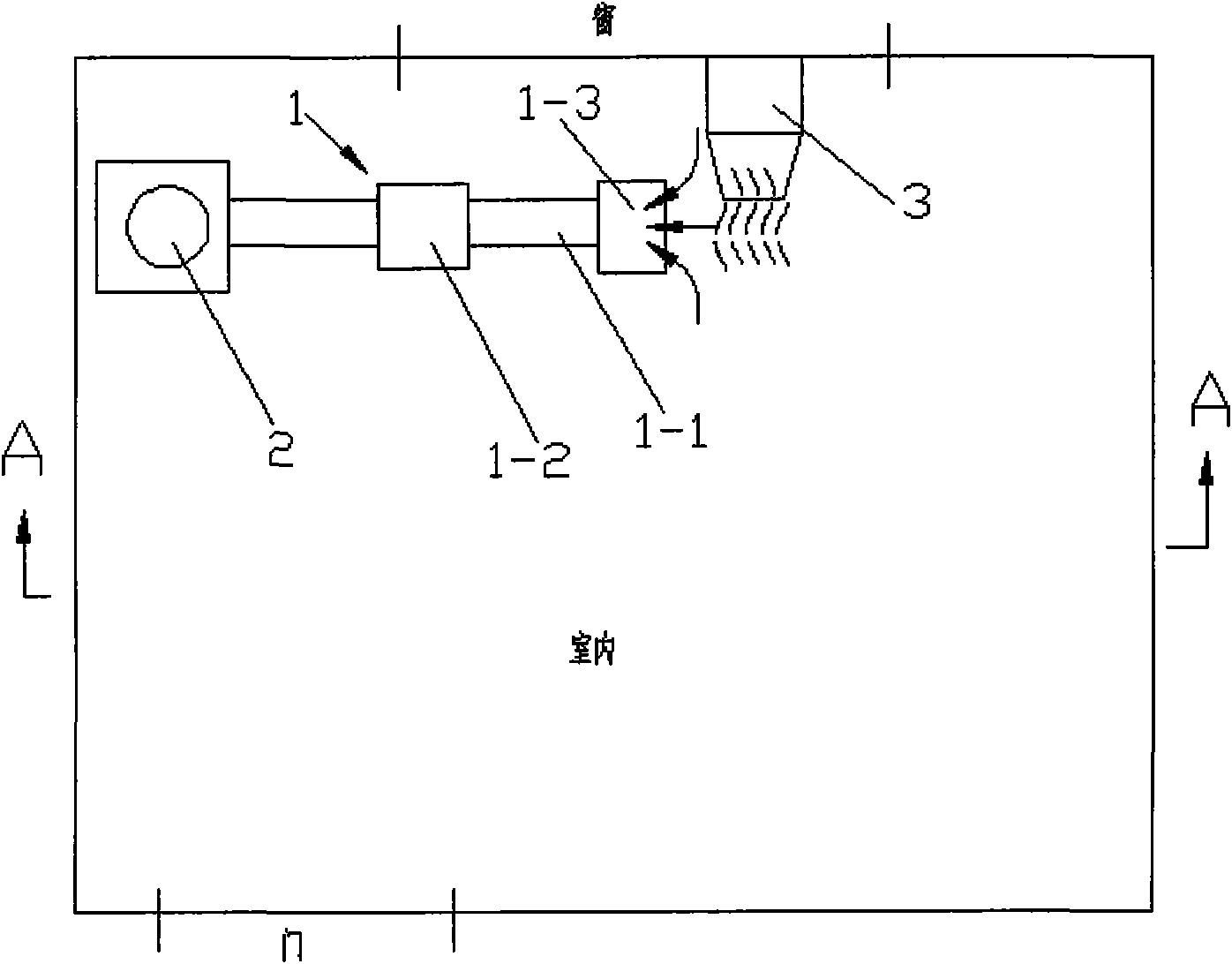

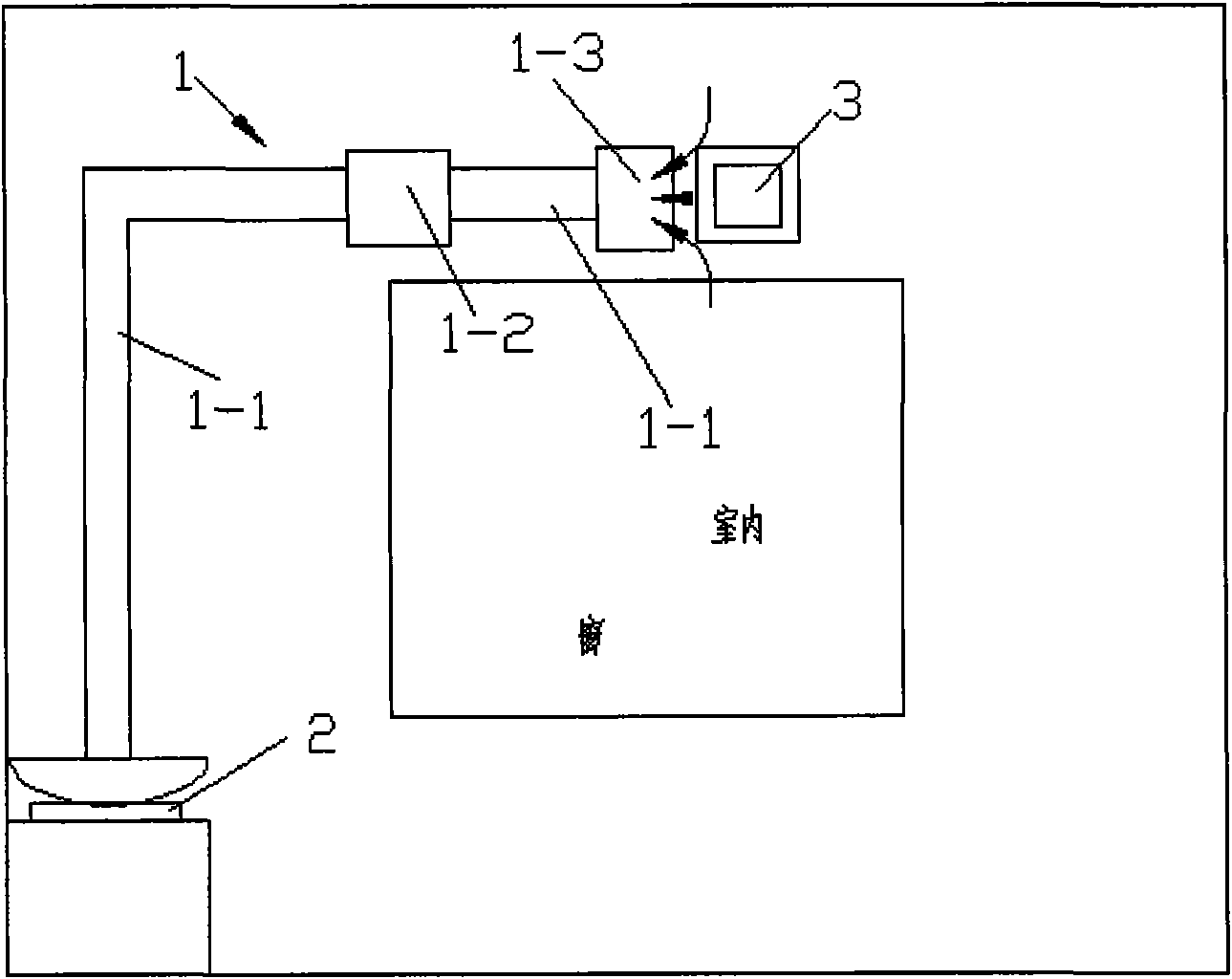

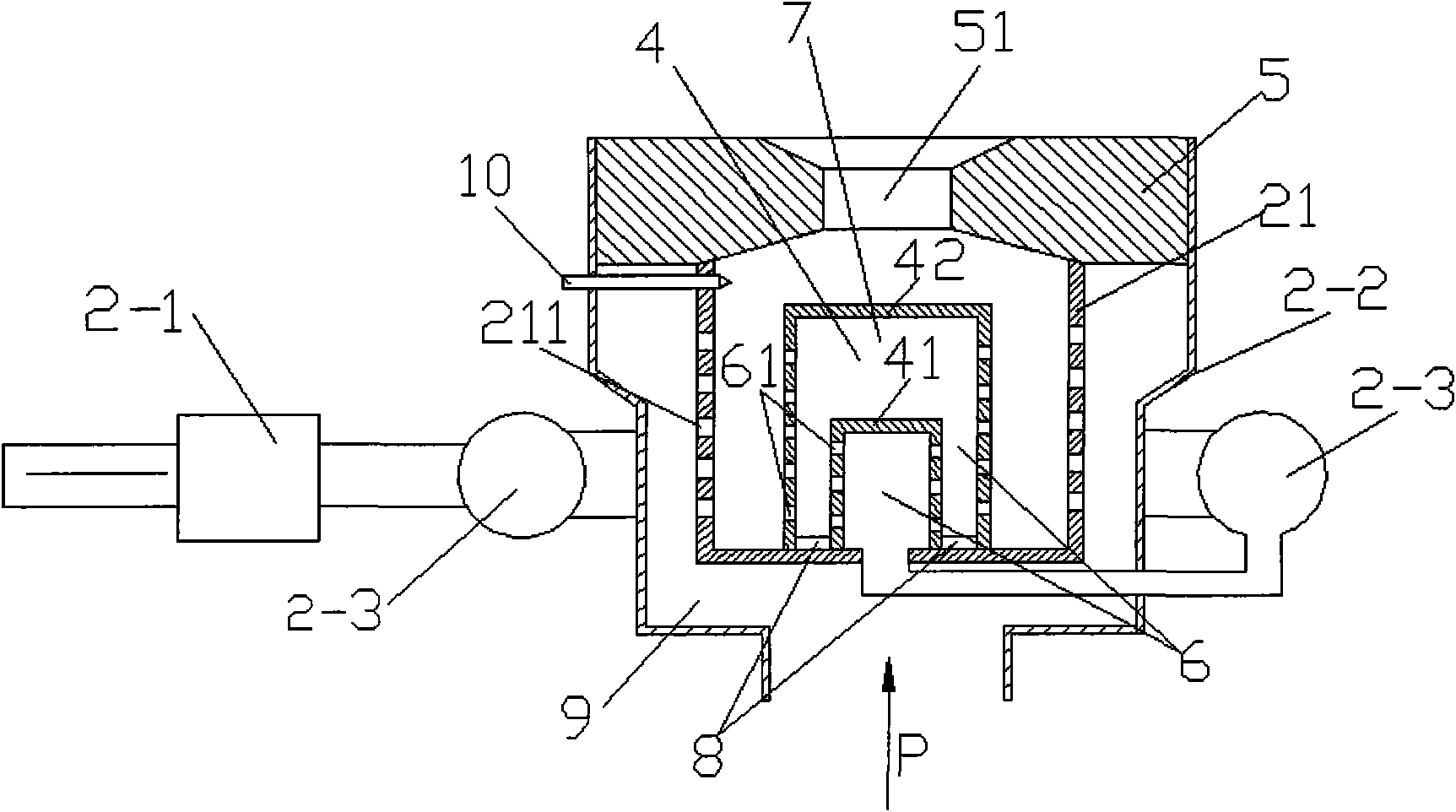

Greenhouse gas treatment method

InactiveCN102121701ASolve the difficult problem of the rapid increase of the global warming effectIncrease profitDispersed particle separationIncinerator apparatusPower stationCombustor

The invention relates to a method for treating greenhouse gases produced by the industries of industry, dining halls, power stations and the like. The treatment method comprises that: the greenhouse gases are recycled into a gas burner (2) by a recycling device (1) for burning treatment. By the treatment method, the problem in the prior art that the greenhouse gases are incompletely treated and finally emitted to the air to pollute the environment and cause the rapid intensification of global warming is solved; combination simplicity and simplicity and convenience of mounting are achieved; when the method is used, conventional facilities are not required to be replaced, so the method is low in cost and convenient to popularize; and when the method is used, the recycled greenhouse gases are utilized as combustion improvers, so more energy can be saved.

Owner:伍镜清

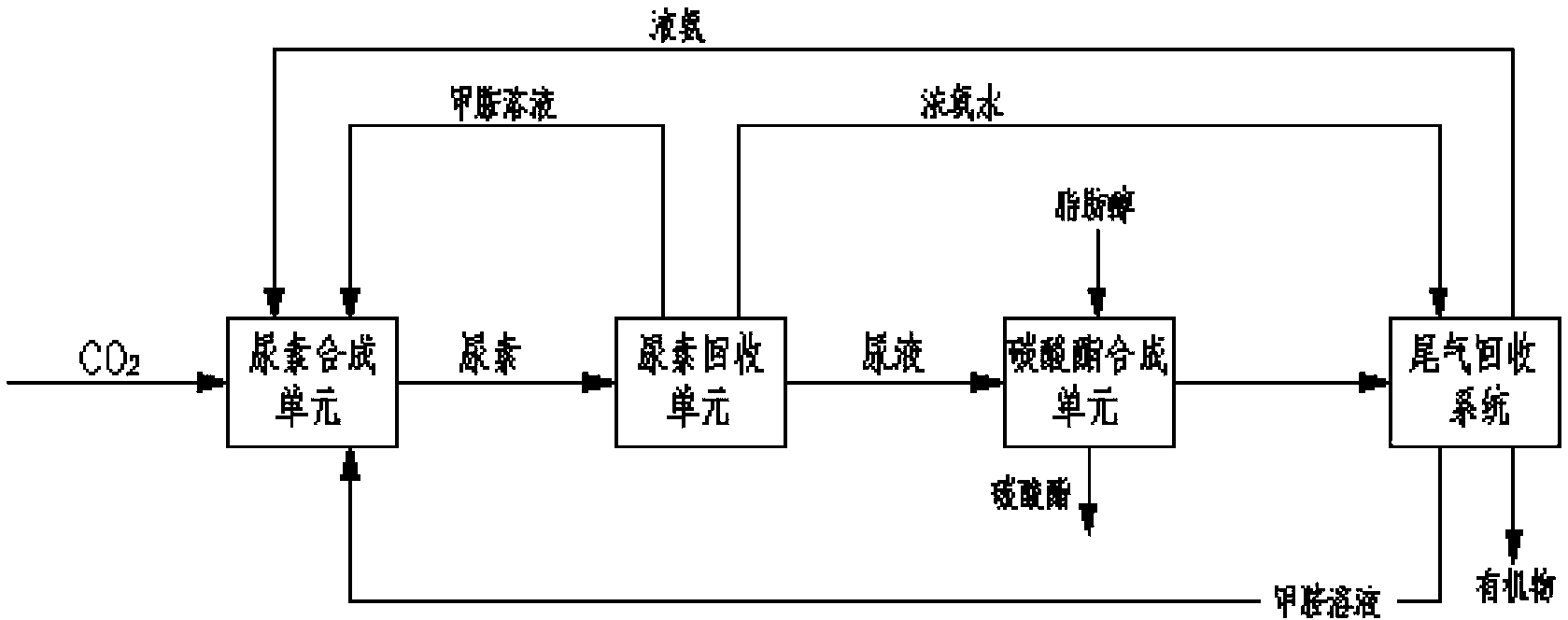

Method for removing organic matter and carbon dioxide from exhaust gas in the process of producing carbonate with carbon dioxide and fatty alcohol

ActiveCN102698567BRich sourcesCheap sourceDispersed particle separationPreparation from carbon dioxide or inorganic carbonatesFatty alcoholMethanol

The invention provides a method for removing organic matters and carbon dioxide in tail gas by using carbonic ester produced from carbon dioxide and fatty alcohol. The method comprises the following steps of: mixing raw materials such as methanol with urea; entering a carbonic ester synthesis unit to obtain a carbonic ester product; feeding synthetic tail gas into a tail gas recovery system; removing organic matters and carbon dioxide; and returning an obtained methylamine solution and liquid ammonia into a urea synthesis unit. According to the method, ammonia consumed by synthesizing urea can be completely replenished through a recovery alcoholysis reaction. Raw materials consumed in the method are mainly cheap carbon dioxide, fatty alcohol and the like, a produced product is carbonic ester with high added value, and the method can be applied to industrial production.

Owner:HUALU ENG & TECH

Low temperature methanol wash method and equipment

ActiveCN102489120BHigh recovery rateEasy to handleDispersed particle separationCombustible gas purificationSulfurDesorption

The invention discloses a low temperature methanol wash method and equipment, wherein the method comprises an absorption step, a desorption step and a methanol heat regeneration step. The absorption step further comprises: adopting first lean methanol solution to absorb virgin gas for the first time, and cooling to form first rich methanol solution; forming first gas and first liquid after gas-liquid separation; adopting second lean methanol solution to absorb the first gas for a second time, and forming second absorbed rich methanol solution after the second lean methanol solution is absorbed for a second time; carrying out flash distillation on the second absorbed rich methanol solution to form second gas and flash distillated rich methanol solution; and adopting third lean methanol solution to absorb the second gas for a third time, forming third gas and reflux rich methanol solution, and respectively recycling the third gas and the reflux rich methanol solution. The method can be high-efficient, flexible, safely and energy-saving to treat carbonyl gas with different pressures, temperatures, moisture contents and sulphur concentrations.

Owner:HUANENG CLEAN ENERGY RES INST

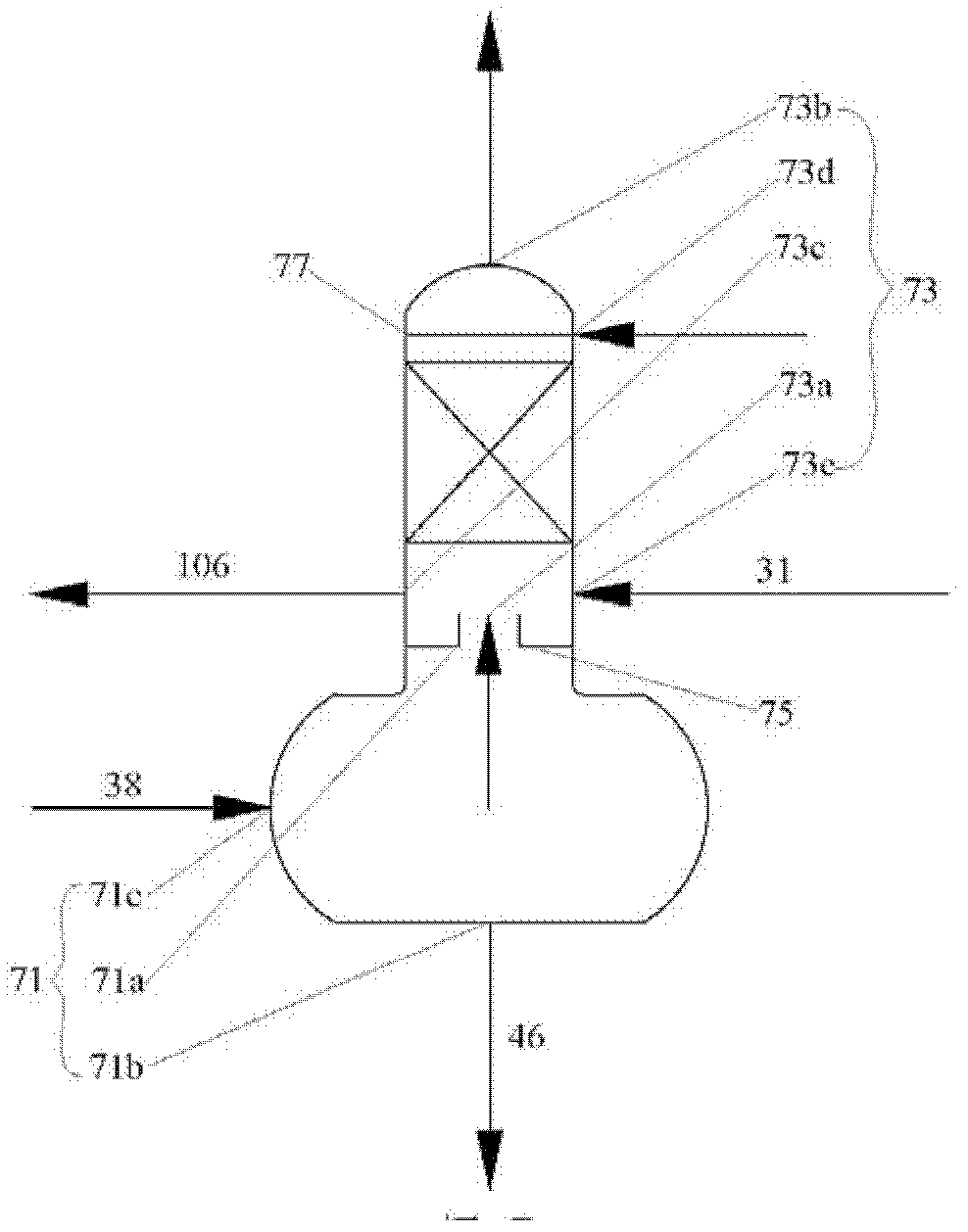

Falling film blow-off device with flash function

ActiveCN106377916BAchieving processing powerReasonable structureDistillation regulation/controlFlash distillationGas phaseChloride

Owner:NANJING UNIV +1

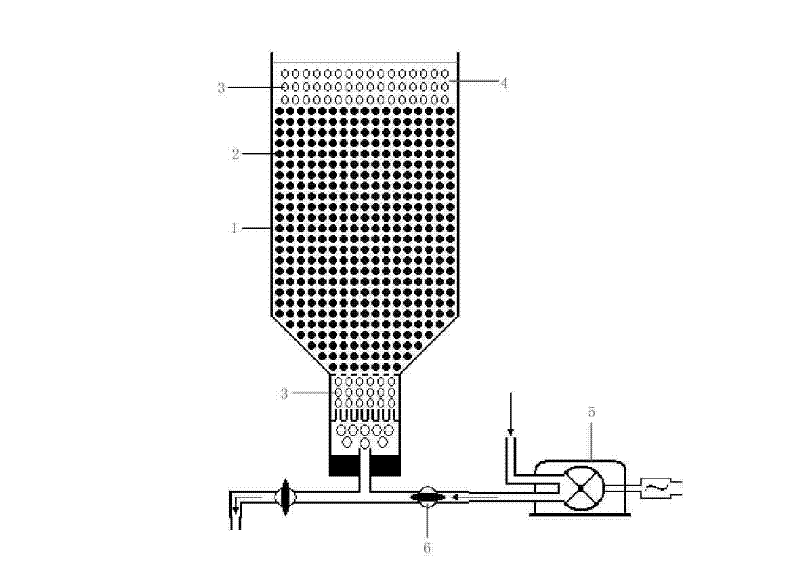

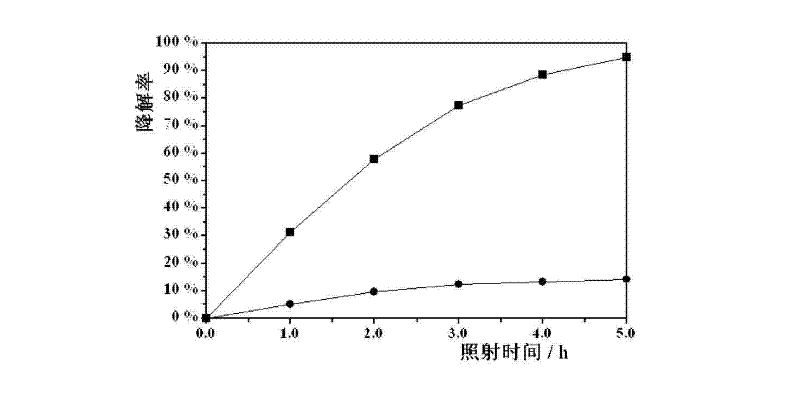

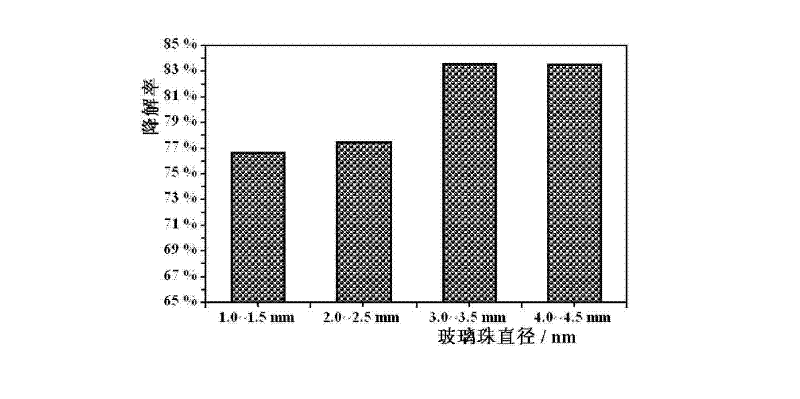

Bubbling cavitation method for degrading organic pollutants in wastewater

InactiveCN102295342BStrong oxidation abilityEasy to handleWater/sewage treatment by oxidationWastewaterSewage

The invention relates to a bubbling cavitation method for degrading organic pollutants in wastewater to solve the problem of water pollution. The technical scheme adopted in the invention comprises the following steps of: adding glass beads into a degradation device; adding wastewater containing organic pollutants into the degradation device with the wastewater level being over the glass beads; letting a gas enter from the bottom of the degradation device, and reacting for 3-5 hours. By the combined action of glass beads and air bubbling, organic pollutants such as acid red B in wastewater can be effectively degraded with the degradation rate being more than 97%. The bubbling cavitation method provided by the invention is a high efficient and energy-saving sewage processing method with nosecondary pollution, requires simple equipment, has practical values, and can be utilized to process various wastewaters on a large scale.

Owner:LIAONING UNIVERSITY

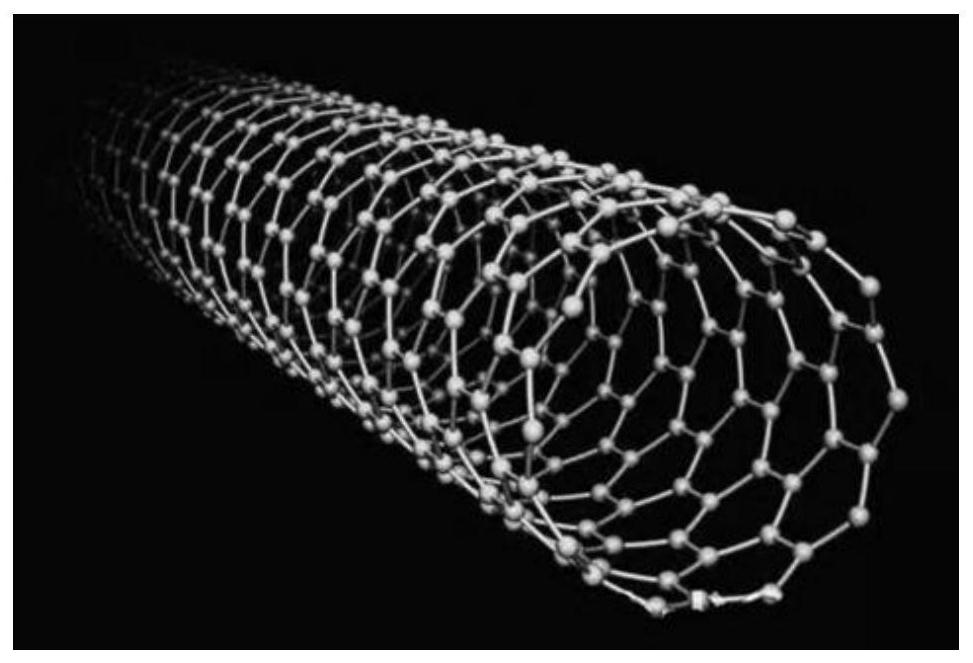

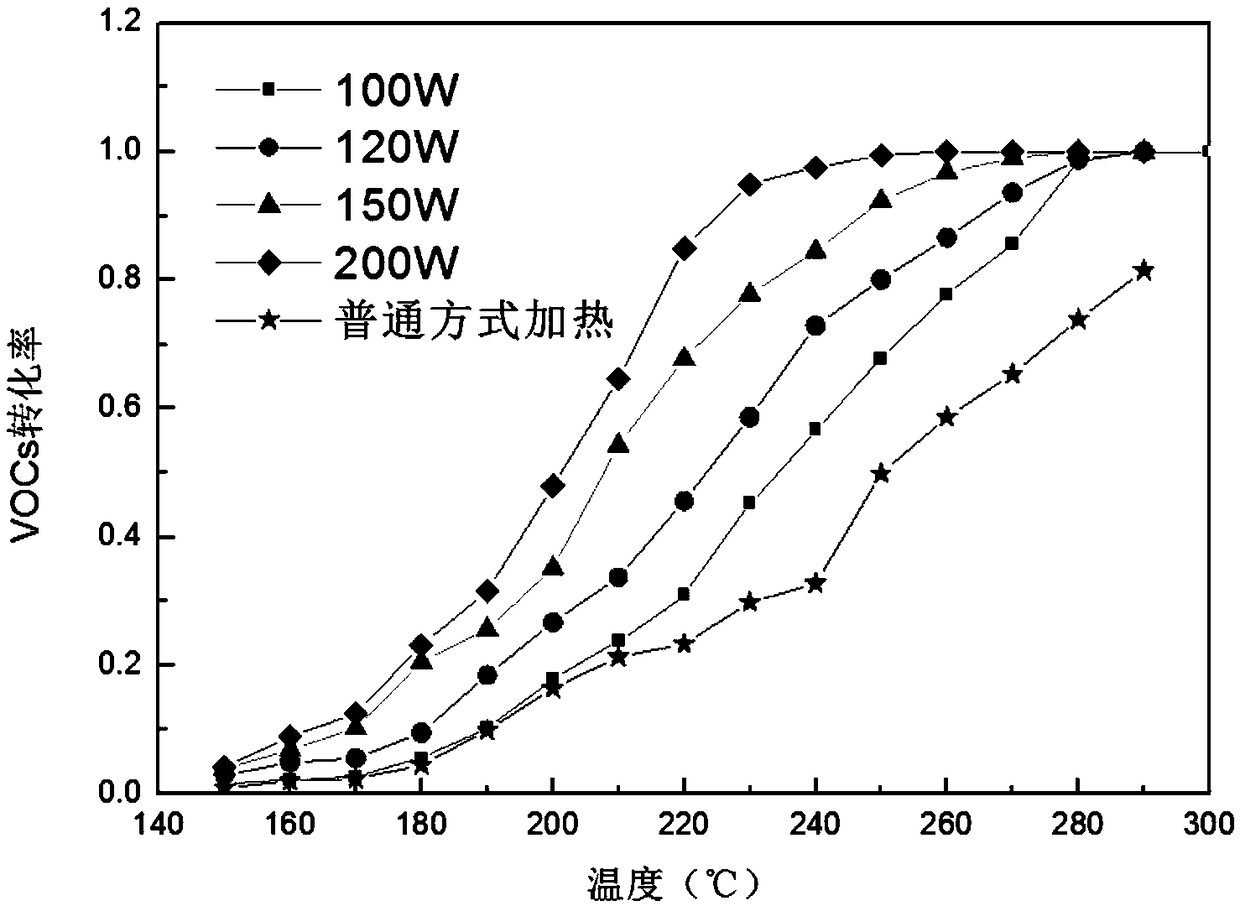

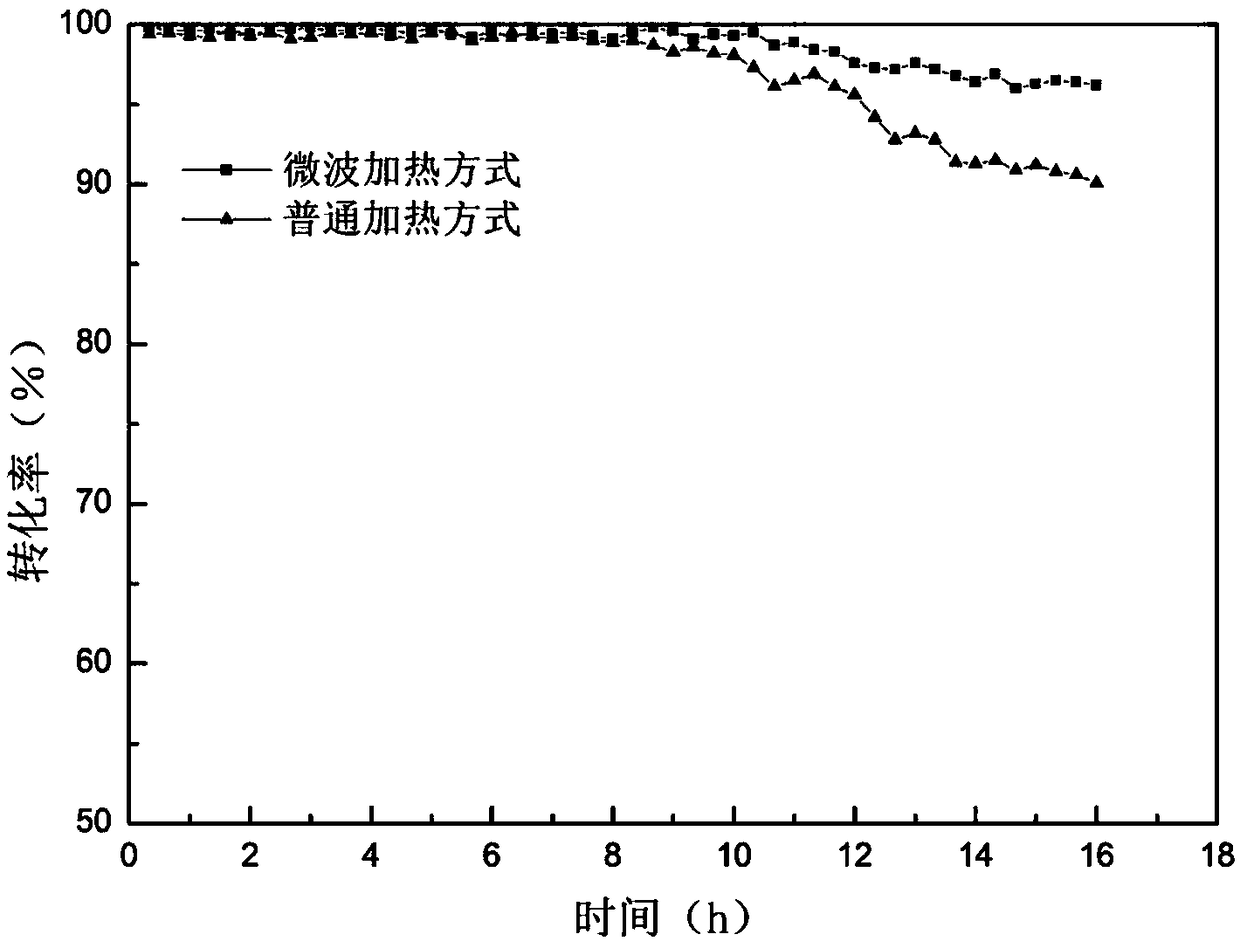

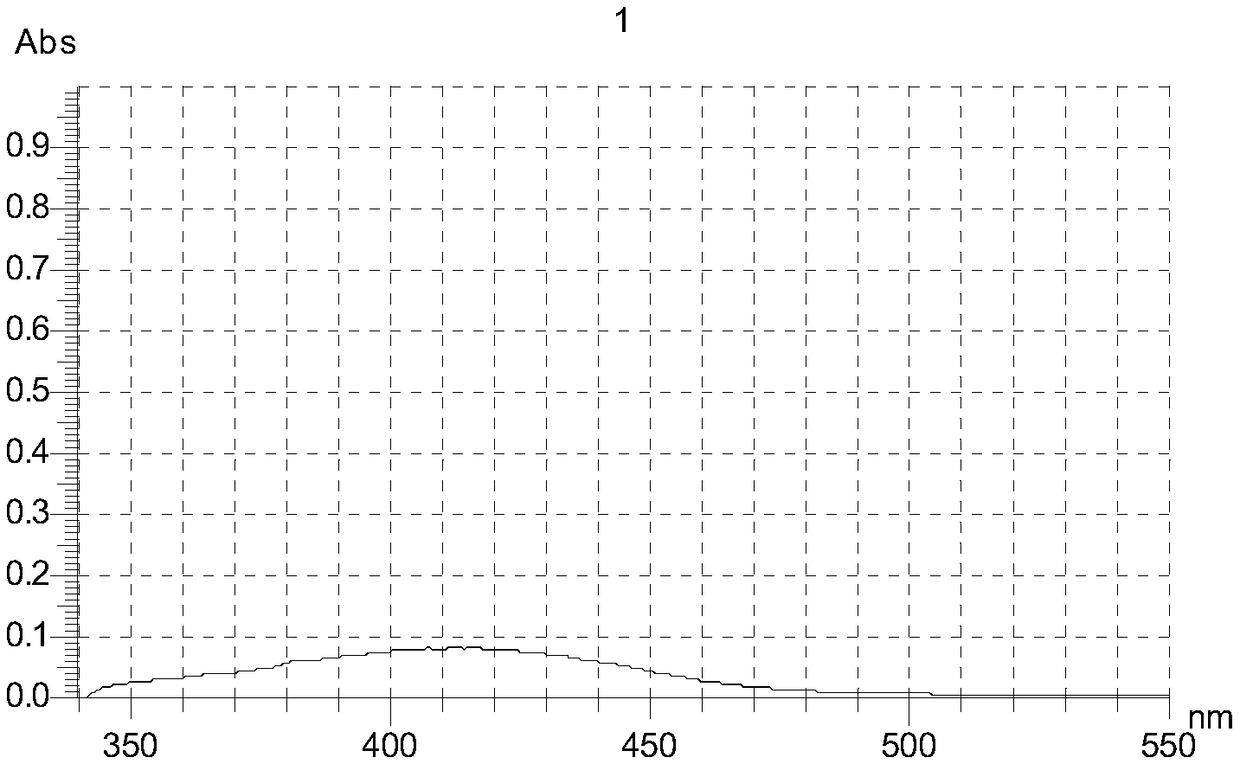

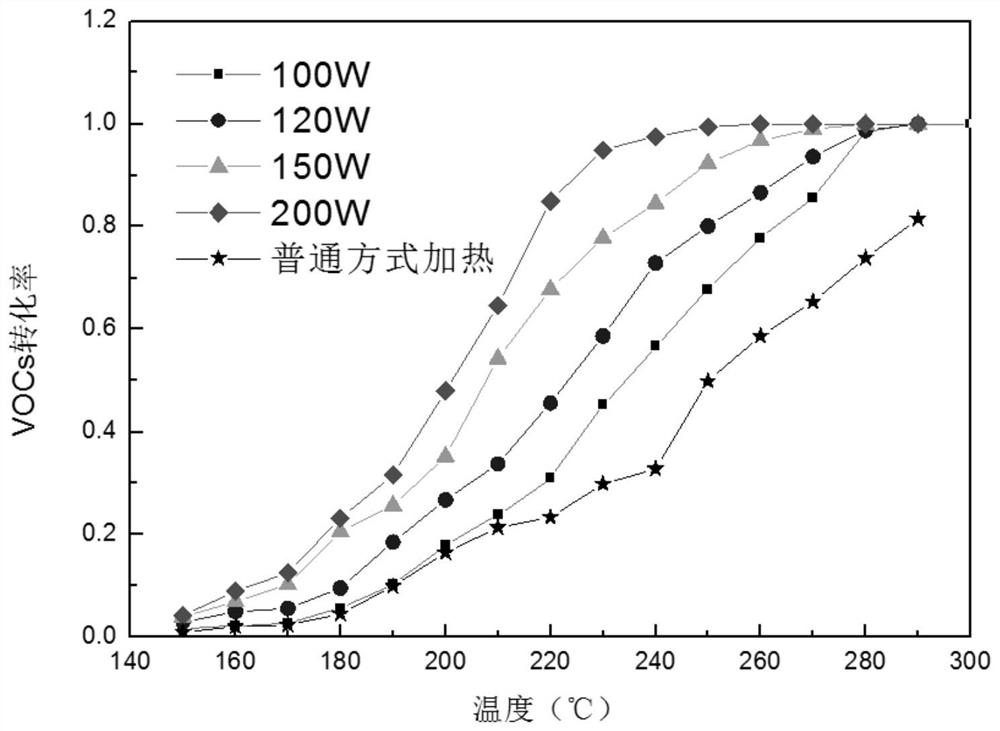

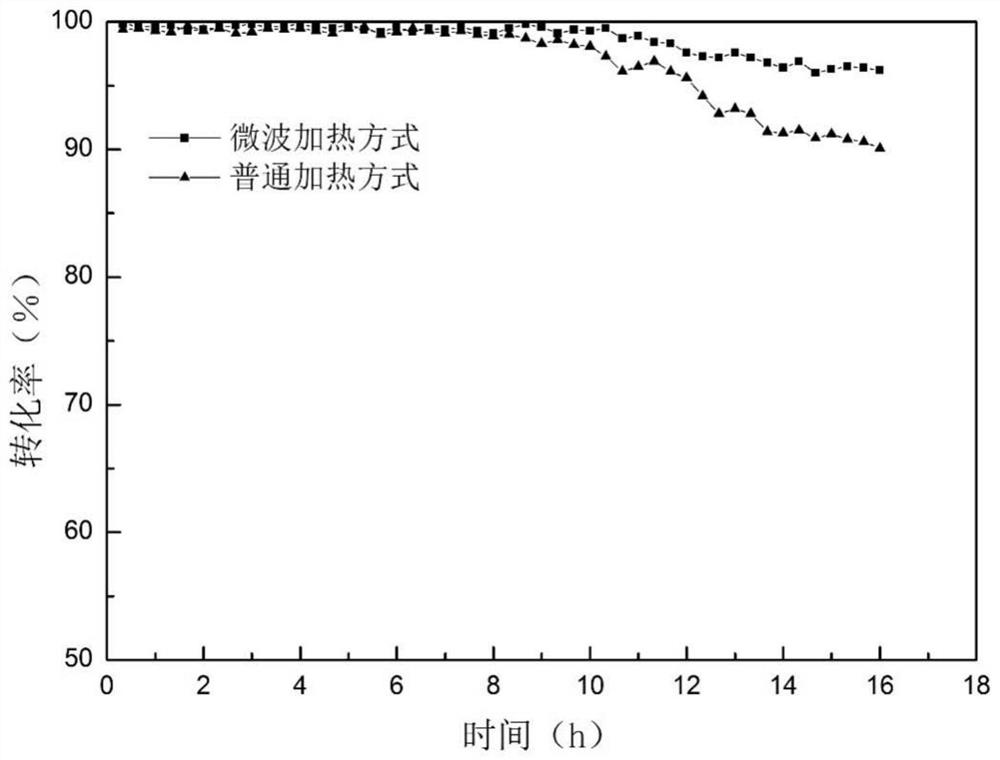

Manganese oxygen composite material for efficiently removing VOCs and preparation method and application thereof

ActiveCN109225205AEasy to prepareLow costGas treatmentDispersed particle separationMicrowaveManganese

The invention discloses a manganese oxygen composite material for efficiently removing VOCs and a preparation method and application thereof. The preparation method comprises the following specific steps: preparing the manganese oxygen composite material doped with Mg and loaded onto carbon nanotubes by a hydrothermal method, mixing the manganese oxygen composite material with quartz sand, then placing in a microwave device, inflating VOC gas and performing a removing reaction, wherein the manganese oxygen composite material is doped with the Mg and is loaded onto the carbon nanotubes. The manganese oxygen composite material has the advantages of high catalytic rate, high catalytic efficiency, low catalyst cost, a simple catalyst synthesizing method, strong catalyst stability, no secondarypollution and no need of retreatment.

Owner:SOUTH CHINA UNIV OF TECH

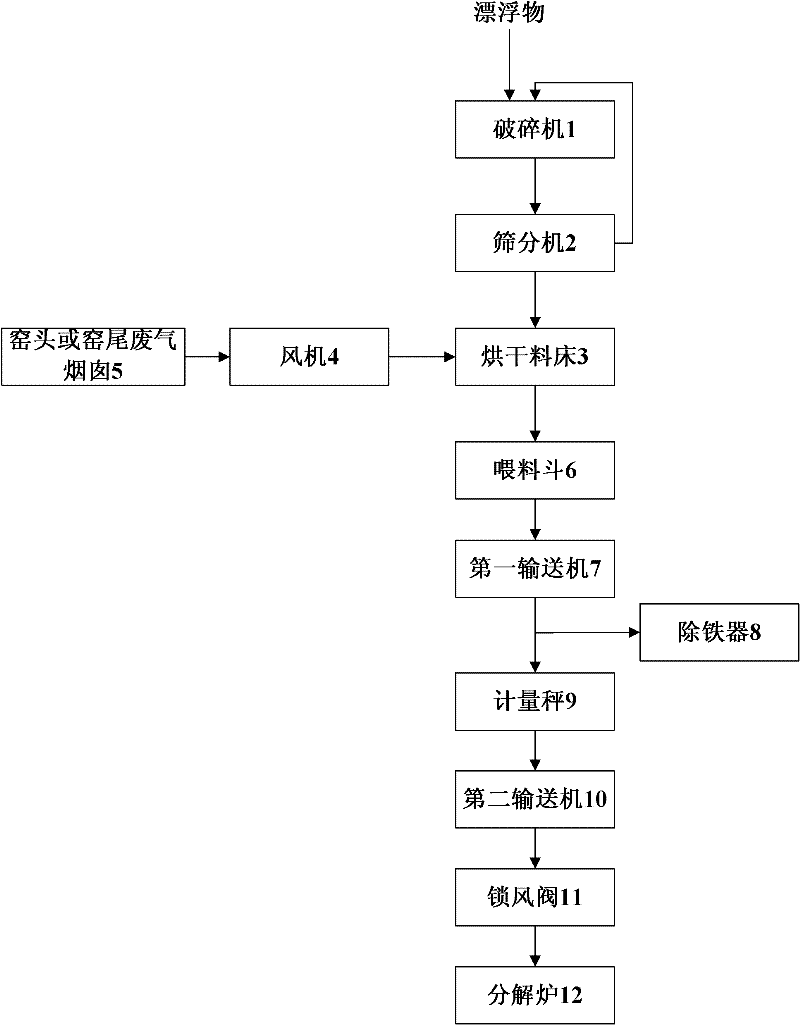

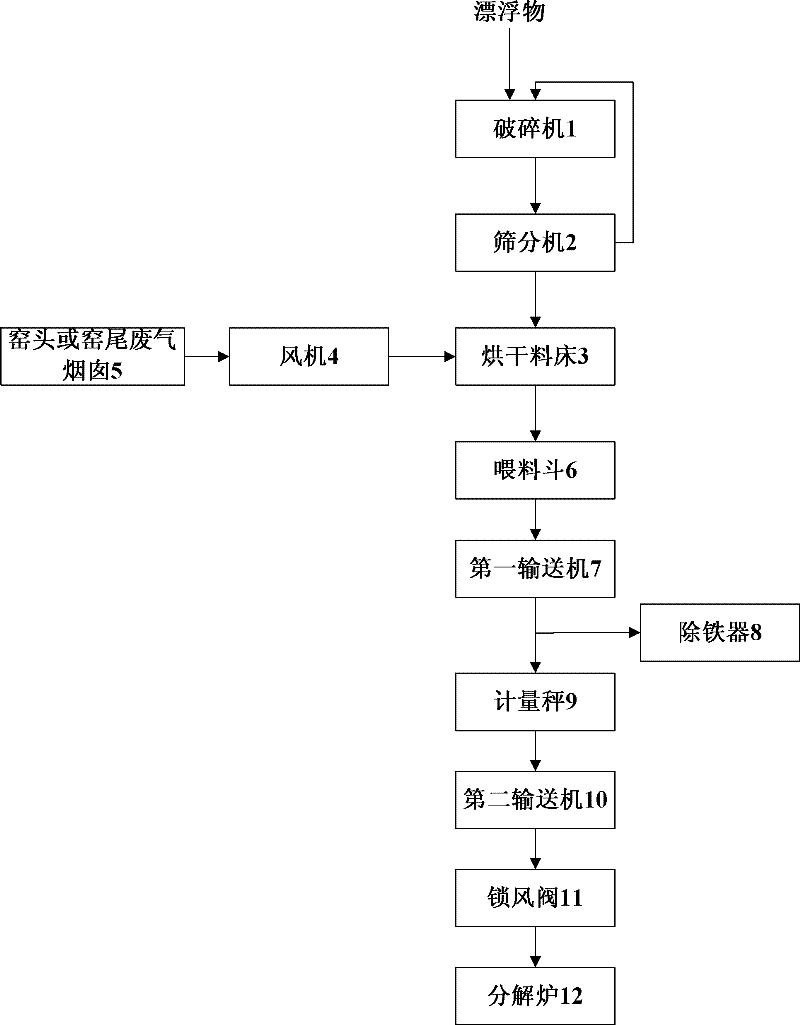

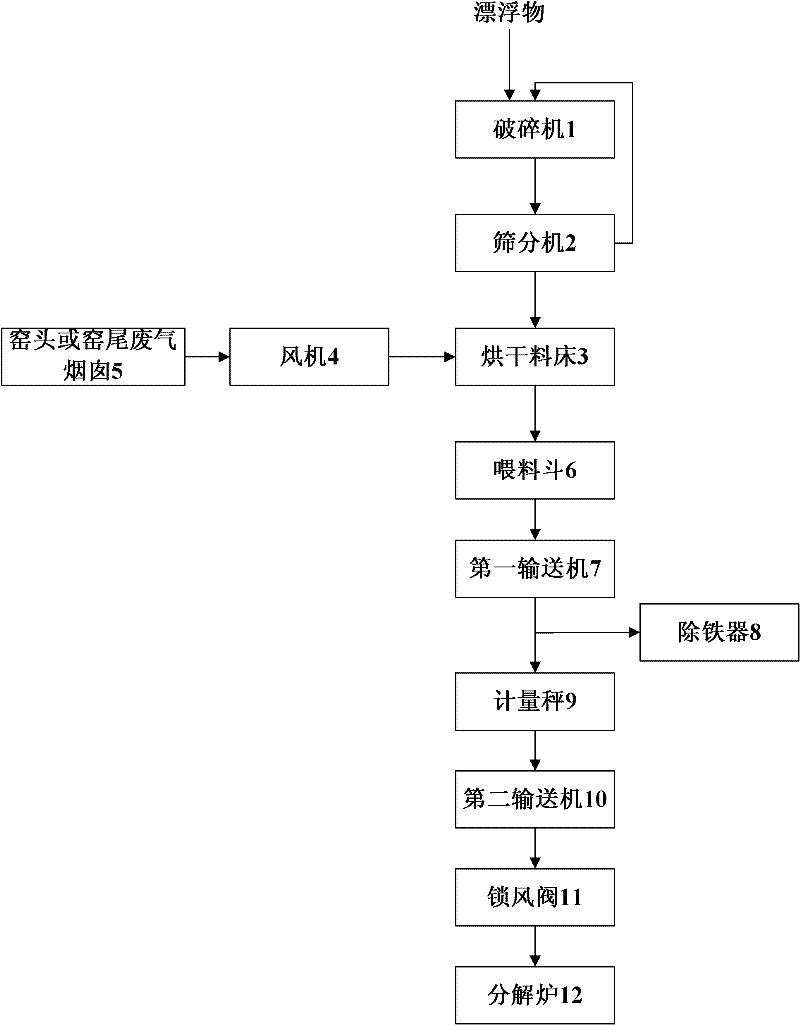

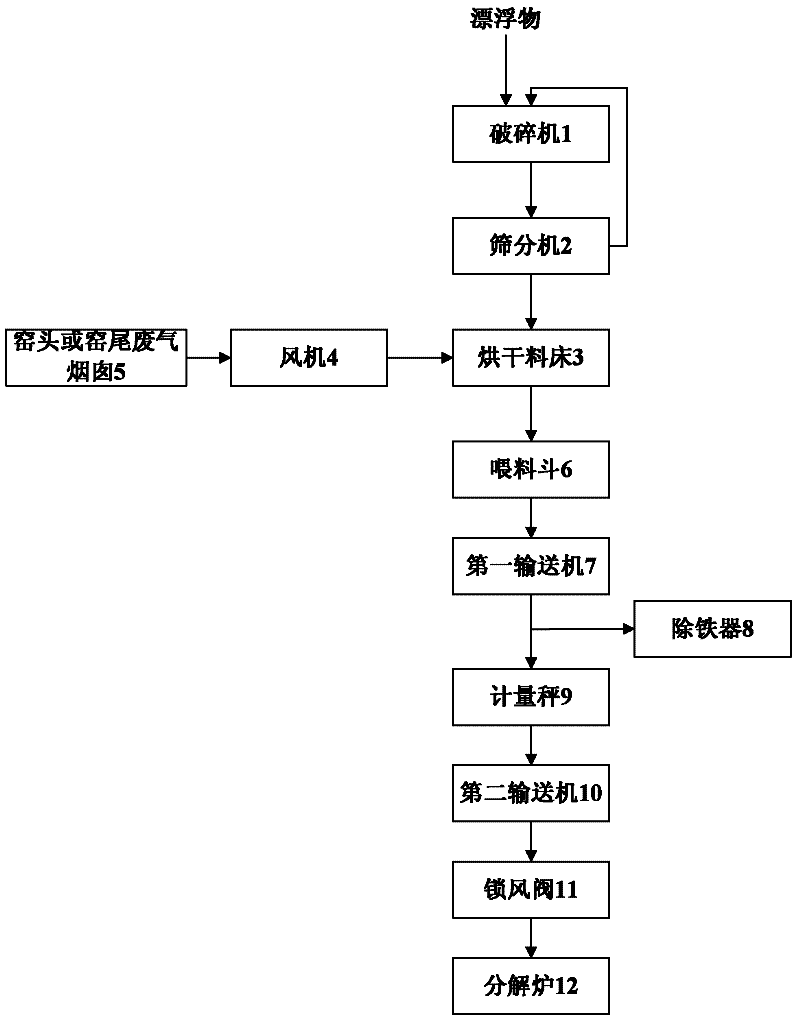

System for comprehensive utilization of floater pretreatment and cement kiln

The invention relates to a system for comprehensive utilization of floater pretreatment and a cement kiln. The invention relates to the system for comprehensive utilization of floater pretreatment and the cement kiln, which comprises a crusher, a screening machine, a material drying bed, a blower fan, a feeding bucket, a first conveyer, a magnetic separator, a weigher and a second conveyer; an outlet of the crusher is connected with an inlet of the screening machine by a conveying apparatus, an outlet of the screening machine for a qualified product is connected with the inlet of the materialdrying bed; an inlet terminal of the blower fan is connected with an exhaust gas chimney of a kiln head or a kiln end of the cement kiln by pipelines, an output terminal of the blower fan is connected with a hot air inlet of material drying bed by pipelines; an outlet of the material drying bed is connected with an inlet of the feeding bucket, an outlet of the feeding bucket is connected with theweigher by the first conveyer, the magnetic separator is arranged on the first conveyer; the weigher is connected with an inlets of the decomposing furnace by the second conveyer, an outlet of the conveyer pipe is connected with an input of the decomposing furnace of the cement kiln. The system realizes safe, harmless, recycling, energy saving disposal and utilization of the floater.

Owner:华新环境工程有限公司

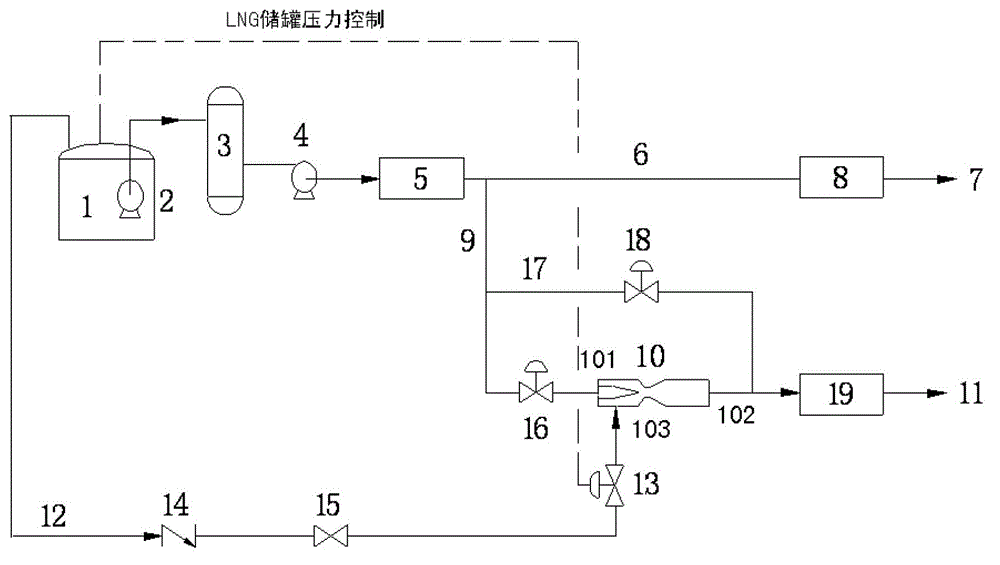

An energy-saving treatment system for evaporated gas in lng receiving station

ActiveCN103225739BEnergy saving treatmentRealize energy-saving processingContainer filling methodsContainer discharging methodsShortest distanceEngineering

The invention relates to an energy-saving processing system for vapor of an LNG receiving station. A high pressure LNG transmission branch is separated from a high pressure LNG outer transmission line of an existing natural gas transmission system of the LNG receiving station; the output end of the high pressure LNG transmission branch is connected with the input end of a gas-gas ejector mixer; the output end of the gas-gas ejector mixer is connected with the input end of a short distance direct sending pipe of a natural gas user; the gas-gas ejector mixer is also provided with a low pressure suction inlet; the low pressure suction inlet is connected with the output end of a vapor-discharging total pipe of an LNG storage tank; and the vapor-discharging total pipe is provided with a vapor flow control valve that can be adjusted according to pressure conditions of the LNG storage tank. Low pressure boil-off gas discharged by cooling the LNG storage tank is absorbed by using the pressure energy of the output high temperature LNG; full mix and energy exchange between the high pressure LNG and the low pressure boil-off gas are completed in the gas-gas ejector mixer; the mixed gas is output to meet requirements of users of medium-high pressure natural gas. The energy-saving processing system is suitable for vapor treatment of large and medium LNG receiving stations with different gas state outer transportation pressure requirements.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A manganese-oxygen composite material that efficiently removes vocs and its preparation method and application

ActiveCN109225205BEasy to prepareLow costGas treatmentDispersed particle separationPtru catalystCarbon nanotube

The invention discloses a manganese-oxygen composite material for efficiently removing VOCs, a preparation method and application thereof. The specific steps of the preparation method are as follows: the manganese-oxygen composite material doped with Mg and supported on carbon nanotubes prepared by the hydrothermal method is mixed with quartz sand, put into a microwave device, and VOCs gas is introduced , for the removal reaction. Among them, the manganese-oxygen composite material is not only doped with Mg but also supported on carbon nanotubes. The invention has the advantages of fast catalytic rate, high catalytic efficiency, low catalyst cost, simple catalyst synthesis method, strong catalyst stability, no secondary pollution and no need for reprocessing.

Owner:SOUTH CHINA UNIV OF TECH

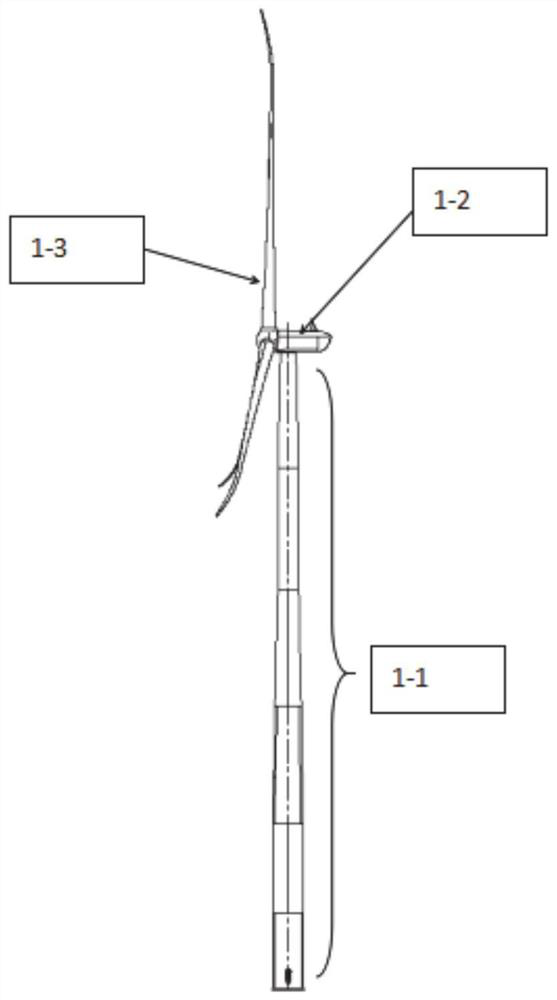

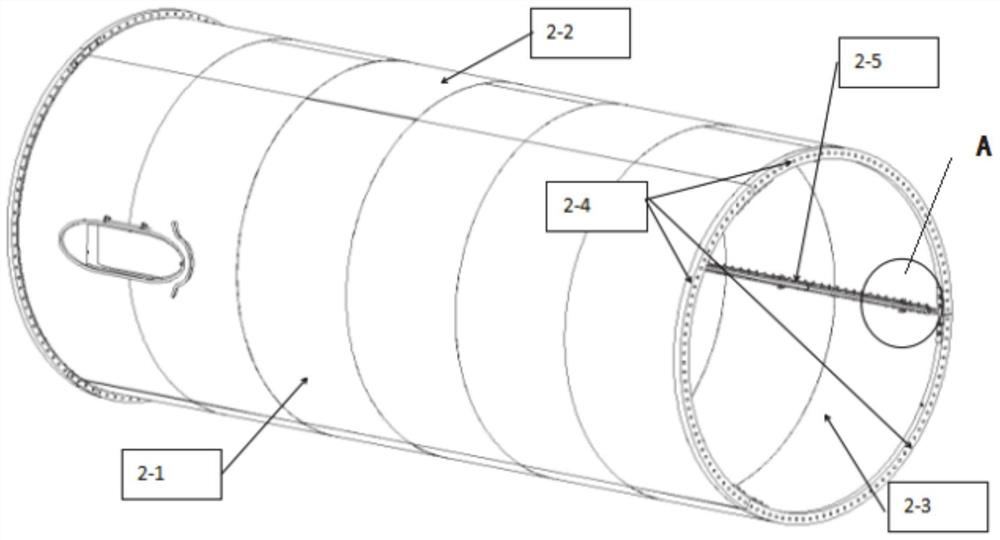

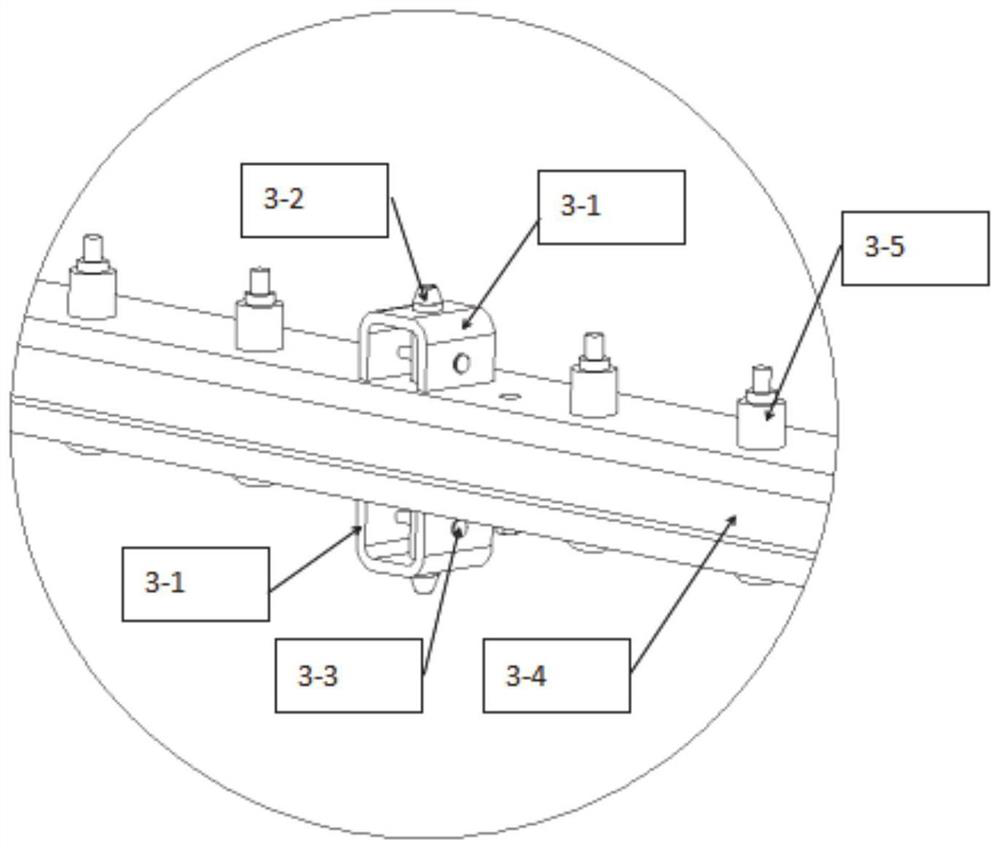

Sheet-mounted tower, manufacturing and mounting method and wind turbine generator

PendingCN112879233AOptimize geometryEliminate micro cracksFinal product manufactureWind motor assemblyEngineeringManufacturing engineering

The invention provides a sheet-mounted tower, a manufacturing and mounting method and a wind turbine generator. The sheet-mounted tower comprises at least one sheet-mounted shell ring, the sheet-mounted shell ring comprises a plurality of sheet bodies and positioning connecting structures, and the plurality of sheet bodies are connected through the positioning connecting structures; and a plurality of sheet-mounted shell rings are arranged, and the sheet-mounted shell rings are connected through flanges. The tower of which the diameter exceeds the transportation size requirement is longitudinally cut to form three or more parts, so that the transportation size requirement is met, the problem that the connection structure of tower sheet bodies is unreasonable in arrangement is solved, and the problems of inaccurate positioning and difficult connection during sheet body assembly, inclination and non-uniform stress of a tower drum caused by sheet body dislocation, damage to electrical equipment caused by gap water leakage, tedious installation caused by diversity of accessories and the like are solved.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

System for comprehensive utilization of floater pretreatment and cement kiln

The invention relates to a system for comprehensive utilization of floater pretreatment and a cement kiln. The invention relates to the system for comprehensive utilization of floater pretreatment and the cement kiln, which comprises a crusher, a screening machine, a material drying bed, a blower fan, a feeding bucket, a first conveyer, a magnetic separator, a weigher and a second conveyer; an outlet of the crusher is connected with an inlet of the screening machine by a conveying apparatus, an outlet of the screening machine for a qualified product is connected with the inlet of the material drying bed; an inlet terminal of the blower fan is connected with an exhaust gas chimney of a kiln head or a kiln end of the cement kiln by pipelines, an output terminal of the blower fan is connected with a hot air inlet of material drying bed by pipelines; an outlet of the material drying bed is connected with an inlet of the feeding bucket, an outlet of the feeding bucket is connected with the weigher by the first conveyer, the magnetic separator is arranged on the first conveyer; the weigher is connected with an inlets of the decomposing furnace by the second conveyer, an outlet of the conveyer pipe is connected with an input of the decomposing furnace of the cement kiln. The system realizes safe, harmless, recycling, energy saving disposal and utilization of the floater.

Owner:华新环境工程有限公司

A device for the treatment of tail gas from the incineration of pesticide packaging waste

InactiveCN103406011BSolve the disadvantages of large lossesReduce lossesDispersed particle separationPesticideExhaust gas

The invention discloses equipment for treating burning tail gas of pesticide package waste. The equipment comprises an atomizing nozzle, a venturi tube mixer, a barrel and a cone, wherein the venturi tube mixer is vertically arranged; an upper air inlet end of the venturi tube mixer is connected with a smoke pipeline; the atomizing nozzle for atomizing alkali liquor is arranged at a central position of the smoke pipeline in front of the upper air inlet of the venturi tube mixer; the lower part of the venturi tube mixer is arranged in the barrel and is positioned at a central position of the barrel; the upper end of the barrel is closed; the upper part of the barrel is provided with a gas outlet; the lower end of the barrel is connected with the cone.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA +1

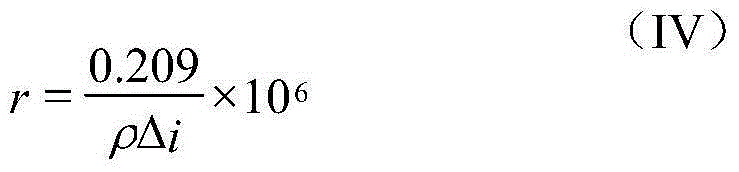

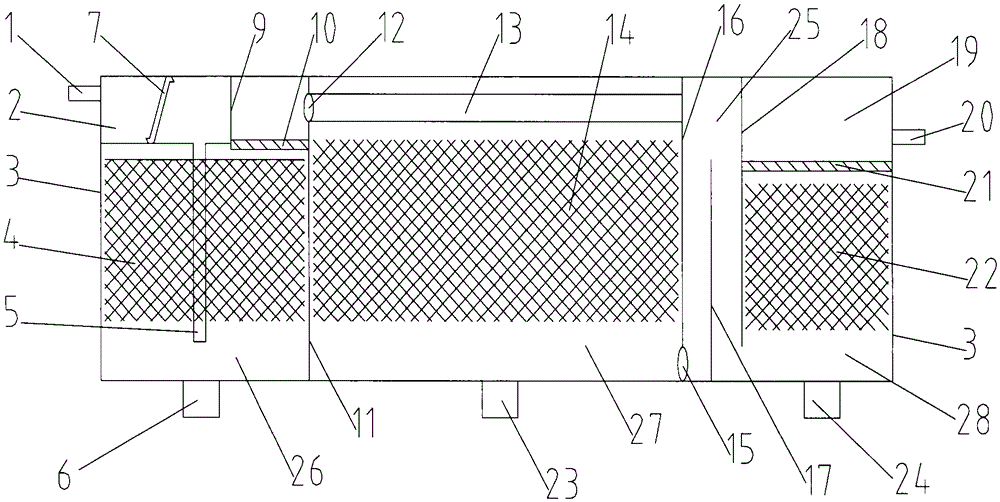

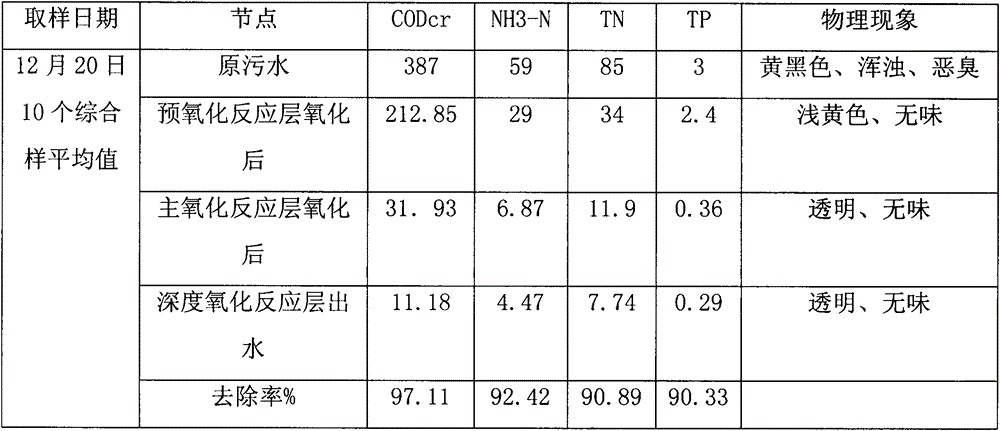

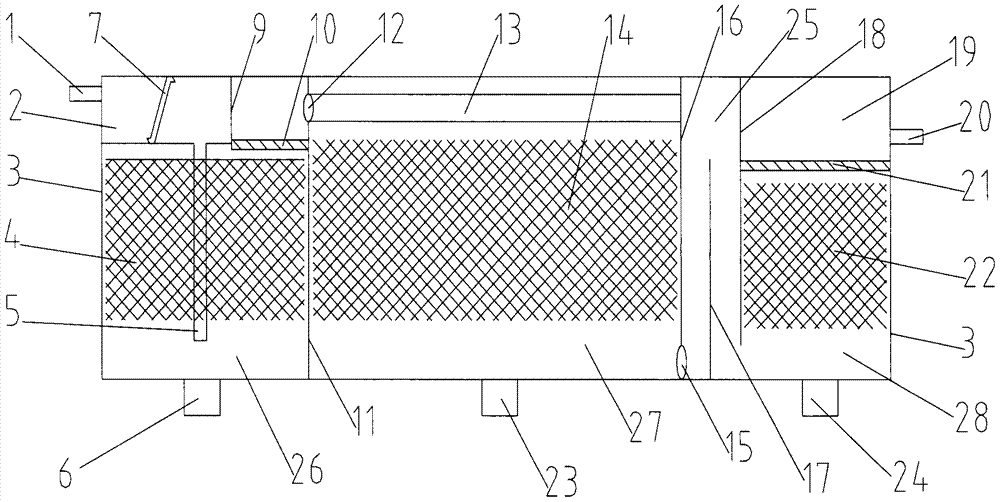

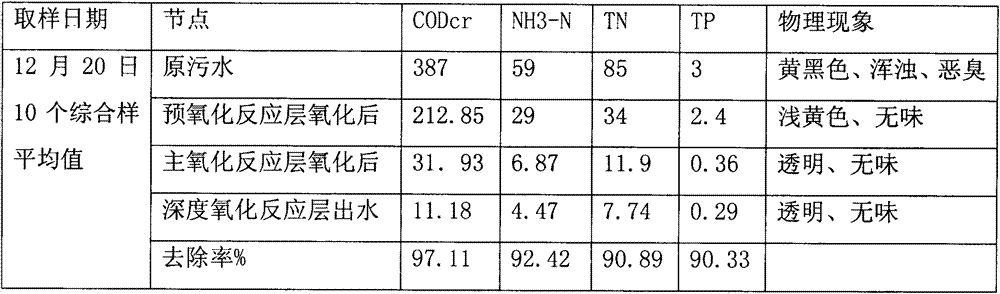

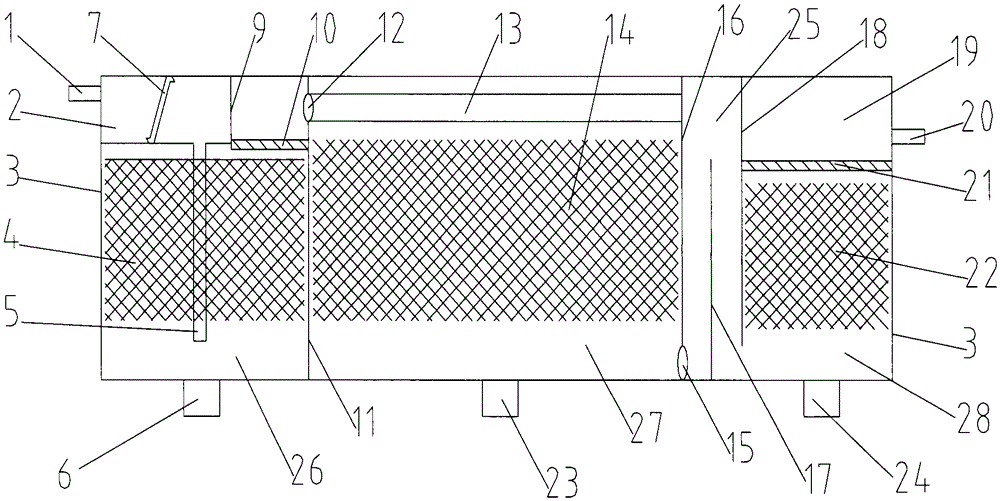

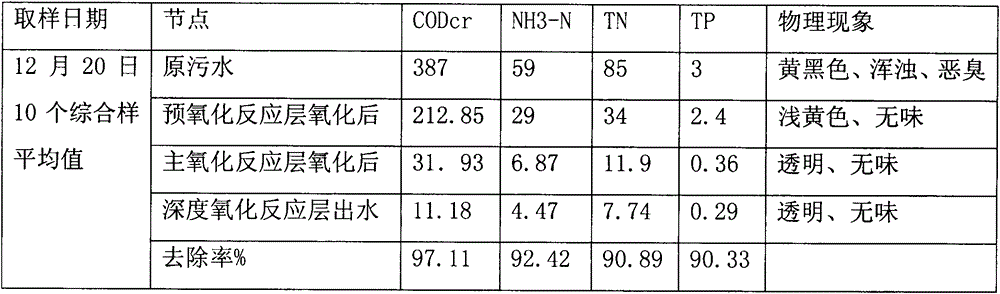

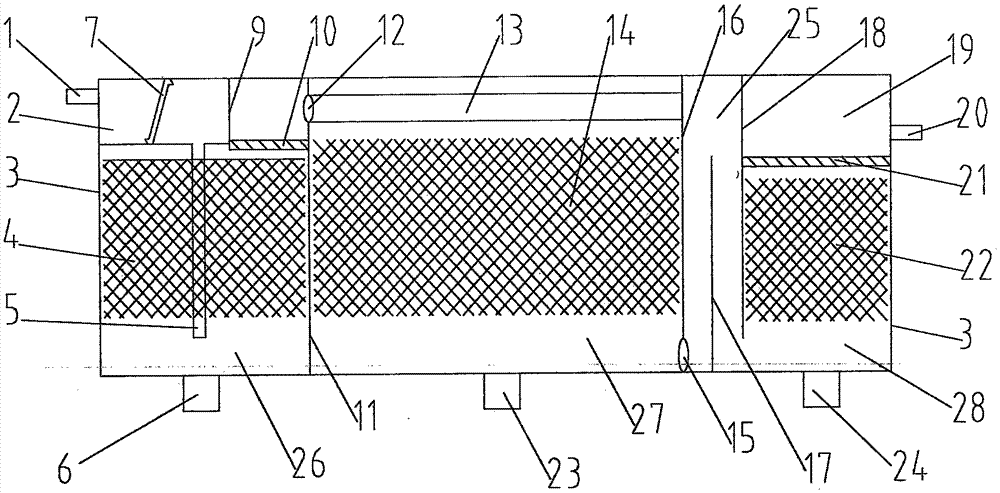

New wastewater treatment micro-power oxidation reactor

ActiveCN105384283AReduce energy consumptionLow clearance operationWater treatment parameter controlTreatment involving filtrationReaction layerDecomposition

The present invention relates to a wastewater direct oxidation treatment reactor, and especially discloses a new wastewater treatment micro-power oxidation reactor, from the perspective of the material science on the basis of hydrodynamic principle combined with electrochemistry, a huge-area particle catalytic reaction layer is prepared by surface finishing modification and sintering of cheap charcoal as a carrier, and the huge-area particle catalytic reaction layer is respectively filled into a pre-oxidation chamber, a main oxidation reactor and a deep oxidation chamber for three-stage oxidation decomposition. The new wastewater treatment micro-power oxidation reactor can immediately start and stop for wastewater treatment aiming at the special conditions of large temperature difference caused by seasonal climate changes and unstable water amount, and the new wastewater treatment micro-power oxidation reactor can achieve low-power gap-type operation, and high-efficiency energy-saving and effective treatment so as to achieve the purpose of protecting the environment.

Owner:中科鑫水源江苏环境科技有限公司

An Improved Microdynamic Oxidation Reactor for Sewage Treatment

InactiveCN105481139BReduce energy consumptionLow clearance operationWater treatment parameter controlTreatment involving filtrationDecompositionElectrochemistry

The invention relates to a reactor for direct oxidation treatment of sewage, especially an improved microdynamic oxidation reactor for sewage treatment. Bamboo charcoal is used as the carrier, modified by surface modification, and sintered to prepare a large-area particle catalytic reaction layer, which is respectively loaded into the pre-oxidation chamber, main oxidation chamber and deep oxidation chamber of the oxidation reactor for three-stage oxidation treatment and decomposition. The oxidation reactor of the present invention is aimed at the special conditions of large temperature difference in seasonal climate changes and unstable water volume, which can be immediately opened and closed to treat sewage. Using this technical device can realize low energy consumption and intermittent operation, and achieve effective treatment with high efficiency and energy saving. So as to achieve the purpose of protecting the environment.

Owner:湖南清渠生态农业股份有限公司

High-efficiency and energy-saving high-concentration sugarcane sugar production wastewater treatment process

PendingCN112876009AEnergy-saving and efficient processingEnergy saving treatmentWater contaminantsWater aerationSludgeAnaerobic reactor

The invention discloses an efficient and energy-saving treatment process for high-concentration sugarcane sugar production wastewater. The sugar production wastewater treatment process mainly comprises the following steps: (1) filtering out large-particle suspended solids and floating objects from sugarcane sugar production wastewater through a grating, adjusting the pH value to 7.0-7.5 by using sodium hydroxide powder, and carrying out adsorption treatment by using modified zeolite -Fe3O4 particles so as to obtain pretreated sugar production wastewater; (2) enabling the pretreated sugar production wastewater to sequentially enter an IC anaerobic reactor, an anoxic tank and a two-stage aerobic tank, and carrying out anaerobic and aerobic biochemical treatment to remove nitrogen and phosphorus in the wastewater; and (3) enabling effluent of the aerobic tank to enter a secondary sedimentation tank, carrying out mud-water separation, enabling separated water to enter a clean water tank to be discharged, enabling the separated sludge to enter a sludge return well, and subjecting the sludge in the sludge return well to concentration, dehydration and drying. The sugar production wastewater treated by the process is low in content of organic matters, suspended matters, nitrogen and phosphorus, and the method is high in wastewater treatment efficiency, low in process energy consumption and environmentally friendly.

Owner:DONGGUAN UNIV OF TECH

Improved micro power oxidation reactor for sewage treatment

InactiveCN105481139ABreakthrough investment is expensiveBreakout feeWater treatment parameter controlTreatment involving filtrationThree levelReaction layer

The invention relates to a reactor for directly performing oxidation treatment on sewage, in particular to an improved micro power oxidation reactor for sewage treatment. The reactor starts from the material science, huge-area particle catalytic reaction layers are prepared by surface finish modification and sintering by utilizing low-cost bamboo charcoal as a carrier, and are filled into a pre-oxidation chamber, a main oxidation chamber and a deep oxidation chamber of the oxidation reactor respectively, so as to undergo three-level oxidation treatment decomposition. According to the special conditions of large seasonal climate temperature difference and instable water volume, the oxidation reactor can be started and shut down in real time to treat sewage, the low-energy-consumption gap type running can be performed by using the technologic device, efficient and energy-saving effective treatment is achieved, and thus the goal of environmental protection is achieved.

Owner:湖南清渠生态农业股份有限公司

Micro-dynamic oxidation reactor applicable to sewage treatment

InactiveCN106892510AReduce energy consumptionEnergy saving treatmentWater treatment parameter controlTreatment involving filtrationWater dynamicsThree level

The invention relates to a reactor for direct oxidation treatment of sewage, especially a microdynamic oxidation reactor suitable for sewage treatment. Bamboo charcoal is used as the carrier, modified by surface modification, and sintered to prepare a huge area of particle catalytic reaction layer, which is respectively loaded into the pre-oxidation chamber, main oxidation chamber and deep oxidation chamber of the oxidation reactor for three-stage oxidation treatment and decomposition. The oxidation reactor of the present invention is aimed at the special conditions of large temperature difference in seasonal climate changes and unstable water volume, which can be immediately opened and closed to treat sewage. Using this technical device can realize low energy consumption and intermittent operation, and achieve effective treatment with high efficiency and energy saving. So as to achieve the purpose of protecting the environment.

Owner:北京浩瀚中清科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com