All-solid-waste ultra-high-performance geopolymer concrete and preparation method thereof

An ultra-high performance, geopolymer technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., which can solve the problem of increasing the steps and difficulty of preparation, increasing cost and energy consumption, and poor tensile and bending resistance and other problems, to achieve the effect of superior bonding performance, improved sustainability, and reduced production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

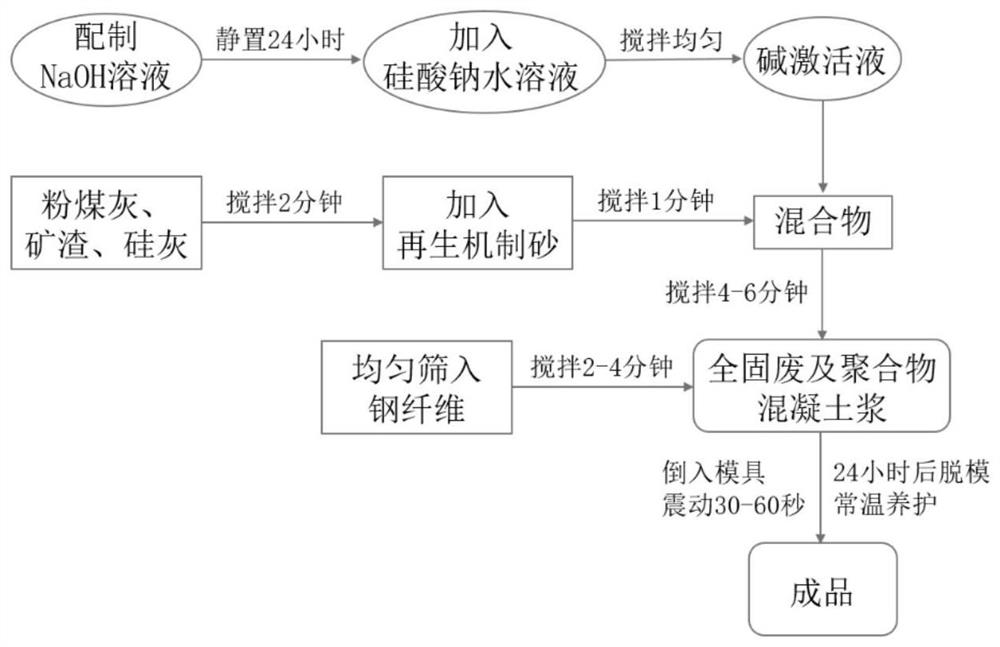

[0049] The schematic diagram of the preparation process of all solid waste ultra-high performance geopolymer concrete in this example is shown in figure 2 ;

[0050] In terms of parts by mass, the following raw materials are taken: 20 parts of aggregate, 80 parts of gelling material (in terms of mass percentage, 30% of fly ash, 60% of slag, 10% of silica fume), carbon nanotubes (aggregate, gelling 2% of the total volume of the material), steel fiber (1% of the total volume of aggregate and cementitious material); alkali activator (the ratio of the total mass of aggregate, cementitious material and alkali activator is 1kg: 400mL);

[0051] The preparation process is as follows:

[0052] (1) Add fly ash, slag, silica fume, and carbon nanotubes into the mixer, stir at a low speed (300 rpm) for 2 minutes, then add aggregate and stir for 1 minute to obtain a solid powder mixture.

[0053] (2) Slowly add the base activator into the mixture, while stirring evenly for 5 minutes.

...

Embodiment 2

[0058] With embodiment 1, difference is, raw material: 20 parts of aggregates, 80 parts of cementitious materials (in terms of mass percentage, fly ash 30%, slag 60%, silica fume 10%), carbon nanotubes (aggregate, gelled 2% of the total volume of the material), steel fiber (2% of the total volume of aggregate and cementitious material); alkali activator (the ratio of aggregate, cementitious material total mass and alkali activator is 1kg: 400mL).

[0059] After demoulding, it was cured for 14 days in an indoor environment with normal temperature and pressure and normal humidity (temperature 25°C, humidity 70%), and then a concrete sample press was used to conduct a compressive test. The results showed that the compressive strength of the sample was 79MPa .

Embodiment 3

[0061] With embodiment 1, difference is, raw material: 20 parts of aggregates, 80 parts of cementitious materials (in terms of mass percentage, fly ash 30%, slag 60%, silica fume 10%), carbon nanotubes (aggregate, gelled 2% of the total volume of the material), steel fiber (3% of the total volume of aggregate and cementitious material); alkali activator (the ratio of the total mass of aggregate, cementitious material and alkali activator is 1kg: 400mL).

[0062] After demoulding, it was cured for 14 days in an indoor environment with normal temperature and pressure and normal humidity (temperature 25°C, humidity 70%), and then a concrete sample press was used to conduct a compressive test. The results showed that the compressive strength of the sample was 85MPa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com