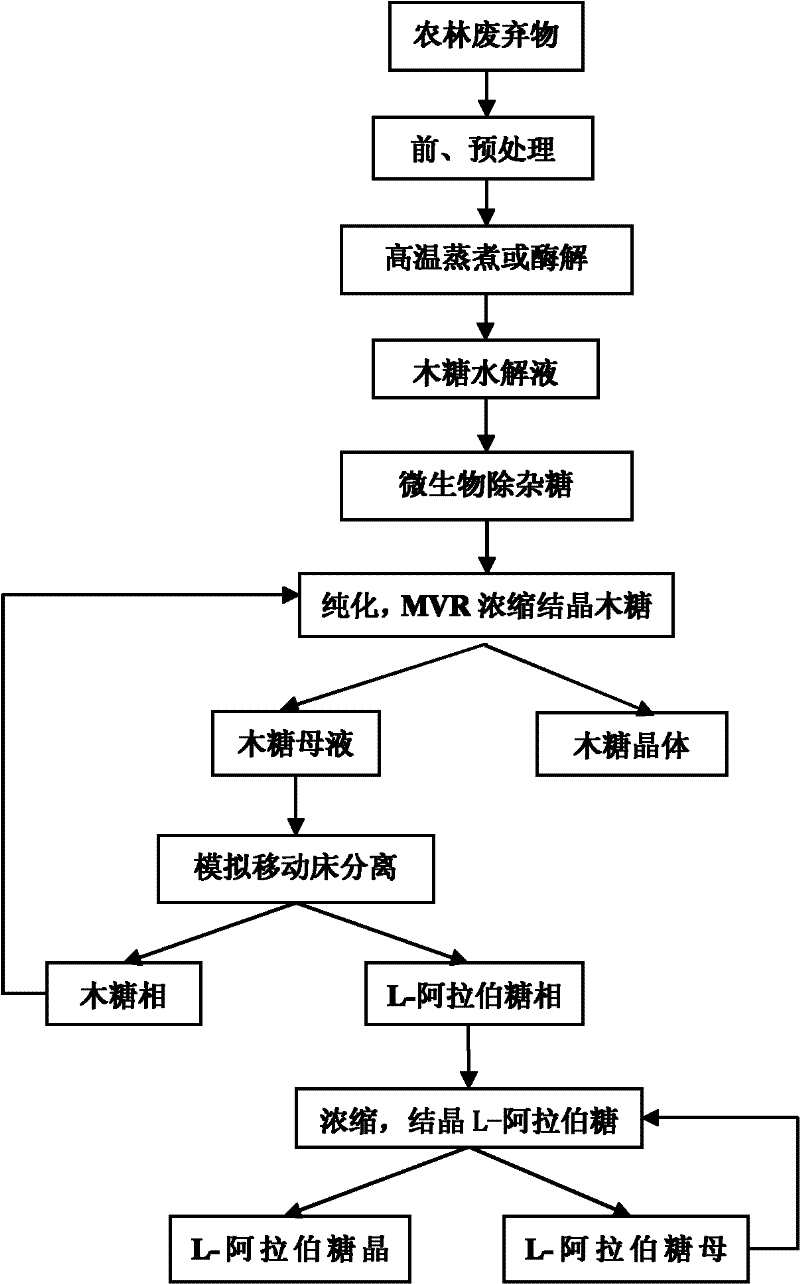

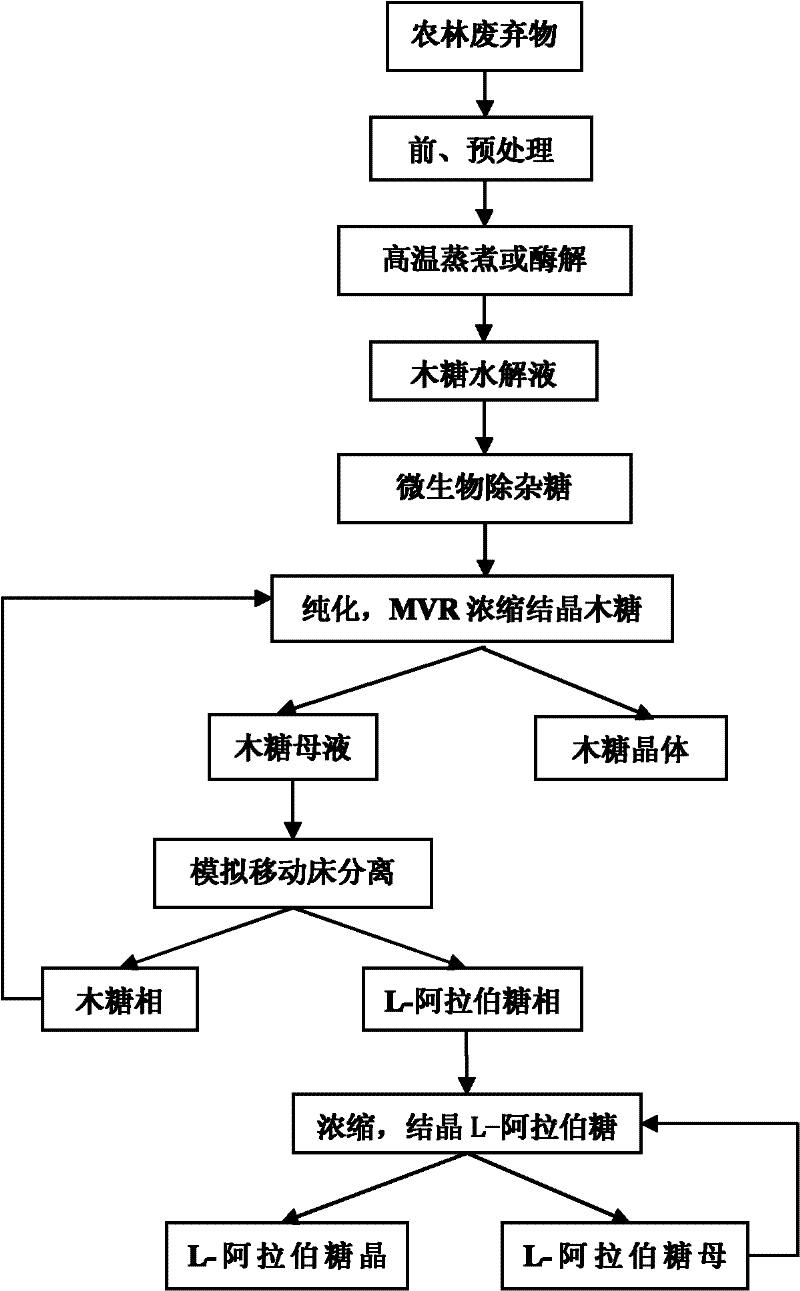

A clean and efficient production process for preparing xylose and l-arabinose

A kind of technology of arabinose and production process, which is applied in the field of clean and efficient preparation of xylose and L-arabinose production process, which can solve the problems of high osmotic pressure, heavy load, great influence of bacteria growth and removal of glucose, and achieve utilization The effect of high efficiency, increased yield, and full and reasonable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Pretreatment combined with high-temperature cooking or cooking combined with enzymatic hydrolysis to prepare xylose liquid

[0065]Choose agricultural and forestry waste cottonseed husks as raw materials. Cottonseed hull pretreatment includes three processes of raw material crushing, dust removal, and water washing. First, the acquired cottonseed hulls are crushed in a pulverizer and sieved into solid particles with a mesh size of 10 mesh. Then, the impurities in the cottonseed hull particles and the silt and dust on the surface layer are dedusted to reduce the burden of the subsequent process. Finally, the agricultural and forestry waste particles such as cottonseed hulls after dust removal are washed with water to remove some impurities such as protein, pigment, pectin, ash, tannin and tea in the fiber. The three-step process of pre-treatment is an important measure to improve the quality of later products and reduce costs.

[0066] The pretreated cottonseed hu...

Embodiment 2

[0082] (1) Pretreatment combined with high-temperature cooking or cooking combined with enzymatic hydrolysis to prepare xylose liquid

[0083] Choose agricultural and forestry waste cottonseed husks as raw materials. Cottonseed hull pretreatment includes three processes of raw material crushing, dust removal, and water washing. First, the purchased cottonseed hulls are crushed in a pulverizer and sieved into solid particles with a mesh size of 20 mesh. Then, the impurities in the cottonseed hull particles and the silt and dust on the surface layer are dedusted to reduce the burden of the subsequent process. Finally, the agricultural and forestry waste particles such as cottonseed hulls after dust removal are washed with water to remove some impurities such as protein, pigment, pectin, ash, tannin and tea in the fiber. The three-step process of pre-treatment is an important measure to improve the quality of later products and reduce costs.

[0084] The pretreated cottonseed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com