Sludge vaporizing furnace

A technology of sludge gasification and gasification furnace, applied in sludge treatment, pyrolysis treatment of sludge, water/sludge/sewage treatment, etc., to improve efficiency, high-efficiency sludge treatment, save dehydration equipment and gas cooling The effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

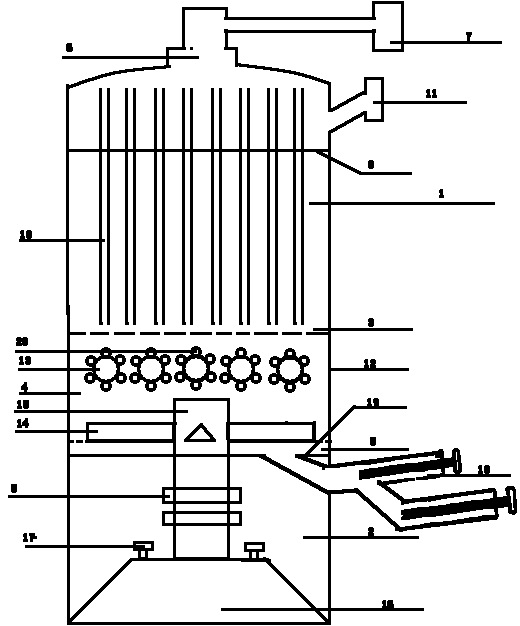

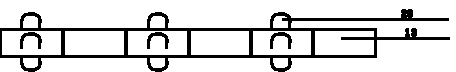

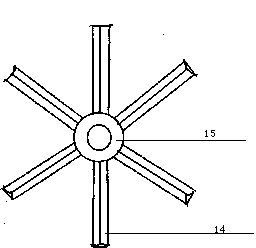

[0022] Such as figure 1 As shown, the gasification furnace is divided into upper and lower parts of the gasification chamber 1 and the motor chamber 2 by the furnace floor 19 with through holes. The gasification chamber 1 is divided into a drying area 3 and a gasification area from top to bottom. Zone 4, high temperature zone 5; the top of the drying zone 3 is provided with an air extraction hole 6, which is connected to the external air extraction system 7; the upper part of the drying area 3 is fixed with a sludge baffle plate 8, and the sludge The baffle plate 8 is provided with a plurality of pipe holes 9 such as Figure 4 As shown, the ventilation pipe 10 in the furnace passes through the pipe hole 9 on the sludge baffle 8 and runs through the entire drying area 3, and is supported by the sludge baffle 8. The diameter of the pipe hole 9 is slightly larger than that of the ventilation pipe 10 in the furnace. outer diameter; also includes a feed port 11, the feed port 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com