Sheet-mounted tower, manufacturing and mounting method and wind turbine generator

A piece-mounted and tower-mounted technology, applied in the fields of manufacturing and installation methods and wind turbines, piece-mounted towers, and accessory modules, can solve electrical equipment damage, uneven force, and affect the load-bearing capacity of the tower and other problems, to achieve good fatigue resistance, eliminate micro-cracks, and improve the effect of geometric shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

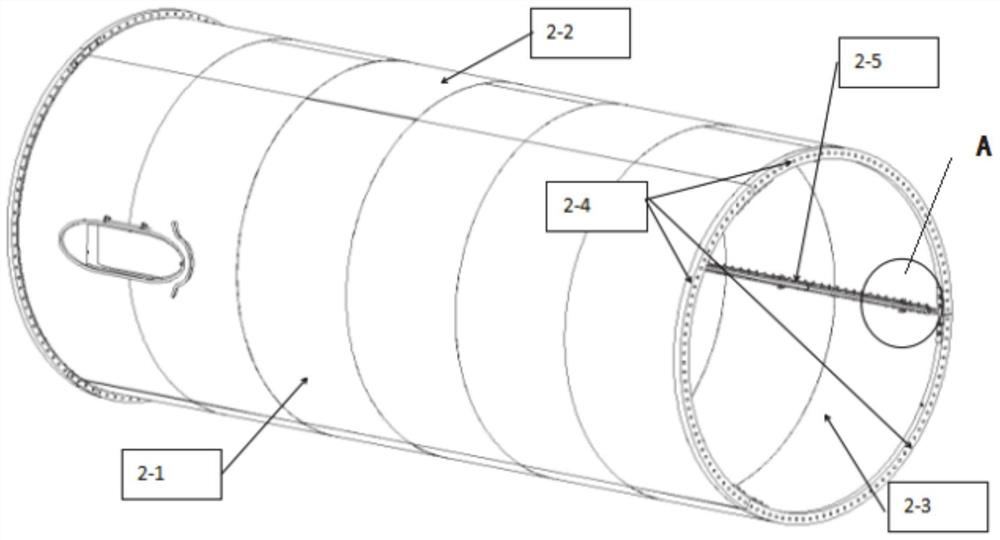

[0043] Such as figure 2 As shown, a sheet-mounted tower includes at least one sheet-mounted barrel section, the sheet-mounted barrel section includes a plurality of sheet bodies and a positioning connection structure, and the plurality of sheet bodies are connected through a positioning connection structure; if There are multiple chip-mounted barrel sections, and the chip-mounted barrel sections are connected by flanges.

[0044] Further, the number of sheets of the sheet-mounted barrel section can be designed as three or more sheets according to requirements. As one of the embodiments of the present application, the number of sheets is three, respectively the first sheet, second sheet and third sheet.

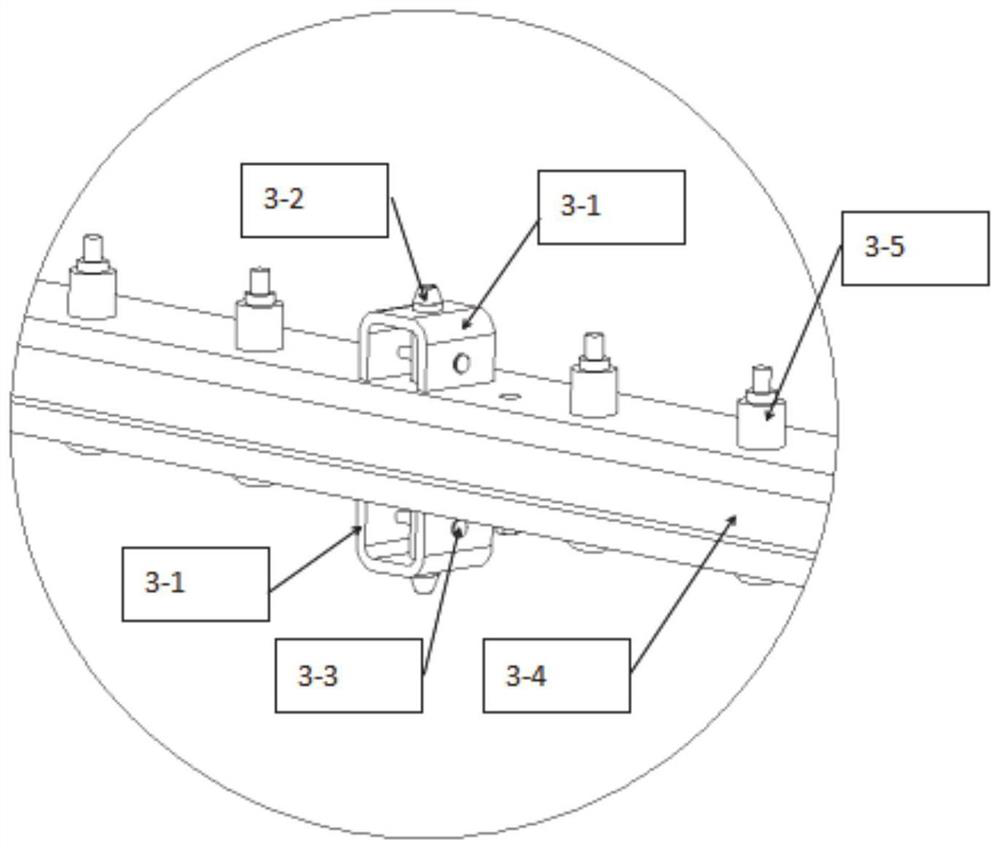

[0045] Further, the positioning connection structure includes maintenance-free high-strength fasteners, and the sheets are connected by maintenance-free high-strength fasteners;

[0046] Further, the positioning connection structure includes arc-shaped steel plates, split-t...

Embodiment 2

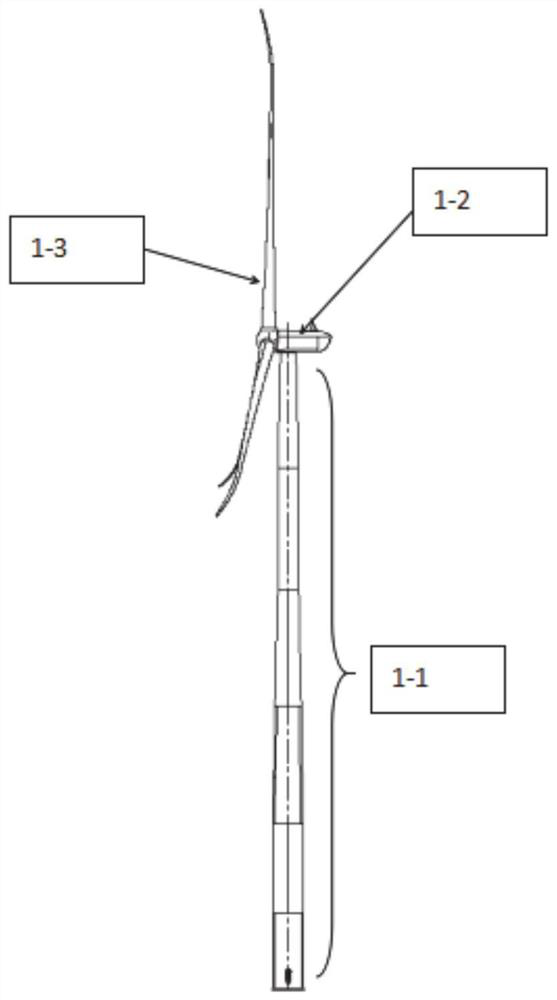

[0056] Such as figure 1 As shown, the present disclosure provides a wind power generating set, including the sheet-mounted tower as described in the above embodiments, and also includes a nacelle system and a wind turbine system connected to the sheet-mounted tower;

[0057] The wind turbine system and nacelle system are customized according to the needs of the wind farm project to meet the power generation requirements of the wind farm project. The chip-mounted tower is designed according to the load data, height requirements, transportation requirements and other conditions of the wind farm project, and the towers exceeding the transportation size limit are determined to be chip-mounted to meet the safety and reliability design requirements of the unit, and further meet the shipping requirements.

[0058] Specifically, as one of the implementations, the wind turbine system includes a hub, blades and a drive shaft, the hub is connected to the blades; one end of the drive sha...

Embodiment 3

[0061] A method for manufacturing a sheet-mounted tower, comprising:

[0062] Obtain a steel plate with a set size, and form a cylindrical structure after processing;

[0063] Install the flanges at both ends of the cylindrical structure to form a piece-mounted barrel section;

[0064] Carry out the cutting of the set line for the piece-packed barrel section, and cut it into multiple pieces;

[0065] A plurality of pieces are assembled to form a piece-mounted tower.

[0066] Specifically, after the steel plate is cut according to the size, use the steel plate rolling equipment to roll the steel plate into a circle;

[0067] Further, the butt joints of the coiled steel plates are automatically welded by submerged arc to form segments;

[0068] Further, use the steel plate rolling equipment to correct the roundness of the segment;

[0069] Further, the segments are butt-welded in a circumferential direction to form a cylindrical structure;

[0070] Further, using fixed tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com