An energy-saving treatment system for evaporated gas in lng receiving station

A treatment system and boil-off gas technology, applied in the field of boil-off gas treatment system of LNG receiving station, can solve the problems of cumbersome operation, complex process, high energy consumption, etc., and achieve the effect of simple equipment, high flexibility of control and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

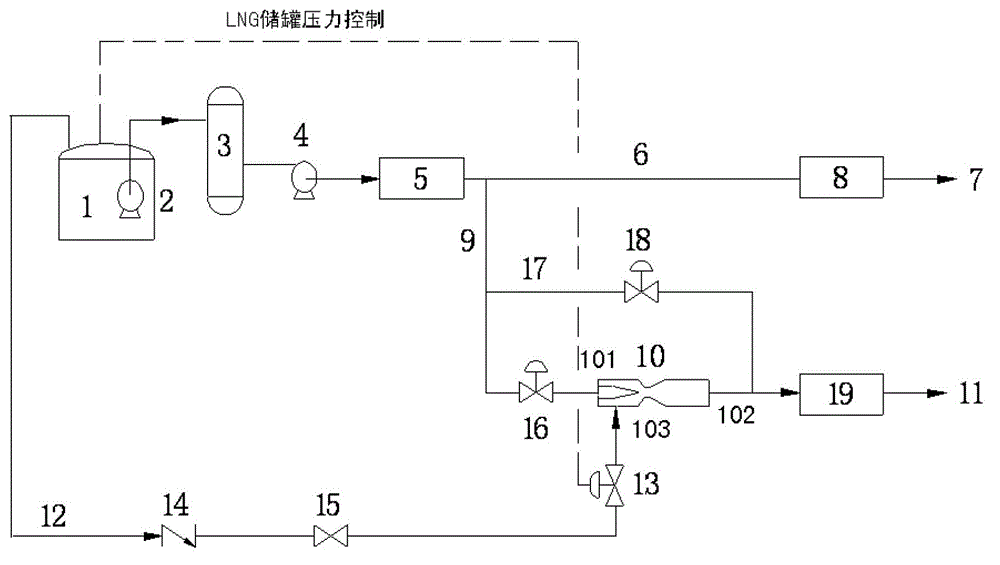

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0013] In the present invention, a high-pressure natural gas export branch is separated from the high-pressure natural gas export pipeline of the existing natural gas export system of the LNG receiving station, and a gas-gas injector mixer is arranged on the high-pressure natural gas export branch to utilize the high-pressure natural gas exported Its own pressure can absorb the low-pressure boil-off gas discharged from the LNG storage tank, and complete the full mixing and energy exchange of high-pressure natural gas and low-pressure boil-off gas in the gas-gas injection mixer. The mixed gas is medium-high pressure natural gas, which can be used by natural gas users Short-distance direct transmission pipelines to medium and high-pressure natural gas users.

[0014] Such as figure 1 As shown, the composition structure of the system of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com