An Improved Microdynamic Oxidation Reactor for Sewage Treatment

An oxidation reactor and sewage treatment technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problems of high operating cost, large equipment investment, high energy consumption, etc. Effective treatment, low energy consumption, energy-saving treatment effect

Inactive Publication Date: 2017-10-03

湖南清渠生态农业股份有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These methods have been improved by scientific and technological personnel for decades, and there are always certain limitations. When using microbial cultivation and domestication to treat sewage, the biggest technical bottleneck is the impact of changes in the concentration of pollutants in the influent and changes in the external temperature, resulting in poor quality of the effluent. Stablize

Large equipment investment, high energy consumption, and high operating costs are also another factor that makes it difficult to break through the technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

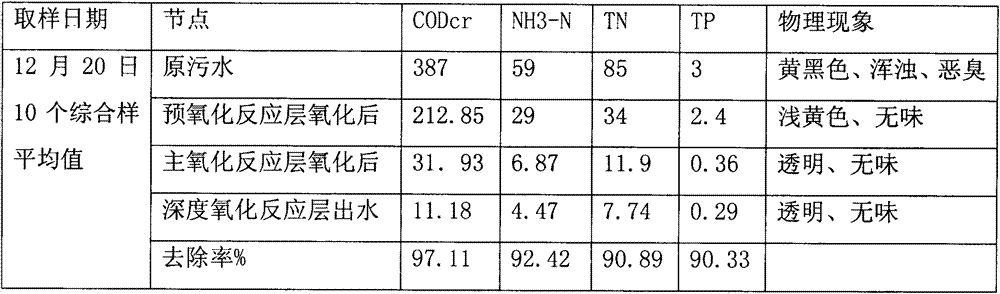

[0034] Sewage nature: domestic sewage

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

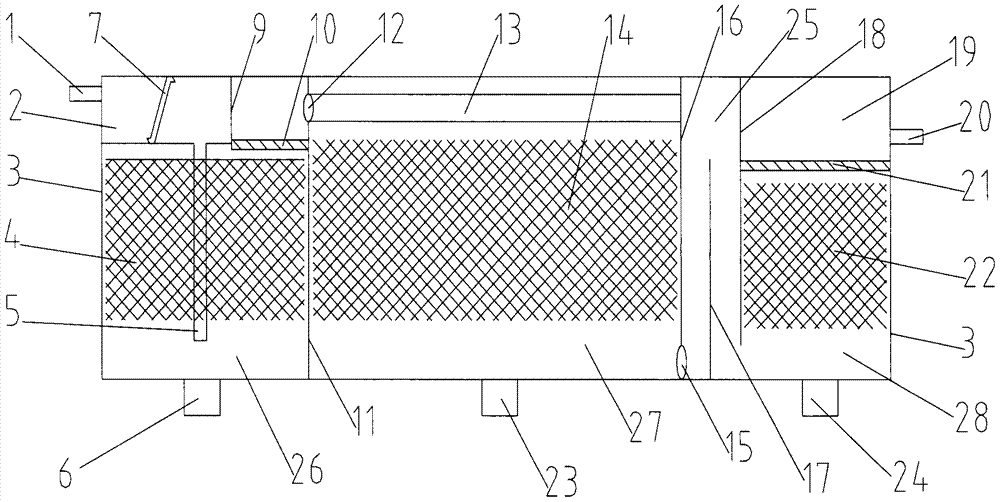

The invention relates to a reactor for direct oxidation treatment of sewage, especially an improved microdynamic oxidation reactor for sewage treatment. Bamboo charcoal is used as the carrier, modified by surface modification, and sintered to prepare a large-area particle catalytic reaction layer, which is respectively loaded into the pre-oxidation chamber, main oxidation chamber and deep oxidation chamber of the oxidation reactor for three-stage oxidation treatment and decomposition. The oxidation reactor of the present invention is aimed at the special conditions of large temperature difference in seasonal climate changes and unstable water volume, which can be immediately opened and closed to treat sewage. Using this technical device can realize low energy consumption and intermittent operation, and achieve effective treatment with high efficiency and energy saving. So as to achieve the purpose of protecting the environment.

Description

technical field [0001] The invention relates to an improved microdynamic oxidation reactor for sewage treatment. Background technique [0002] With the development of industrial society, a large amount of wastewater containing organic matter will be produced in the process of industrial production. If these wastewater is discharged directly without treatment, it will cause very serious harm to the environment. Therefore, the treatment of organic wastewater has become the current domestic and foreign environment. A difficult problem to be solved in the field of conservation technology. [0003] The relatively mature treatment technologies for sewage treatment at home and abroad are biological contact oxidation method, activated sludge method, and improved membrane treatment method. These methods have been improved by scientific and technological personnel for decades, and there are always certain limitations. When using microbial culture and domestication to treat sewage, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/04

CPCC02F1/001C02F1/725C02F9/00C02F2201/002C02F2209/40C02F2301/08

Inventor 欧阳志谦

Owner 湖南清渠生态农业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com