Energy-saving type garbage dry distillation gas preparation and gas power generation method

An energy-saving and waste-free technology, applied in the direction of solid waste removal, etc., can solve the problem of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

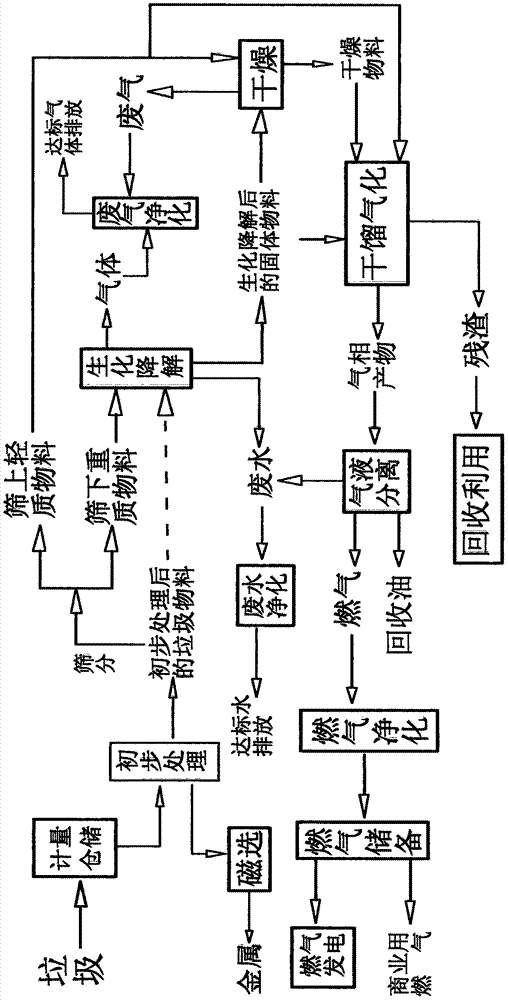

[0051] as attached figure 1 As shown, the specific steps are:

[0052] i) Pretreatment: Municipal domestic waste is transported by garbage vehicles, weighed by the ground scale and added to the garbage pool. The volume of the garbage pool is about 1000-2000m 3 , a grab crane is installed on the top of the garbage pool for stacking and feeding of garbage; first, the ferrous metal is separated by a magnetic separator, and then manually selected to remove large waste such as masonry, baskets, etc. Another harmless treatment; grab 1000KG of domestic garbage with a grab crane and move it into the bag breaking machine, and the garbage will be broken into bags, and the broken bags will fall into the conveyor and be transported to the drum screening machine for screening 203 kg (water content 9.7%, wt%) of garbage light materials such as waste plastics, paper scraps, cloth, ropes, etc. on the sieve of the sorting machine are collected and utilized, and melon and fruit peels, vegetabl...

Embodiment 2

[0092] as attached figure 1 As shown, the specific steps are:

[0093] i) pretreatment: same as the operation method of embodiment one; Obtain 203 kilograms (water content 9.7%, wt%) of the garbage light material on the sieve, 729 kilograms of garbage heavy material and stone and ironware 68kg under the sieve;

[0094] ii) Biochemical degradation: the same operation method as in Example 1, 729 kg of heavy material under the sieve obtained by pretreatment was subjected to fermentation treatment, and 208 kg of degradation products after fermentation were obtained;

[0095] iii) Retort gasification: adopt the equipment (downdraft gasifier) and operation of "A Pyrolysis Catalytic Gasifier for Domestic Garbage" ZL201320182361.3 authorized by the applicant, and use a reciprocating hydraulic press to convert the above i) 203 kg of light materials collected on the sieve and 208 kg of ii) collected fermentation degradation products are not dried and dehydrated, but are directly tran...

Embodiment 3

[0125] as attached figure 1 As shown, the specific steps are:

[0126] i) Pretreatment: 1000 kilograms of rural garbage (among them, 15 kilograms of waste plastics, accounting for 1.5%, wt%) is transported by garbage vehicles, manually removing large pieces of garbage, masonry and ironware in the garbage, and separating ironware by magnetic separation , and then use the knuckle crusher to shred the garbage into a size below 20 centimeters; the result is: 58 kilograms of stones and metals are separated, and 942 kilograms of other garbage after removing stones and ironware (including waste plastics) 15 kg), collect and reserve;

[0127] ii) Biochemical degradation:

[0128] The method is the same as that in Example 1. The 942 kilograms of garbage collected in the above i) pretreatment are added as fermentation materials into the fermentation equipment for biochemical degradation to carry out the fermentation treatment of biochemical degradation. Through the fermentation treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com