Falling film blow-off device with flash function

A falling film, functional technology, applied in flash evaporation, distillation separation, distillation adjustment/control, etc., can solve the problem of temperature rise of feed liquid, and achieve the effect of energy saving, simple design and reasonable structure in the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

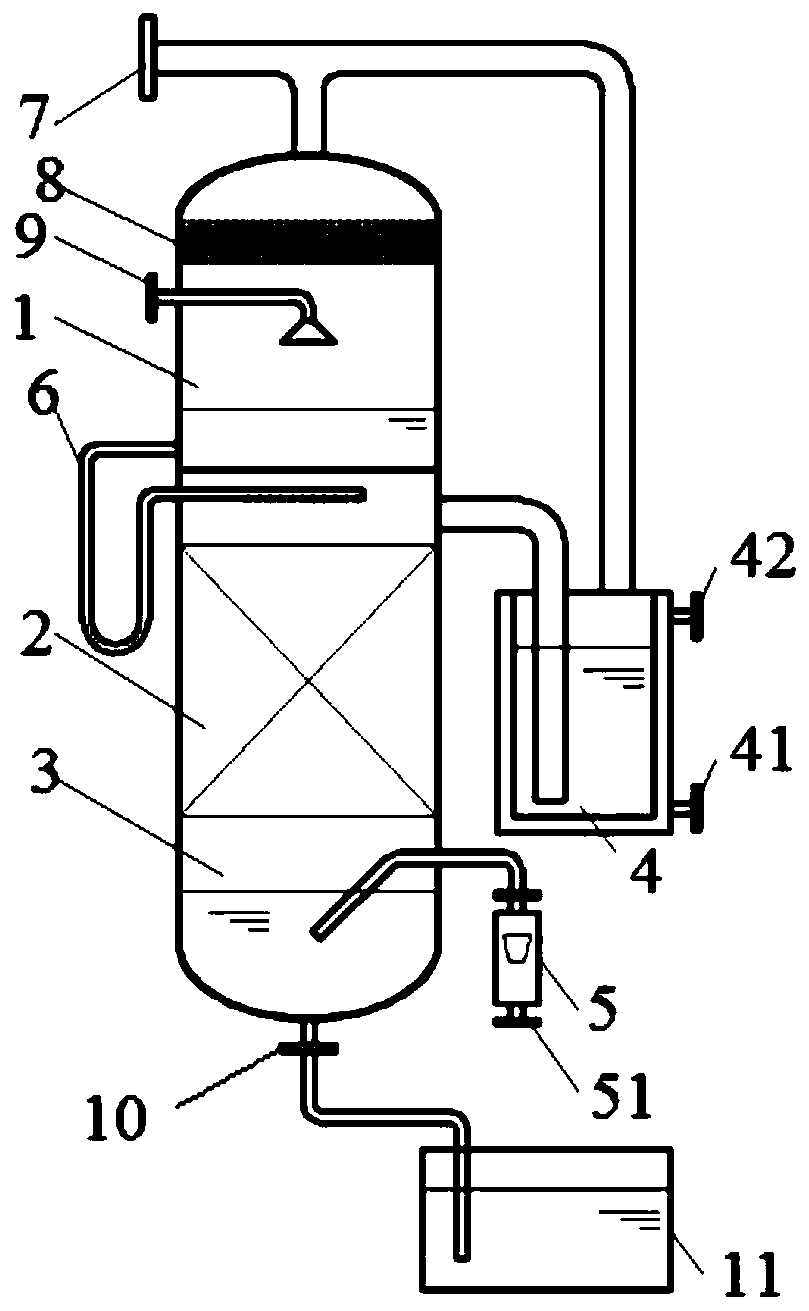

[0032] combine figure 1 As shown, a falling film blow-off device with a flash function in this embodiment. It includes a flash chamber 1, a falling film stripping tower 2, a stripping chamber 3 and a constant pressure cold well 4.

[0033] The saponification raffinate of vinylidene chloride containing 1836mg / L of halogenated hydrocarbons and a temperature of 65°C enters the flash chamber 1 through atomization from the feed port 9 of the flash chamber 1 for flash evaporation, and the gas phase outlet 7 is connected to a vacuum condensing system and finally to the exhaust gas disposal system.

[0034] After flash evaporation, the concentration of halogenated hydrocarbons in the feed liquid drops to 1020mg / L, and the temperature is 45°C. It enters the falling film stripping tower 2 by gravity through the U-shaped transfer pipe 6, and contacts with the stripping air entering from the lower part, and the halogenated hydrocarbons further transfer to the gas phase;

[0035] The st...

Embodiment 2

[0037] The present embodiment processing process is the same as embodiment 1, wherein difference is that the vacuum degree of flash chamber 1, the water seal temperature of constant pressure cold well 4 and the thickness values of defoaming wire mesh 8 are different, but they can all be equal To achieve the same effect as in the specific embodiment, Table 1 shows the values and results of the parameters in each embodiment in this embodiment.

[0038] Parameter value and result in the embodiment 2 of table 1

[0039] index Example 2-1 Example 2-2 Example 2-3 Example 2-4 Flash vacuum (MPa) 0.05 0.01 0.01 0.022 Cold well temperature (℃) 30 10 0 30 Feed halogenated hydrocarbon concentration mg / L 1990 1990 1860 1860 Thickness of defoaming screen 8 (mm) 500 100 100 300 Output halogenated hydrocarbon concentration mg / L 201 158 155 192

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com