System for comprehensive utilization of floater pretreatment and cement kiln

A technology of cement kiln and floating matter, which is applied in the field of floating matter pretreatment and cement kiln comprehensive utilization system, and can solve the problems of no floating matter in cement kiln, low thermal efficiency, insufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

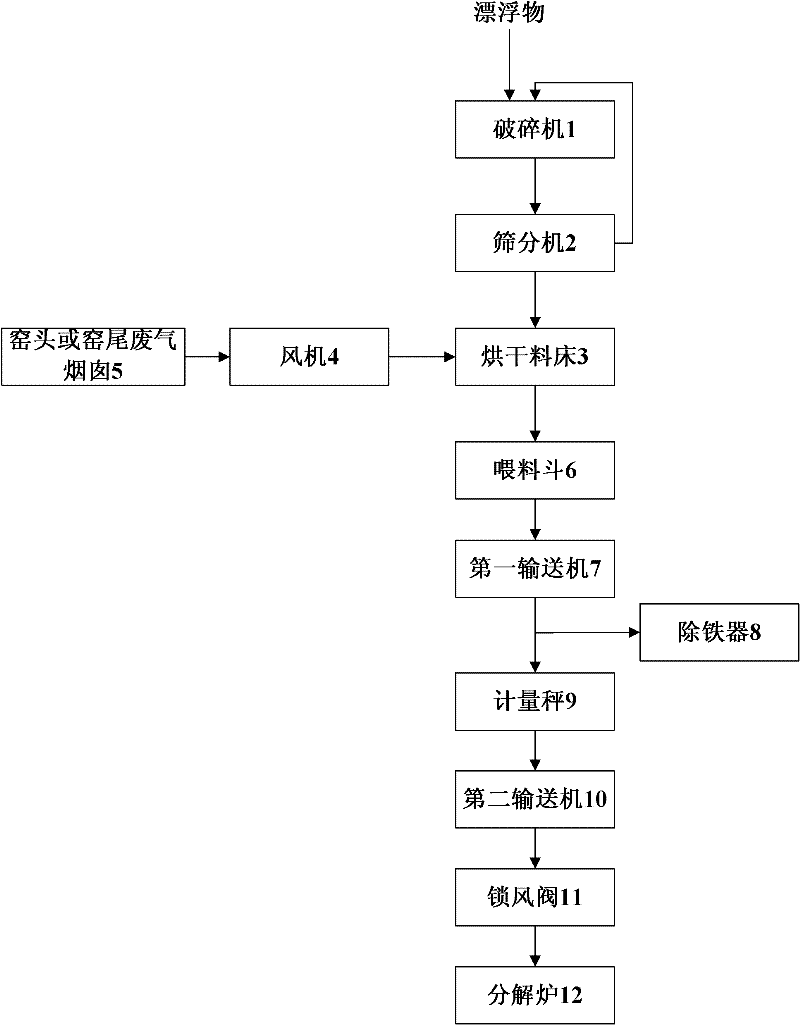

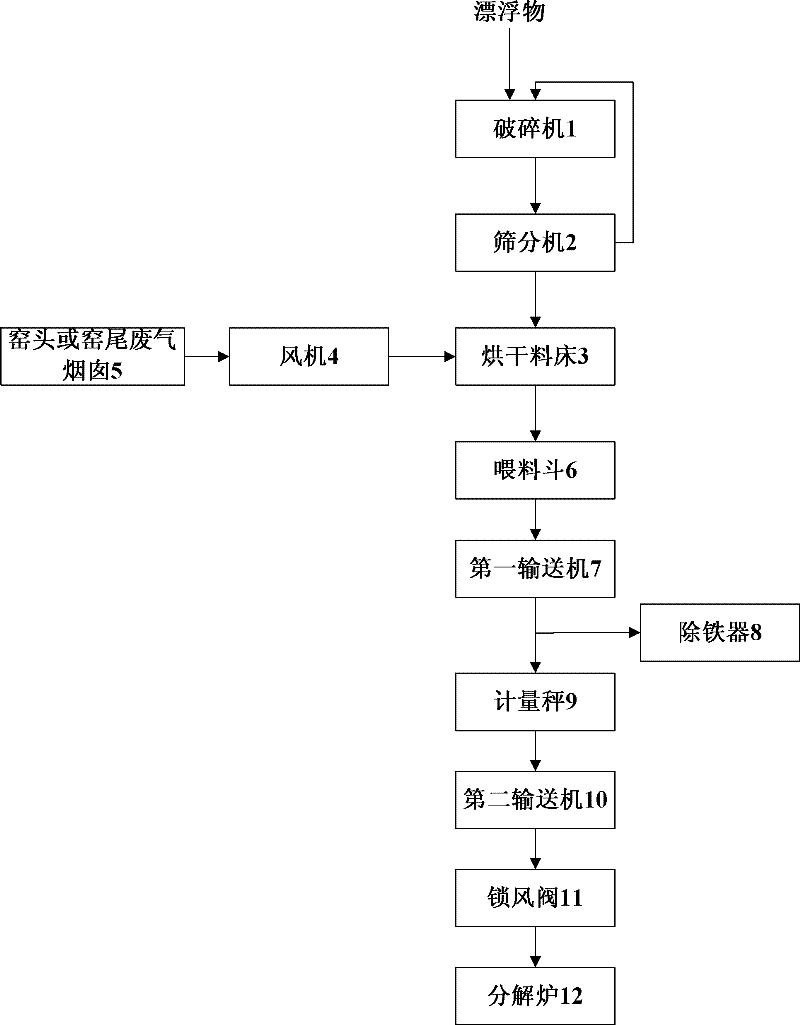

[0008] Such as figure 1 As shown, a floating matter pretreatment and cement kiln comprehensive utilization system includes a crusher 1, a screening machine 2, a drying material bed 3, a fan 4, a feeding hopper 6, a first conveyor 7, an iron remover 8, a metering Scale 9, second conveyor 10; the input port of crusher 1 receives floating objects, the output port of crusher 1 and the input port of screening machine 2 are connected by a conveying device, the output port of unqualified products of screening machine 2 is connected with the crushing The input port of machine 1 is connected by conveying device, the qualified product output port of screening machine 2 is connected with the input port of drying material bed 3; the input end of fan 4 is connected with the kiln head or kiln tail exhaust gas chimney 5 The output end of fan 4 is connected with the hot air input port of drying material bed 3 by pipeline; the output port of drying material bed 3 is connected with the input po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com