Bubbling cavitation method for degrading organic pollutants in wastewater

A technology for organic pollutants and wastewater, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of difficult to achieve industrialization, low degradation efficiency, lack of ultrasonic cavitation technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

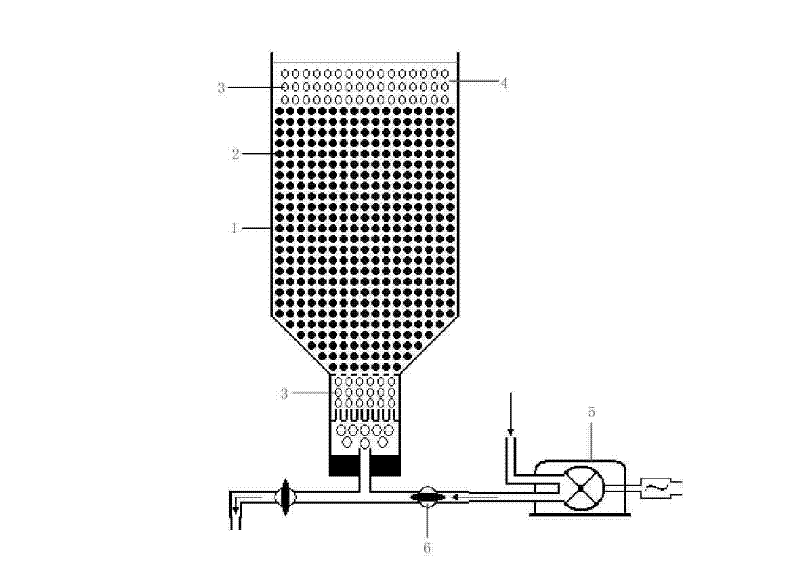

Image

Examples

Embodiment 1

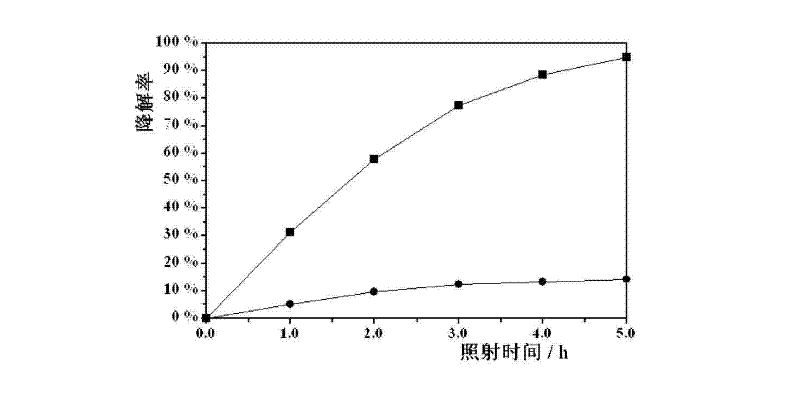

[0030] Example 1 Degradation of Organic Pollutants in Wastewater by Bubbling Cavitation——Effect of Bubbling Time on Degradation Rate

[0031] Proceed as follows:

[0032] 1) Glass beads with a diameter of 2.0-2.5 mm are added to the degrader, and the amount of glass beads added is three quarters of the volume of the degrader;

[0033] 2) Adjust the concentration of acid red B aqueous solution to 10 mg L -1 , the acidity is pH=6.0, add in the degrader, the addition is 3cm higher than the glass beads;

[0034] 3) Gas is introduced from the bottom of the degrader, and the gas flow rate is controlled at 4.5 L min -1 , react for 1 to 5 hours. Samples were taken at different times to measure the UV-vis spectrum, and the concentration of the acid red B aqueous solution was determined. Quantitative analysis was carried out by UV-vis spectrophotometry. A series of acid red B solutions were scanned by UV-vis spectrum to determine the wavelength of the maximum absorption peak (λ...

Embodiment 2

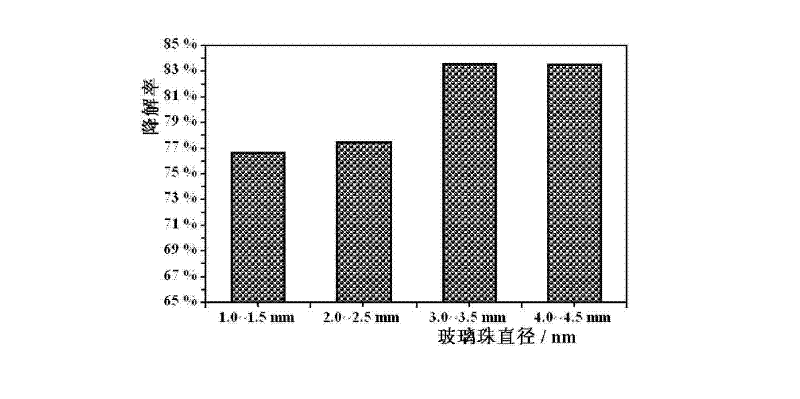

[0037] Example 2 Degradation of Organic Pollutants in Wastewater by Bubbling Cavitation——Effect of Glass Bead Diameter on Degradation Rate

[0038] Proceed as follows:

[0039] 1) Glass beads with a diameter of 1.0-1.5 mm, 2.0-2.5 mm, 3.0-3.5 mm and 4.0-4.5 mm are added to the degrader, and the amount of glass beads added is three quarters of the volume of the degrader;

[0040] 2) Adjust the concentration of acid red B aqueous solution to 10 mg L -1 , the acidity is pH=6.0, add in the degrader, the addition is 3cm higher than the glass beads;

[0041] 3) Gas is introduced from the bottom of the degrader, and the gas flow rate is controlled at 4.5 L min -1 , reacted for 3 hours. Using UV-vis spectrophotometry (λ max = 510 nm) to measure the concentration of the solution, and calculate the degradation rate of acid red B from the concentration change. The result is as image 3 .

[0042] The diameter of the glass beads determines the size and number of air bubbles blow...

Embodiment 3

[0043] Example 3 Degradation of Organic Pollutants in Wastewater by Bubbling Cavitation——Influence of Initial Concentration on Degradation Rate

[0044] Proceed as follows:

[0045] 1) Glass beads with a diameter of 2.0-2.5 mm are added to the degrader, and the amount of glass beads added is three quarters of the volume of the degrader;

[0046] 2) Adjust the initial concentration of acid red B aqueous solution to 5 mg·L respectively -1 , 10mg·L -1 , 15mg·L -1 , 20mg·L -1 , 25mg·L -1 , the acidity is pH=6.0, add in the degrader, the addition is 3 cm higher than the glass beads;

[0047] 3) Gas is introduced from the bottom of the degrader, and the gas flow rate is controlled at 4.5 L min -1 , reacted for 3 hours. Using UV-vis spectrophotometry (λ max = 510 nm) to measure the concentration of the solution, and calculate the degradation rate of acid red B from the concentration change. The result is as Figure 4 .

[0048] The initial concentration of wastewater s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com