Moulding sand cooling dedusting tower as well as casting moulding sand processing device and method

A technology for dust removal towers and molding sand, which is applied in foundry molding equipment, machinery for cleaning/processing mold materials, and manufacturing tools, etc. The effect of reducing labor intensity, high work efficiency and high-quality treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

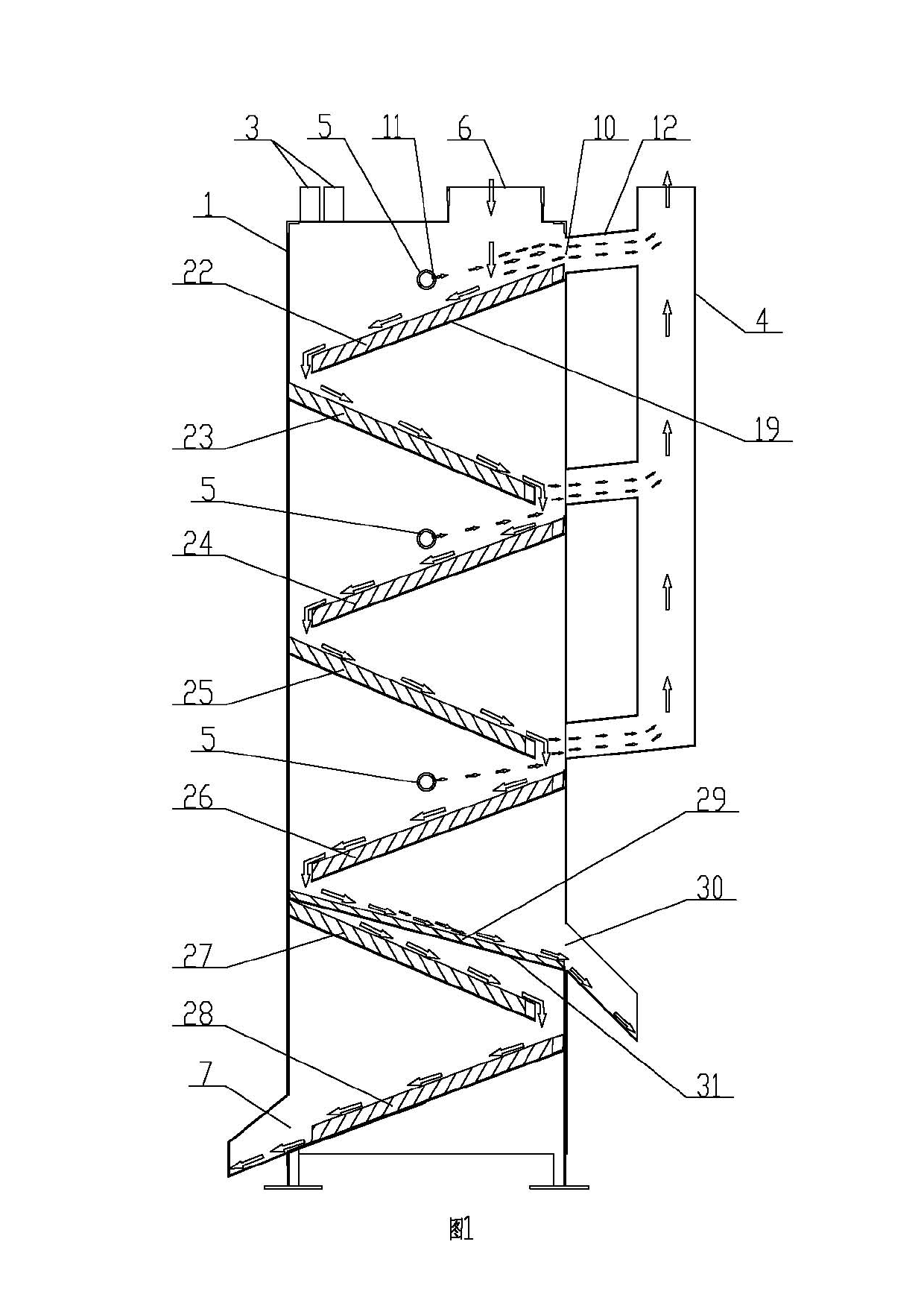

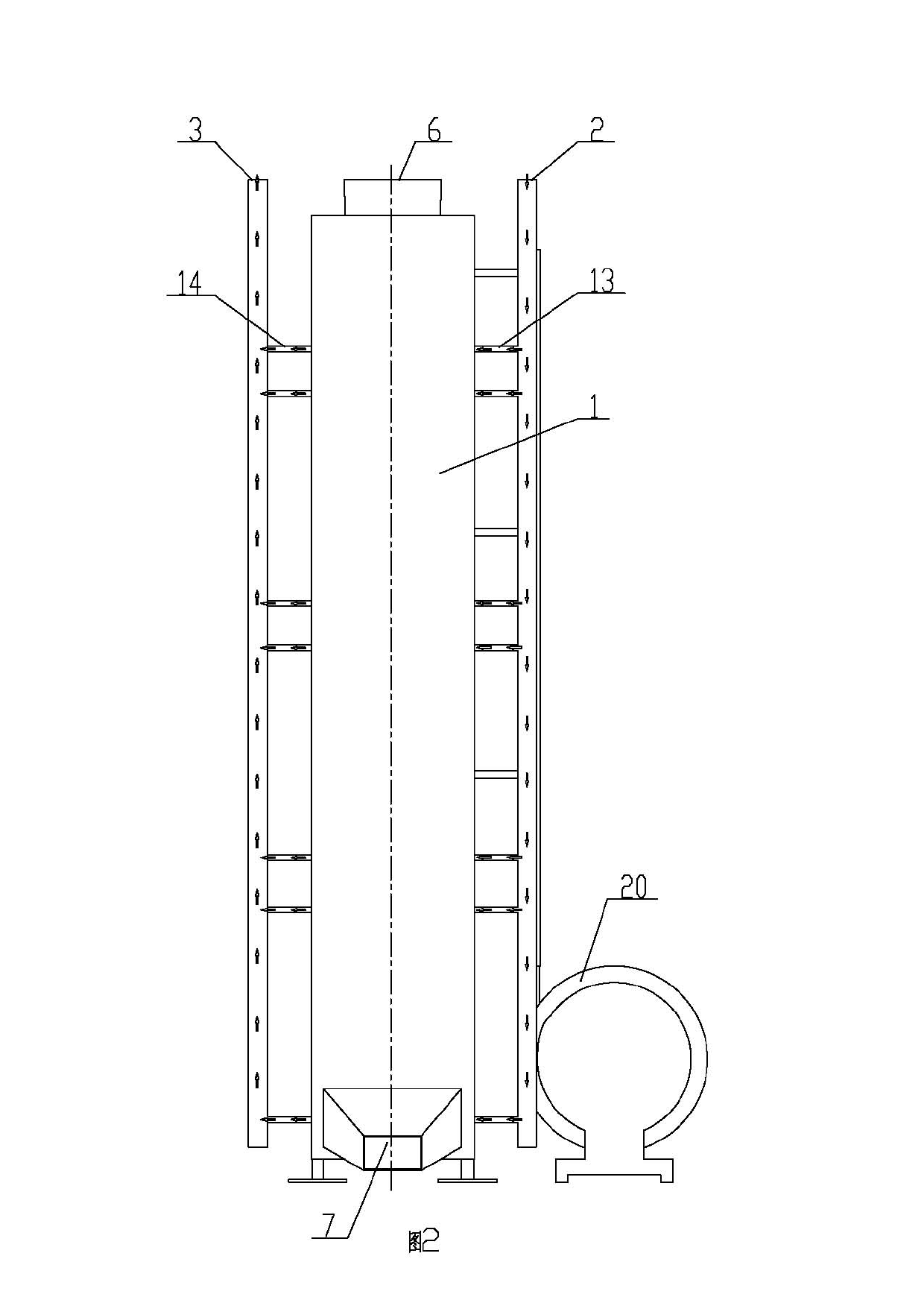

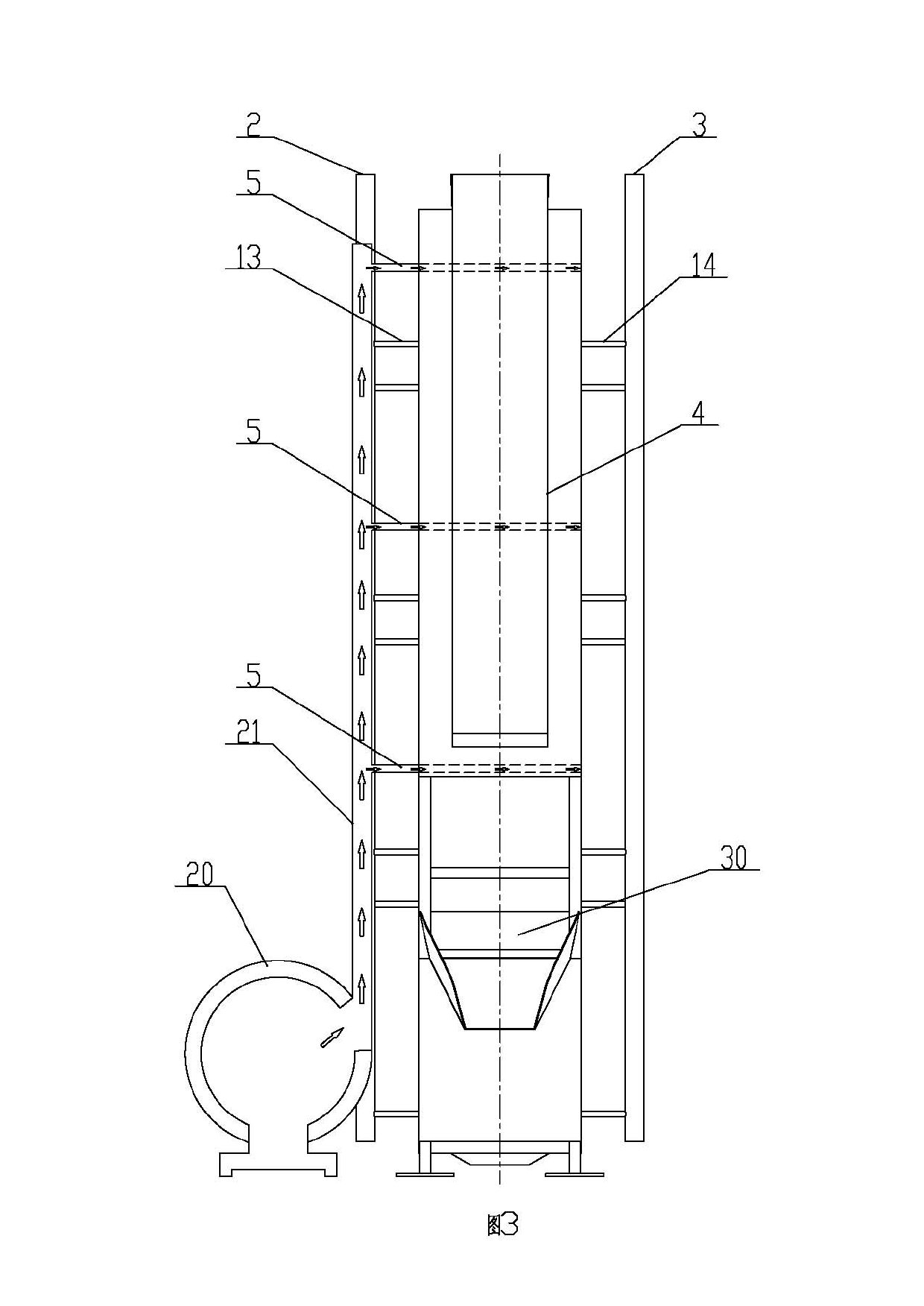

[0035] Embodiment 1: as attached figure 1 , 2 As shown, the molding sand cooling and dedusting tower includes a vertical box 1, a cooling box, an inlet pipe 2, an outlet pipe 3, a dust removal pipe 4 and an air duct 5; the upper end of the vertical box 1 has a sand inlet 6, and the vertical box The inner cavity of the body 1 is fixed with a cooling box whose upper surface is an inclined surface. The upper end of the cooling box is the molding sand inflow end and communicates with the sand inlet 6. The lower end of the cooling box is the molding sand outflow end, corresponding to the vertical cooling box at the lower end. There is a sand outlet 7 on the outside of the box body 1 and it is connected with the outflow end of the molding sand; the water inlet pipe 2 and the water outlet pipe 3 are fixed on the vertical box body 1, the water inlet 8 and the water outlet 9 are on the cooling box, and the water inlet of the cooling box 8 is connected with the water inlet pipe 2, ...

Embodiment 2

[0041] Embodiment 2: as attached Figure 6 , 7 , 9, the foundry sand processing device includes a frame 32, a sand storage tank 33, a longitudinal belt conveyor 34, a transverse belt conveyor 35, a sand collection bucket 36, a magnetic separation conveyor 37, a first sand storage bin 38, a first Bucket elevator 39, first molding sand cooling and dust removal tower 40, second sand storage bin 41, second bucket elevator 42, second molding sand cooling and dust removal tower 43, third sand storage bin 44, third bucket elevator 45, parallel Belt conveyor 46 and sand warehouse 47; sand storage tank 33 is fixedly installed on the left part of frame 32, and filter screen 48 is fixedly installed on the frame 32 above sand storage tank 33, and the lower end of sand storage tank 33 has sand falling port 49. There is a longitudinal belt conveyor 34 below the sand falling port 49. A longitudinal belt 50 capable of transporting materials to the rear is installed on the longitudinal bel...

Embodiment 3

[0045] Embodiment 3: a kind of foundry sand processing method, comprises the following steps:

[0046] (1) The molding sand is coarsely screened by the filter screen 48 , and the larger plastics, larger iron particles and other debris in the molding sand are left above the filter screen 48 , and the separated molding sand falls from the shakeout port 49 ;

[0047] (2) The roughly screened molding sand falls from the shakeout port 49 and moves backward with the longitudinal belt 50 of the longitudinal belt conveyor 34. When it reaches the front of the longitudinal belt sand cutting baffle 52, the longitudinal belt sand cutting baffle 52 pushes the molding sand It falls onto the transverse belt 51 of the transverse belt conveyor 35, and the transverse belt 51 moves to the right to send the molding sand into the sand collection bucket 36, and the sand collection bucket 36 falls into the magnetic separation conveyor 37 for magnetic separation, and the fine iron in the molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com