A manganese-oxygen composite material that efficiently removes vocs and its preparation method and application

A technology of composite materials and manganese oxide, which is applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as ineffective effects, and achieve excellent continuous working ability, energy saving in the processing process, and fast reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation and application of a new type of composite material that efficiently removes VOCs, the specific steps are as follows:

[0037] Step 1: Add 5 g of carbon nanotubes to 50 mL of deionized water to form a solution, and stir at room temperature until the carbon nanotubes are completely dissolved;

[0038] Step 2: Add 0.10mol / L KMnO to the above solution 4 50 mL of the solution, and then add 0.01 moL of magnesium nitrate and 1.7895 g of manganese nitrate to the solution, react in an oven at 100°C for 2 hours, wash, filter, and dry to obtain a manganese-oxygen composite material.

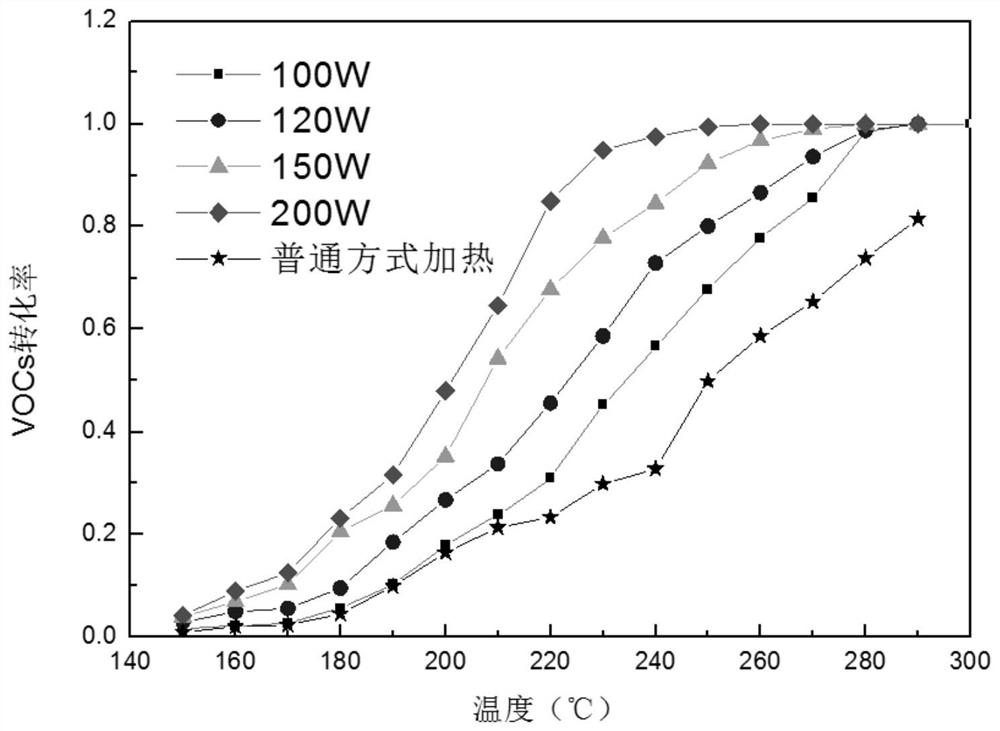

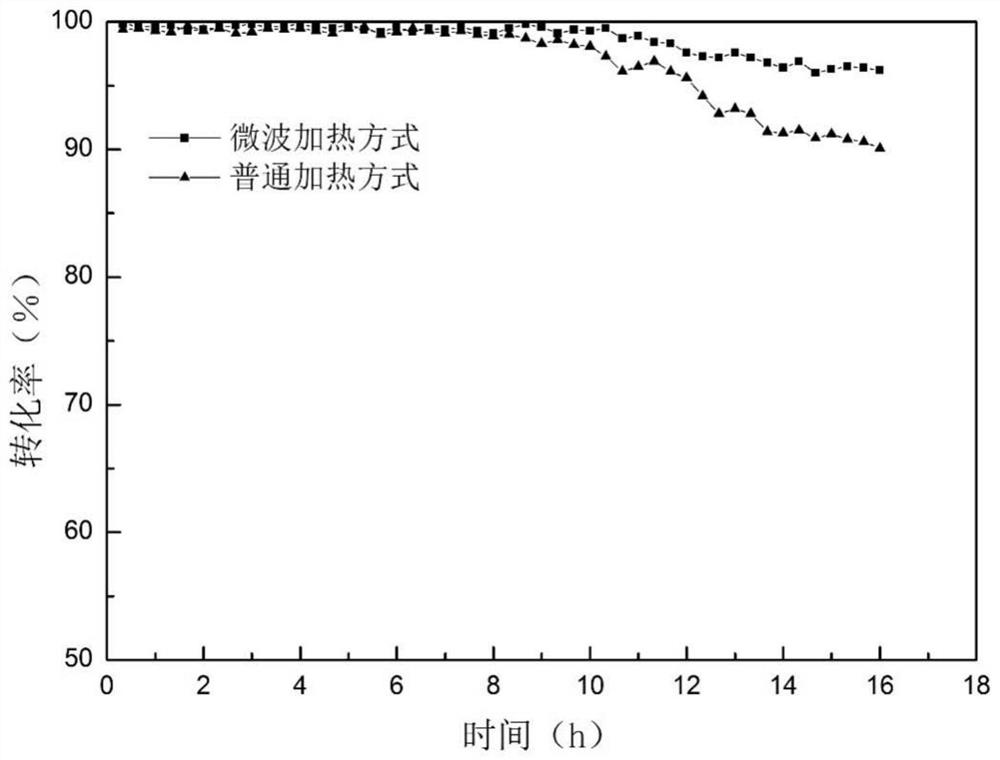

[0039] Step 3: After mixing and packaging the manganese-oxygen composite material and quartz sand at a mass ratio of 1:2, put them into a microwave reactor with a microwave frequency of 2.45GHz±50MHz, a reaction temperature of 240°C, and an intake concentration of VOCs of 200ppm , the dry air is the equilibrium gas (about 21%O 2 , 79%N 2 ), the microwave power is 100W, and the inl...

Embodiment 2

[0044] The preparation and application of a new type of composite material that efficiently removes VOCs, the specific steps are as follows:

[0045] Step 1: Add 5 g of carbon nanotubes to 50 mL of deionized water to form a solution, and stir at room temperature until the carbon nanotubes are completely dissolved;

[0046] Step 2: Add 0.20mol / L of KMnO to the above solution 4 50 mL of the solution, and then add 0.01 moL of magnesium nitrate and 1.7895 g of manganese nitrate to the solution, react in an oven at 120°C for 3 hours, wash, filter, and dry to obtain a manganese-oxygen composite material.

[0047] Step 3: After mixing and packaging the manganese-oxygen composite material and quartz sand at a mass ratio of 1:2, put them into a microwave reactor with a microwave frequency of 2.45GHz±50MHz, a reaction temperature of 240°C, and an intake concentration of VOCs of 300ppm , the dry air is the balance gas (about 21%O 2 , 79%N 2 ), the microwave power is 100W, and the inle...

Embodiment 3

[0052] The preparation and application of a new type of composite material that efficiently removes VOCs, the specific steps are as follows:

[0053] Step 1: Add 5 g of carbon nanotubes to 50 mL of deionized water to form a solution, and stir at room temperature until the carbon nanotubes are completely dissolved;

[0054] Step 2: Add 0.30mol / L of KMnO to the above solution 4 50 mL of the solution, and then add 0.01 moL of magnesium nitrate and 1.7895 g of manganese nitrate to the solution, react in an oven at 140°C for 4 hours, wash, filter, and dry to obtain a manganese-oxygen composite material.

[0055] Step 3: After mixing and packaging the manganese-oxygen composite material and quartz sand at a mass ratio of 1:2, put them into a microwave reactor with a microwave frequency of 2.45GHz±50MHz, a reaction temperature of 240°C, and an intake concentration of VOCs of 400ppm , the dry air is the balance gas (about 21%O 2 , 79%N 2 ), the microwave power is 100W, and the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com