Patents

Literature

30results about How to "Strong continuous work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

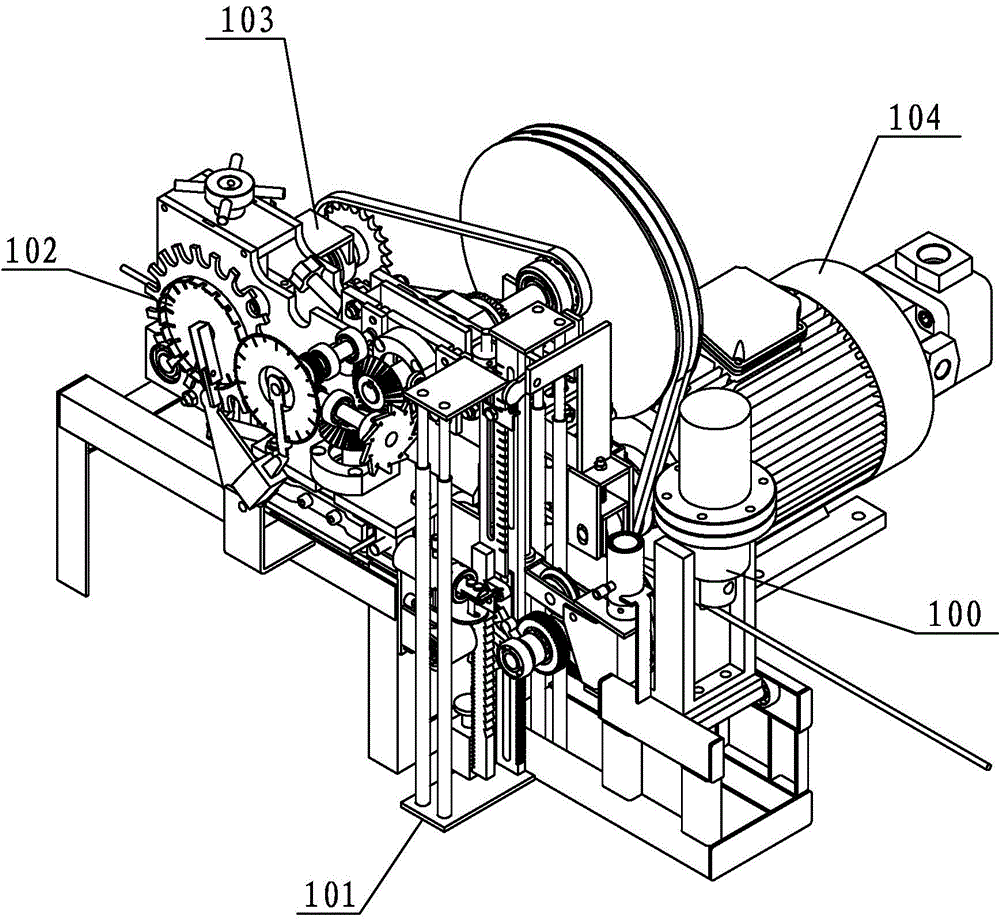

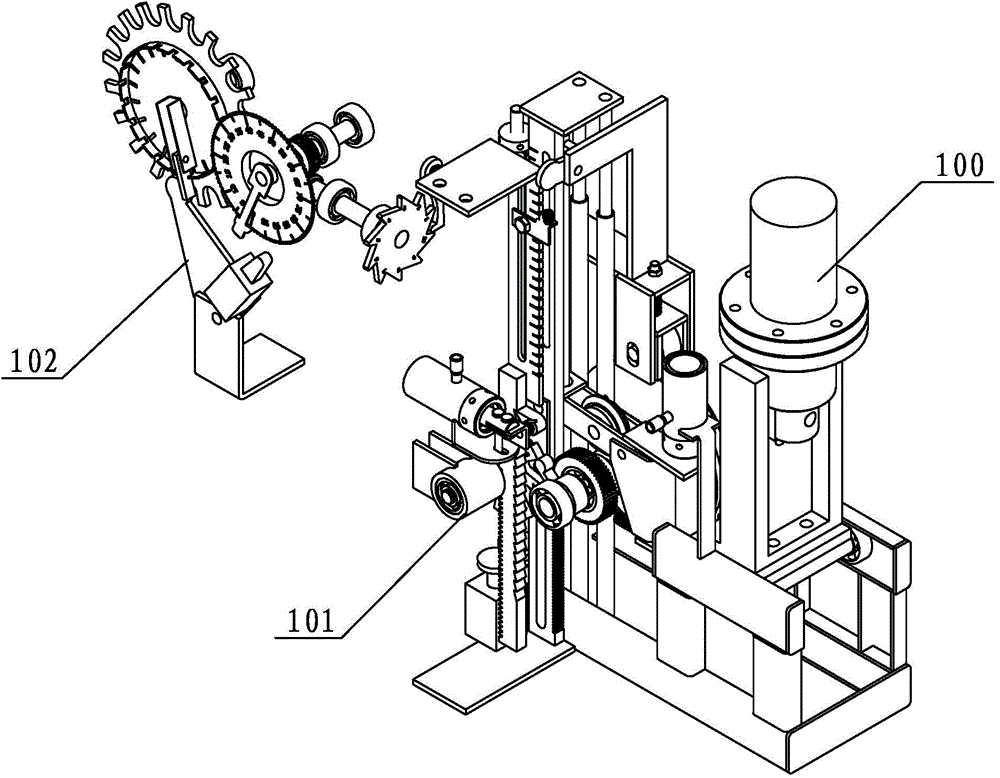

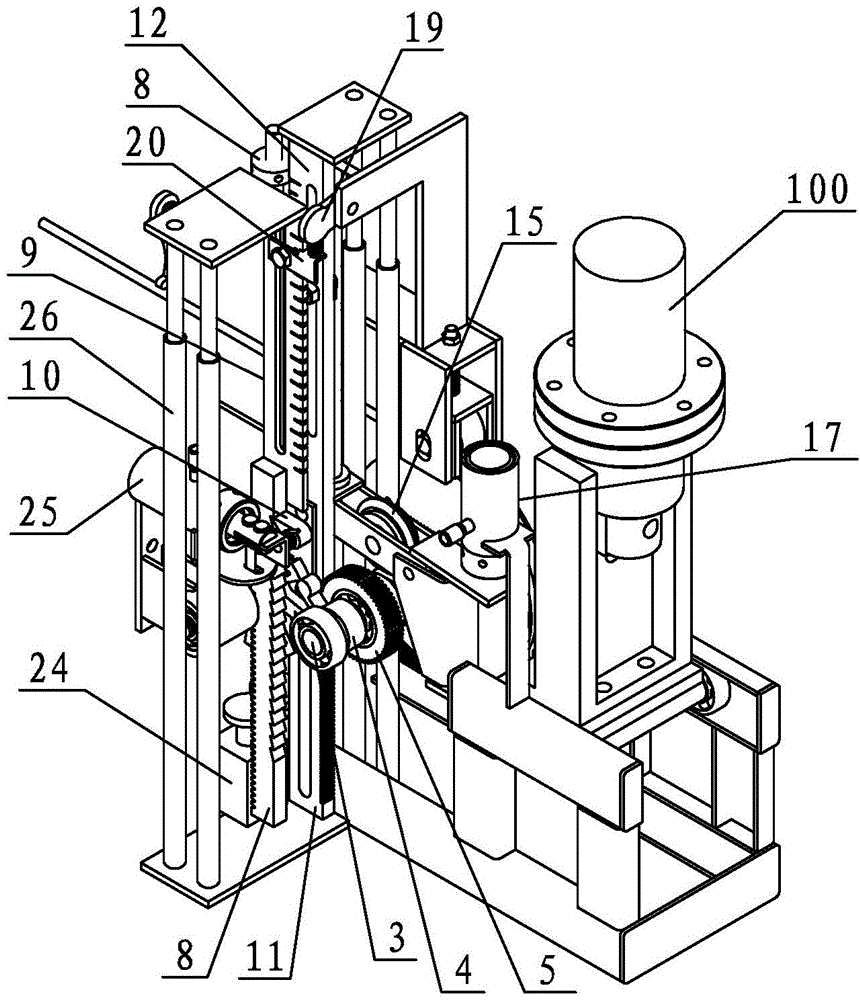

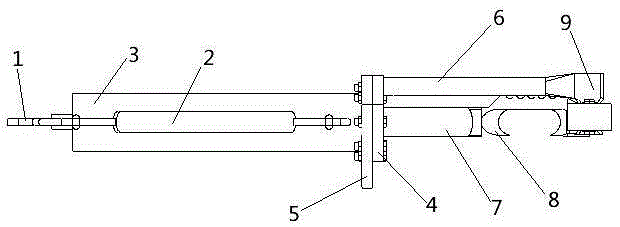

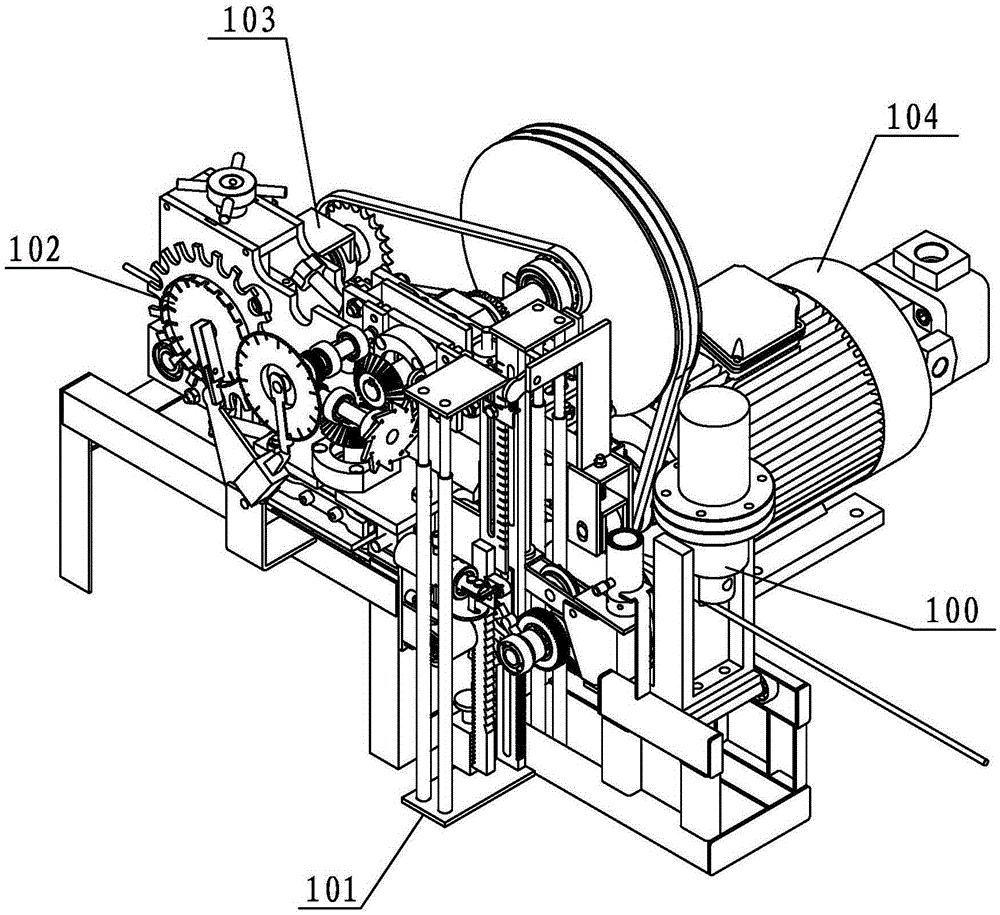

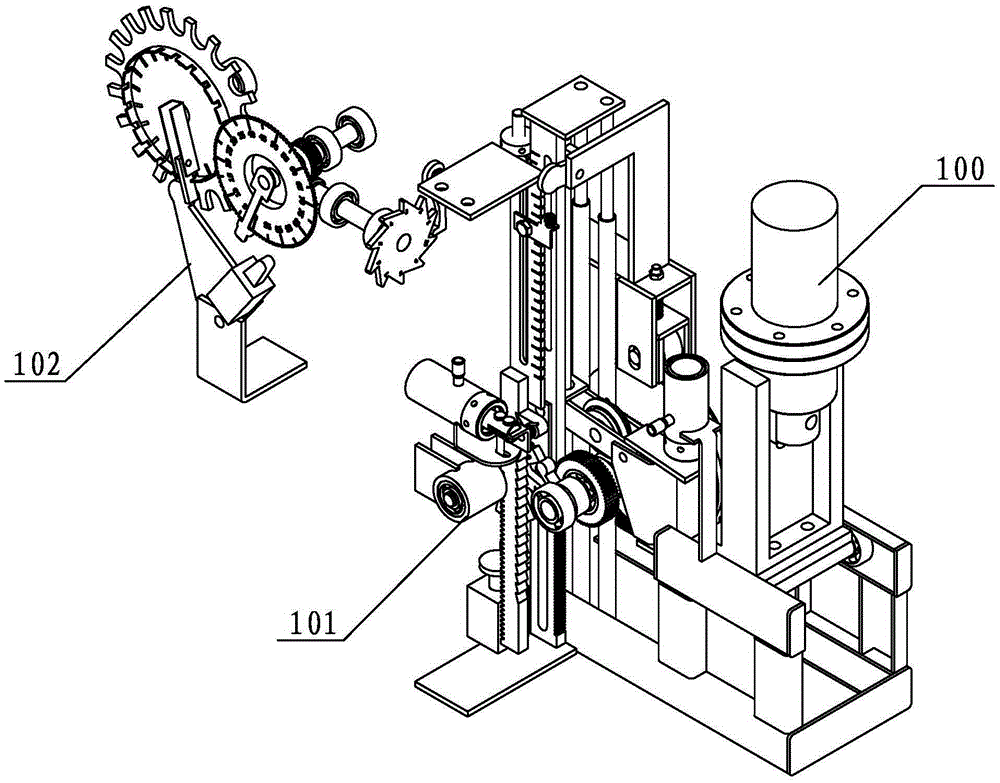

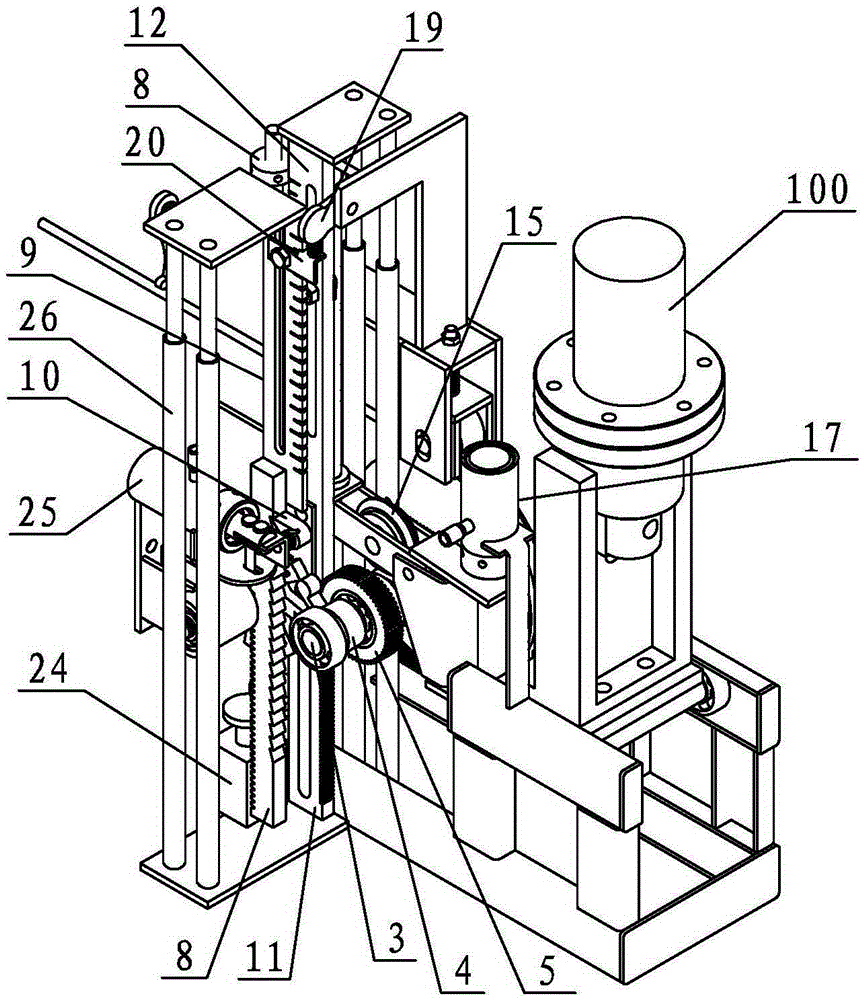

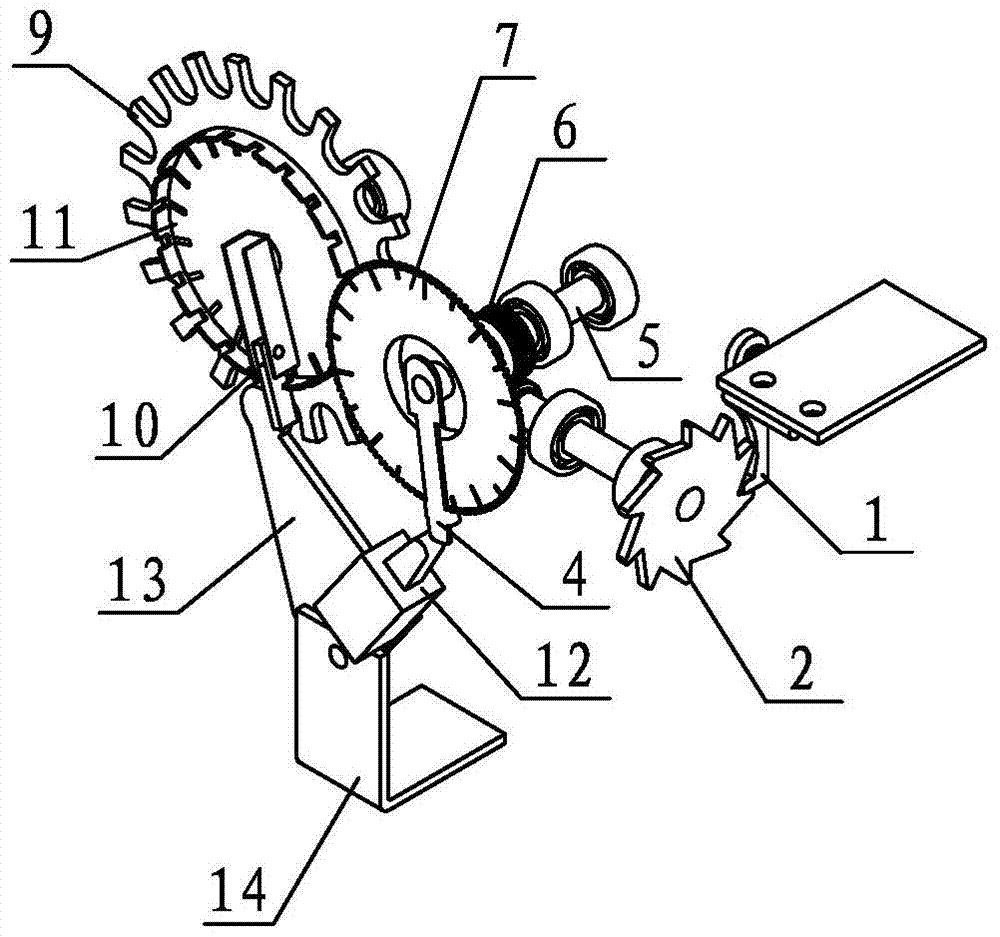

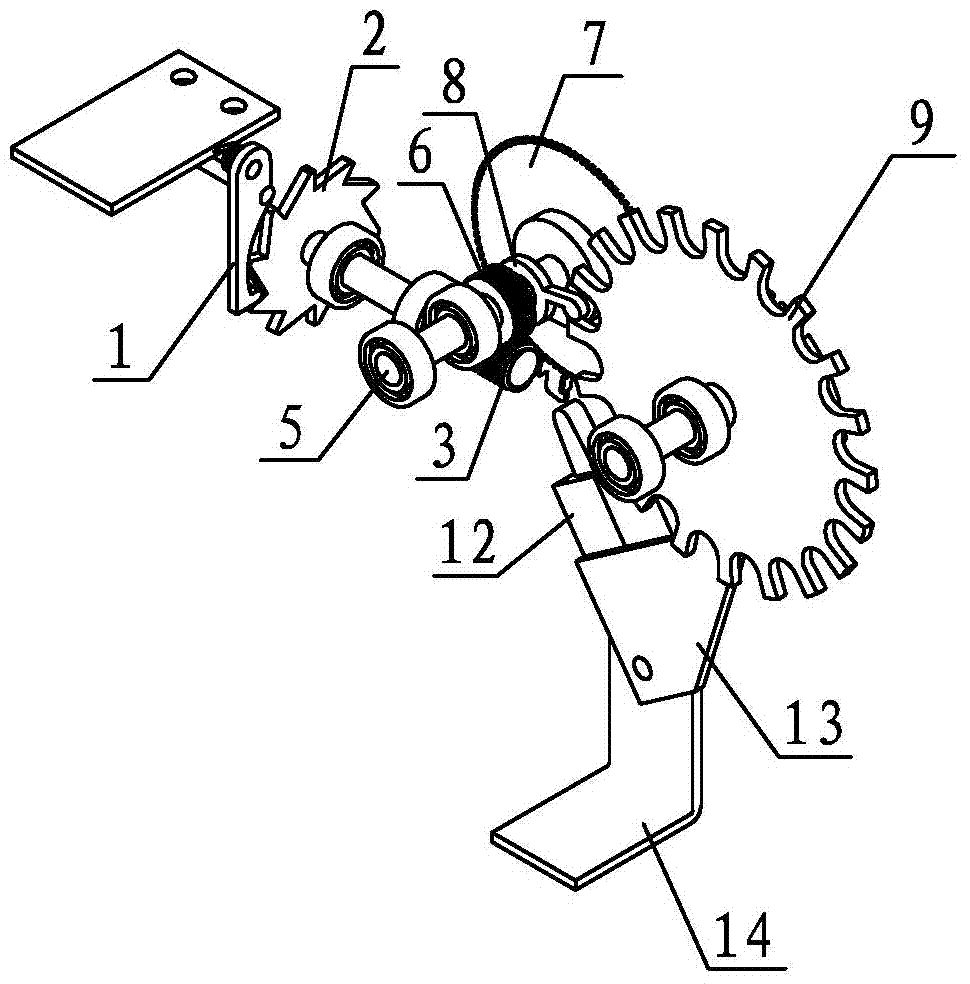

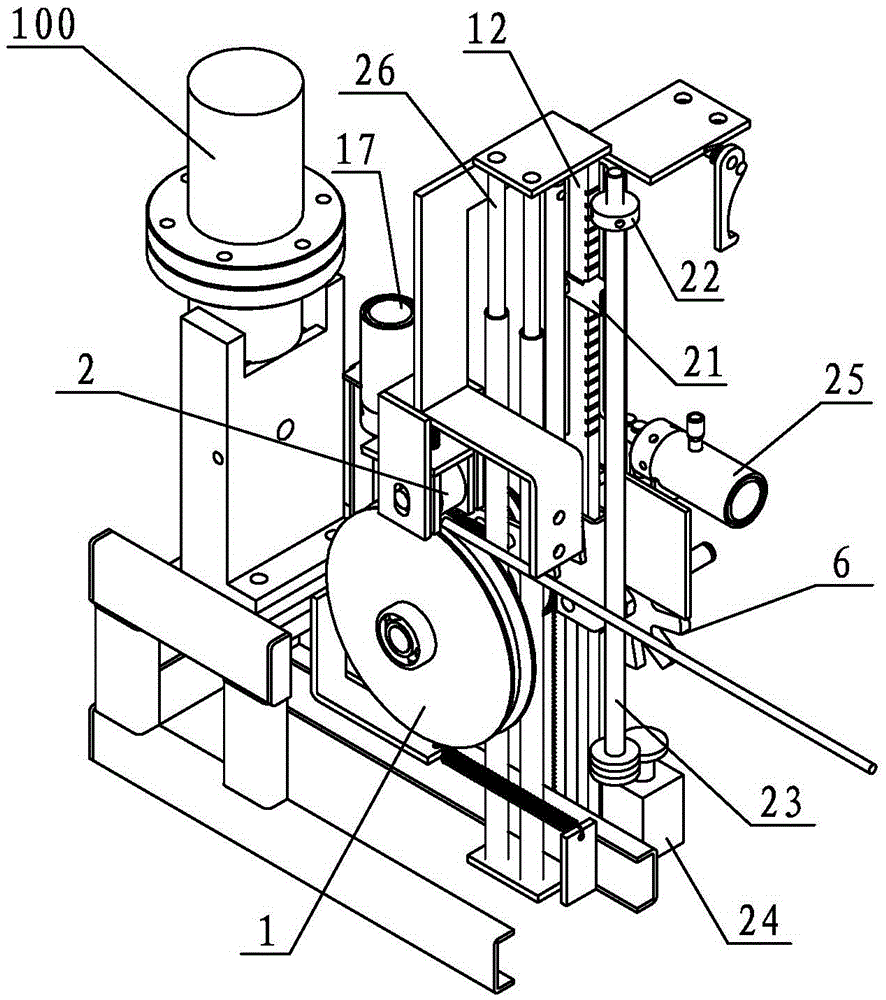

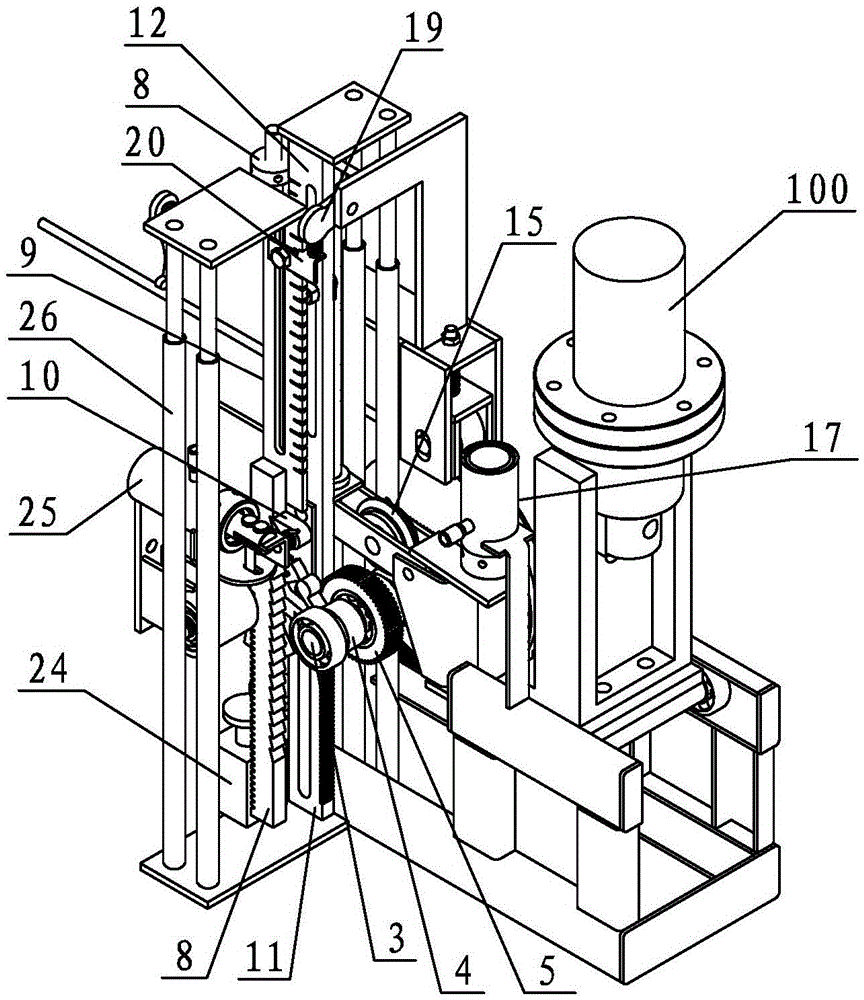

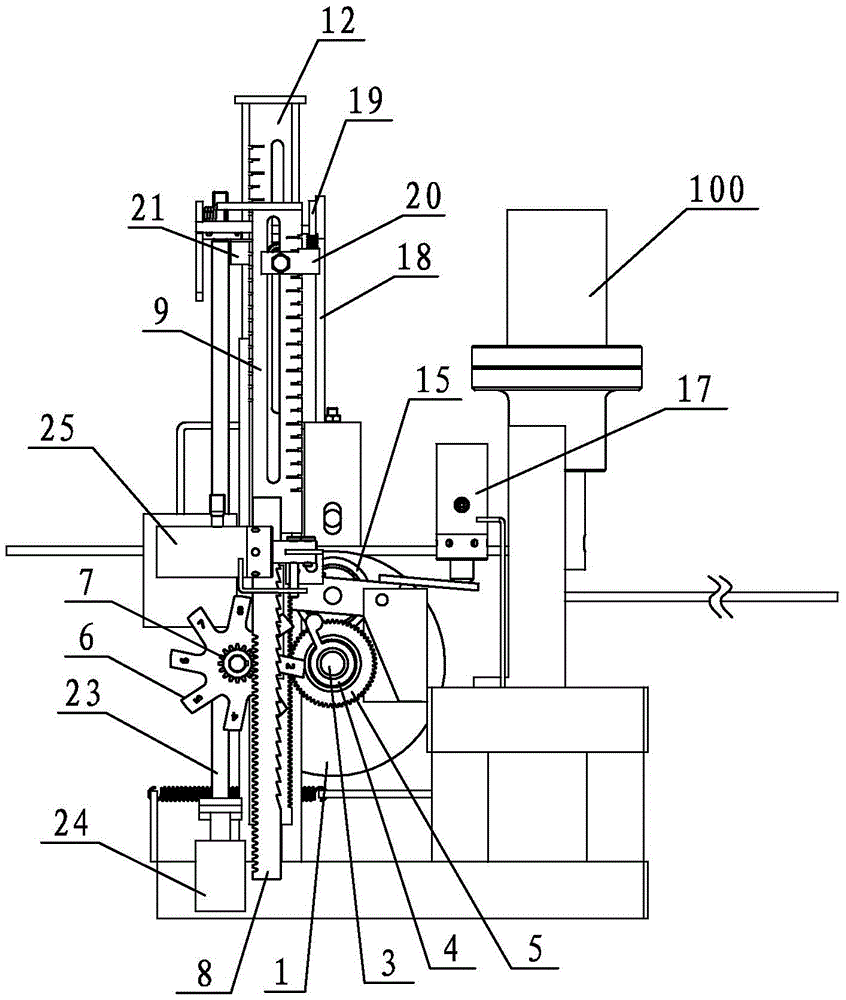

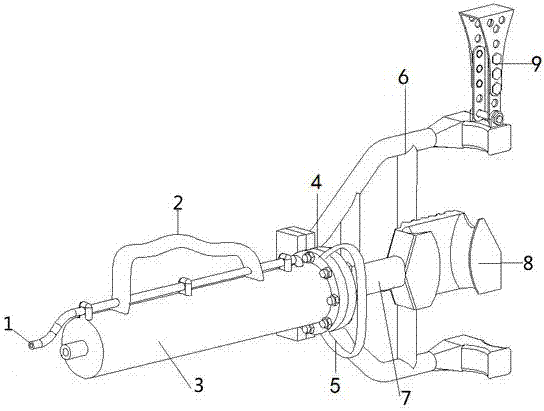

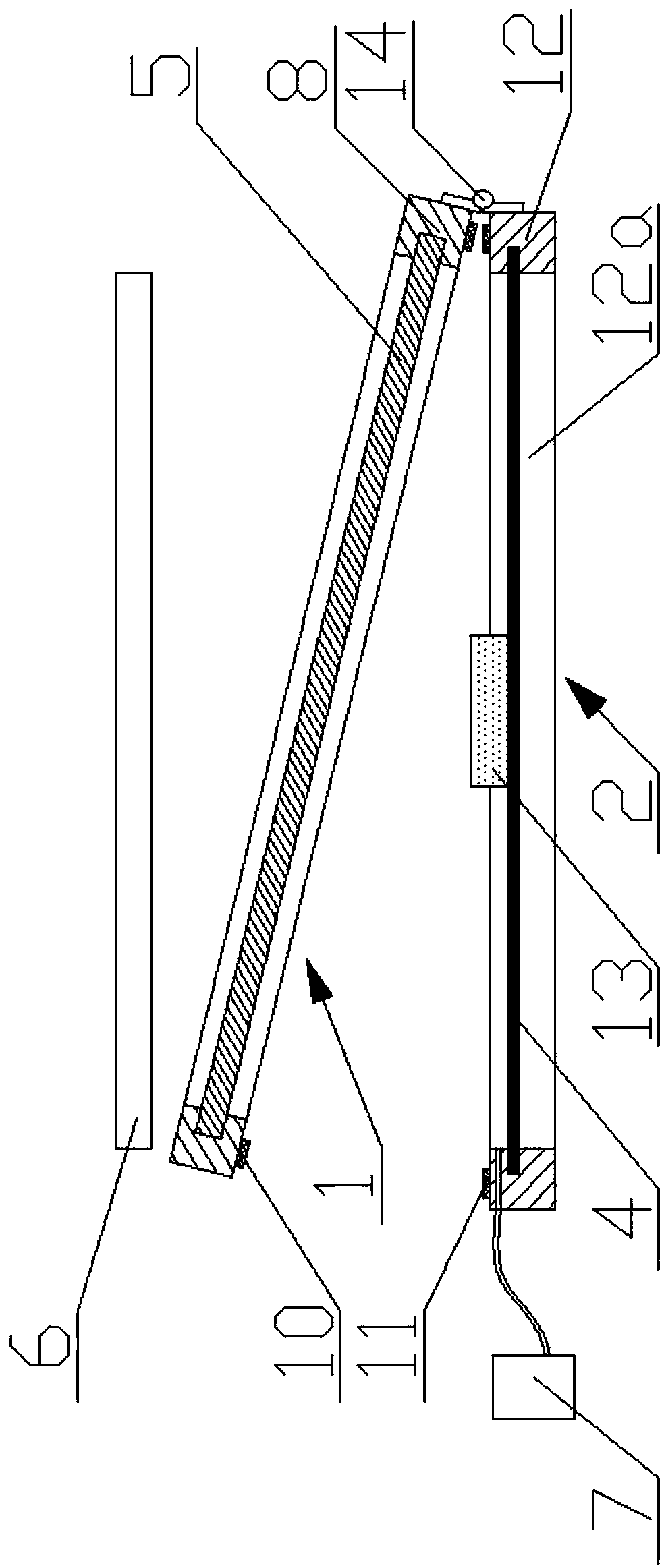

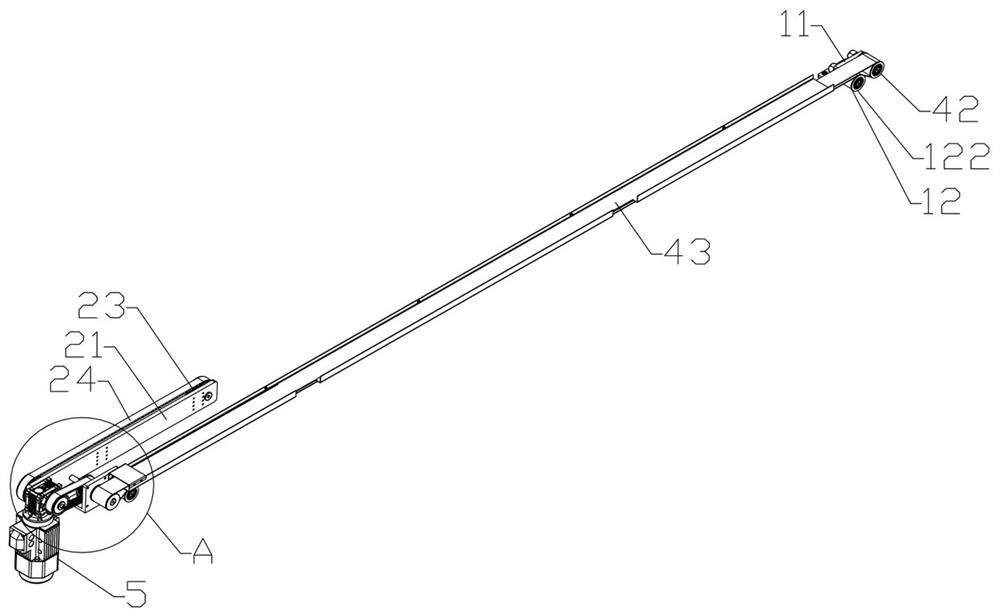

Automatic rebar cutting machine with sizing device and metering device

ActiveCN104128539AEasy to processStrong reliabilityMetal working apparatusMechanical componentsPulp and paper industry

The invention discloses an automatic rebar cutting machine with a sizing device and a metering device. The automatic rebar cutting machine comprises a cutting device. The sizing device for automatically measuring the length of rebars and the metering device for counting the number of cut rebars are arranged in the front of the cutting device, and the sizing device, the metering device and the cutting device are in linkage. According to the automatic rebar cutting machine with the sizing device and the metering device, the length of the rebars is measured through the sizing device, when the measured length of the rebars reaches a preset value, the cutting device is triggered to cut the rebars, and meanwhile the number of the cut rebars is recorded through the metering device. According to the automatic rebar cutting machine, quantitative sizing cutting of the rebars can be automatically finished, machining capacity is high, the machine is wholly composed of mechanical components, cost is low, reliability is high, and continuous working capacity is high; due to the fact the machine is not provided with electronic accessories, maintenance is simple; general staff can use and operate the machine without being trained, and the automatic rebar cutting machine is convenient to use and high in practicability.

Owner:冯广建

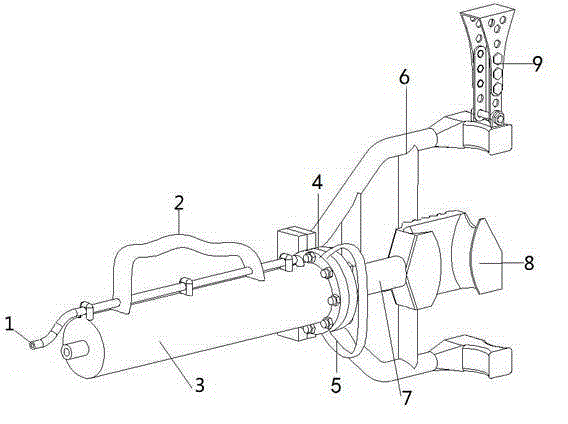

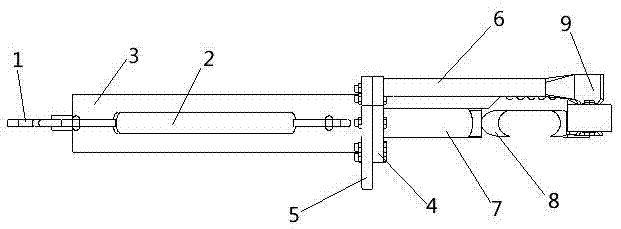

Portable multi-jacking multifunctional high-tensile reinforcement bar bending and straightening machine and operation method thereof

ActiveCN105170836AImprove construction qualityImprove construction efficiencyEngineeringHigh intensity

The invention discloses a portable multi-jacking multifunctional high-tensile reinforcement bar bending and straightening machine and an operation method thereof. A jack is adopted as a power mechanism. A vertical handle is arranged on the side wall of a body of the jack. A transverse handle is arranged on a sealing flange of the jack. A detachable bender is arranged at the tail end of an ejector rod of the jack and comprises two slots with different radiuses and a right-deflection-angle slot. A support comprises two symmetrical supporting frames and a reinforcement transverse connector between the two supporting frames. The bottoms of the two supporting frames are provided with supporting bases with steel bar grooves. The plane where the two supporting frames are located is located below the plane where the ejector rod is located. The tops of the two supporting frames are fixedly connected with the sealing flange. The device can carry out bending, straightening construction and preformed deflection angle abutting construction on high-tensile reinforcement bars rapidly, is provided with multiple operation ends, has the good using performance and sufficient power, and can be applied to on-site steel bar abutting, bending, straightening and other procedures such as bending and straightening construction similar to drilling pile horn mouth standard bend manufacturing.

Owner:THE SECOND CONSTR OF CTCE GROUP

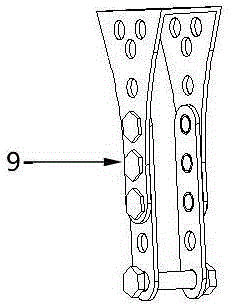

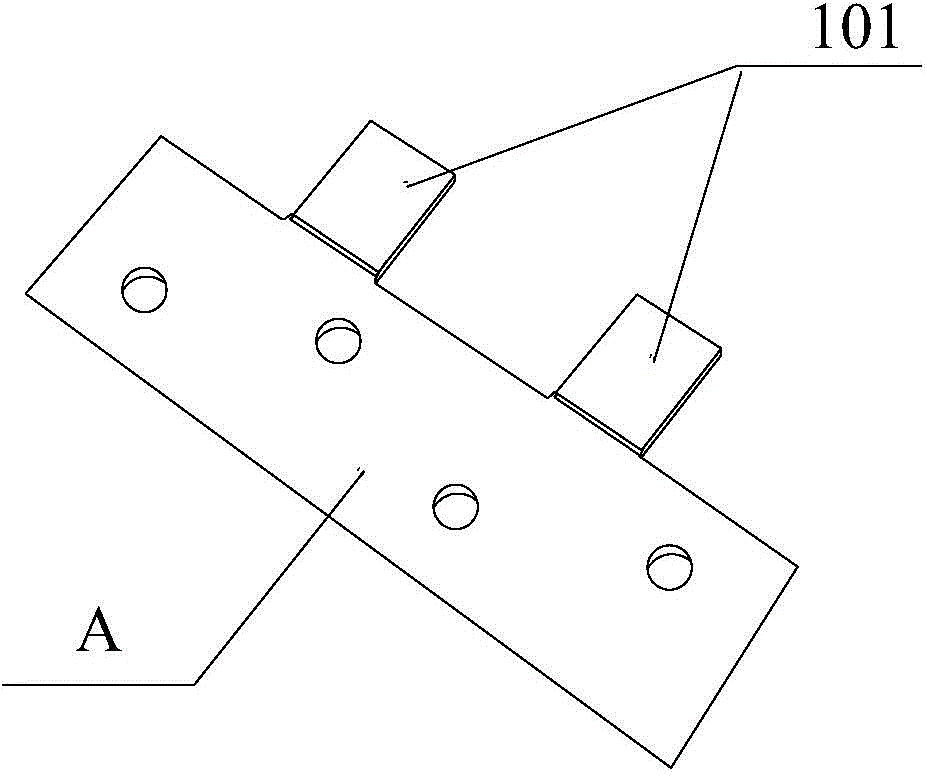

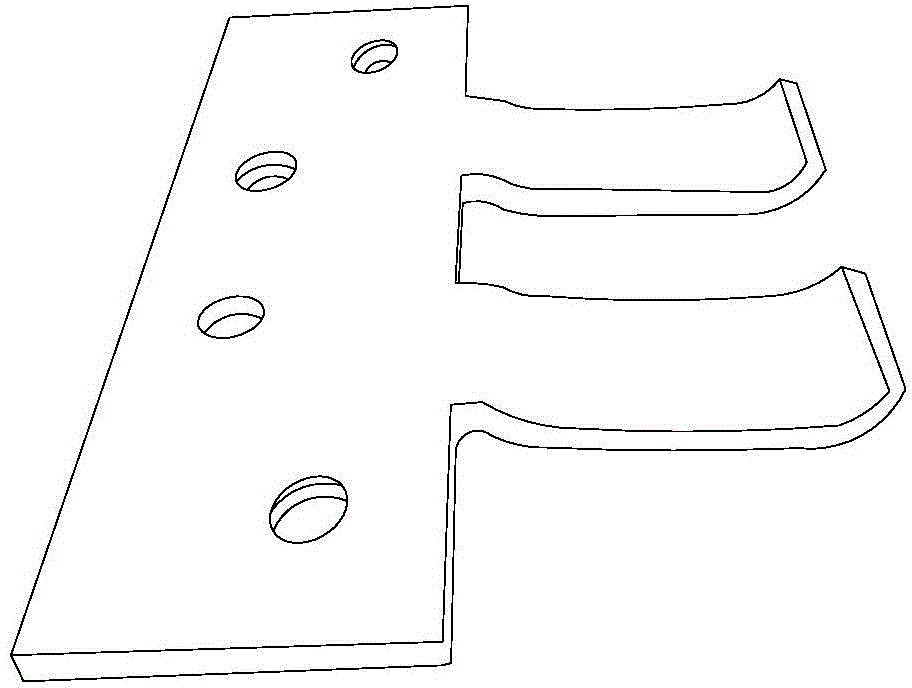

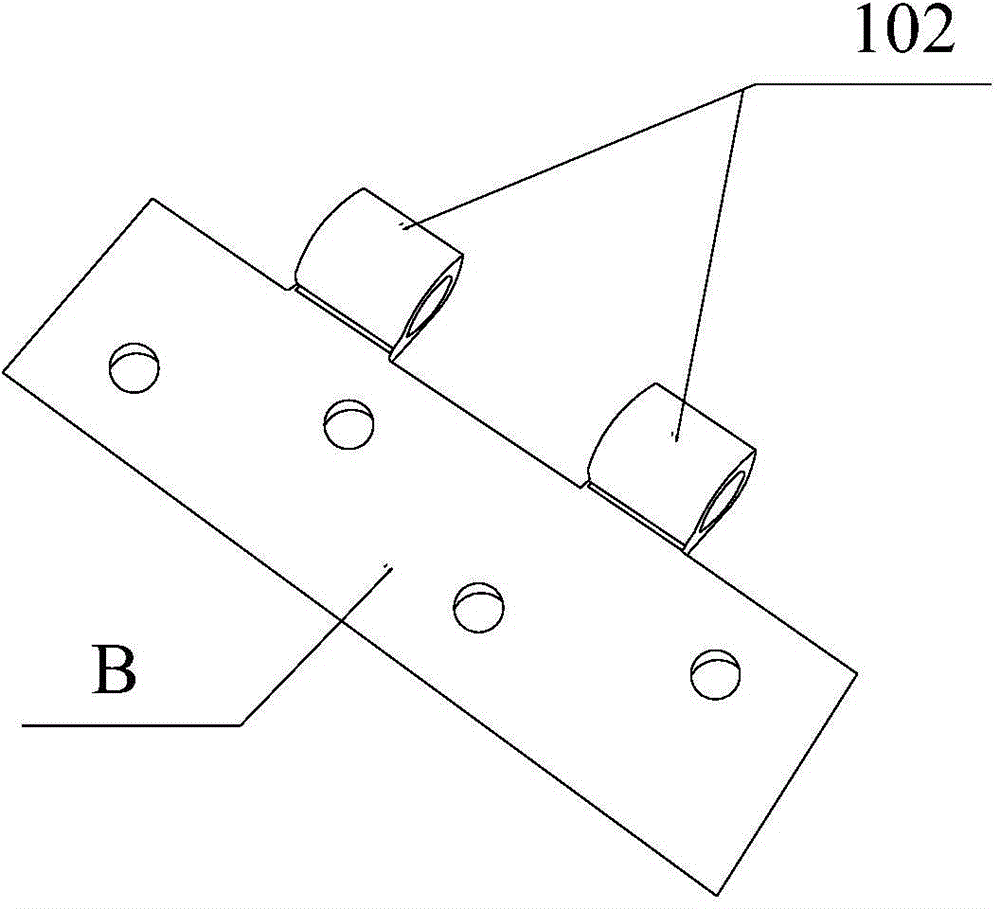

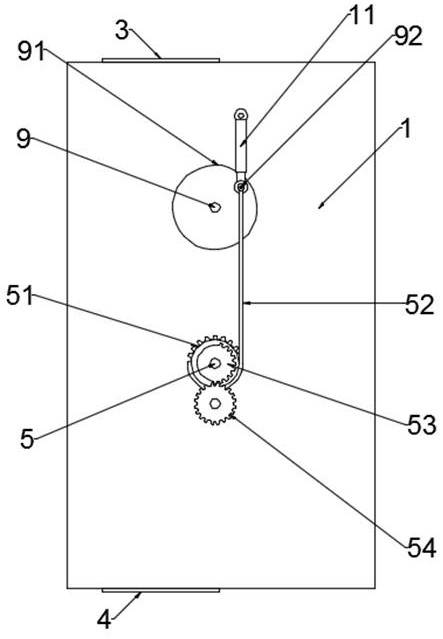

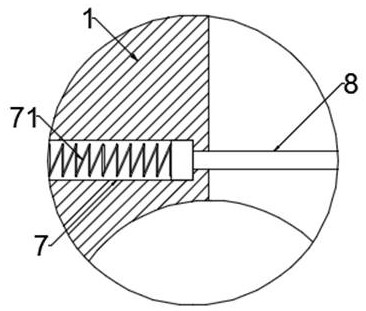

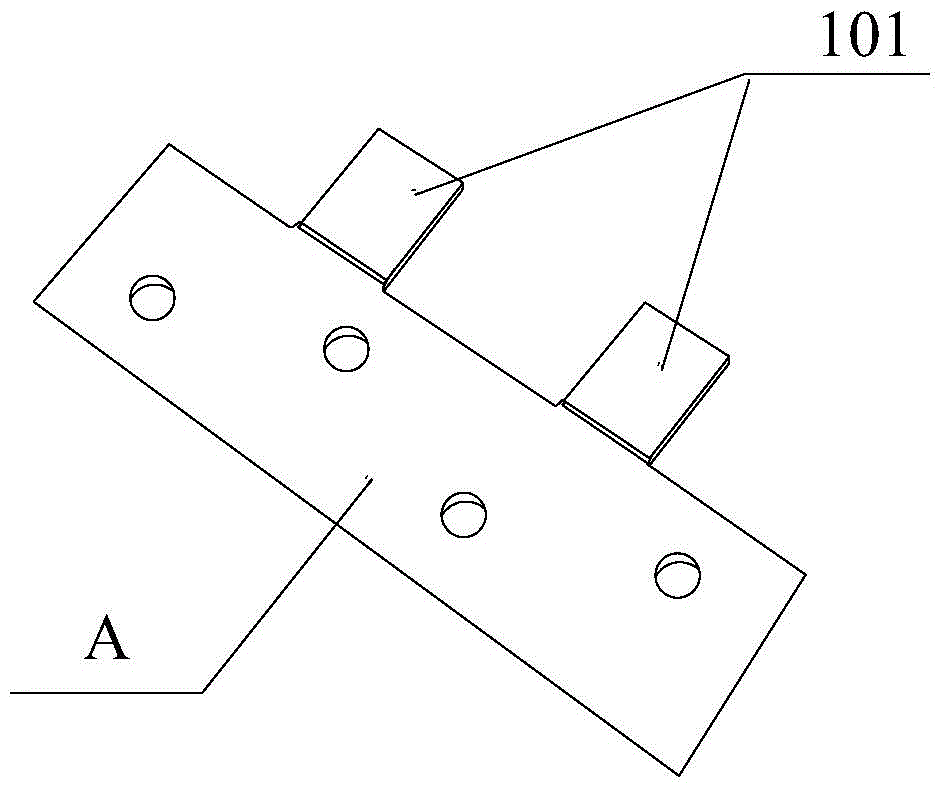

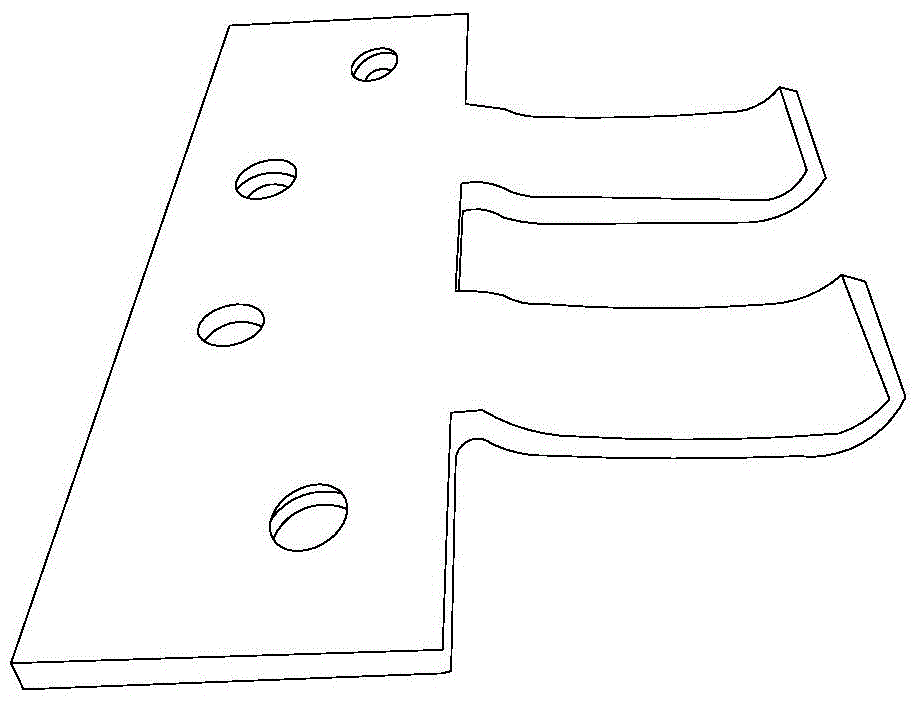

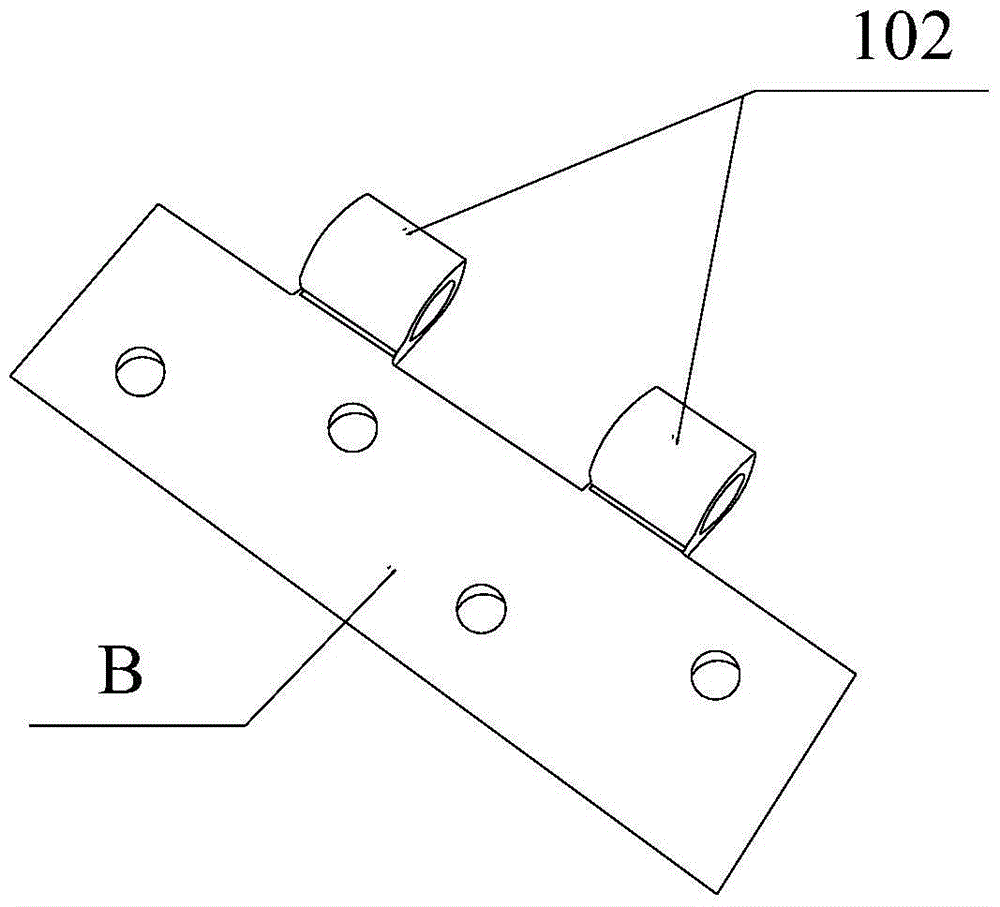

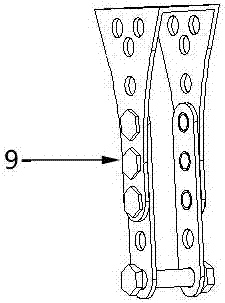

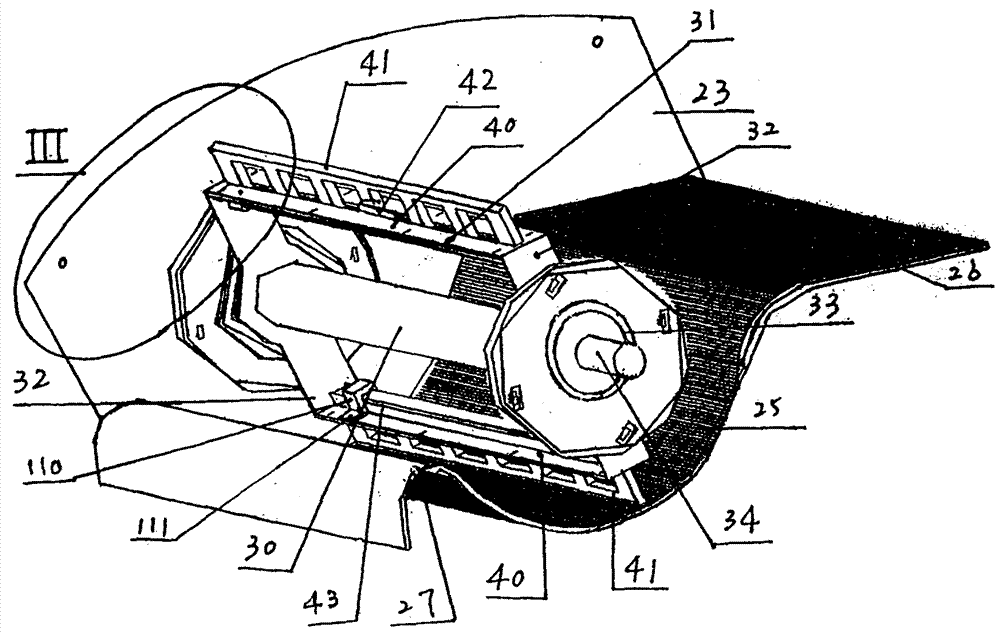

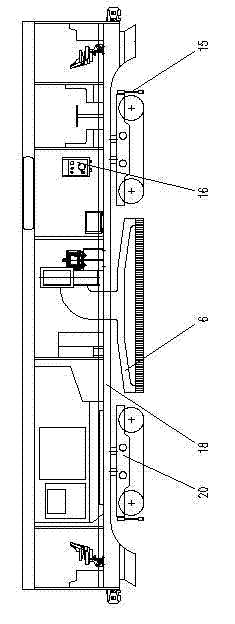

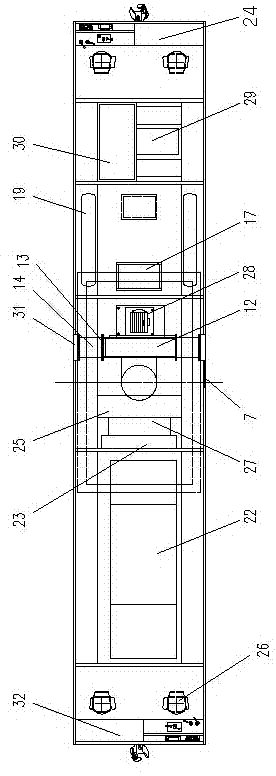

Hinge-leaf shaft-position mold processing machine

ActiveCN104889286AStrong continuous workSuitable for mass productionHingesHinge teethContinuous operation

The invention discloses a hinge-leaf shaft-position mold processing machine. The hinge-leaf plates comprises an automatic feeding mechanism used for conveying hinge-leaf plates, a material groove used for holding the hinge-leaf plates, a prebending mechanism used for prebending shaft positions on the hinge-leaf plates, a shaft-position curling mechanism used for curling the shaft positions on the hinge-leaf plates to form tooth positions and shaft holes, a tooth position shaping mechanisms used for shaping the tooth positions formed on the hinge leaf plates and a discharge cylinder used for pushing out the hinge leaves. The hinge-leaf shaft-position mold processing machine is compact in structure, is capable of automatically conveying the hinge-leaf plates, prebending the leaf shaft positions, curling, shaping the hinge tooth positions and discharging the hinge leaves, realizes automatic continuous feeding and is continuous in working procedures, high in working efficiency, high in continuous operation capability and suitable for factory batch production, the tooth positions meeting product design requirements are processed, and labor cost is lowered effectively.

Owner:刘栓群

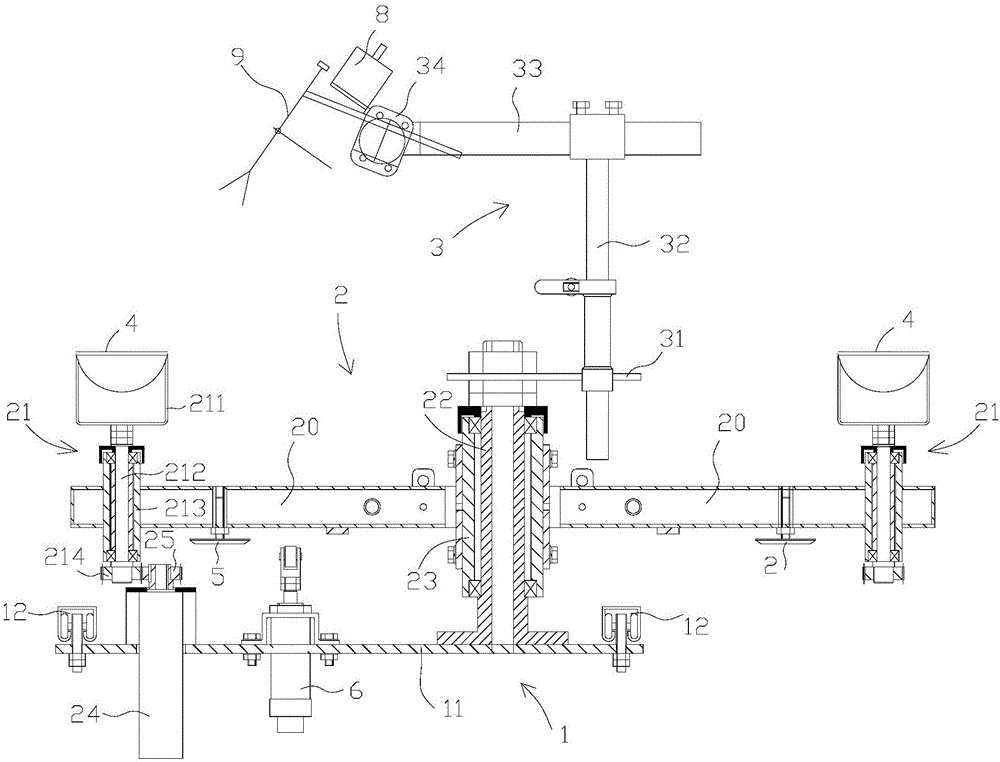

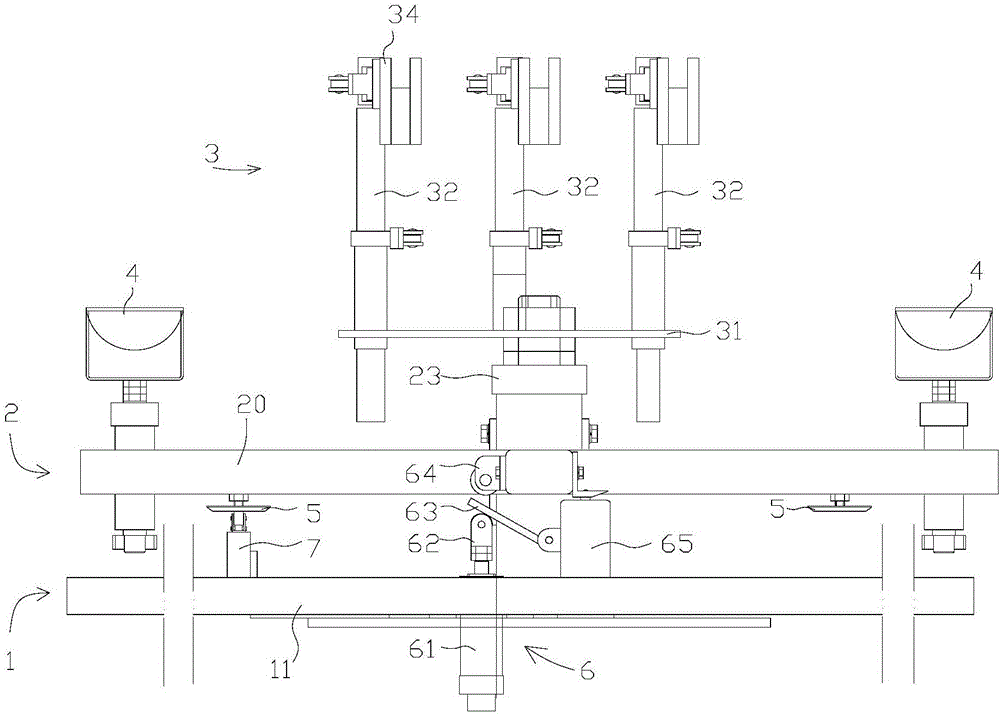

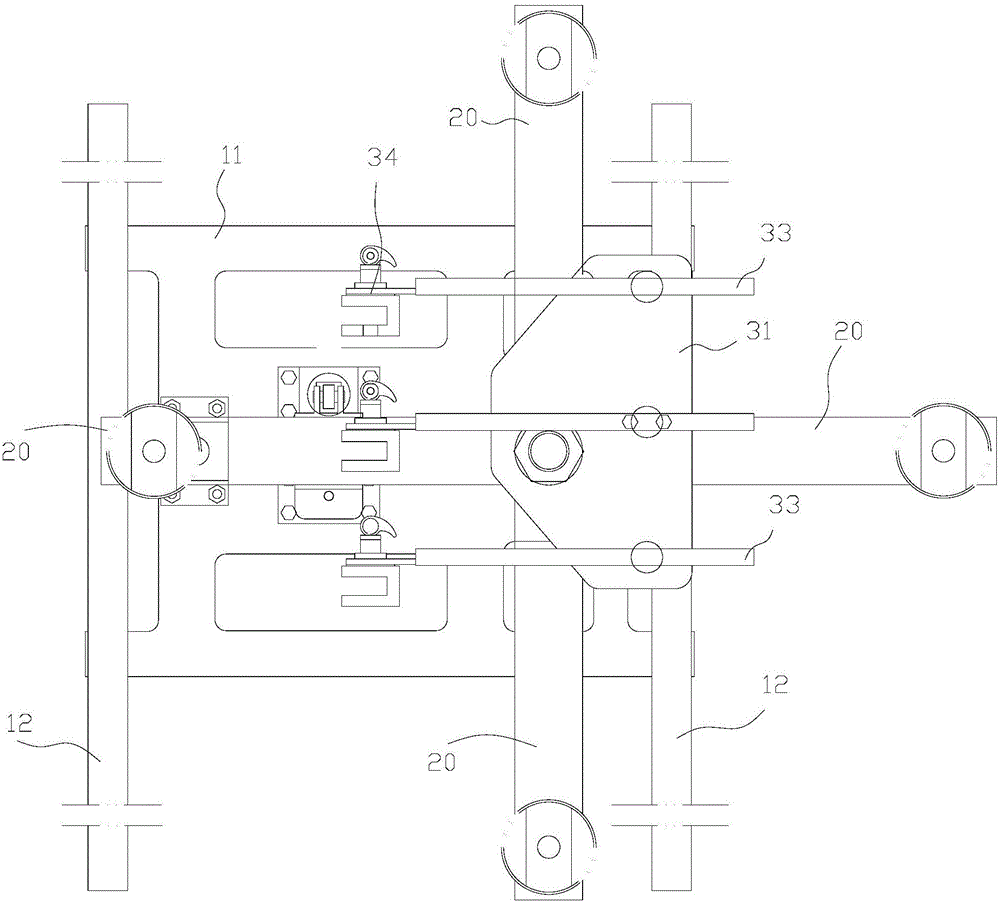

Semi-automatic paint spraying machine

ActiveCN106733320AReduce usageSimple structureLiquid surface applicatorsCoatingsSemi automaticPneumatic valve

The invention discloses a semi-automatic paint spraying machine and belongs to the technical field of paint spraying equipment. The semi-automatic paint spraying machine comprises a base plate assembly, a rotating assembly, spraying frame assemblies, spraying gun assemblies, an air supply device and a control box. The base plate assembly comprises a base plate and supporting rods. The rotating assembly comprises a cross-shaped rotating frame, a pneumatic motor, a holding frame assembly, a push assembly and a fixing seat. The spraying frames assemblies are arranged at the upper end of the base plate assembly and used for clamping the spraying gun assemblies. Each spraying gun assembly comprises a spraying gun and a spraying gun air cylinder. The control box comprises a box body, an electro connecting pressure gauge installed in the box body, a first electromagnetic pneumatic valve, a second electromagnetic pneumatic valve, a first time relay and a second time relay. According to the semi-automatic paint spraying machine, through a simple and compact mechanism and low cost, semi-automatic spraying over general parts such as reflecting mirrors is achieved, the labor intensity is lowered, the influence of gunner factors on the product quality is solved, and corporate profitability is improved.

Owner:南宁星焱科技有限公司

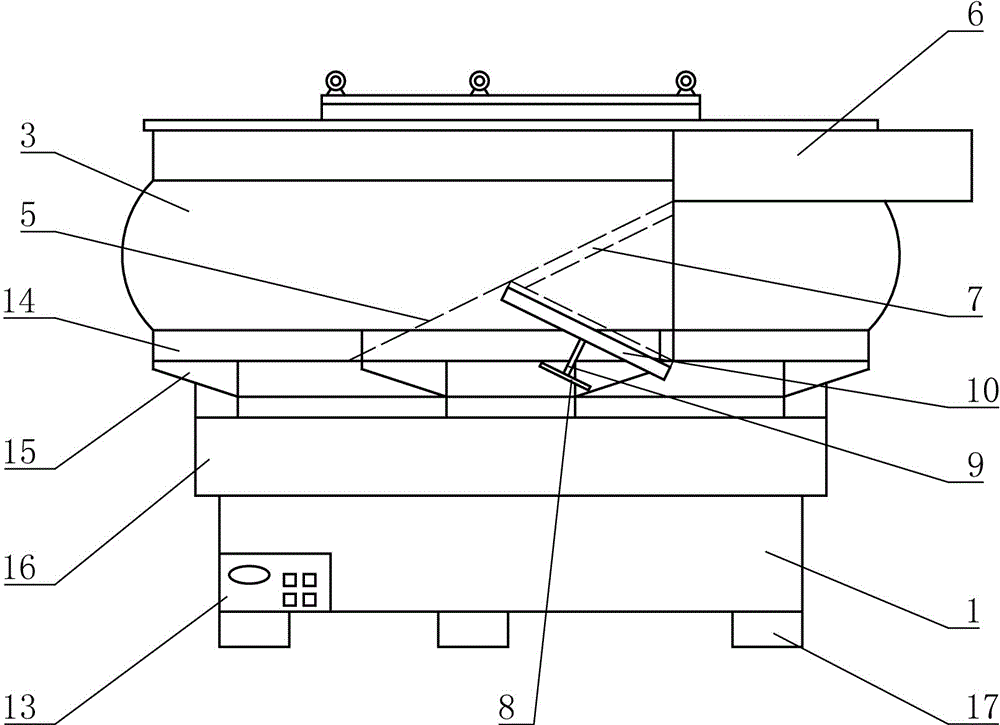

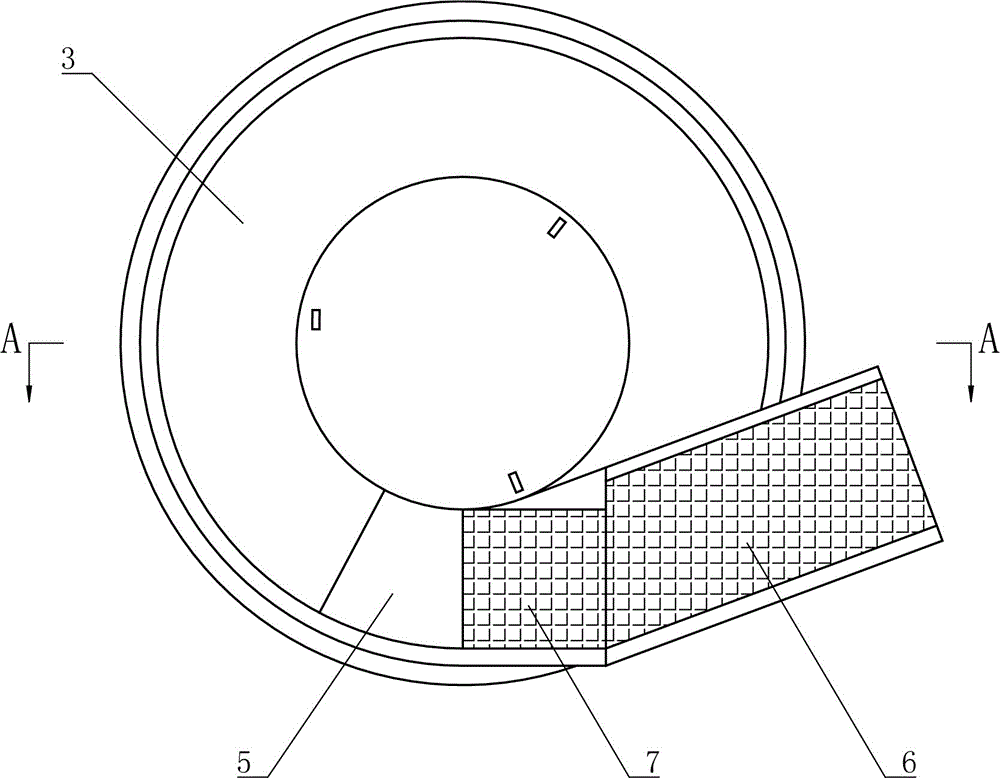

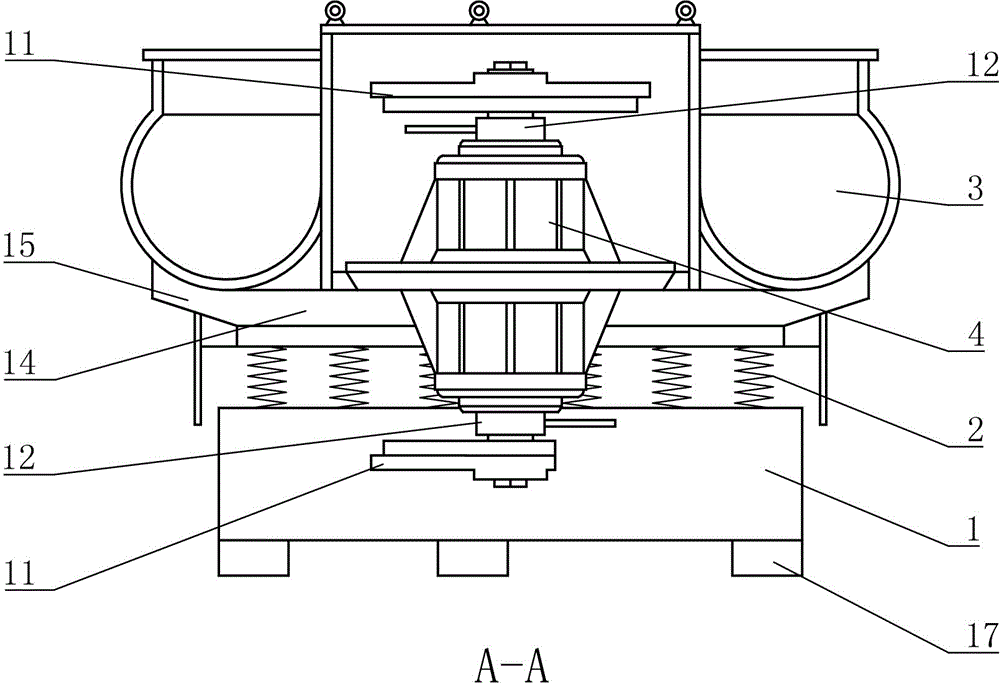

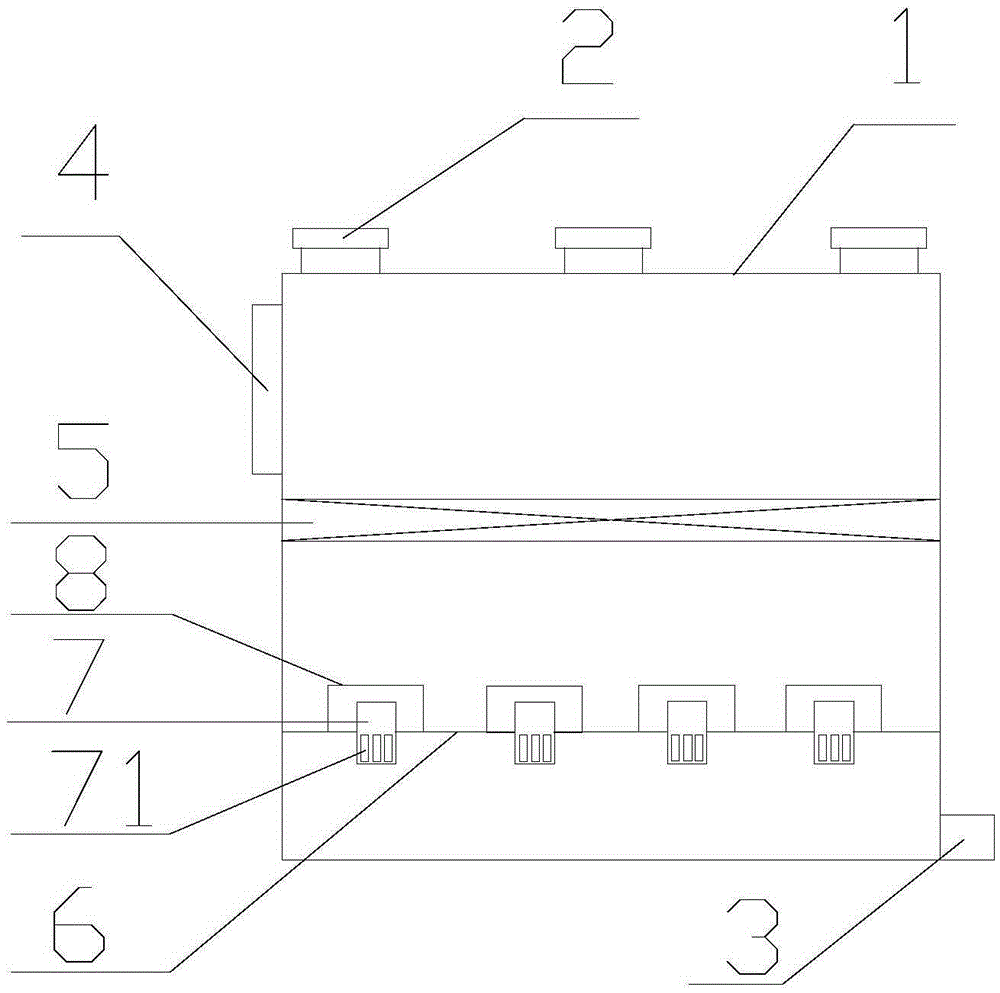

Vibration grinding and polishing machine capable of sorting automatically

InactiveCN102862115ASimple structureEasy to operateEdge grinding machinesPolishing machinesMechanical engineeringVibration motor

The invention relates to vibration grinding equipment, in particular to a vibration grinding and polishing machine capable of sorting automatically which can separate and select workpieces and grinding materials without stop operation and can grind unqualified workpieces continuously. The vibration grinding and polishing machine capable of sorting automatically comprises a base (1), a vibration disc (3) and a vibration motor (4), wherein the vibration disc (3) is connected with the base (1) through a spring (2); and the vibration motor (4) is fixedly arranged in the centre of the vibration disc (3). The vibration grinding and polishing machine capable of sorting automatically is characterized in that the lower part of the outside wall of the vibration disc (3) and the bottom longitudinal section are connected into a whole to form an arc shape; a bump (5) of which the longitudinal section is triangular is formed at the bottom of the vibration disc (3); a discharging groove (6) is horizontally formed at the upper end of the vibration disc (3); a feeding plate (7) is arranged on one side of the bump (5); one end of the feeding plate (7) is hinged with the top end of the bump (5); the lower part of the feeding plate (7) is connected with a change-over switch arranged outside the vibration disc (3); the other end of the feeding plate (7) is lapped with the opening of the discharging groove (6) after being opened; and screen meshes are respectively arranged at the bottom of the discharging groove (6) and on the feeding plate (7).

Owner:马静蓓

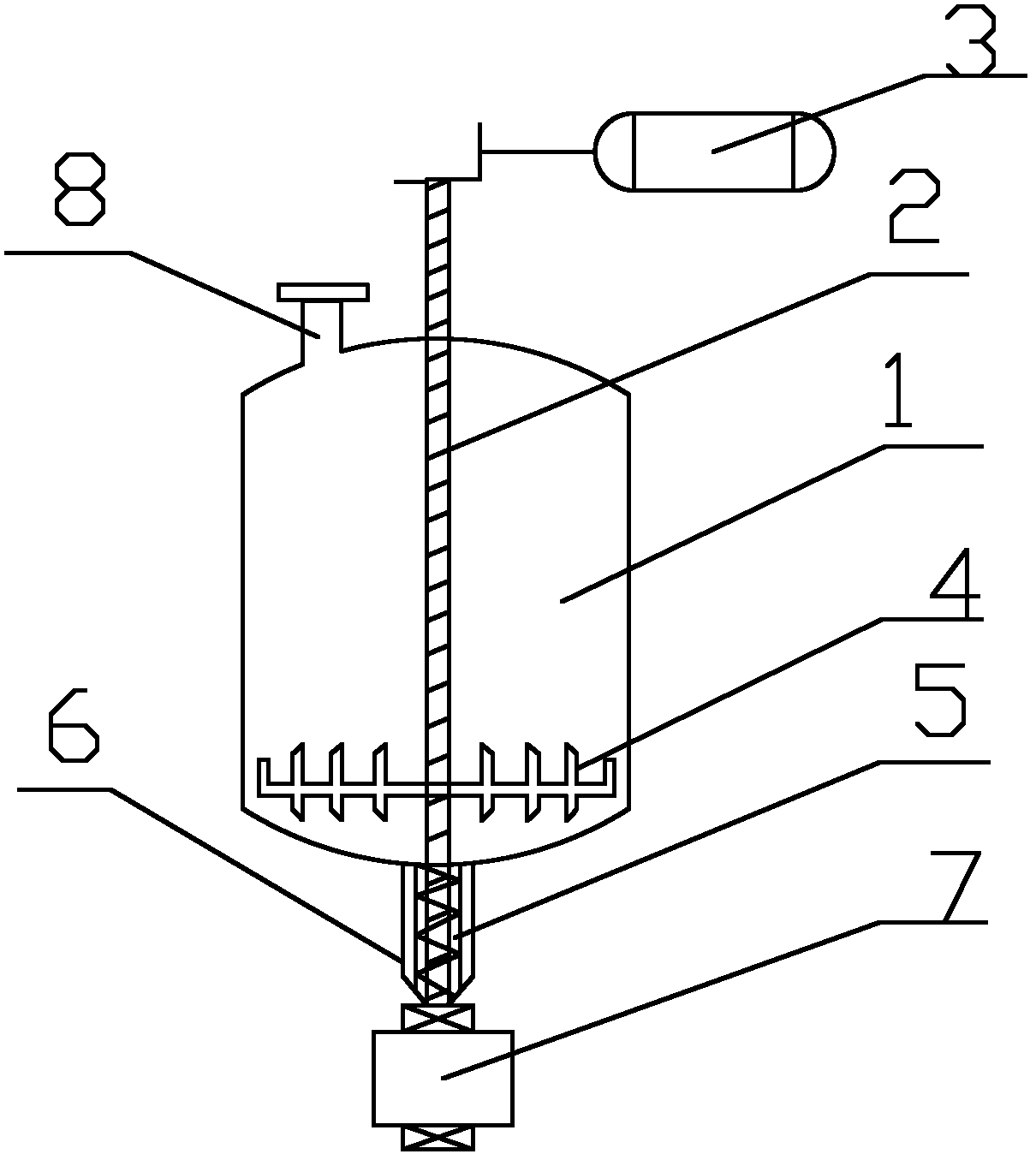

Stirring device for calcium carbonate

InactiveCN105413604AReasonable designStrong continuous workCalcium/strontium/barium carbonatesRotary stirring mixersEngineeringWorking capacity

The invention discloses a stirring device for calcium carbonate. The stirring device comprises a shell. A feed port is formed in the top end of the shell. A discharge port is formed in the bottom of the shell. A stirring stick is arranged in the shell and connected with an electric head outside the shell. Stirring blades are arranged on the stirring stick in a staggered mode. Heating devices are fixed to the stirring blades. The stirring device is reasonable in design and high in continuous working capacity; by fixing the heating devices to the stirring blades, it is ensured that heating is uniform in the device, and production efficiency is improved.

Owner:宜兴天力化工纳米科技有限公司

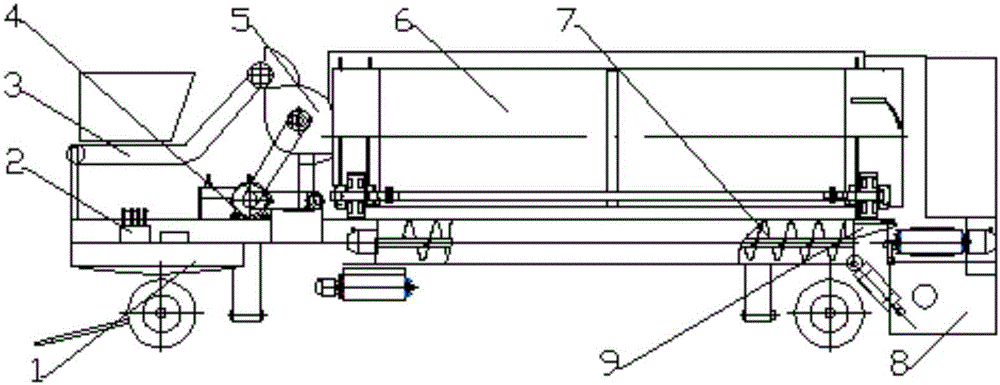

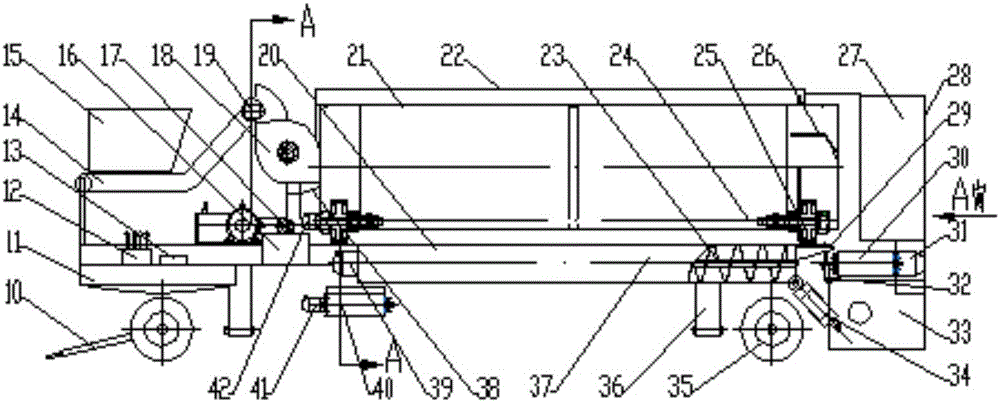

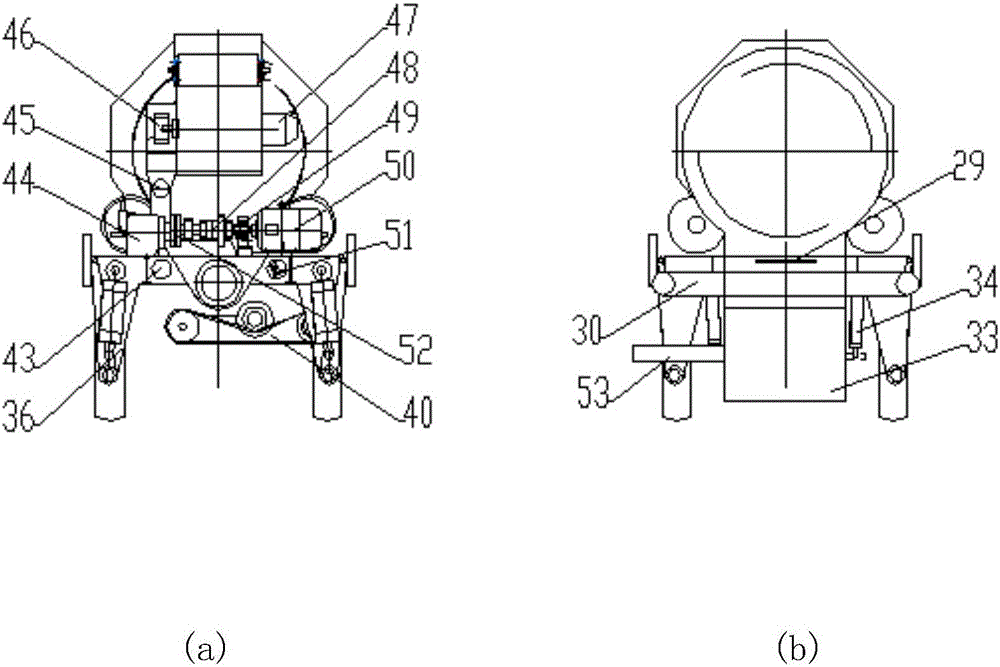

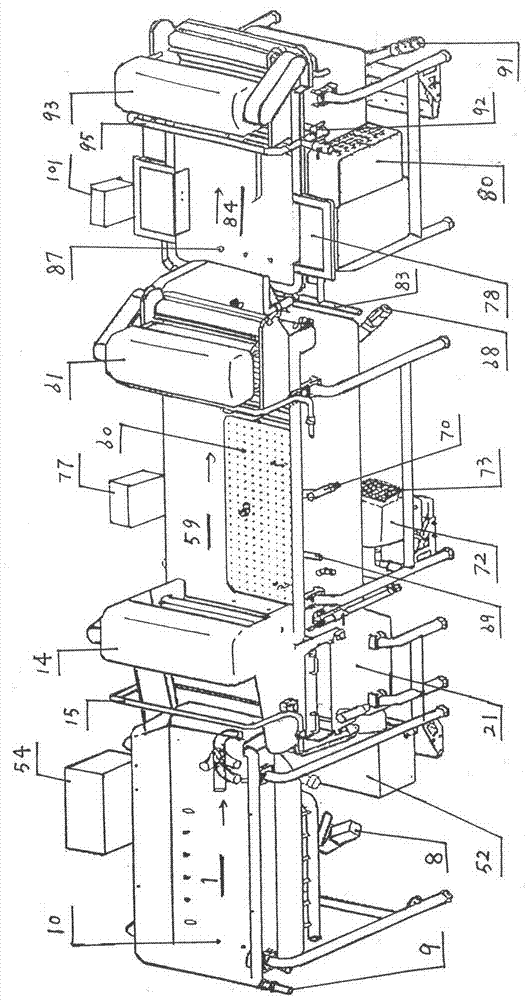

Moveable garbage sorting machine

InactiveCN106179965ACompact structureVersatileSievingGas current separationOperational costsVehicle frame

The invention discloses a moveable garbage sorting machine. The garbage sorting machine comprises a vehicle frame base plate, an electric energy and fuel engine hybrid power system, a hydraulic driving system, a material even conveying system, a bag breaking system, a roller screen system, a material separating conveying system, an air sorting system and a plastic packing system. All functions of garbage comprehensive sorting are set on a vehicle; and electric energy and a fuel engine are used for providing power, flexible change is conducted between the two types of kinetic energy, and then the hydraulic driving system is driven by a power distributing shaft to drive all the functional systems to operate. The moveable garbage sorting machine has the advantages of being compact in structure, complete in function, high inmaneuverability, simple in operation, high in continuous working capability, low in operating cost and the like, and is suitable for restoration of urban household garbage and municipal buried garbage.

Owner:XI AN JIAOTONG UNIV

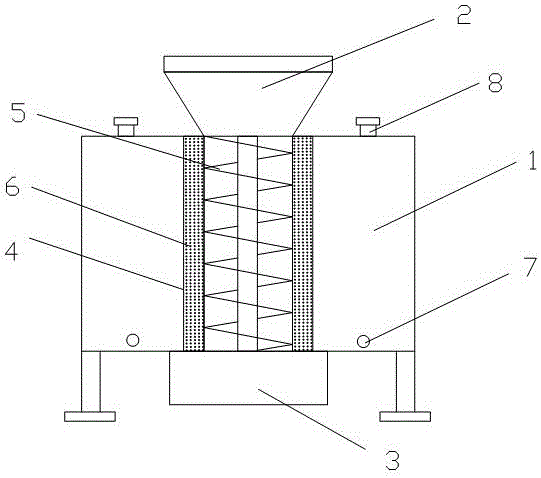

Solid-liquid separator for garbage

InactiveCN106731114ADesign scienceThe principle is simpleStationary filtering element filtersPulp and paper industryWorking capacity

The invention discloses a solid-liquid separator for garbage. The separator comprises a reactor, wherein a feed hopper is arranged at the top of the reactor, a waste discharge port is formed in the bottom, a cylinder is arranged in the reactor, a spiral stirrer is arranged in the cylinder, through holes are uniformly formed in the surface of the cylinder, the top end of the cylinder is connected with the feed hopper, the bottom end of the cylinder is communicated with the waste discharge port, and a liquid discharge port is formed in the side wall of the reactor. Compared with the prior art, the separator is scientific in design, simple in principle, high in continuous working capacity and free of any secondary pollution.

Owner:江苏荣豪生物环保科技有限公司

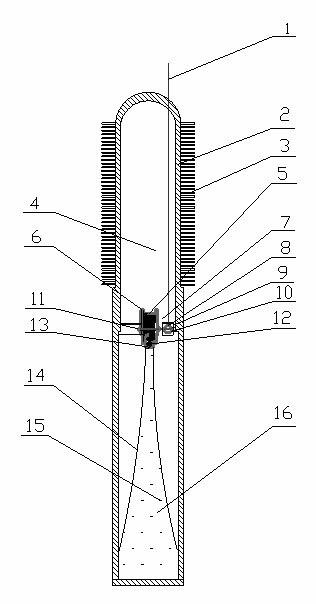

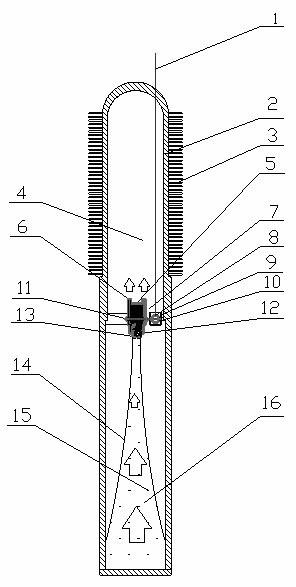

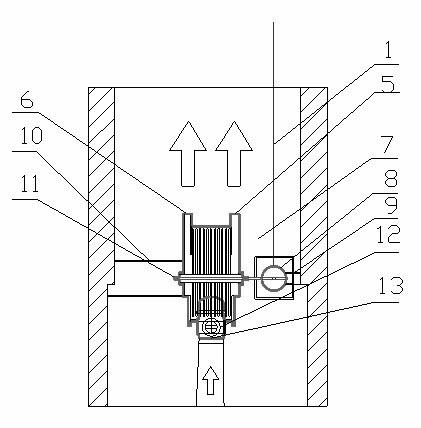

Heat pipe battery

InactiveCN102094683ASave energyEfficient use ofMachines/enginesEngine componentsThermodynamicsElectric machine

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sewage purification device for environmental protection

A disclosed sewage purification device for environmental protection comprises a shell, a filter channel is arranged in the shell in a penetrating mode, a filter screen plate used for filtering is arranged in the filter channel in a rotating connection mode through a first rotating shaft, and a self-cleaning mechanism which is arranged on the filter channel in a telescopic fit mode is arranged on one side of the filter screen plate in an attached mode; and a second rotating shaft is rotationally connected to the side, away from the filter screen plate, of the self-cleaning mechanism in the filter channel, a water baffle matched with the filter channel is fixedly connected to the periphery of the second rotating shaft, and the first rotating shaft and the second rotating shaft alternately rotate through a linkage mechanism. The filter screen plate rotates to press the self-cleaning mechanism, surface impurities are removed through the self-cleaning mechanism, a water baffle rotates for blocking, sewage is prevented from flowing out without being filtered during impurity removal, continuous water flow is also prevented from affecting impurity removal, intermittent impurity removal and water filtration can be formed through intermittent transmission of the linkage mechanism, and the continuous working capability of the device is higher.

Owner:TARIM UNIV

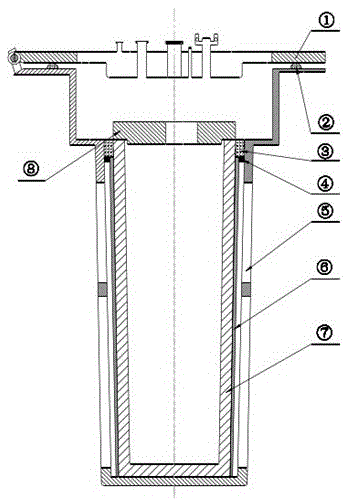

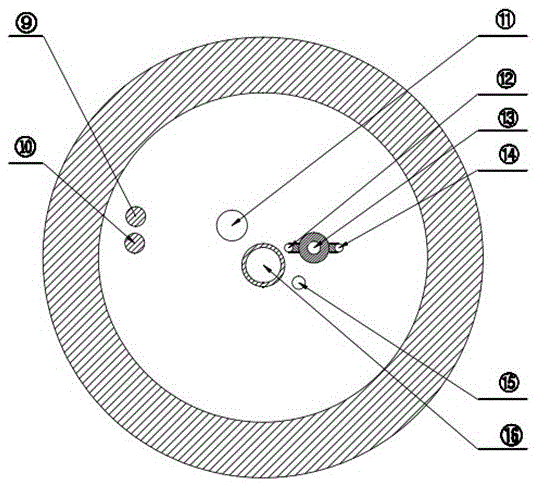

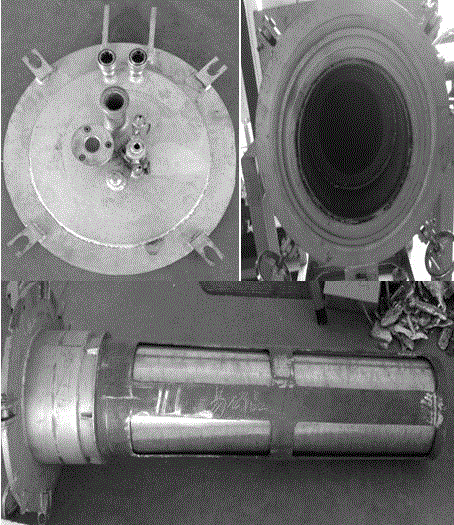

A furnace device and method for preparing ultra-high-purity aluminum

ActiveCN104263969BExtended service lifeReduce bearing deformationWorking capacityElectromagnetic stirring

The invention belongs to the technical field of metal purification, and relates to a furnace pipe device and a method for preparing ultra-high purity aluminum. The furnace pipe device is characterized by sequentially comprising a furnace pipe outer frame, a thin-wall seal sleeve and a graphite crucible from outside to inside, wherein a hinge furnace lid is arranged at the upper part of the furnace pipe; a water inlet hole, a water outlet hole, an observation hole, an air exhaust hole, an air inlet hole, an exhaust vent, a temperature measuring hole and a pressure measuring hole are formed in the furnace lid; a rubber seal strip is arranged between the furnace lid and the furnace pipe outer frame; and the furnace lid is connected and fastened with the furnace pipe through buckles and bolts. The furnace pipe device disclosed by the invention is capable of melting aluminum one time; the crystal is 65Kg; the height of a crystal aluminum ingot can reach 90cm; the single production can be increased by 2.5 times in comparison with that of a conventional high-purity aluminum production technology; an argon protection environment is only kept in the furnace pipe; the furnace pipe device has no environmental requirements on heating and electromagnetic stirring devices, and is strong in continuous working ability; compared with a conventional production technology, the furnace pipe device and the method have the advantages that the power consumption is reduced by 2 / 3; and the energy consumption cost is saved by 3 / 5.

Owner:江苏金海铝业有限公司

An automatic steel bar cutting machine with a fixed-length measuring device

ActiveCN104128539BEasy to processStrong reliabilityMetal working apparatusMechanical componentsEngineering

The invention discloses an automatic rebar cutting machine with a sizing device and a metering device. The automatic rebar cutting machine comprises a cutting device. The sizing device for automatically measuring the length of rebars and the metering device for counting the number of cut rebars are arranged in the front of the cutting device, and the sizing device, the metering device and the cutting device are in linkage. According to the automatic rebar cutting machine with the sizing device and the metering device, the length of the rebars is measured through the sizing device, when the measured length of the rebars reaches a preset value, the cutting device is triggered to cut the rebars, and meanwhile the number of the cut rebars is recorded through the metering device. According to the automatic rebar cutting machine, quantitative sizing cutting of the rebars can be automatically finished, machining capacity is high, the machine is wholly composed of mechanical components, cost is low, reliability is high, and continuous working capacity is high; due to the fact the machine is not provided with electronic accessories, maintenance is simple; general staff can use and operate the machine without being trained, and the automatic rebar cutting machine is convenient to use and high in practicability.

Owner:冯广建

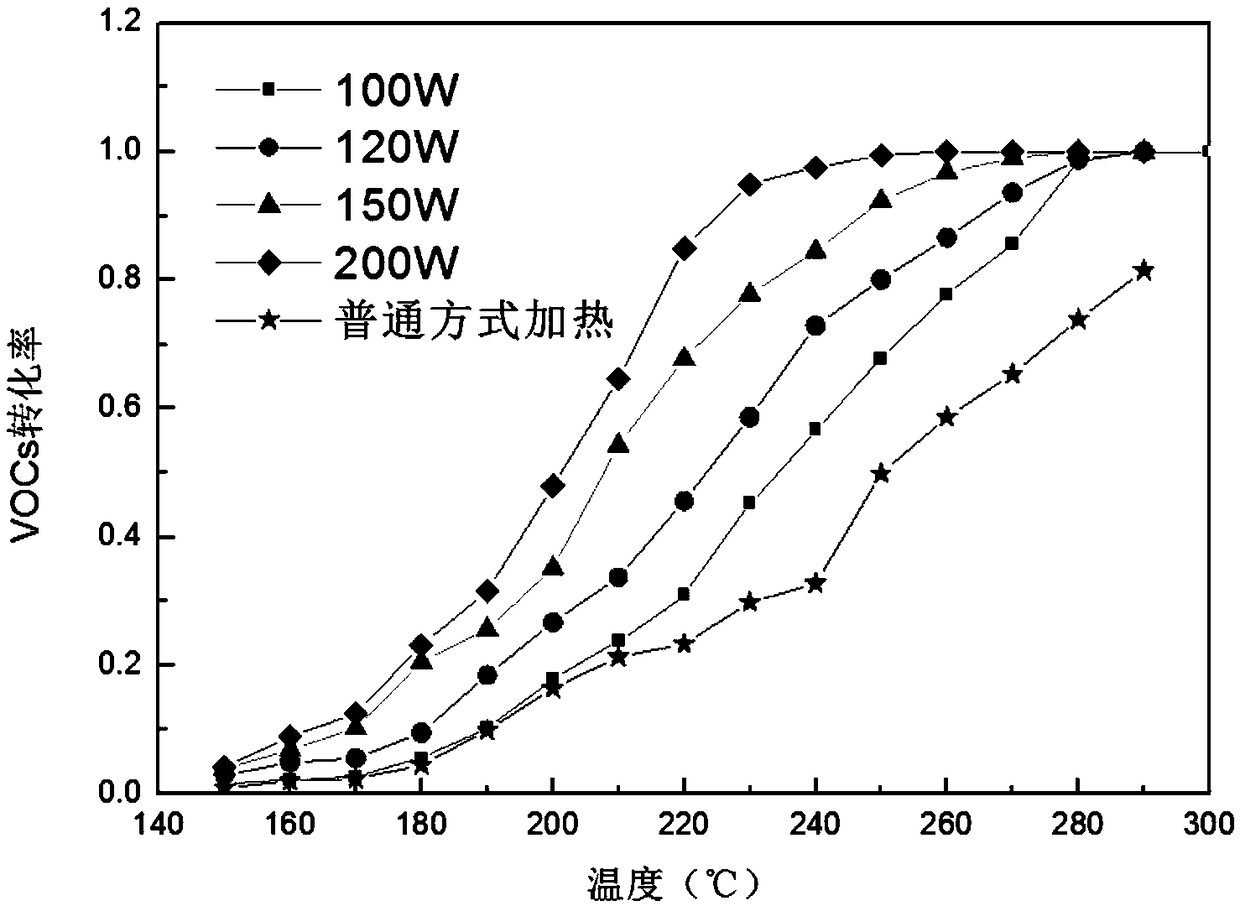

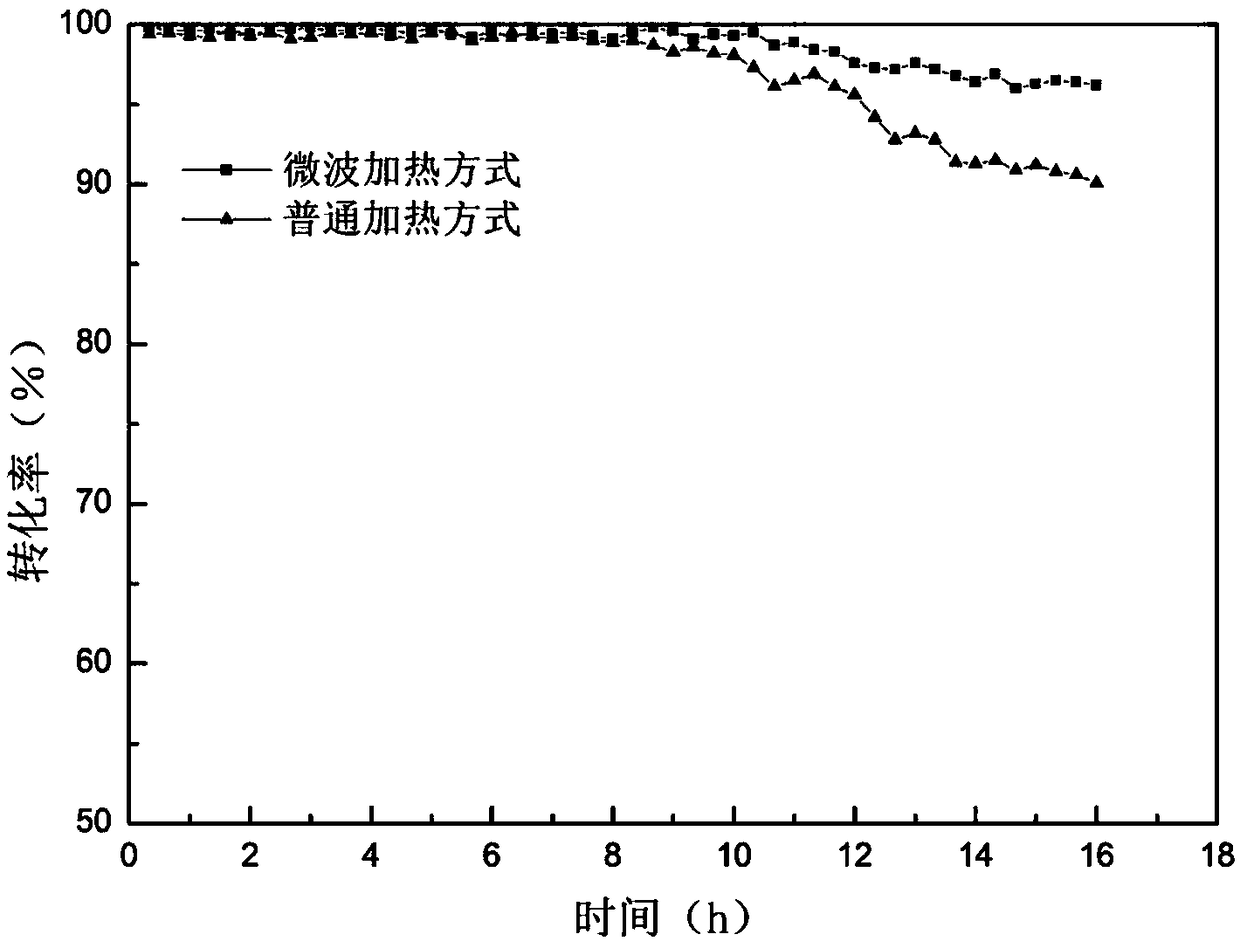

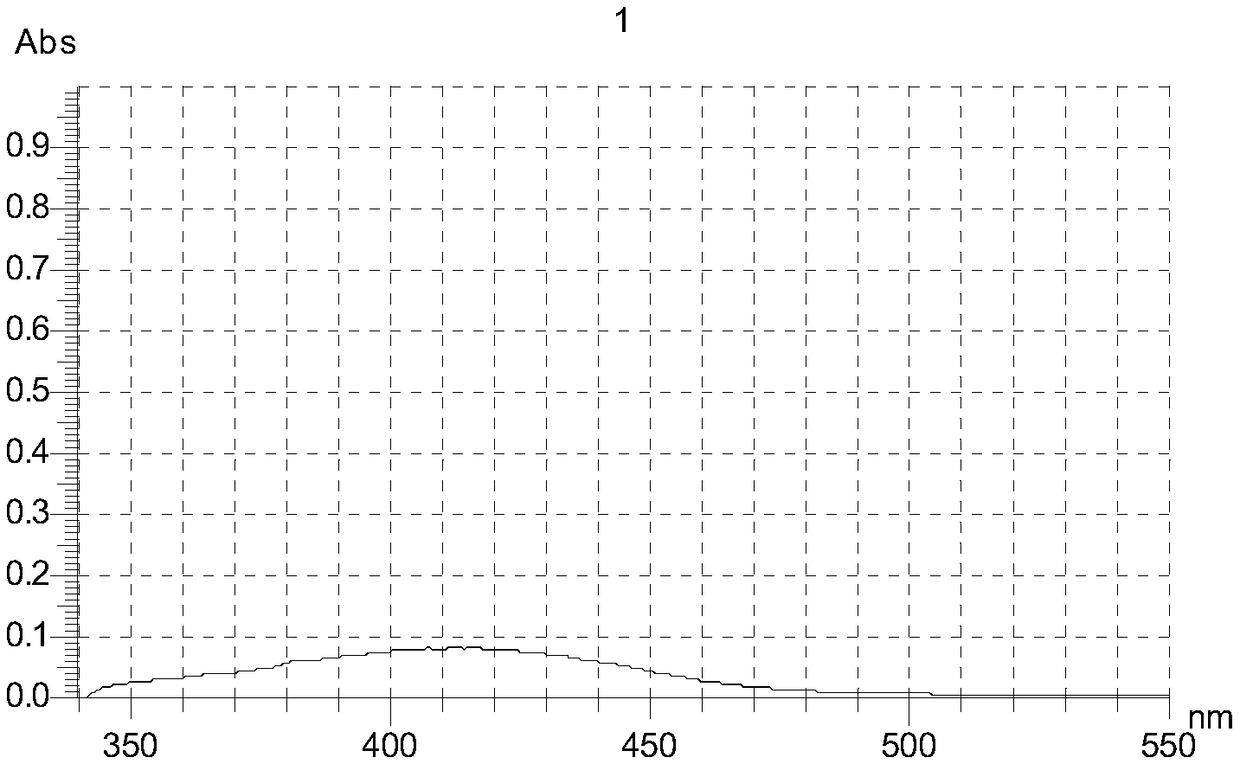

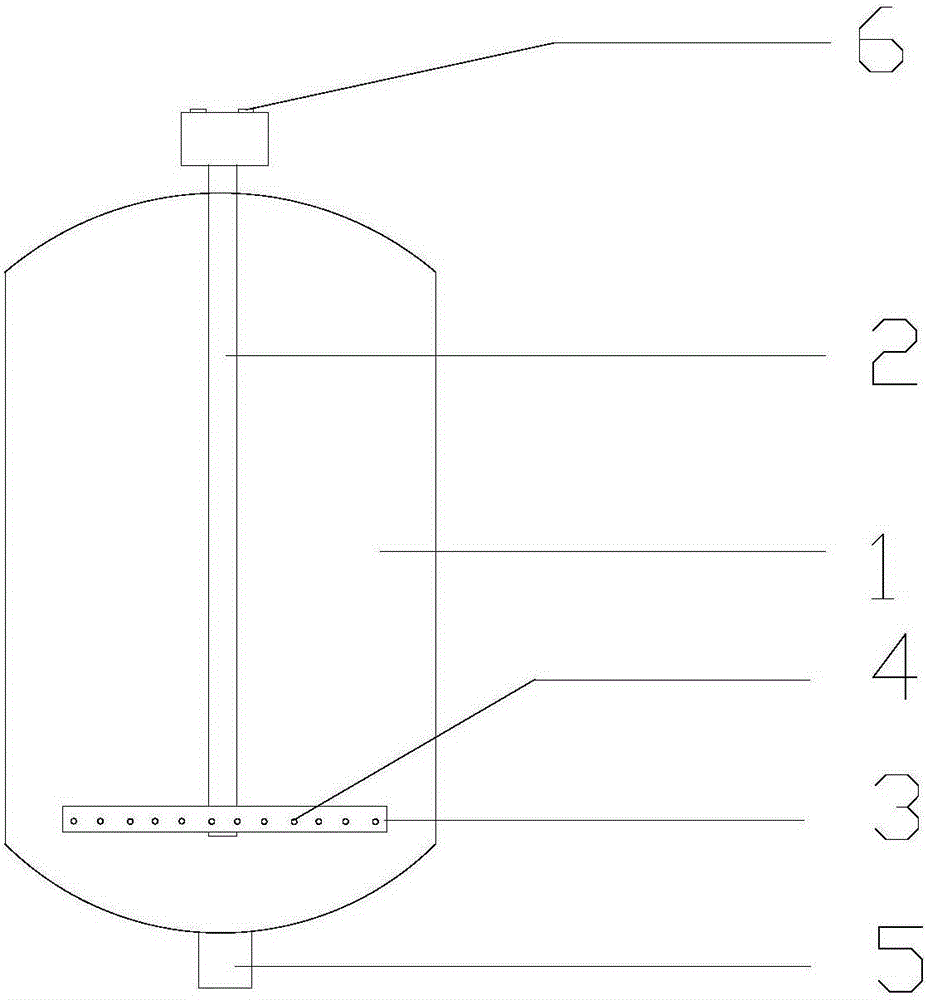

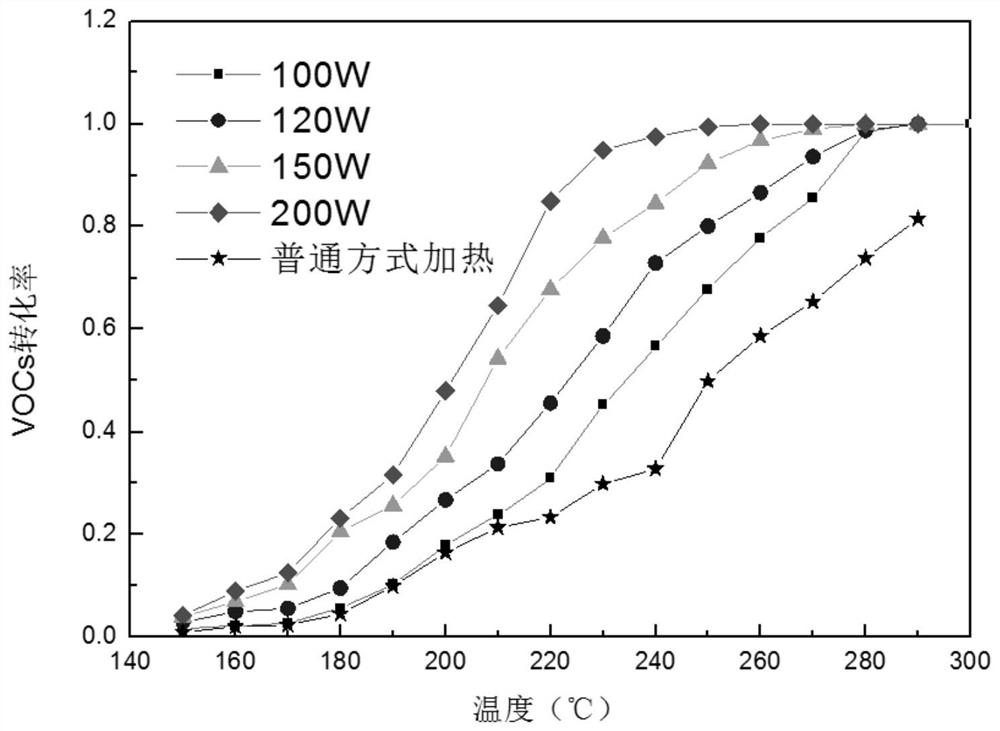

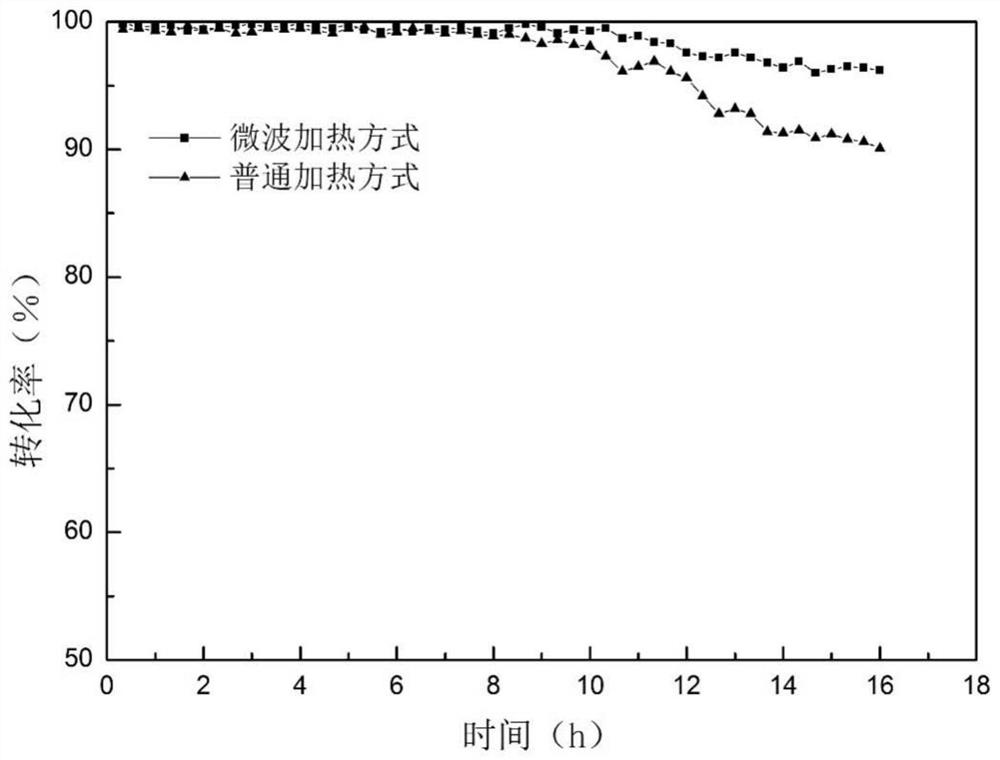

Manganese oxygen composite material for efficiently removing VOCs and preparation method and application thereof

ActiveCN109225205AEasy to prepareLow costGas treatmentDispersed particle separationMicrowaveManganese

The invention discloses a manganese oxygen composite material for efficiently removing VOCs and a preparation method and application thereof. The preparation method comprises the following specific steps: preparing the manganese oxygen composite material doped with Mg and loaded onto carbon nanotubes by a hydrothermal method, mixing the manganese oxygen composite material with quartz sand, then placing in a microwave device, inflating VOC gas and performing a removing reaction, wherein the manganese oxygen composite material is doped with the Mg and is loaded onto the carbon nanotubes. The manganese oxygen composite material has the advantages of high catalytic rate, high catalytic efficiency, low catalyst cost, a simple catalyst synthesizing method, strong catalyst stability, no secondarypollution and no need of retreatment.

Owner:SOUTH CHINA UNIV OF TECH

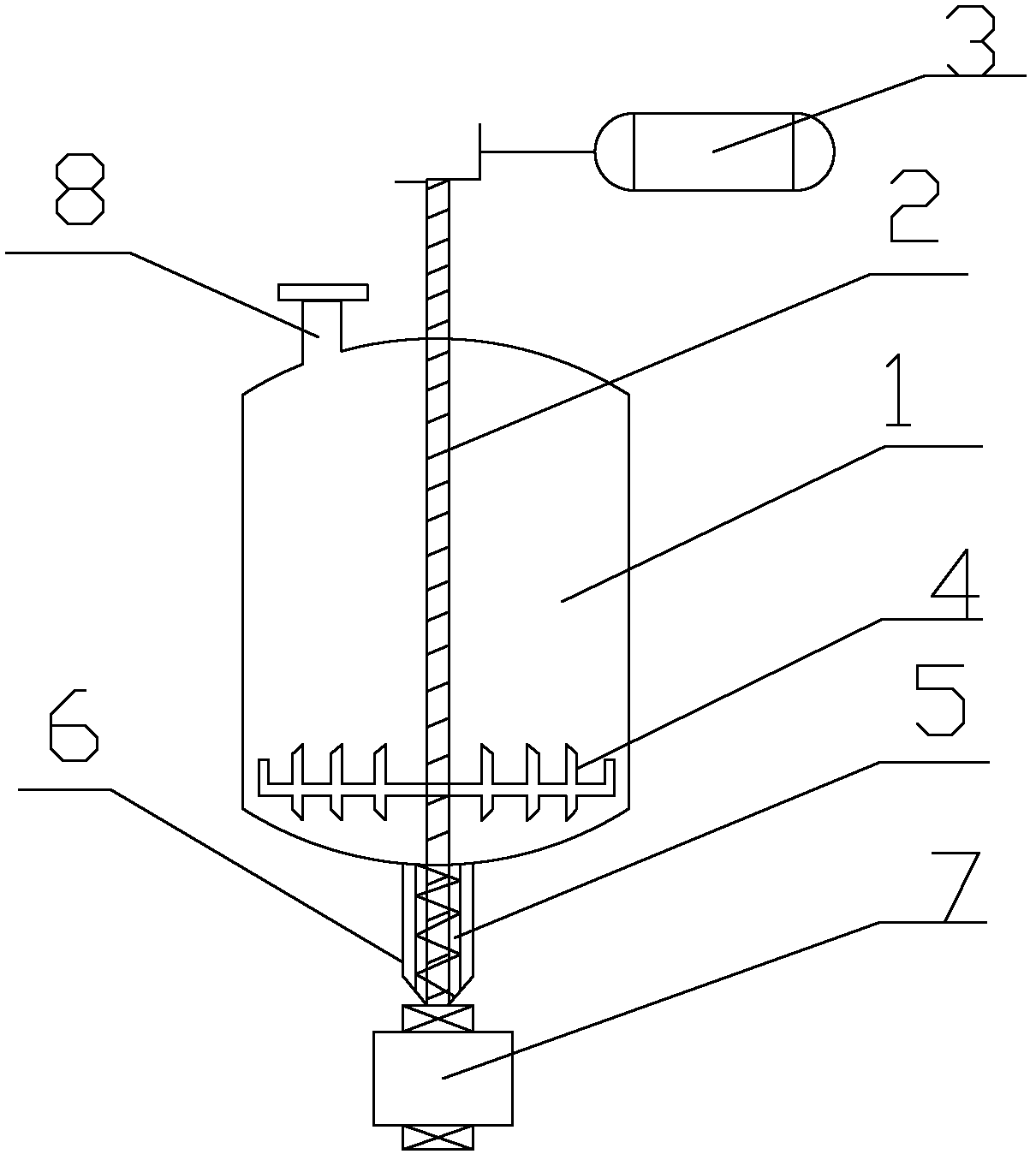

Closed calcium carbonate reaction device

InactiveCN105214588APrevent bringing inReduce generationCalcium/strontium/barium carbonatesChemical/physical/physico-chemical stationary reactorsDrive shaftEngineering

The invention discloses a closed calcium carbonate reaction device. The closed calcium carbonate reaction device comprises a reaction still. A transmission shaft penetrating through the reaction still is arranged above the reaction still. The transmission shaft stretches into the reaction still. A stirring vane is arranged at the bottom end of the transmission shaft. Cavities are formed in the transmission shaft and the middle of the stirring vane. The cavity of the transmission shaft and the cavity of the stirring vane are connected to form a channel which is enterable from the exterior of the reaction still. Through holes are formed in the surface of the stirring vane. A discharge port is formed in the bottom of the reaction still. The closed calcium carbonate reaction device is reasonable in design and high in continuous operational capacity, discharging is carried out through the cavity of the transmission shaft and the cavity of the stirring vane, excessive impurities are prevented from being brought in, meanwhile, it is guaranteed that the reaction is continuously conducted in the forward direction, and generated intermediates are reduced.

Owner:宜兴天力化工纳米科技有限公司

A manganese-oxygen composite material that efficiently removes vocs and its preparation method and application

ActiveCN109225205BEasy to prepareLow costGas treatmentDispersed particle separationPtru catalystCarbon nanotube

The invention discloses a manganese-oxygen composite material for efficiently removing VOCs, a preparation method and application thereof. The specific steps of the preparation method are as follows: the manganese-oxygen composite material doped with Mg and supported on carbon nanotubes prepared by the hydrothermal method is mixed with quartz sand, put into a microwave device, and VOCs gas is introduced , for the removal reaction. Among them, the manganese-oxygen composite material is not only doped with Mg but also supported on carbon nanotubes. The invention has the advantages of fast catalytic rate, high catalytic efficiency, low catalyst cost, simple catalyst synthesis method, strong catalyst stability, no secondary pollution and no need for reprocessing.

Owner:SOUTH CHINA UNIV OF TECH

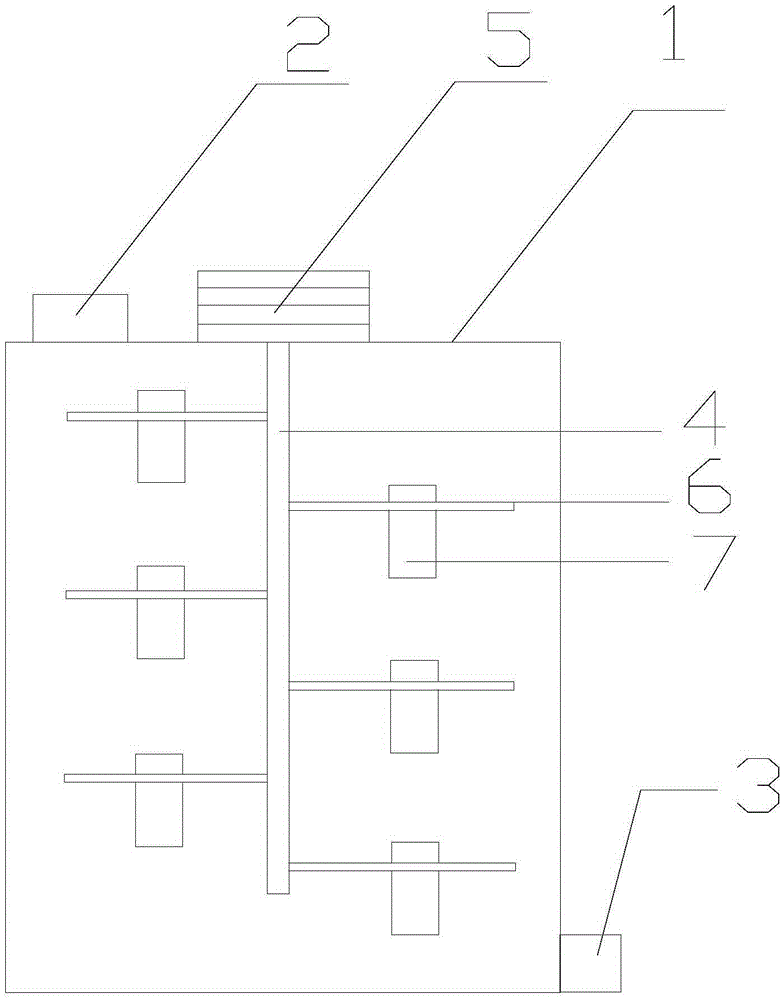

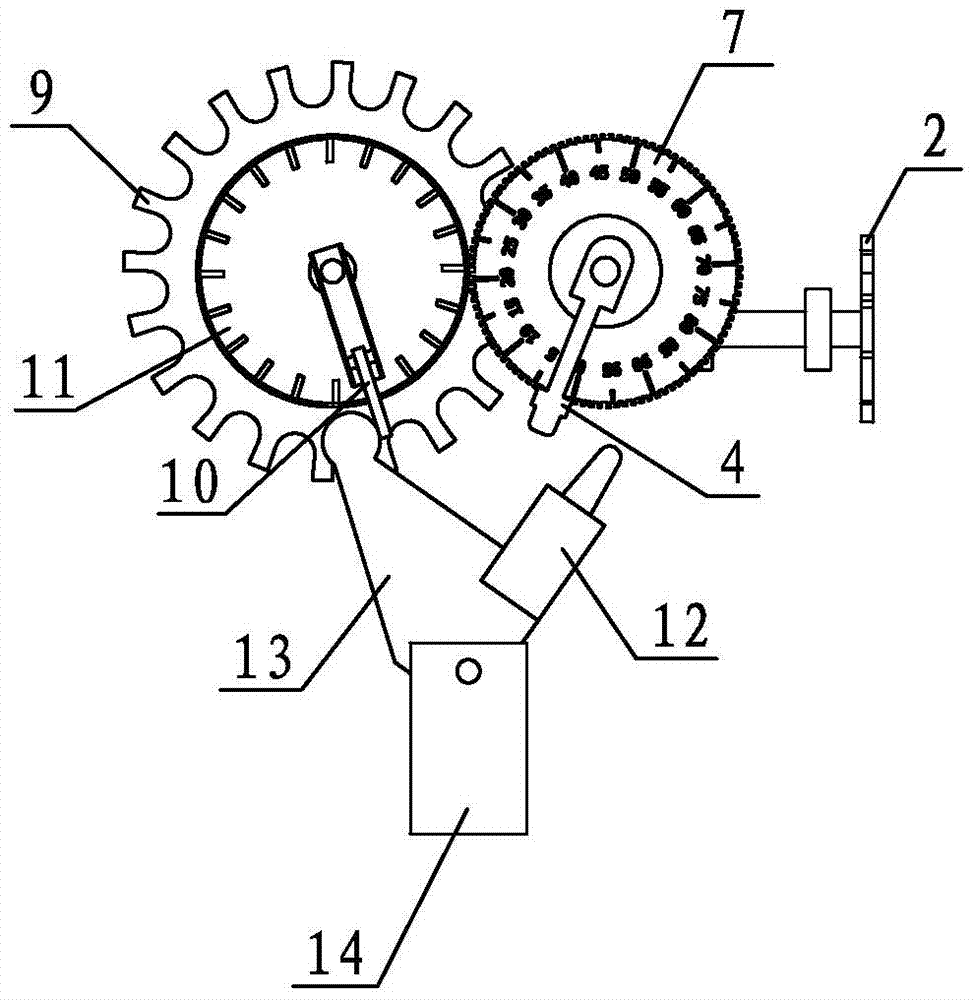

A periodic quantitative counting device

ActiveCN104143113BLow costStrong reliabilityCounting mechanisms/objectsMechanical componentsElectronic component

The invention discloses a peripheral quantitative counting device, which comprises a shifting block, a one-way dial, a counting needle, a counting dial and a travel switch. When the one-way dial rotates, the counting needle is driven to rotate, and the count increases by 1 each time the one-way dial is rotated; the counting dial is set behind the counting dial, and the scale value is set on the counting dial; the travel switch is set at the counting In front of the turning of the setting needle, the travel switch is triggered after the counting setting needle turns to the set number. Compared with the existing numerical control measuring instrument, the whole counting process of the periodic quantitative counting device of the present invention is automatically completed by mechanical components, and has low cost, strong reliability and strong continuous working ability. Since the device does not contain electronic accessories, the maintenance is simple, and ordinary employees can use it without training, so it is convenient to use and has strong practicability.

Owner:冯广建

Portable multi-functional high-strength steel bar bending and straightening machine and its operation method

Owner:THE SECOND CONSTR OF CTCE GROUP

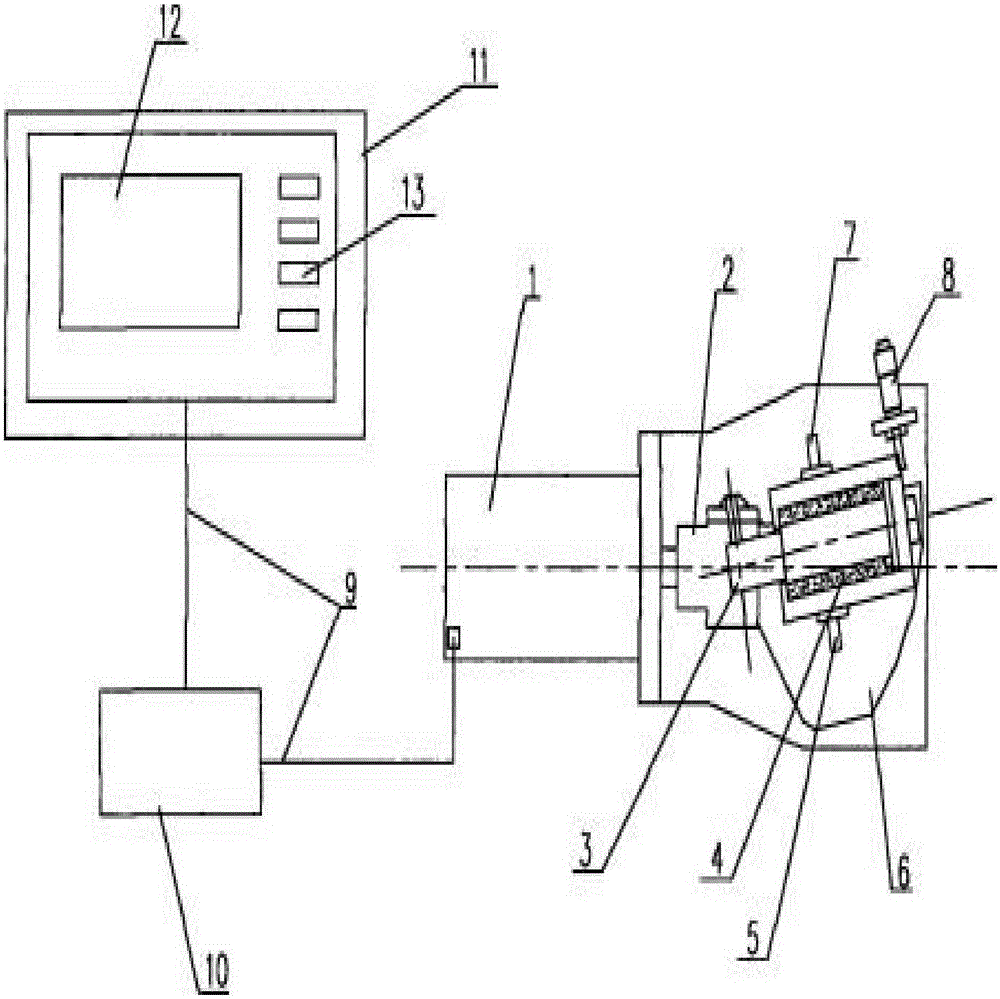

Efficient liquid charge pump device for production of lithium iron batteries

InactiveCN105201772AMeet the use requirementsHigh injection precisionPositive displacement pump componentsPump controlHuman–machine interfaceLiquid-crystal display

The invention discloses an efficient liquid charge pump for production of lithium ion batteries. The efficient liquid charge pump device comprises a step motor, a connection sleeve, a ceramic plunger, a ceramic pump body, a liquid outlet, an inclined fixing mechanism, a liquid inlet, a micrometer depth gauge, data lines, a PLC (programmable logic controller) system, a man-machine interface operation system, a liquid crystal display screen and parameter setting buttons, wherein the step motor is horizontally arranged on one side of the inclined fixing mechanism and penetrates through the inclined fixing mechanism to be connected with the connection sleeve; the connection sleeve is connected with the ceramic plunger in a ceramic liquid charge pump; the ceramic liquid charge pump comprises the ceramic plunger and the ceramic pump body; the liquid inlet is formed in one side of the ceramic pump body, and the liquid outlet is formed in the other side of the ceramic pump body; the ceramic liquid charge pump is arranged in a cavity of the inclined fixing mechanism, and the micrometer depth gauge is arranged at the upper part of the other side of the inclined fixing mechanism and connected with the tail end of the ceramic pump body of the ceramic liquid charge pump; the PLC system is connected with the man-machine interface operation system and the step motor respectively through the data lines.

Owner:TIANJIN NENGXIN TECH

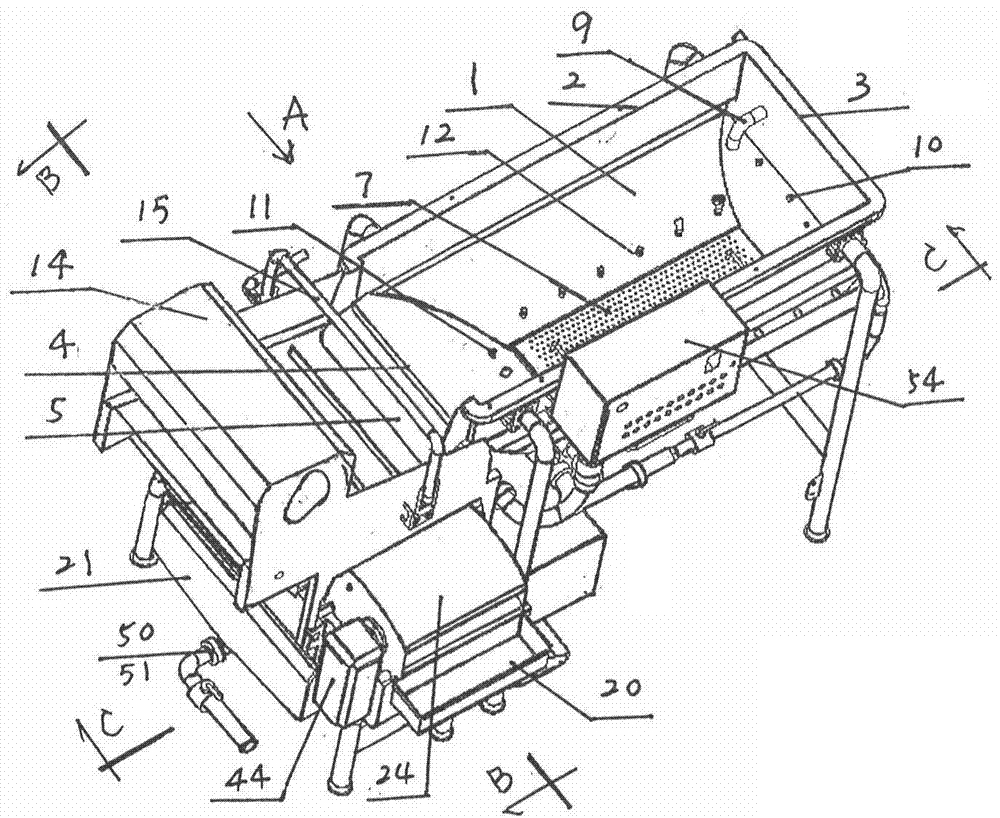

Compound fruit and vegetable cleaning device

InactiveCN104351593BImprove cleaning qualityQuality improvementClimate change adaptationFood treatmentSingle processSingle stage

The invention discloses a combined fruit and vegetable cleaning device, belongs to the field of food cleaning equipment, and overcomes defects of a single-process and single-stage single machine. The combined fruit and vegetable cleaning device sequentially comprises a first-stage water washing type coarse cleaning machine, a second-stage bubble type fine cleaning machine and a third-stage water catalyst sterilization and purification machine which are correlatively connected together, wherein each stage of machine comprises a rack, a water circulation system and a matched conveyor belt assembly, fruits and vegetables are coarsely cleaned by strong swirling flow in the first-stage machine, and simultaneously, a fruit and vegetable dreg filter device is arranged on the side of the first-stage machine; a fishbone-shaped bubble guide pipe is arranged in the secondary-stage machine, bubbles are powerful and balanced, and the fine cleaning effect is good; and water catalyst generators (100) are mounted on two NO.3 side walls (9) of a cleaning tank (8) of the third-stage machine respectively, the blockage is prevented, circulating water is clean, and sterilization and purification can be performed sufficiently. The combined fruit and vegetable cleaning device has simple structure and low cost, is easy to manufacture and mount and convenient to use and maintain, and occupies small space; and all stages of machines can be separately used and are not disturbed during overall operation after correlative connection, and the device is particularly applicable to continuous cleaning of a large quantity of fruits and vegetables and has high speed, high efficiency and good cleaning quality.

Owner:民银工业(北京)有限公司

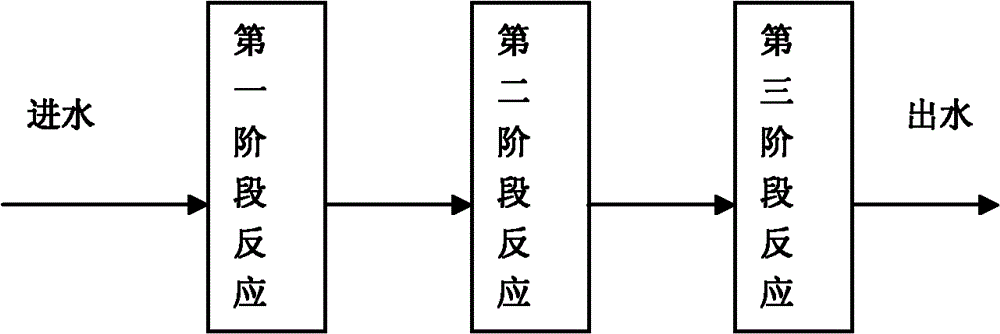

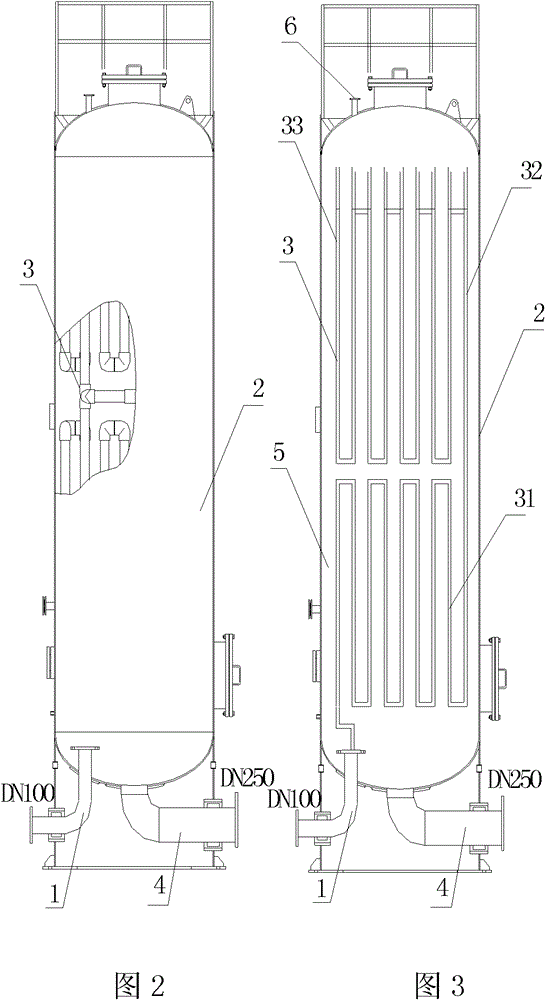

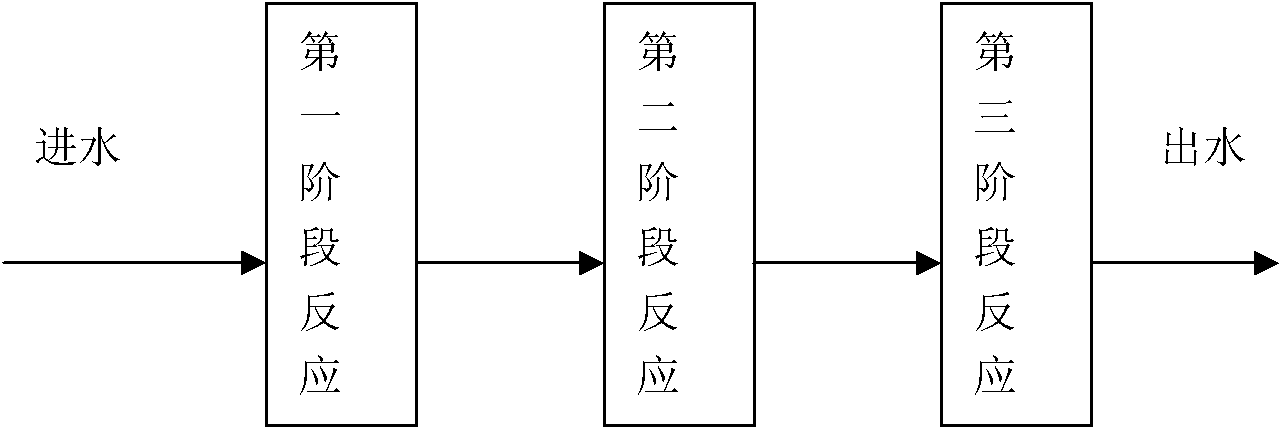

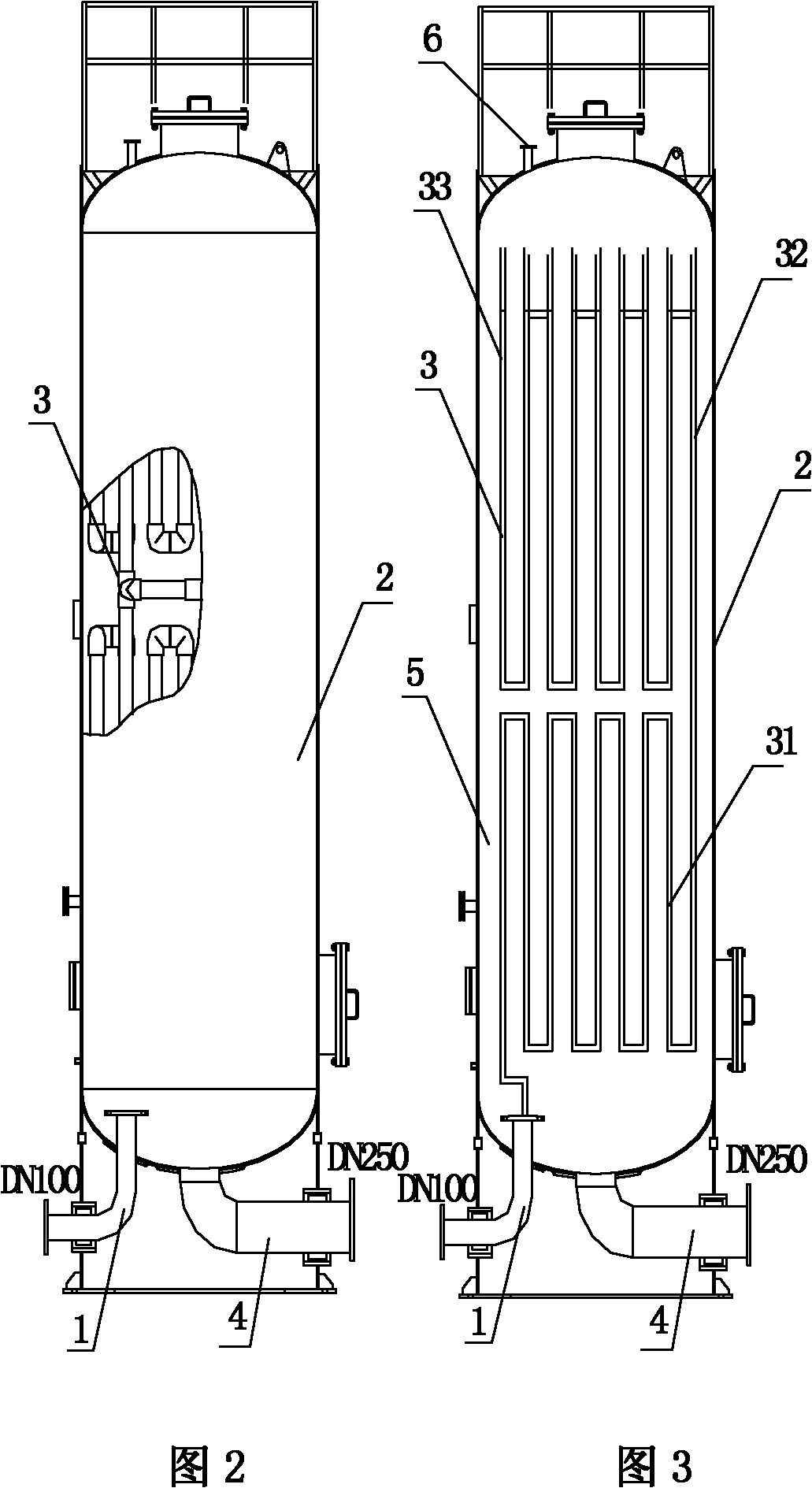

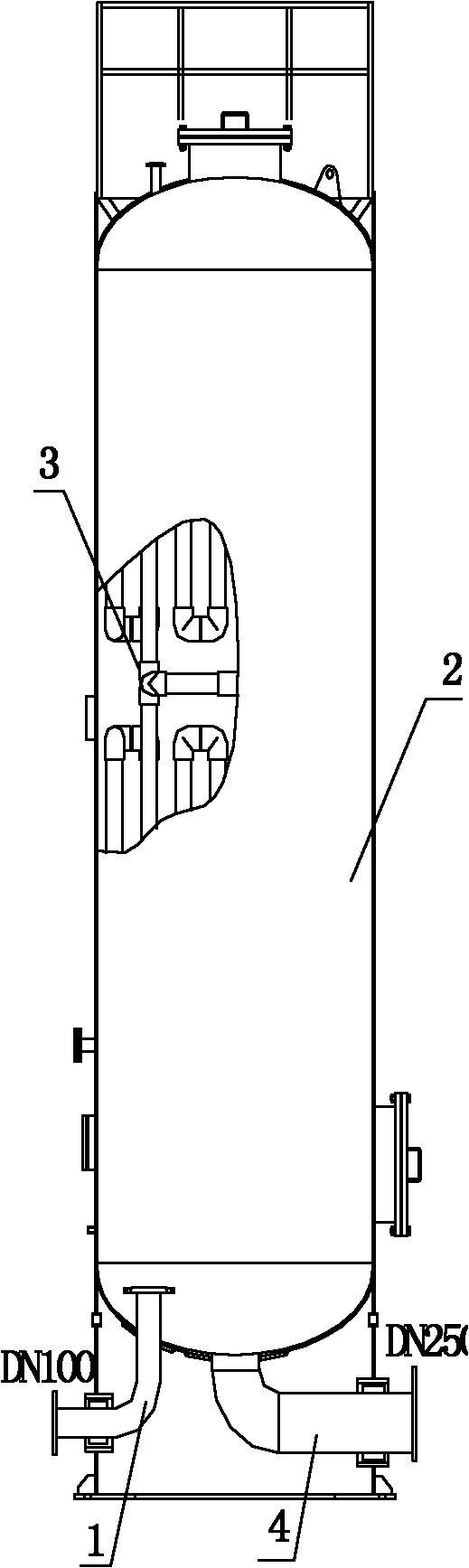

Unpowered cyclone reaction method and reactor

ActiveCN101912764BGood destabilizing flocculation effectReasonable structure layoutMixing methodsChemical/physical/physico-chemical stationary reactorsWater flowEngineering

The invention relates to an unpowered cyclone reaction method and a reactor, wherein the method comprises the following steps of: (1) adding a flocculating agent into water containing suspended substances; (2) enabling the water with the flocculating agent to flow through a section of high-speed pipeline through an inlet pipeline, wherein the diameter of the high-speed pipeline is smaller than that of the inlet pipeline; (3) enabling the water flowing through the high-speed pipeline to flow through a section of middle-speed pipeline, wherein the diameter of the middle-speed pipeline is larger than that of the high-speed pipeline but smaller than that of the inlet pipeline; (4) enabling the water flowing through the middle-speed pipeline to flow through a section of low-speed pipeline, wherein the diameter of the low-speed pipeline is equal to that of the middle-speed pipeline; (5) enabling the water flowing through the low-speed pipeline to flow through a section of full-flow pipeline, wherein the diameter of the full-flow pipeline is much larger than that of the inlet pipeline; and (6) enabling the water flowing through the full-flow pipeline to flow through a section of outlet pipeline, wherein the diameter of the outlet pipeline larger than that of the inlet pipeline but smaller than that of the full-flow pipeline. The invention solves the technical problems of incapability of continuous working, large maintenance difficulty, low utilization ratio and high cost of traditional mechanical stirring and coagulation reaction and has the advantages of wide application range and continuous working.

Owner:陕西雷光环保科技有限公司

High-precision gesture rotation system

PendingCN108608422AHigh positioning accuracySimple structureProgramme-controlled manipulatorJointsHarmonicReduction drive

The invention provides a high-precision gesture rotation system. The system comprises a fixed base, a harmonic speed reducer, a servo motor and a main rotating shaft, the harmonic reducer is installedon the fixed base, the servo motor is installed on a shell body of the harmonic speed reducer, the driving end of the servo motor is provided with a synchronization belt wheel, the input end of the harmonic speed reducer is also provided with a synchronization belt wheel, and the synchronization belt wheel on the harmonic speed reducer is in transmission connection with the synchronization belt wheel on the servo motor through a synchronous belt; and the main rotating shaft is fixedly connected with the output end of the harmonic speed reducer, the main rotating shaft and the output end of the harmonic speed reducer synchronously rotate, and the main rotating shaft is used for being used as a load installing platform. The high-precision gesture rotation system is simple in structure, highin positioning accuracy, good in stability, low in cost and convenient to move; and compared with existing general related equipment, the system is capable of realizing high-precision and fast rotating gesture control and positioning, and is particularly suitable for the application fields in which the high-precision and fast rotation gesture control needs to be carried out, such as wafer carrying in the semiconductor production industry.

Owner:昀智科技(北京)有限责任公司

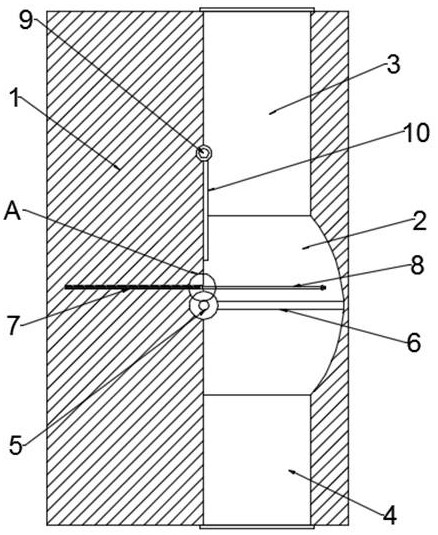

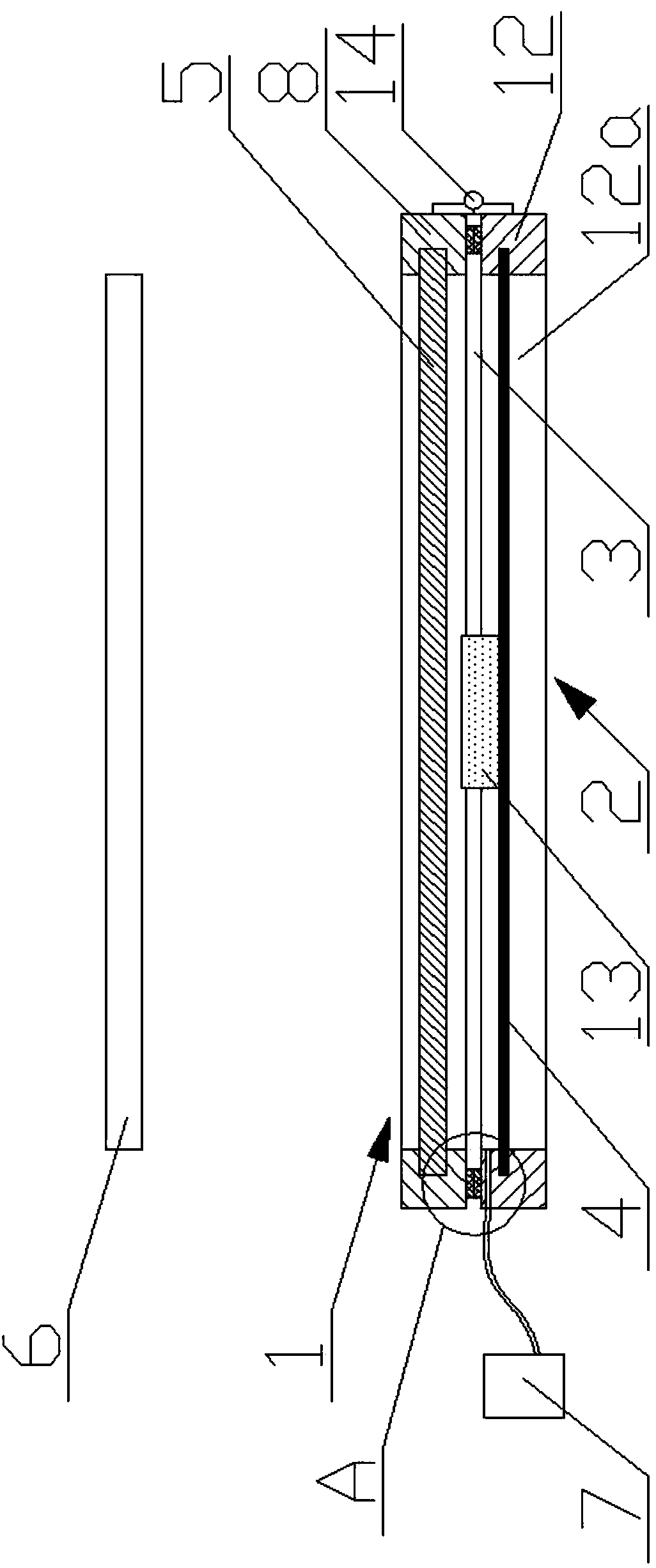

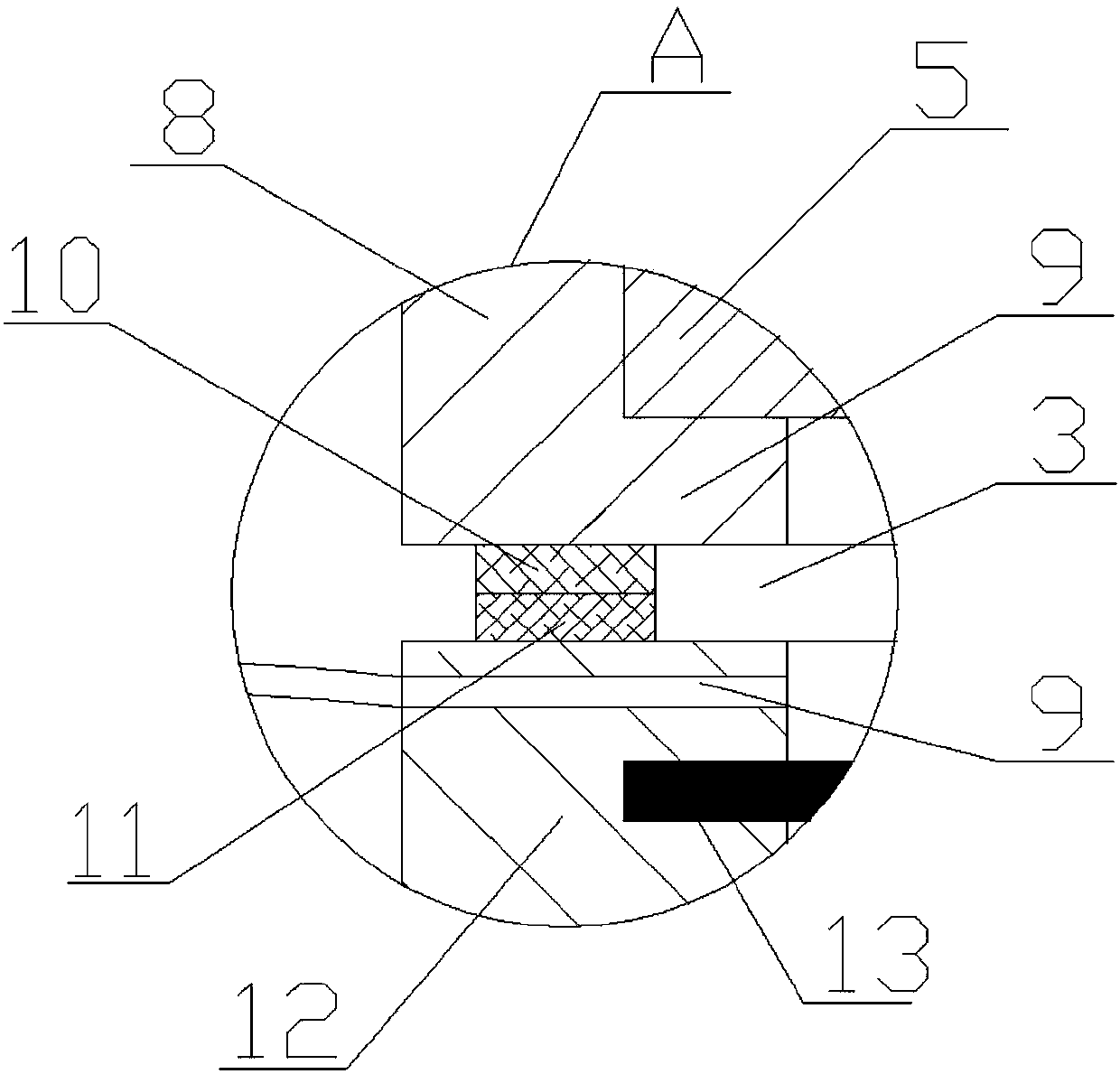

Vacuum exposure device for exposure machine

PendingCN107908080AMonitoring statusGuaranteed reliabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusVisual monitoringEngineering

The invention discloses a vacuum exposure device for an exposure machine. The vacuum exposure device is used for exposure platemaking of a screen (13) and comprises an exposure lamp (6) and a vacuum suction system (7); the vacuum exposure device for the exposure machine also comprises an upper sealing component (1) and a lower sealing component (2) which are arranged below the exposure lamp (6), wherein an airtight space (3) is formed between the upper sealing component (1) and the lower sealing component (2); the vacuum suction system (7) can vacuumize the space (3); a moving part (4) for putting the screen (13) is arranged on the lower sealing component (2); the upper sealing component (1) comprises a glass plate (5); when the vacuum suction system (7) vacuumizes the space (3), the moving part (4) moves upwards and drives up the screen (13) to be laminated with the glass plate (5). The vacuum exposure device for the exposure machine, disclosed by the invention, has the advantages that the state of the screen can be monitored in real time, so that the reliability of the exposure platemaking is better ensured.

Owner:LOBON SCREEN PRINTING EQUIP

Filtering device used for calcium carbonate

InactiveCN105396345AReasonable designStrong continuous workCalcium/strontium/barium carbonatesStationary filtering element filtersEngineeringMetal

The invention discloses a filtering device used for calcium carbonate, comprising a reaction kettle, wherein a group of feeding holes is formed at the top of the reaction kettle, a discharge hole is formed in the bottom of the reaction kettle, a manhole is formed in the side wall of the reaction kettle; a filter plate is arranged in the middle of the reaction kettle, a clapboard is arranged at the bottom of the reaction kettle, a group of flow dividing devices are arranged on the clapboard, and the clapboard is located above the horizontal position of the discharge hole. The filtering device is reasonable in design and strong in continuous working capability, and can control the fineness of materials respectively through the filter plate, a metal cover, the clapboard and the flow dividing devices, so as to ensure the normal operation of subsequent processes.

Owner:宜兴天力化工纳米科技有限公司

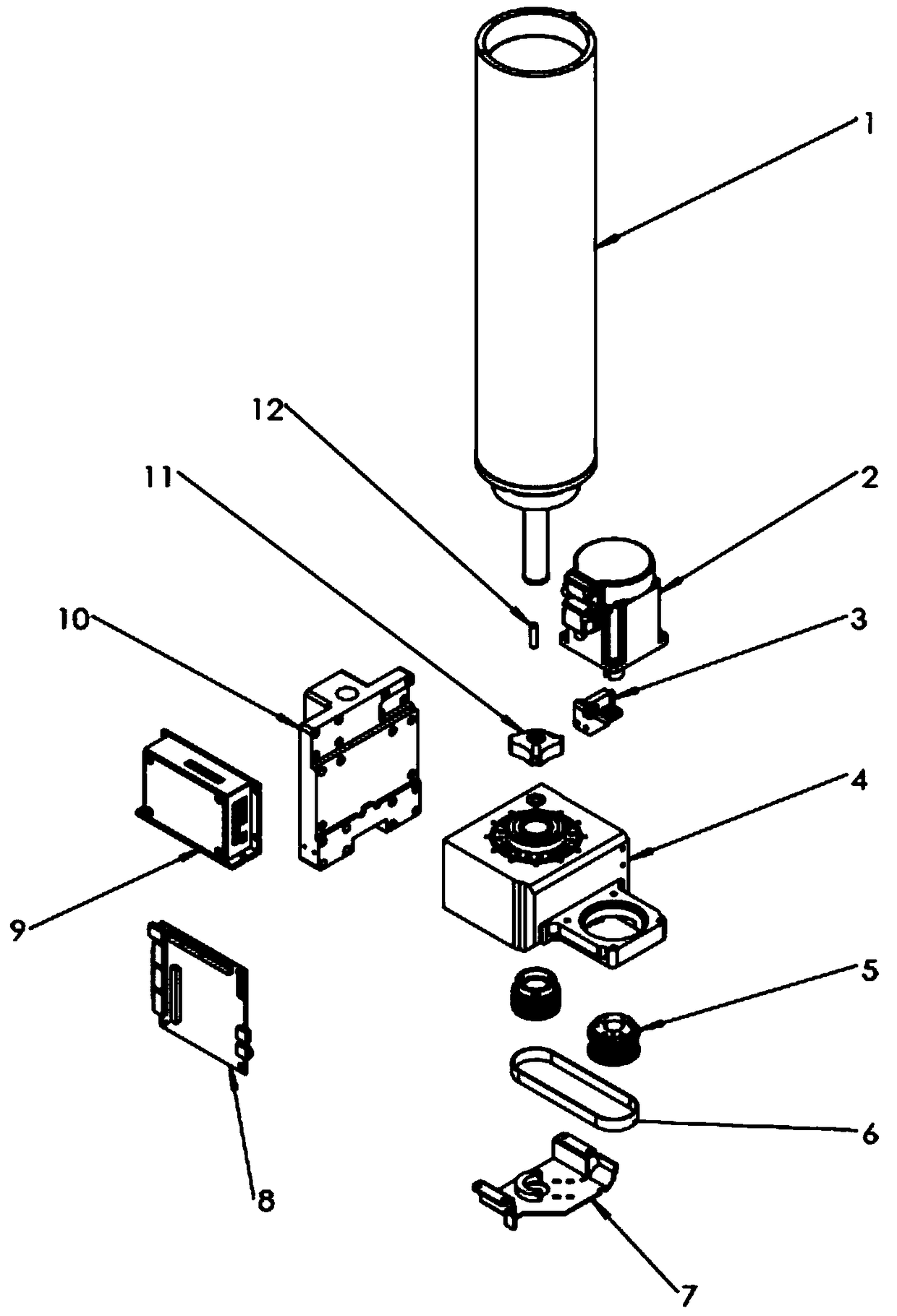

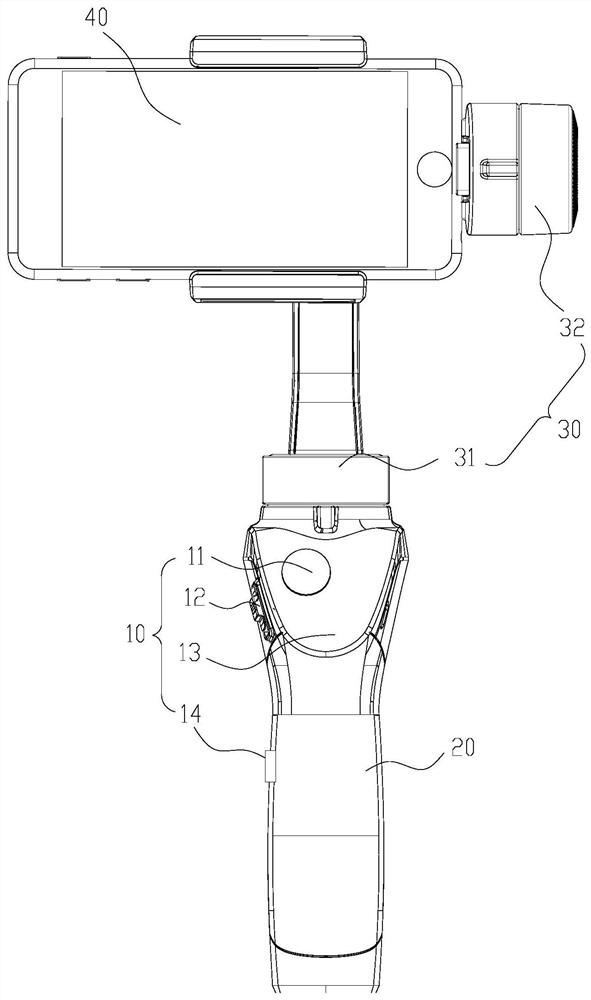

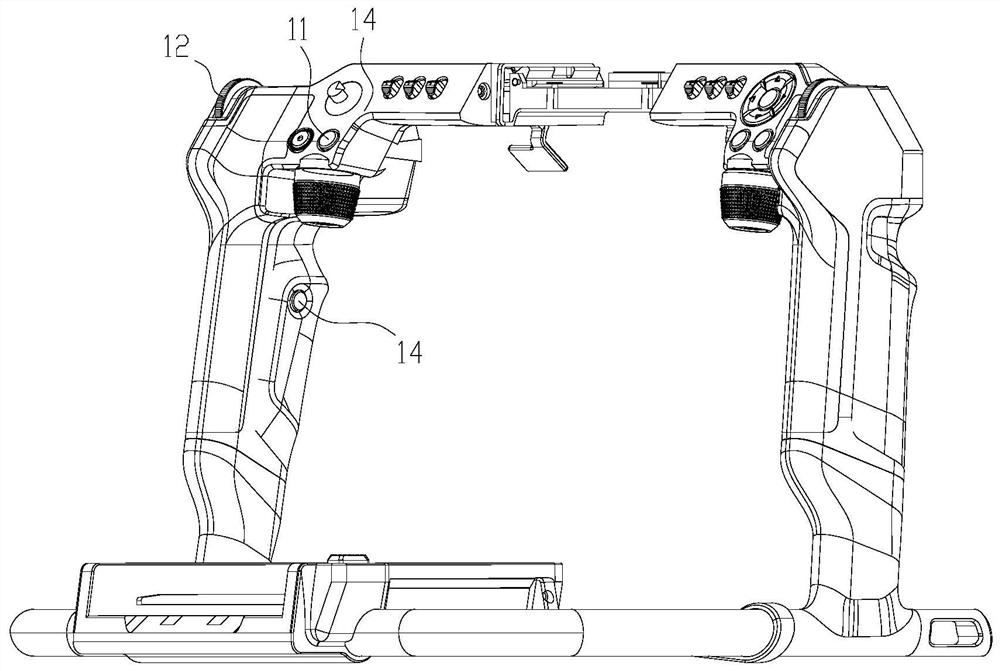

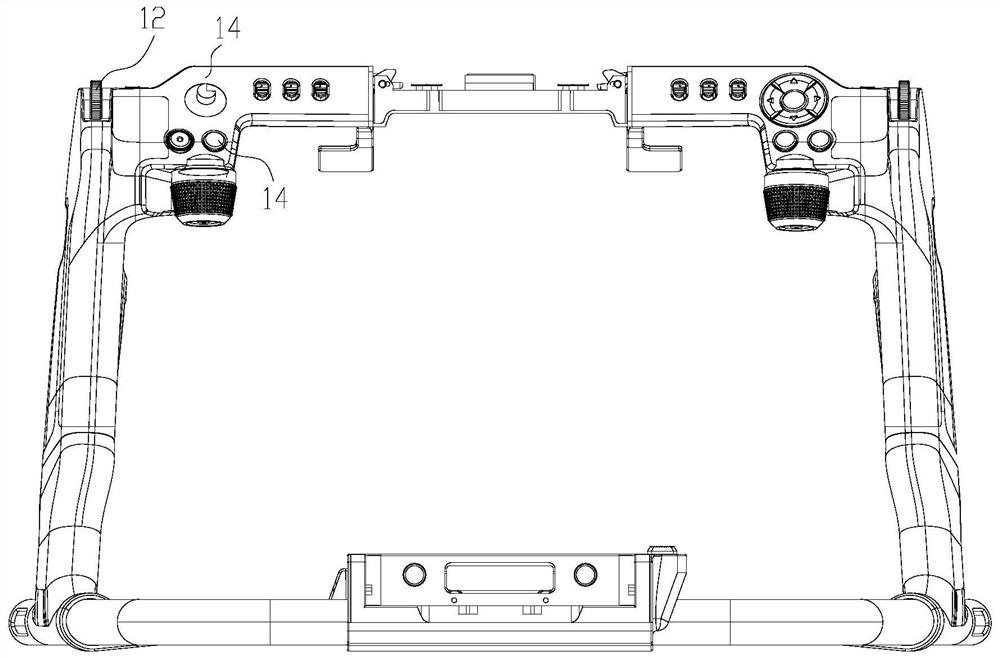

Control Modules and Handheld Devices

ActiveCN110337559BStrong continuous workImprove the shooting effectStands/trestlesCamera body detailsControl engineeringControl cell

A control module and a handheld device. The control module (10) is used to adjust the rotational speed of the stabilizer (30), and the control module (10) includes a key body (14), a control unit, a trigger (11) arranged on the key body (14), and an adjustment A part (12), wherein, the trigger part (11) and the adjustment part (12) are respectively connected to the control unit in communication; the trigger part (11) is used to send a trigger signal to the control unit, and the The control unit controls the stabilizer (30) and the adjustment member (12) to enter the speed setting state, the adjustment member (12) is used to send a speed signal to the control unit, and the control unit according to the adjustment adjust the speed of the stabilizer (30) to the speed corresponding to the speed signal.

Owner:SZ DJI TECH CO LTD

Metal deactivator discharge device

InactiveCN102614816AReasonable designStrong continuous workChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringMetal deactivator

The invention discloses a metal deactivator discharge device, which comprises a reactor. A rotating shaft penetrates through the reactor, the outer side of the rotating shaft is connected with a motor, the rotating shaft is further connected with a scraper blade in the reactor, a discharge stirring cage is disposed outside the rotating shaft below the reactor, a storage box is disposed right below the discharge stirring cage, and a material inlet is arranged at the top of the reactor. The metal deactivator discharge device is reasonable in design, high in continuous work ability and convenient in repair, and reduces waste of energy.

Owner:宜兴汉光高新石化有限公司

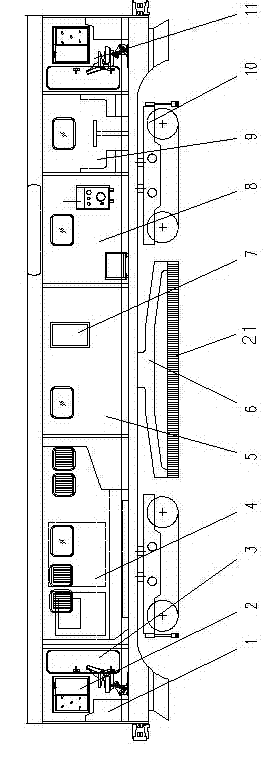

Sand removal engineering truck

ActiveCN103526714BSolve the problem of sand removalStrong continuous workRailway cleaningBogieControl system

The invention relates to the technical field of large railway engineering machinery, in particular to a sand removal engineering truck. A bogie is arranged at two ends of the lower portion, a sand sucking device is arranged in the middle of the lower portion, and a driver's cab I, a power room, a work room, an auxiliary room, a living room and a driver's cab II are sequentially arranged at the upper portion. A sand throwing machine is arranged in the work room, cleaning devices are arranged in front of wheels on the outer side of the bogie, and the sand sucking device, the sand throwing machine, a sand blowing device, a movable air duct, a hydraulic station and the cleaning devices form a sand removal system. Sand is thrown to regions located outside railways and appointed by users through two working processes of sand suction and sand blowing of the sand throwing machine. In addition, the sand removal engineering truck is provided with a self-walking system and an integrated control system, integrates self-walking and sand removal functions, can perform continuous and automatic removal operation on large-area accumulated and buried sand of railway lines, is a large sand removal engineering truck for a railway, can be used for daily sand removal and maintenance operations of the railway lines in windy and sandy regions and is especially suitable for quick sand removal and cleaning operation of large-area railways after sand storms.

Owner:CRRC QISHUYAN CO LTD

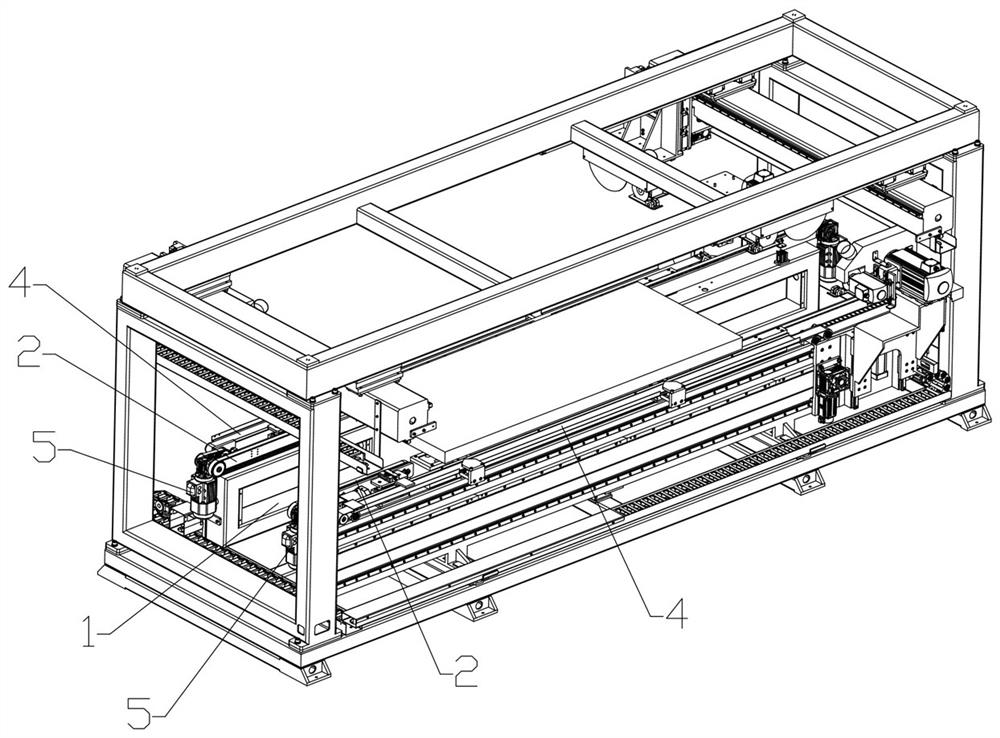

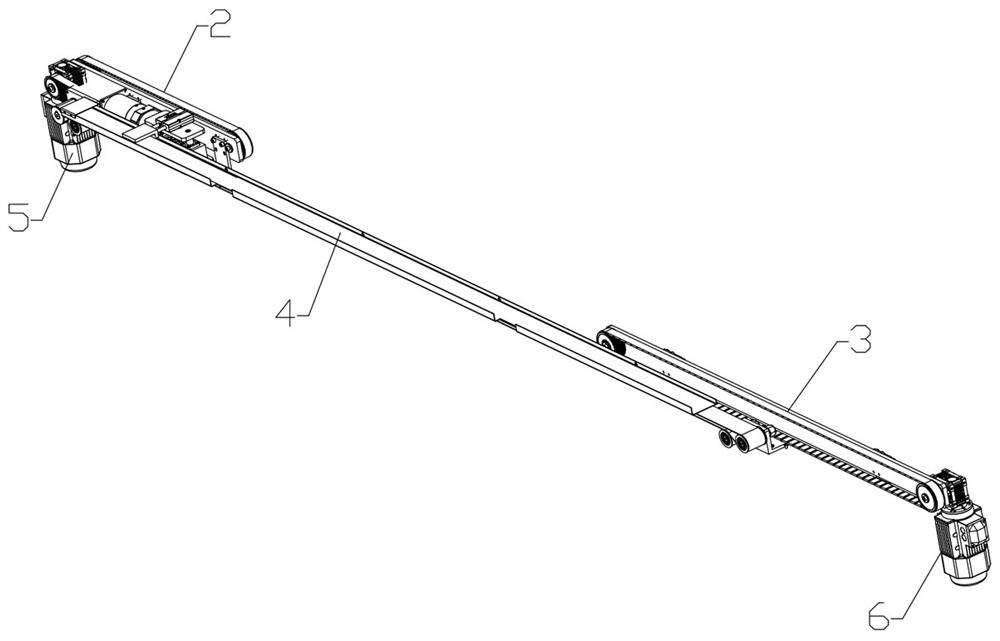

Waste discharging devices of quadrilateral cutting saw and quadrilateral cutting saw

InactiveCN113134650ARealize the collectionRealize unloadingMetal sawing accessoriesWaste collectionStructural engineering

The invention discloses waste discharging devices of a quadrilateral cutting saw and the quadrilateral cutting saw. The waste discharging devices are arranged at the two sides of a workbench respectively. Each waste discharging device comprises a first short-edge discharging mechanism, a second short-edge discharging mechanism, a long-edge discharging mechanism and driving components used for driving the first short-edge discharging mechanism, the second short-edge discharging mechanism and the long-edge discharging mechanism respectively, wherein the first short-edge discharging mechanism and the second short-edge discharging mechanism are arranged at the inner side of the long-edge discharging mechanism and arranged at the two ends of the long-edge discharging mechanism respectively. The quadrilateral cutting saw comprises the waste discharging devices. According to the waste discharging devices of the quadrilateral cutting saw and the quadrilateral cutting saw, waste collection and discharging are facilitated, the automation degree is high, and the continuous working capacity is high.

Owner:三倍机械科技(佛山)有限公司

Unpowered cyclone reaction method and reactor

ActiveCN101912764AGood destabilizing flocculation effectReasonable structure layoutMixing methodsChemical/physical/physico-chemical stationary reactorsLow speedWater flow

The invention relates to an unpowered cyclone reaction method and a reactor, wherein the method comprises the following steps of: (1) adding a flocculating agent into water containing suspended substances; (2) enabling the water with the flocculating agent to flow through a section of high-speed pipeline through an inlet pipeline, wherein the diameter of the high-speed pipeline is smaller than that of the inlet pipeline; (3) enabling the water flowing through the high-speed pipeline to flow through a section of middle-speed pipeline, wherein the diameter of the middle-speed pipeline is largerthan that of the high-speed pipeline but smaller than that of the inlet pipeline; (4) enabling the water flowing through the middle-speed pipeline to flow through a section of low-speed pipeline, wherein the diameter of the low-speed pipeline is equal to that of the middle-speed pipeline; (5) enabling the water flowing through the low-speed pipeline to flow through a section of full-flow pipeline, wherein the diameter of the full-flow pipeline is much larger than that of the inlet pipeline; and (6) enabling the water flowing through the full-flow pipeline to flow through a section of outlet pipeline, wherein the diameter of the outlet pipeline larger than that of the inlet pipeline but smaller than that of the full-flow pipeline. The invention solves the technical problems of incapabilityof continuous working, large maintenance difficulty, low utilization ratio and high cost of traditional mechanical stirring and coagulation reaction and has the advantages of wide application range and continuous working.

Owner:陕西雷光环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com