Heat pipe battery

A heat pipe, battery technology, used in engine components, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

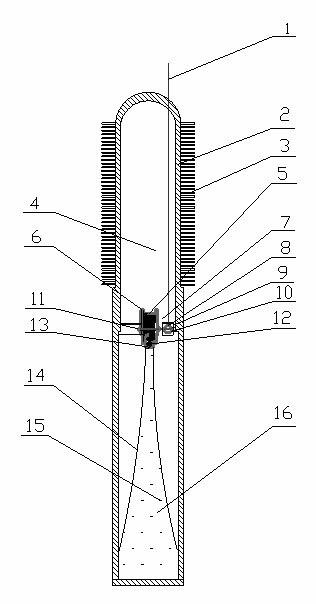

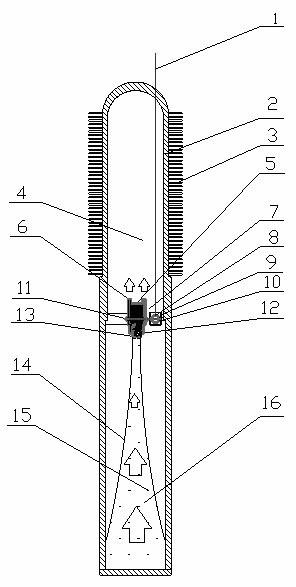

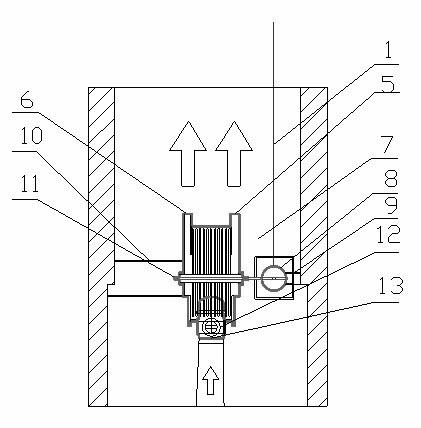

[0016] Referring to the accompanying drawings, the present invention provides a heat pipe battery, which includes a heat pipe, a disk turbine 5 and a generator 8 . The heat pipe is divided into three chambers: the evaporating chamber 16, the adiabatic chamber 7, and the condensing chamber 4. The disk turbine and generator are installed in the adiabatic chamber. In the illustrated example, the heat pipe is a gravity heat pipe. The working medium 15 in the evaporation chamber 16 completes the circulation by its own gravity. The siphon channel 14 is a tapered nozzle. The working medium 15 is heated and evaporated into gas in the evaporation chamber 16, and the gas passes through the siphon The passage 14 accelerates the flow upwards, and when reaching the throat of the siphon pipe 14, the vapor velocity reaches a maximum. The throat part of the siphon channel 14 is connected with the steam inlet pipe 13 by flange bolts, and the figure 2 It can be seen that the gas enters the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com