Stirring device for calcium carbonate

A stirring device, calcium carbonate technology, applied in mixers with rotary stirring devices, calcium carbonate/strontium/barium, mixer accessories, etc. Strong continuous working ability, reasonable design, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

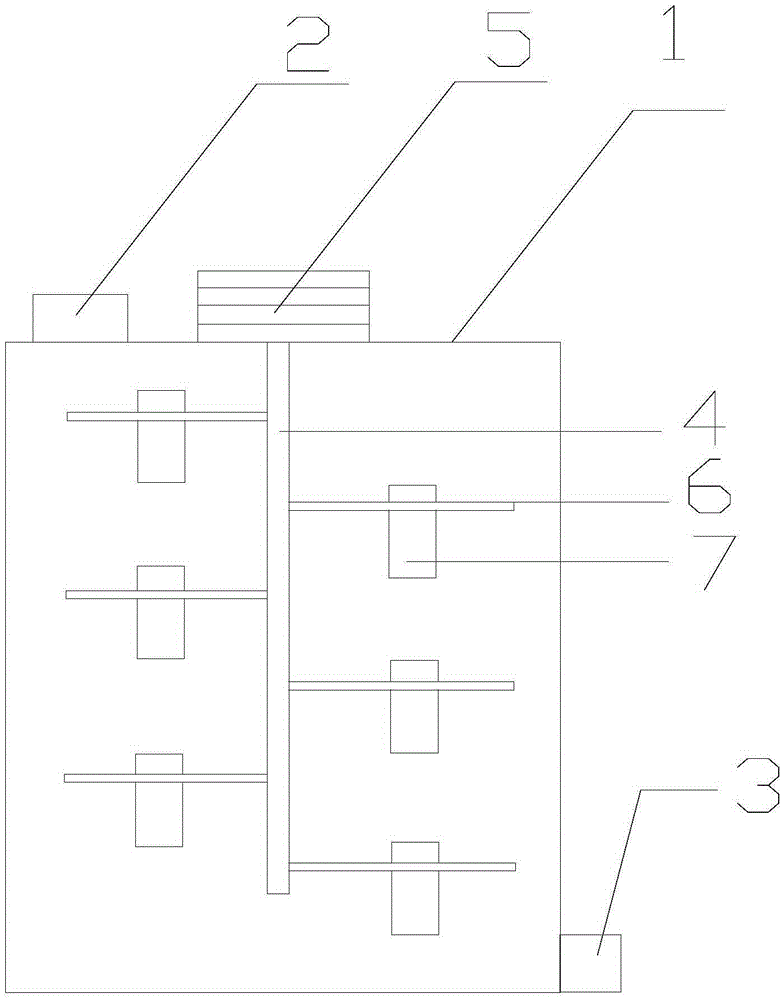

[0009] like figure 1 A kind of stirrer that the present invention provides as shown is used for calcium carbonate, comprises housing 1, and housing 1 top is provided with feed inlet 2, the bottom is provided with discharge outlet 3, is provided with stirring bar 4, in housing 1, And the stirring rod 4 is connected to the electric head 5 outside the housing 1; the stirring rod 4 is provided with stirring blades 6 alternately, and the heating device 7 is fixed on the stirring blade 6; the heating device 7 is an electric heating device covered with a metal shell. Wire; the stirring rod 4 is hollow, and the electric wire of the heating device 7 is connected to the power supply equipment outside the housing 1 through the stirring rod 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com