Unpowered cyclone reaction method and reactor

A swirl reaction and reactor technology, which is applied in the fields of mixing methods, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc., can solve the problems of inability to work continuously, difficult maintenance, and low utilization rate, etc. To achieve the effect of good destabilization and flocculation effect, strong continuous working ability and stable operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

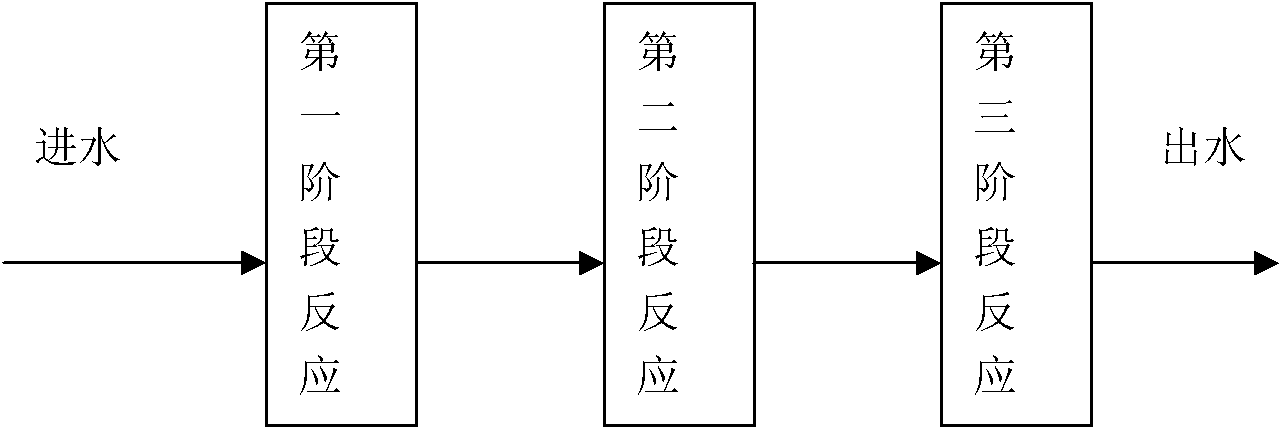

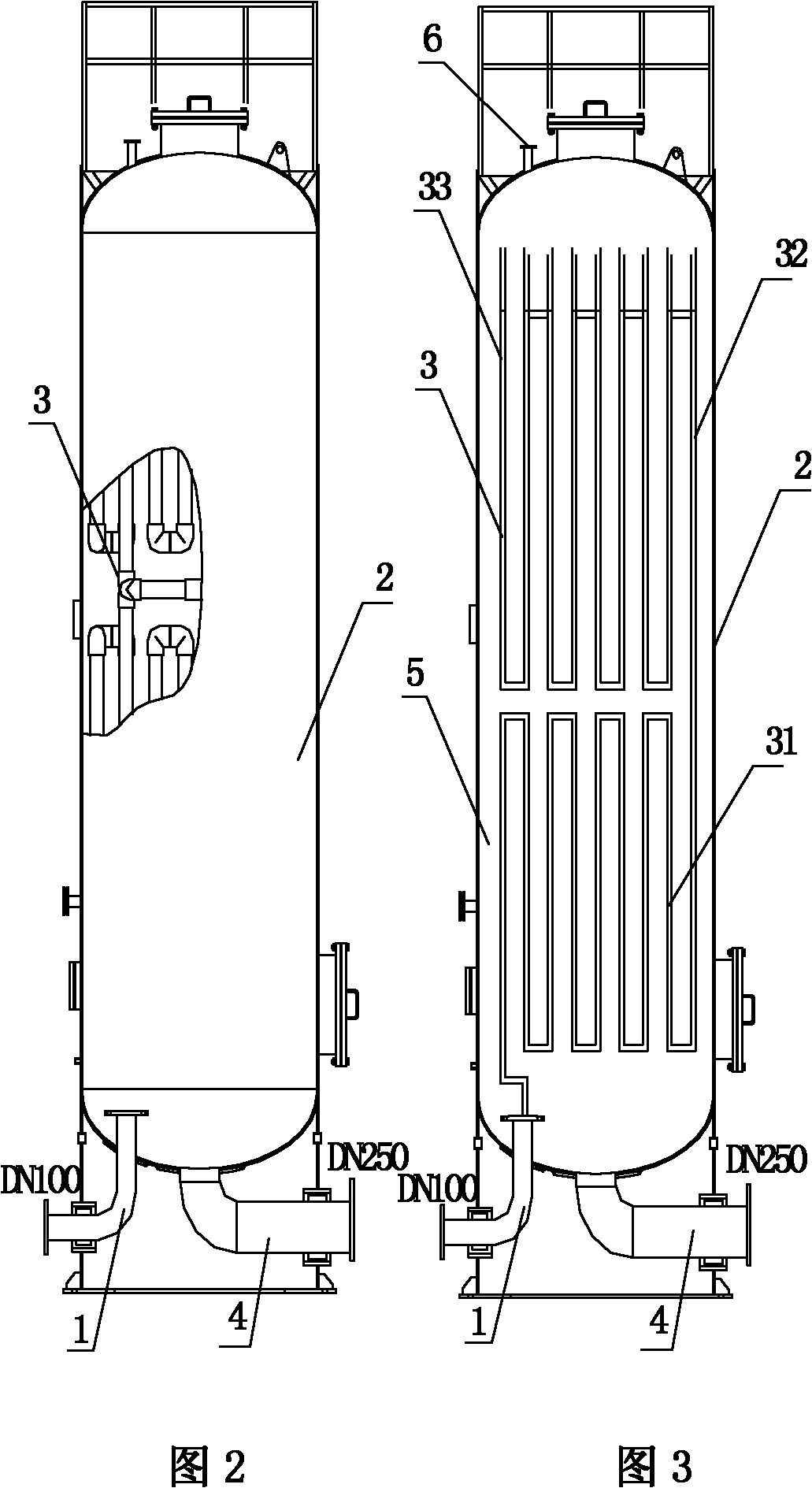

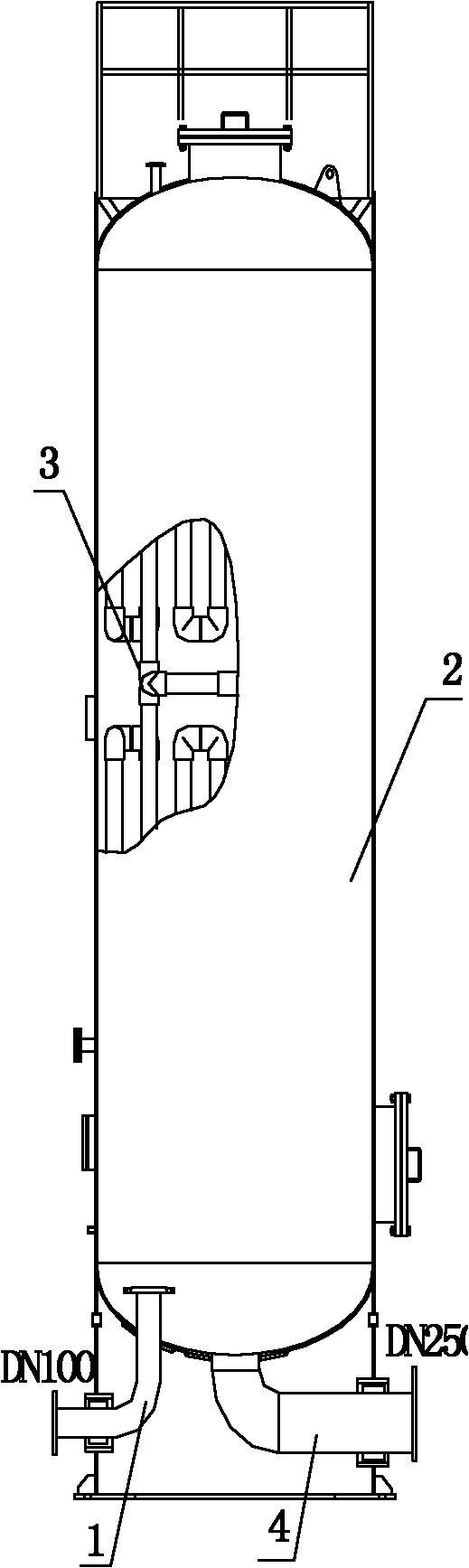

[0031] See figure 2 with image 3 , An unpowered cyclone reactor, comprising a tank body 2, an inlet pipe 1 and an outlet pipe 4, the top of the tank body is provided with an automatic exhaust valve 6, the inlet pipe 1 and the outlet pipe 4 are arranged below the tank body 2, the tank body 2 There is an internal pipe 3 inside, and the internal pipe 3 is folded back and installed in the tank body 2, one end of which is connected to the inlet pipe 1, and the other end is open above the inside of the tank body 2; the outlet pipe 4 is connected to the internal pipe 3 of the tank body 2. The gap 5 between them is connected.

[0032] In order to achieve the best mixing effect, the inner diameter of the inlet pipe is 125mm; the inner diameter of the outlet pipe is 250mm; the inner diameter of the inner pipe is arranged in one of the following two ways: A. Starting from the end of the inlet pipe, the first half is the high-speed pipe 31, Its inner diameter is 65mm, the first two-thirds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com