Portable multi-jacking multifunctional high-tensile reinforcement bar bending and straightening machine and operation method thereof

A high-strength steel bar, portable technology, applied in the field of portable multi-top multi-functional high-strength steel bar bending and straightening machines, can solve the problems of not meeting the development requirements of refinement, mechanization, and humanization, large diameter of steel bars, poor quality, etc. Conducive to construction period control, small construction space and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

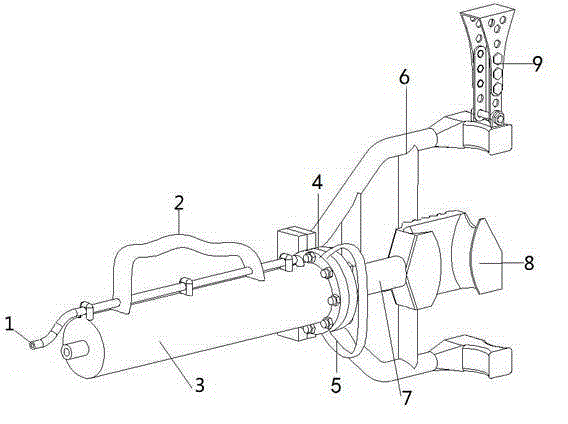

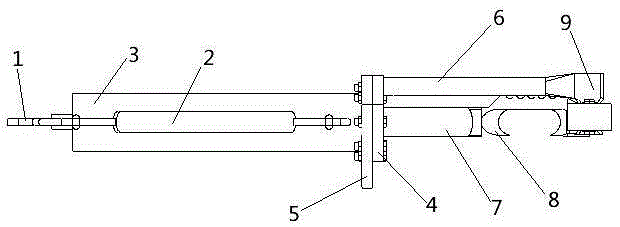

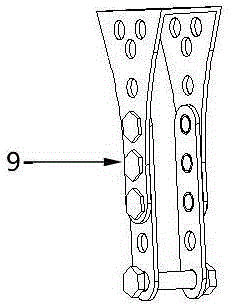

[0018] Such as figure 1 , figure 2 The illustrated embodiment includes a jack (3), a vertical handle (2) is provided on the side wall of the main body of the jack, a horizontal handle (5) is provided on the sealing flange (4) of the jack, and the top of the jack There is a detachable bender (8) at the end of the rod (7), which includes two notches with different radii and a square angle notch, two support frames (6) arranged symmetrically, and a Reinforced horizontal connection, the bottom of the two support frames is provided with a support base with a steel bar groove, the plane where the two support frames are located is below the plane where the ejector rod is located, and the top of the two support frames is fixedly connected with the sealing flange .

[0019] The middle position of the sealing flange (4) is provided with a hole for the jack, and the jack (7) of the jack passes through the hole of the jack to connect with the main body of the jack.

[0020] Any one of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com