Hinge page shaft mold processing machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] refer to Figure 1 to Figure 6 , propose an embodiment of the hinge sheet axial mold processing machine of the present invention:

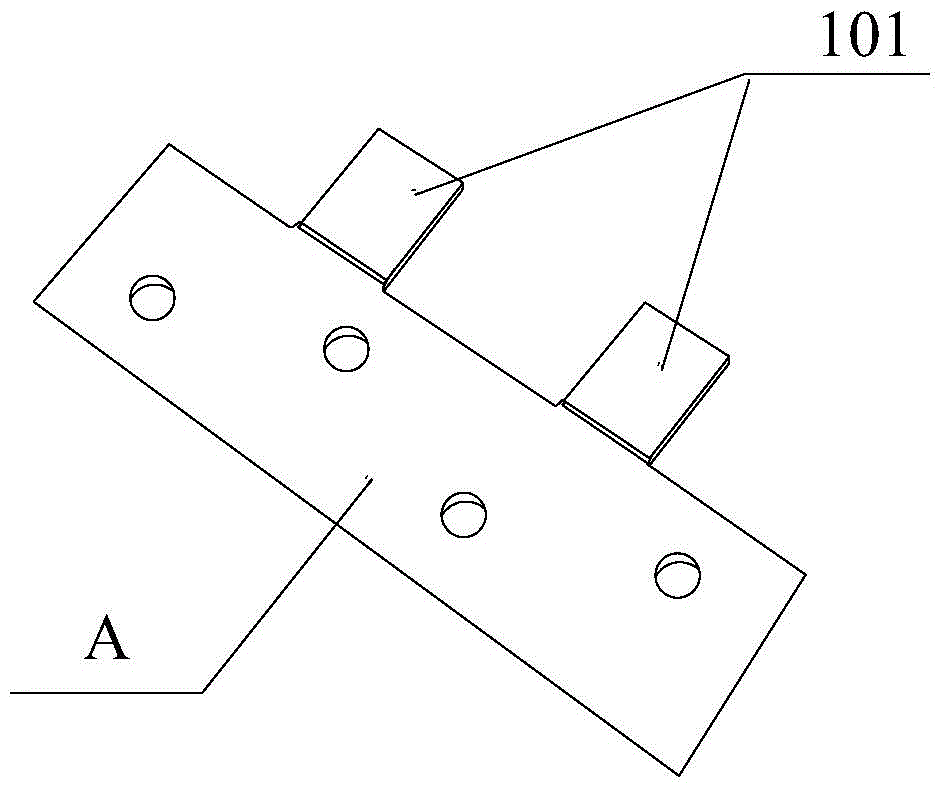

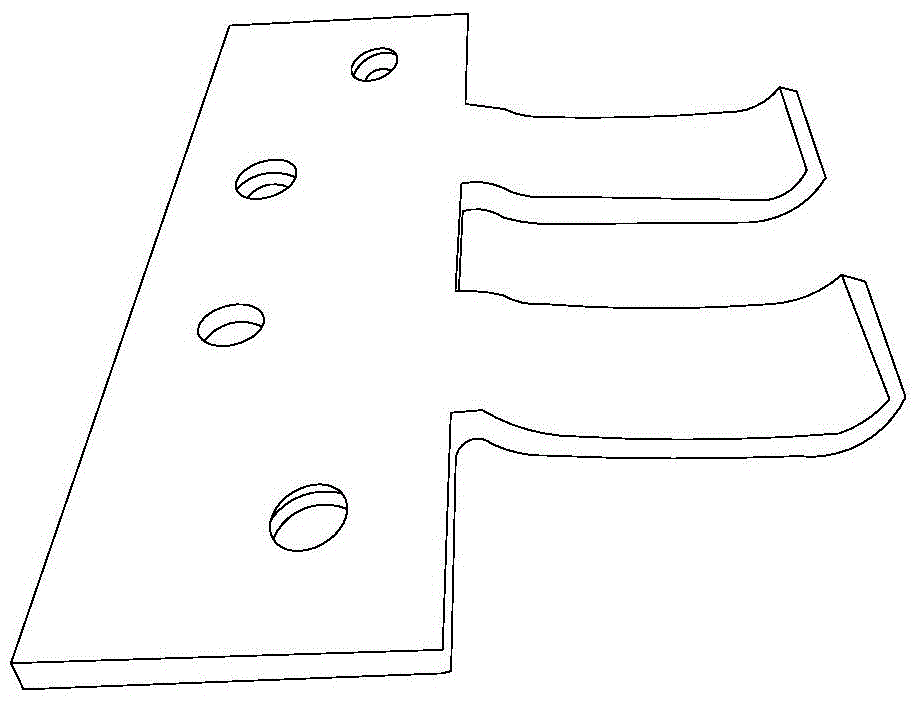

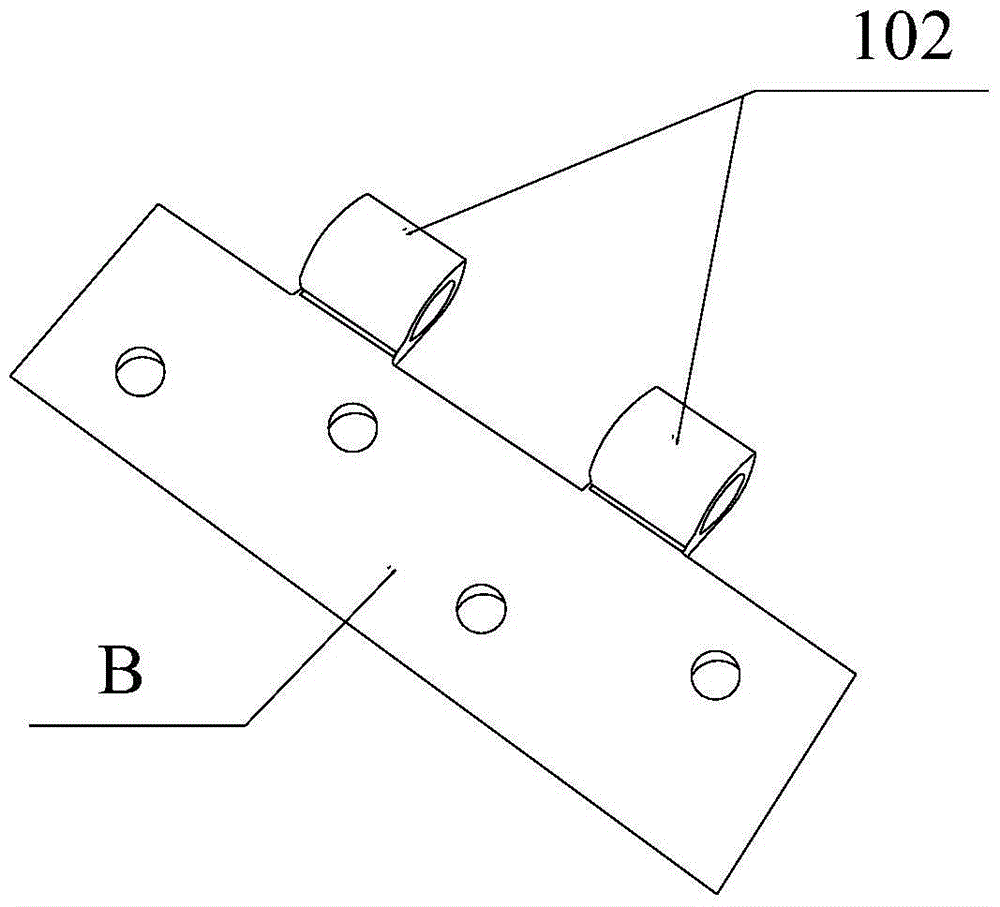

[0025] A hinge page shaft mold processing machine, which is used to process the shaft position 101 on the hinge page into a tooth position 102, such as figure 1 As shown, it is the hinge sheet A to be processed; as figure 2 As shown, it is the hinge sheet B processed by the gear position 102, and the shaft hole is a through hole passing through the gear position 102.

[0026] The hinge axis mold processing machine includes an automatic feeding mechanism for transporting the hinge sheet A, a material tank 20 for placing the hinge sheet A, and a material tank 20 for aligning the hinge sheet A. A pre-bending mechanism for pre-bending the shaft position 101, a shaft rolling mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com