Vacuum exposure device for exposure machine

A technology of exposure device and exposure machine, which is applied in the direction of photolithography exposure device, photomechanical equipment, microlithography exposure equipment, etc., can solve the problem that water circulation pipelines and water storage tanks take up a lot of space, cannot monitor the exposure quality intuitively, and cannot Seeing problems such as screen state changes, achieving the effects of strong continuous working ability, fast heat dissipation, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

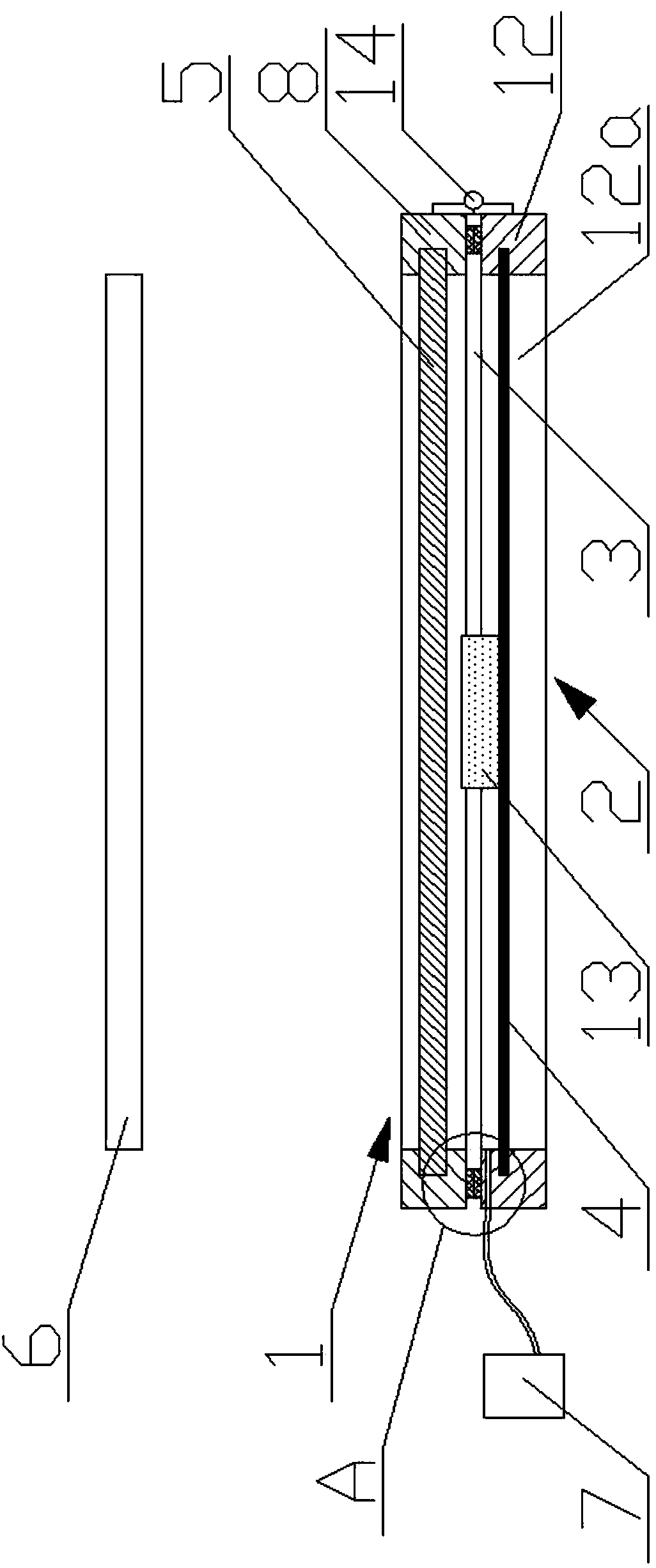

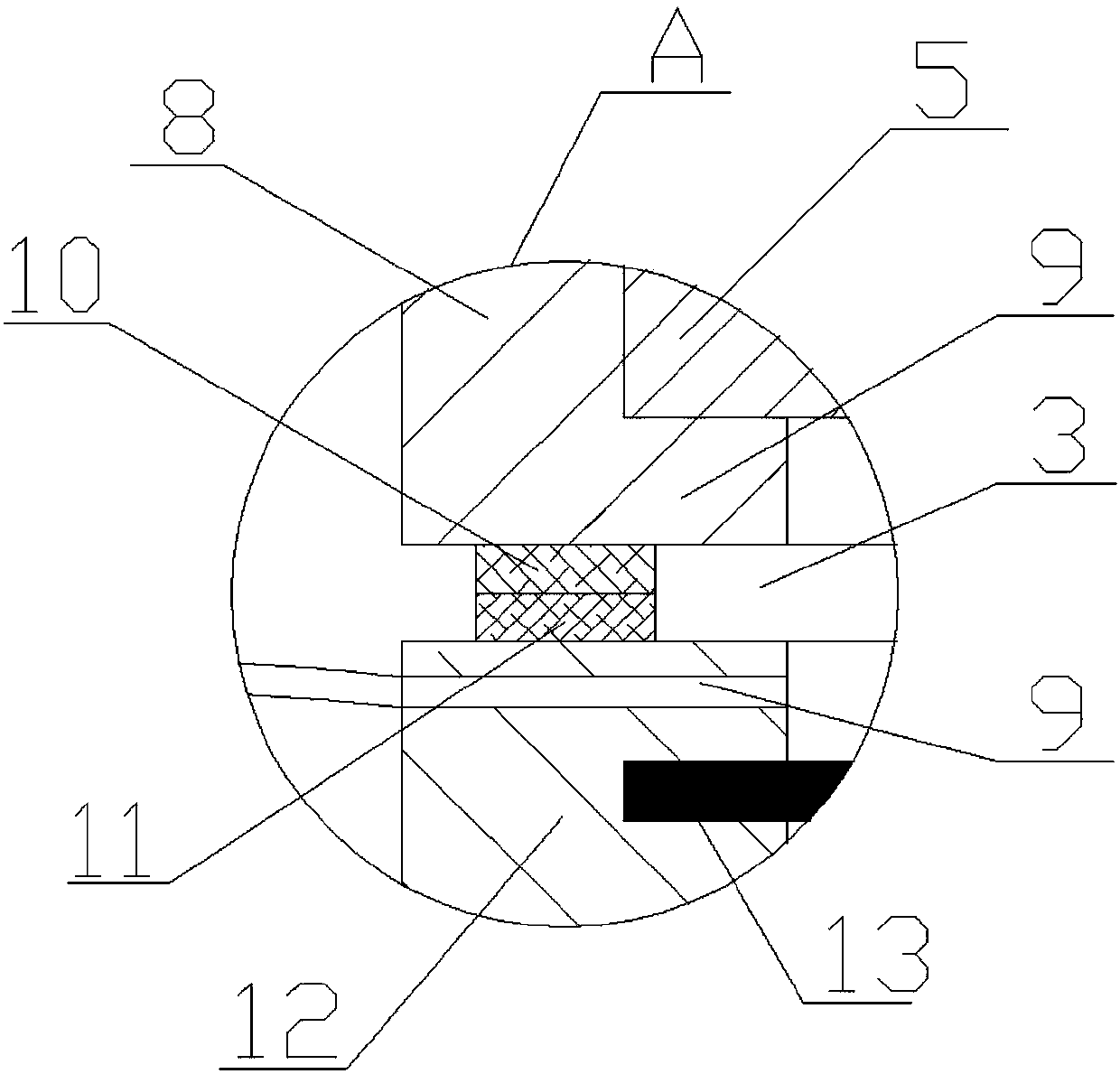

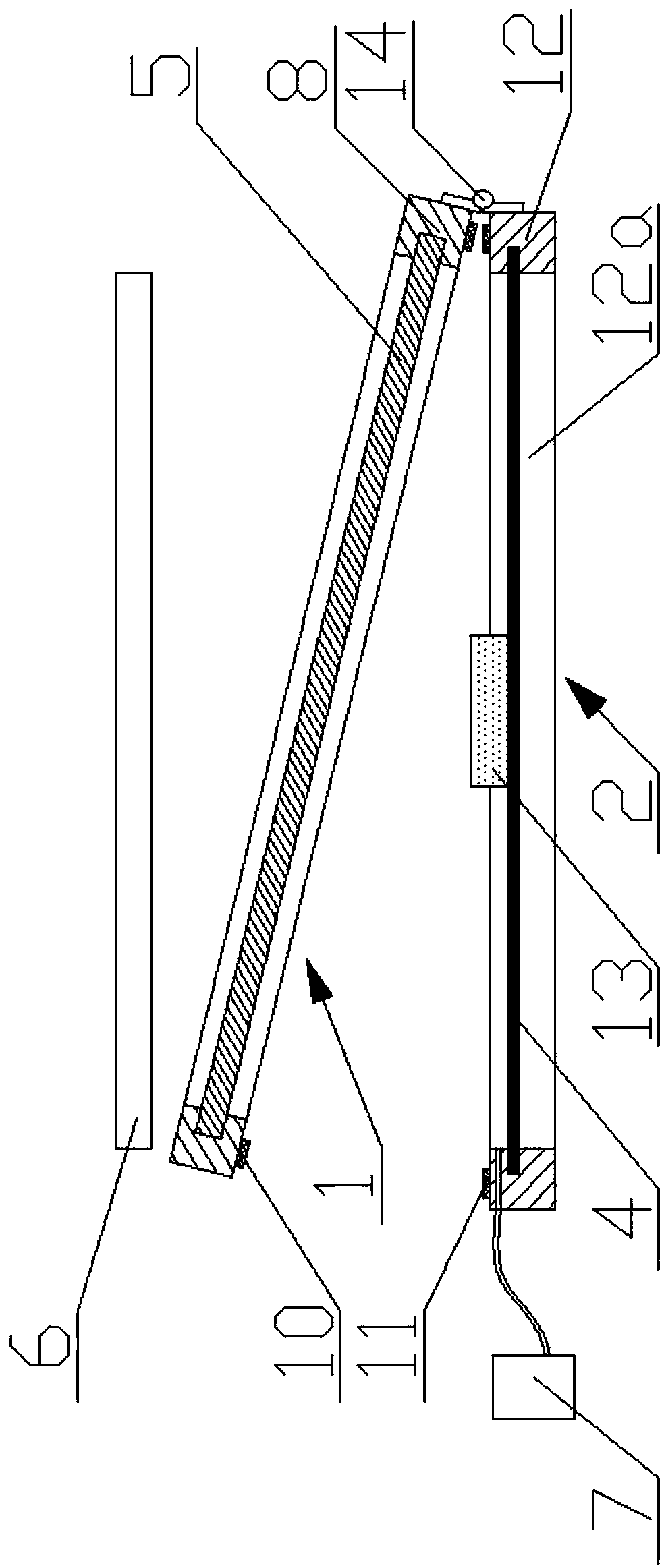

[0018] Such as figure 1 and figure 2 As shown, the vacuum exposure device of the exposure machine of the present invention is used for exposing the screen plate 13 for plate making, which includes an exposure lamp 6 , a vacuum suction system 7 , an upper sealing assembly 1 and a lower sealing assembly 2 . The exposure lamp 6 is arranged directly above the upper sealing assembly 1 , and the lower sealing assembly 2 is arranged directly below the upper sealing assembly 1 . The upper and lower sealing components 1, 2 cooperate to form a closed space 3, and the vacuum suction system 7 can evacuate the space 3.

[0019] The upper sealing assembly 1 includes a glass plate 5 and a second fixing frame 8 for fixing the glass plate 5 . In this embodiment, the glass plate 5 is rectangular, and the second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com