Filtering device used for calcium carbonate

A filter device, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, filtration separation, fixed filter element filter, etc., can solve the problems affecting product purity, calcium carbonate is not very stable, etc., to achieve strong continuous working ability, Guarantee normal operation, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

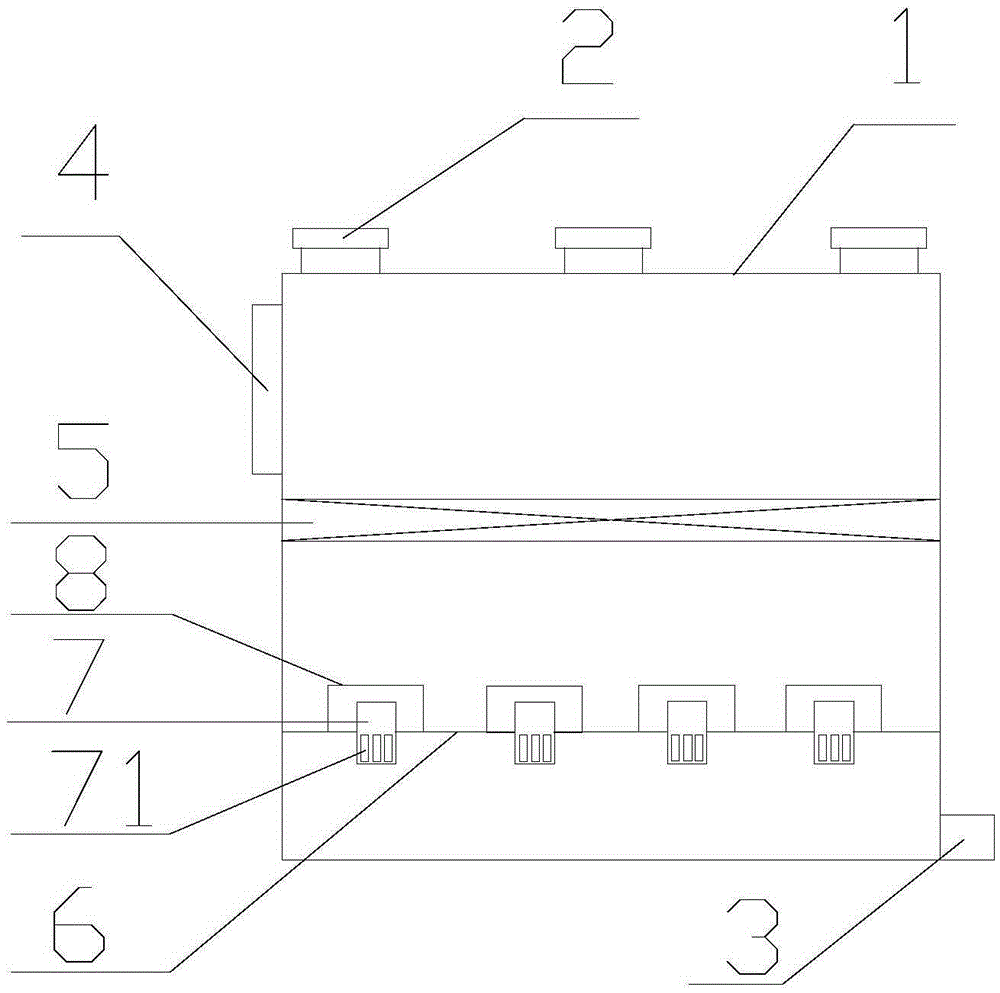

[0010] Such as figure 1 A kind of filtering device that the present invention provides as shown is used for calcium carbonate, comprises reactor 1, and reactor 1 top is provided with a group of feed inlet 2, and the bottom is provided with discharge outlet 3, and reactor 1 side wall is provided with manhole 4 The middle part of the reaction kettle 1 is provided with a filter plate 5, the bottom is provided with a dividing plate 6, and a group of flow devices 7 are arranged on the dividing plate 6, and the dividing plate 6 is located above the horizontal position of the discharge port 3; the dividing plate 7 is a cuboid structure , the bottom is provided with 3 to 4 water outlets 71, and the shunt device 7 is provided with a metal cover 8; the filter plate 5 is provided with through holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com