Patents

Literature

44results about How to "High injection precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

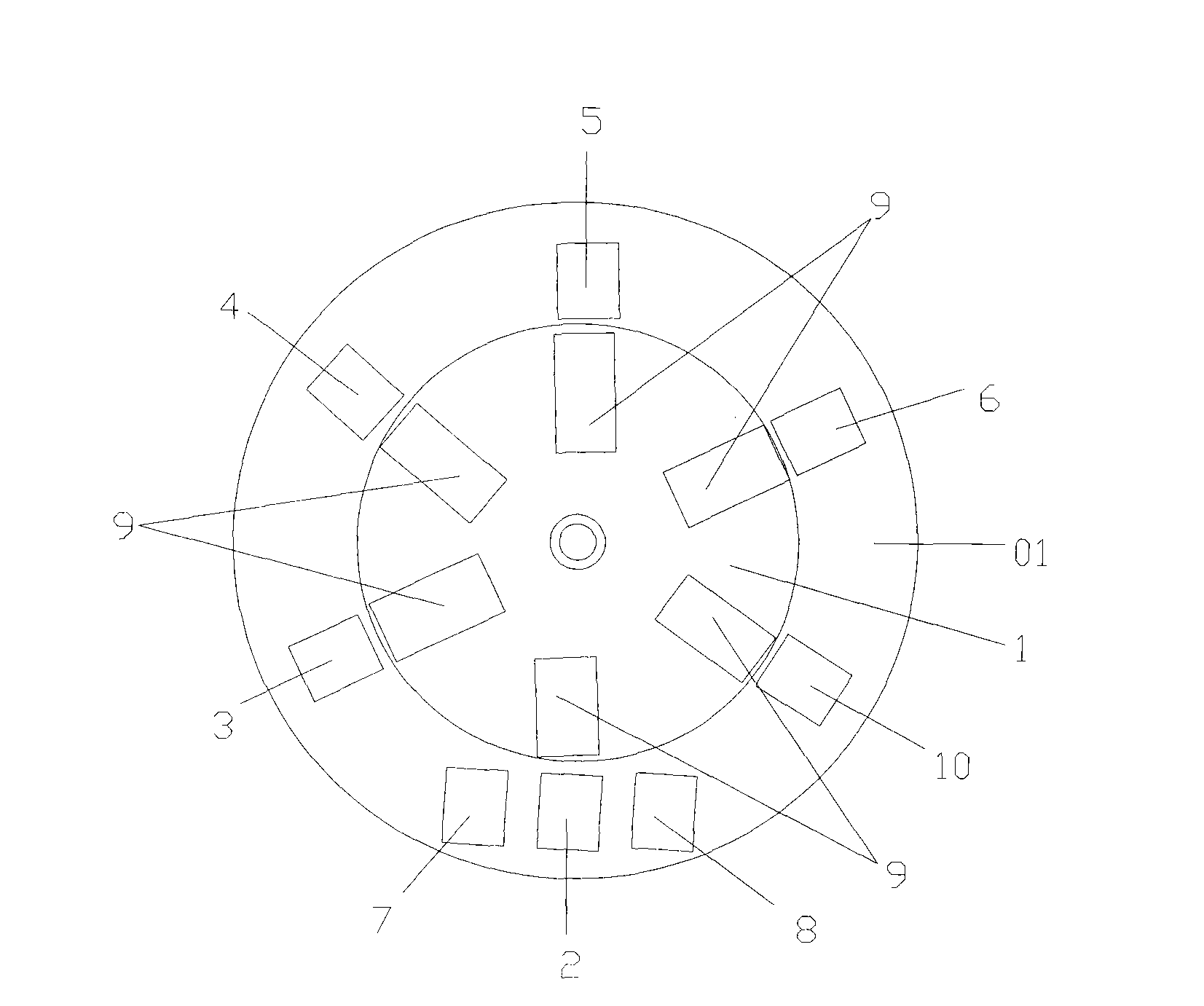

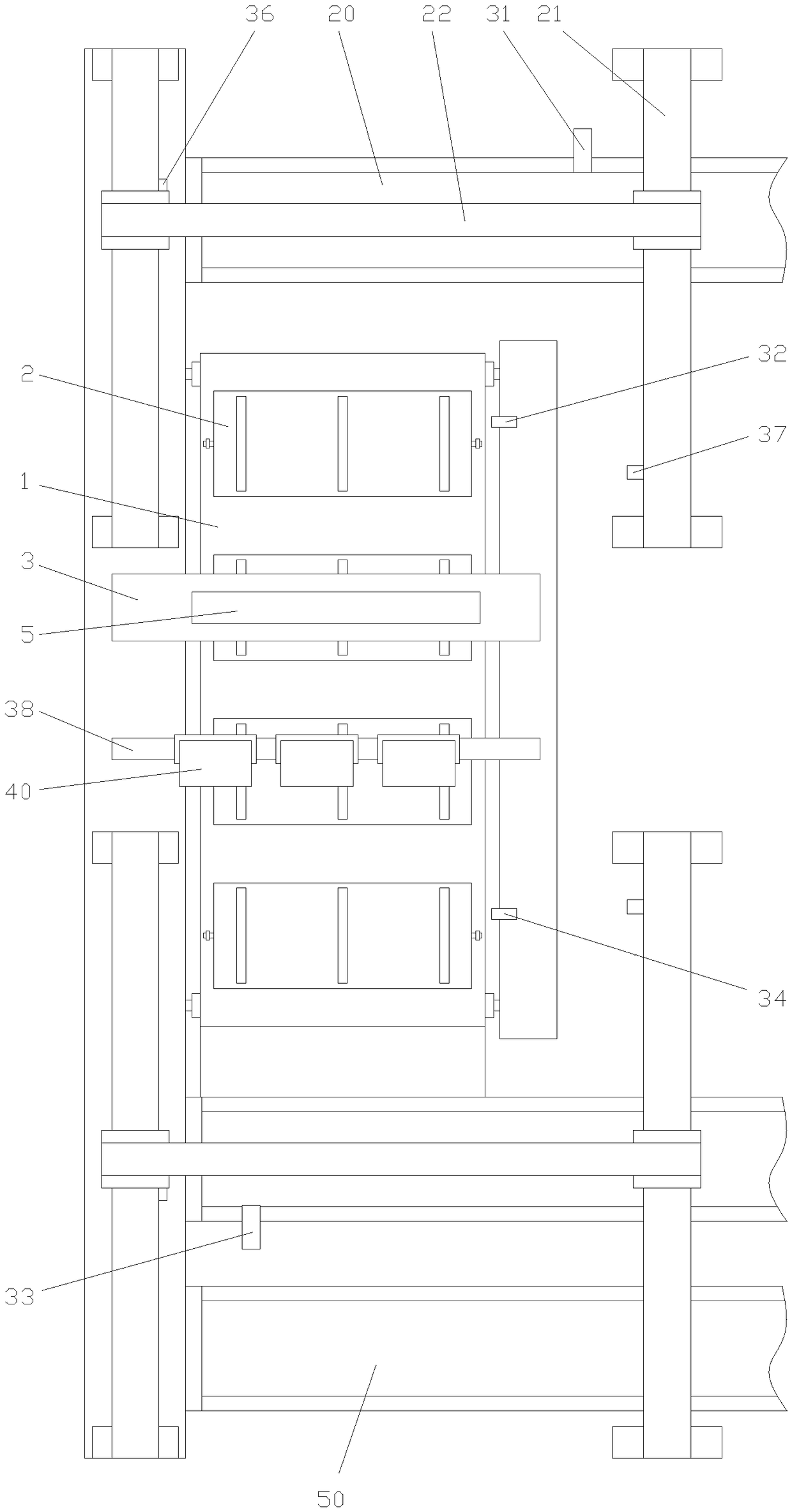

Vacuum liquid filling equipment for soft-package battery

InactiveCN102496691AShorten the soaking timeShorten the production cycleCell component detailsElectrical batteryEngineering

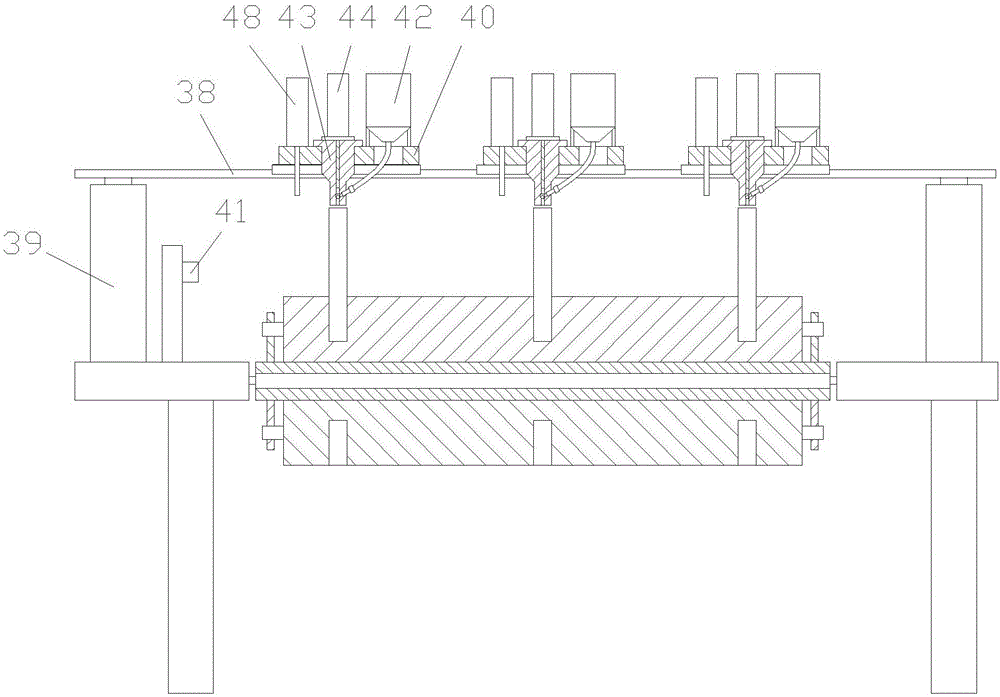

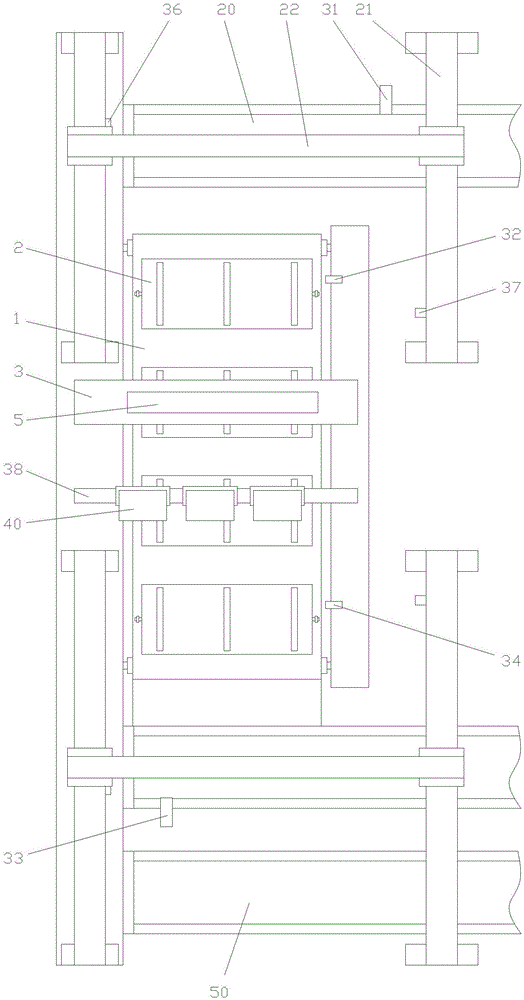

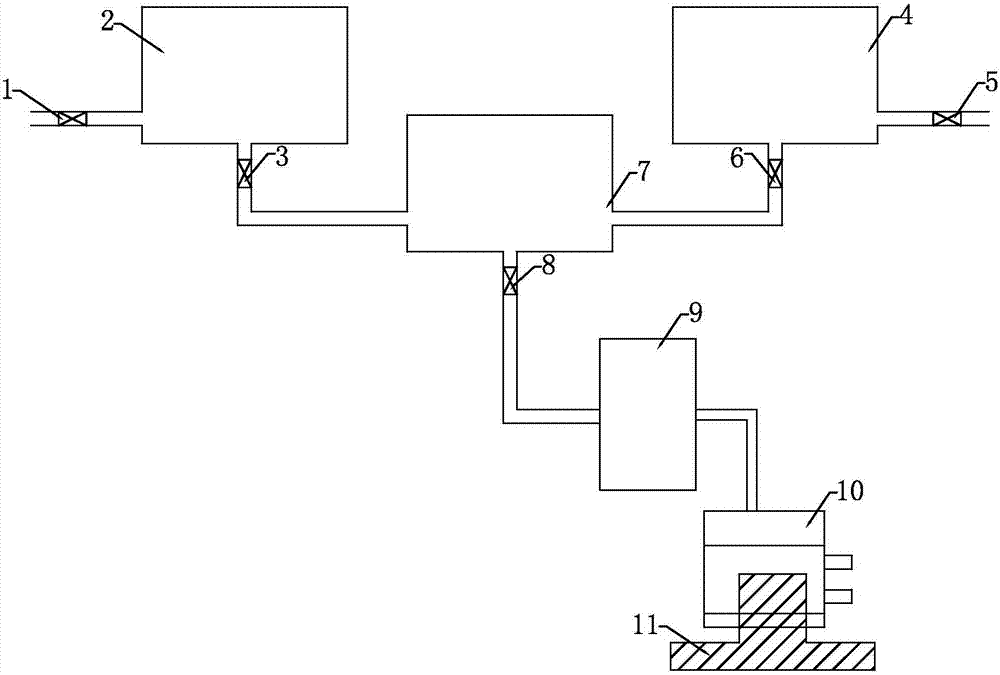

The invention belongs to the field of production equipment for lithium ion batteries, and particularly relates to vacuum liquid filling equipment for a soft-package battery. The vacuum liquid filling equipment for the soft-package battery comprises a machine frame and a multi-workstation turnplate which is arranged on the machine frame, wherein a drawer-type sealed box body is installed on any workstation of the multi-workstation turnplate; a battery fixing clamp is fixedly installed inside the drawer-type sealed box body; a battery loading and unloading unit, a battery packaging bag sucking-open unit, a vacuumizing unit, a liquid filling unit and a sealing unit which correspond to the workstations of the multi-workstation turnplate are fixedly arranged on the periphery of the multi-workstation turnplate sequentially; two sides of the battery loading and unloading unit are fixedly connected with a front filled liquid weighing unit and a back filled liquid weighing unit respectively; and each unit is fixedly connected on the machine frame. Compared with the prior art, the vacuum liquid filling equipment for the soft-package battery has the advantages that the electrolyte soaking time can be reduced, the space occupied by the equipment can be reduced, a surplus liquid filling pump can be saved, the investment cost of the equipment can be reduced, the liquid filling precision and the stability can be improved and the waste of the electrolyte can be reduced.

Owner:DONGGUAN AMPEREX TECH +1

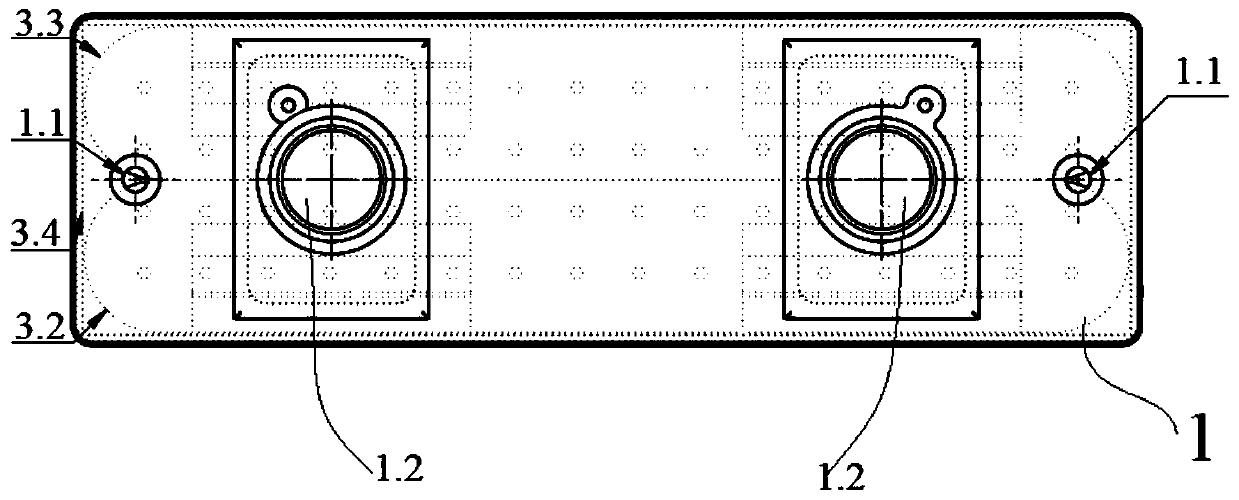

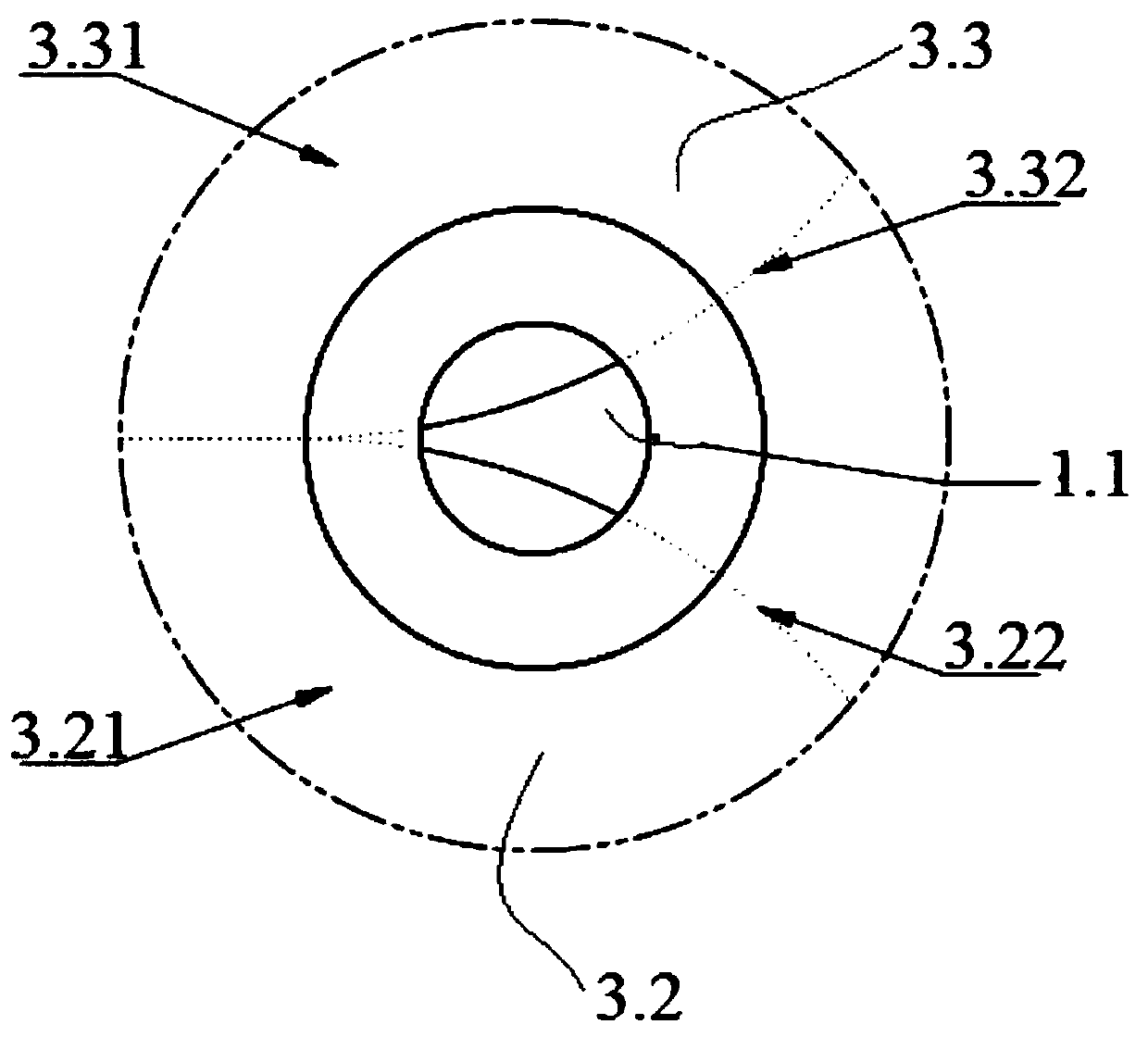

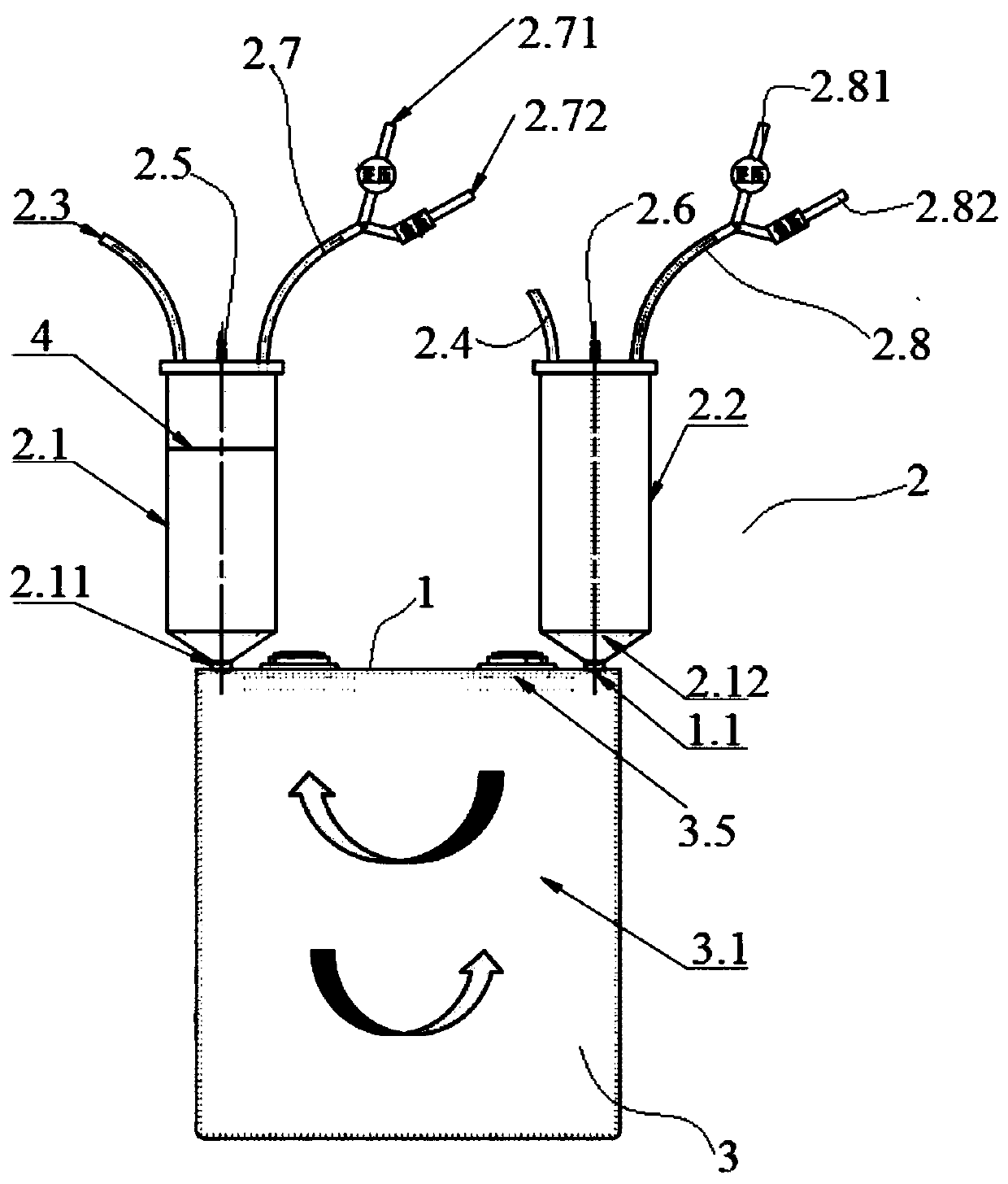

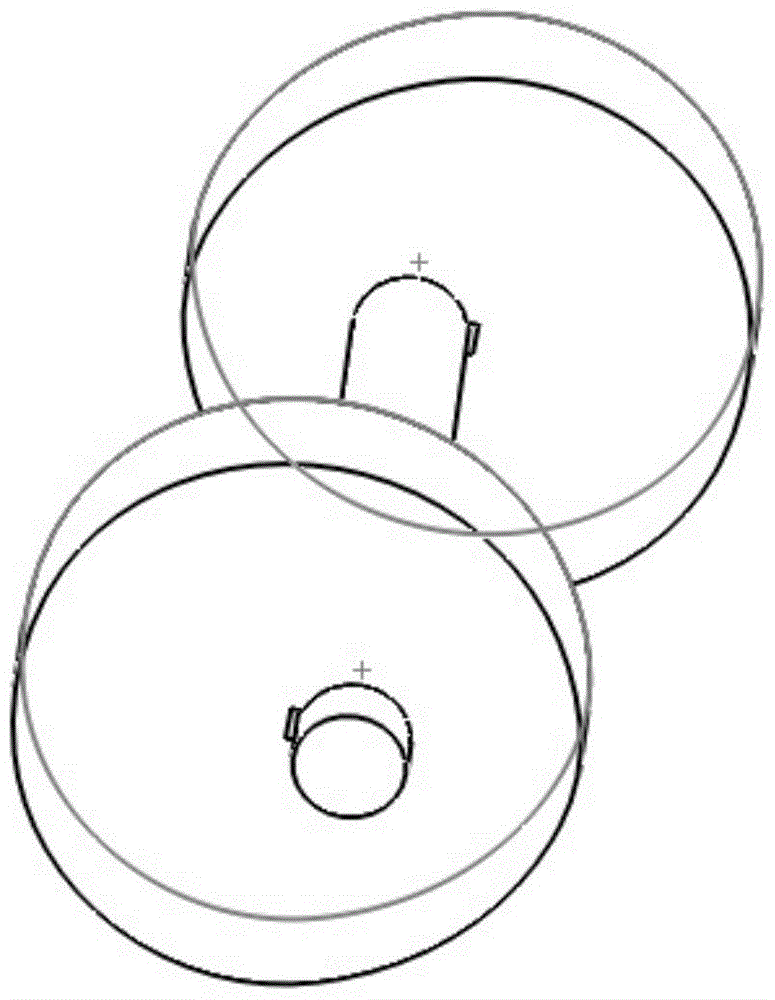

Double-hole lithium ion cover plate and rocking-chair type liquid injection device and method thereof

InactiveCN110416445ALower hair drumRapid infiltrationSecondary cellsCell lids/coversEngineeringLithium-ion battery

The invention discloses a double-hole lithium ion cover plate and a rocking-chair type liquid injection device and method thereof, and belongs to the technical field of lithium ion battery process preparation. The double-hole lithium ion cover plate comprises a first liquid injection hole and a second liquid injection hole which are formed in the two ends of the cover plate respectively, wherein each liquid injection hole is located above an r angle of an A pole core and a B pole core of a lithium ion battery. The cover plate is also provided with welding sites used for being fixedly connectedwith positive and negative lugs. During liquid injection, the double-hole lithium ion cover plate is arranged above the lithium ion battery body and welded and fixed together, and liquid is injectedthrough the liquid injection cups at the left end and the right end, enters the battery in a vacuum state, and can be dispersed in multiple directions and quickly infiltrated after entering a batterycell. The liquid injection time of a single battery is short, and the quick liquid injection requirement is met; and during formation and capacity grading, the internal produced gas can be divided anddischarged through the double liquid injection holes, so that the exhaust area is increased, the bulging of the battery is reduced, and the abnormal phenomenon of liquid overflow is eliminated.

Owner:湖北锂诺新能源科技有限公司

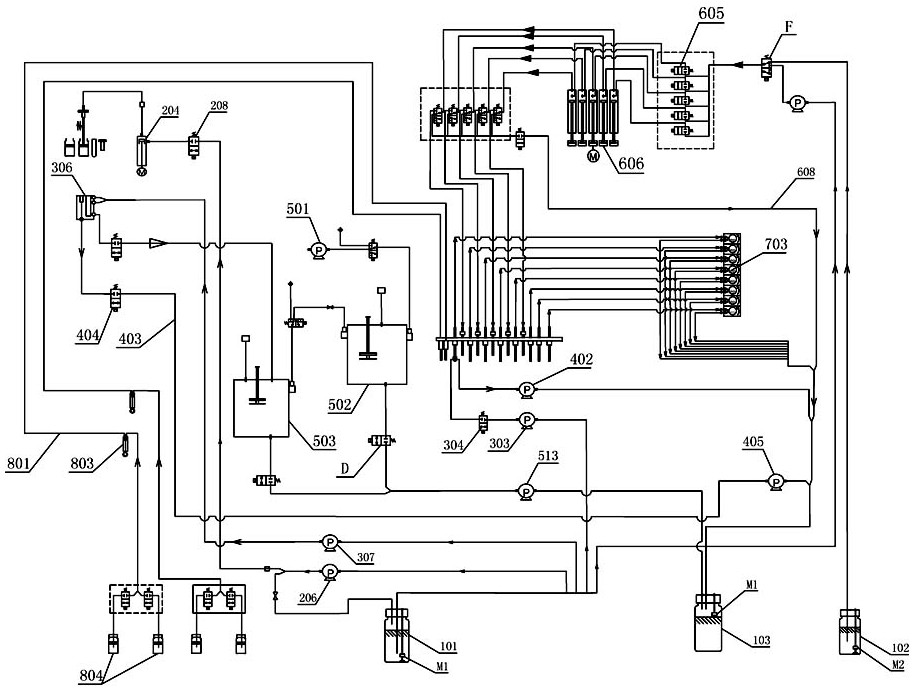

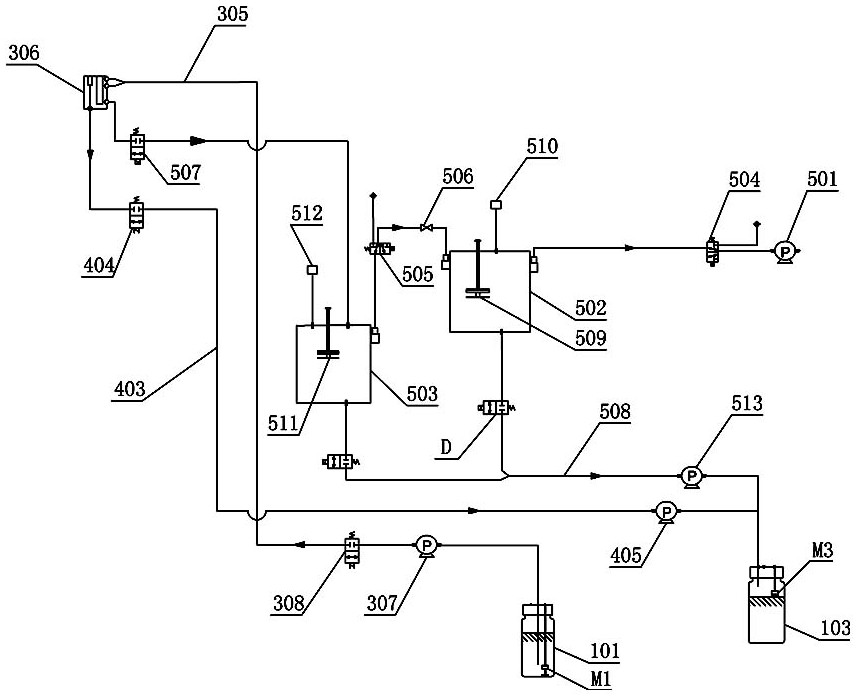

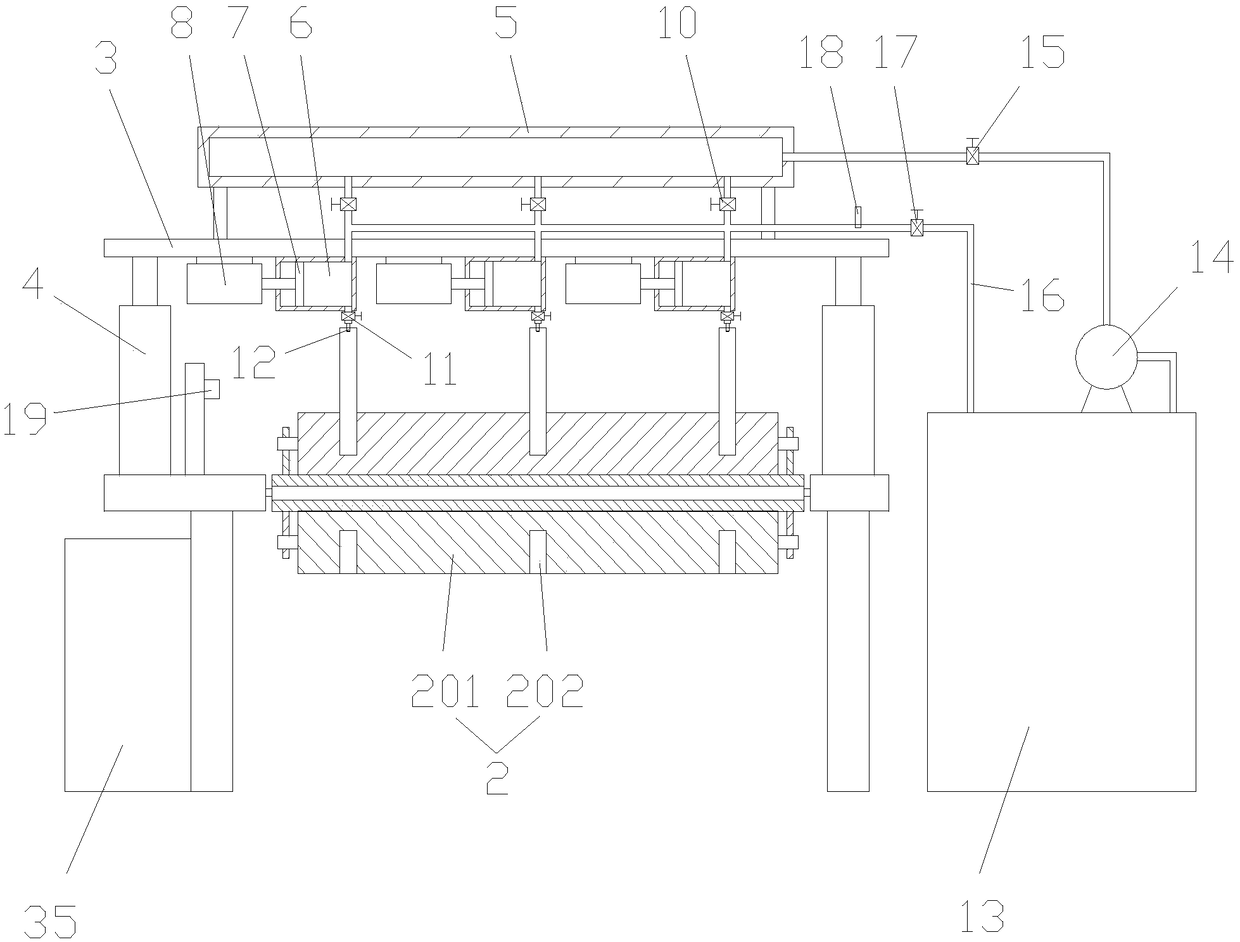

Electrolyte injection system with vacuumizing function for lithium battery

ActiveCN106067536AHigh injection precisionAffect healthCell component detailsElectrical batteryEngineering

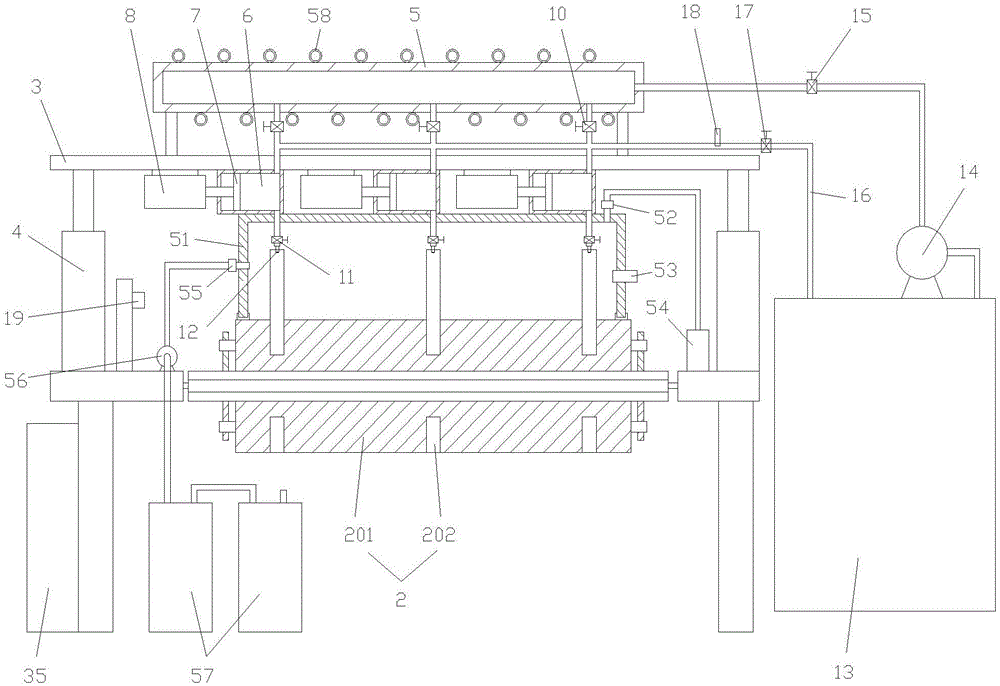

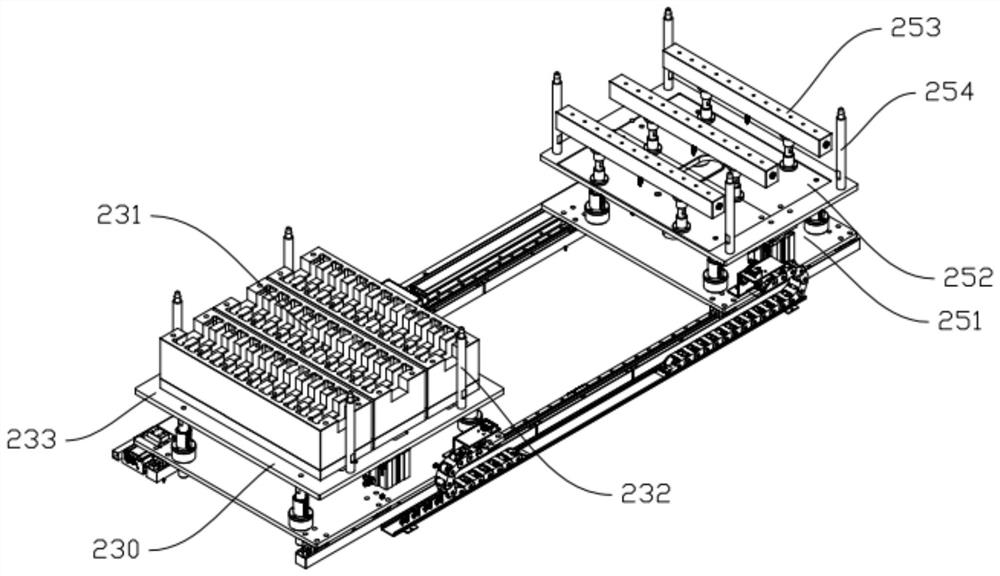

The invention discloses an electrolyte injection system with a vacuumizing function for a lithium battery. The electrolyte injection system comprises a feeding unit, a liquid injection unit, a vacuumizing unit, a sealing unit, a weighing and detecting unit and a discharging unit, wherein the liquid injection unit comprises an intermediate belt conveyor, a battery positioning mold, a lifting board, a first lifting cylinder, a quantitative liquid injector and the like; the weighing and detecting unit comprises a front weighing sensor, a rear weighing sensor, a waste conveyor and the like; the vacuumizing unit comprises a seal cover, a gas-type fitting, a vacuum sensor and a vacuum pump. The capacity of the inner chamber of a quantitative cylinder of the quantitative liquid injector is equal to the standard liquid injection amount of the lithium battery, so that the amount of an electrolyte pushed out by a liquid injection cylinder every time is equal to the standard liquid injection amount of the lithium battery, and the liquid injection precision is high; the vacuumizing unit can prevent a reaction between moisture in air in the seal cover and electrolyte solute lithium hexafluorophosphate to avoid generation of hydrofluoric acid, so that the problem that hydrofluoric acid adversely influences the electrochemical property and the safety performance of the battery is solved.

Owner:重庆市中欣维动力科技有限公司

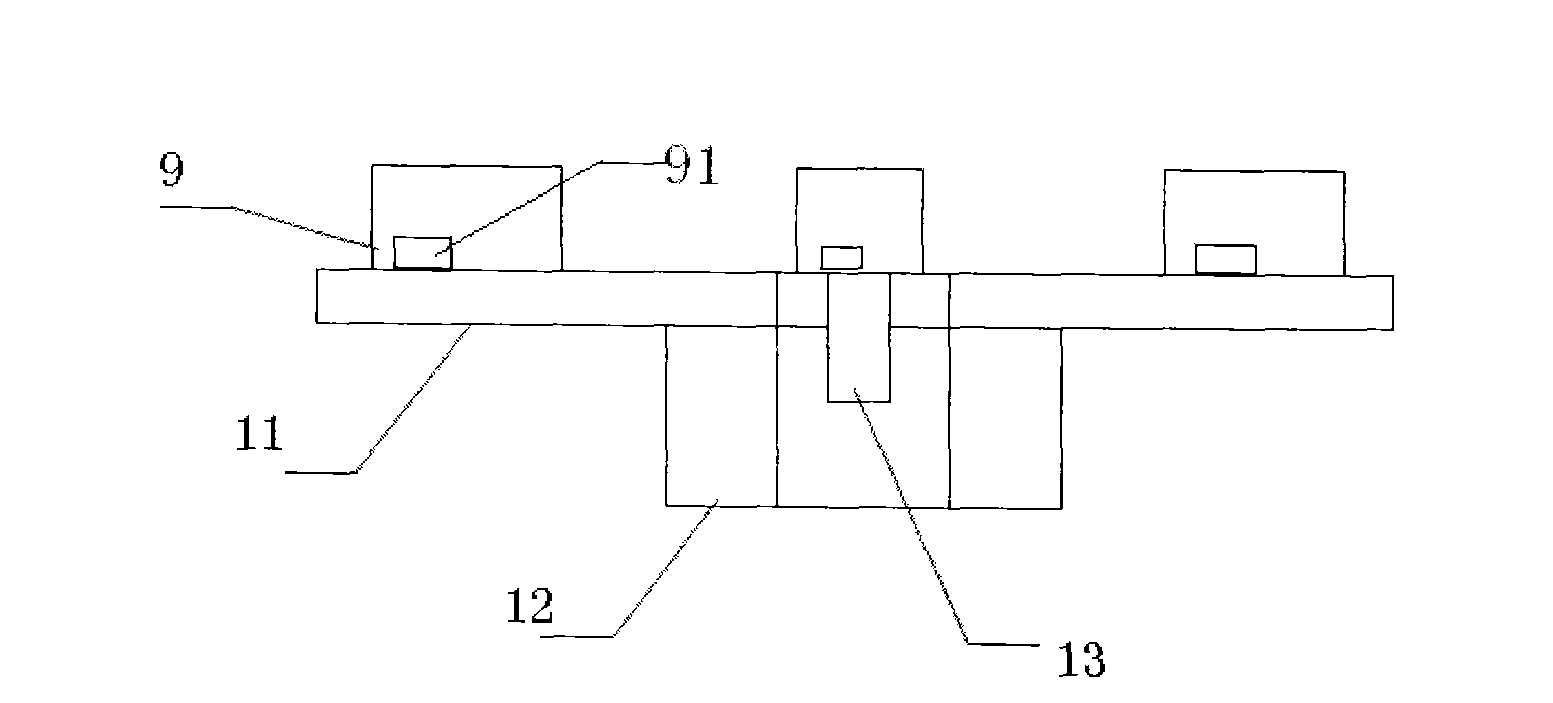

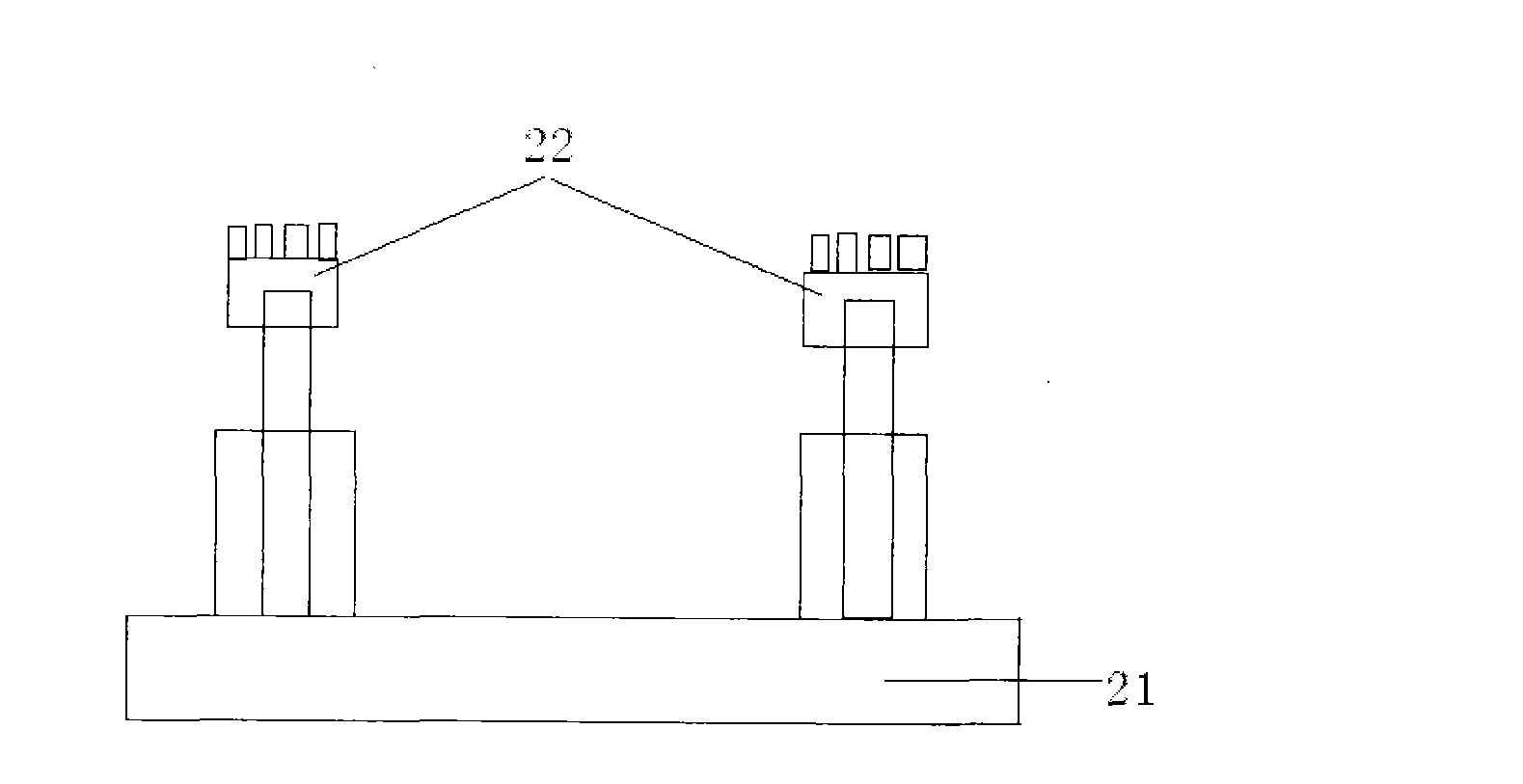

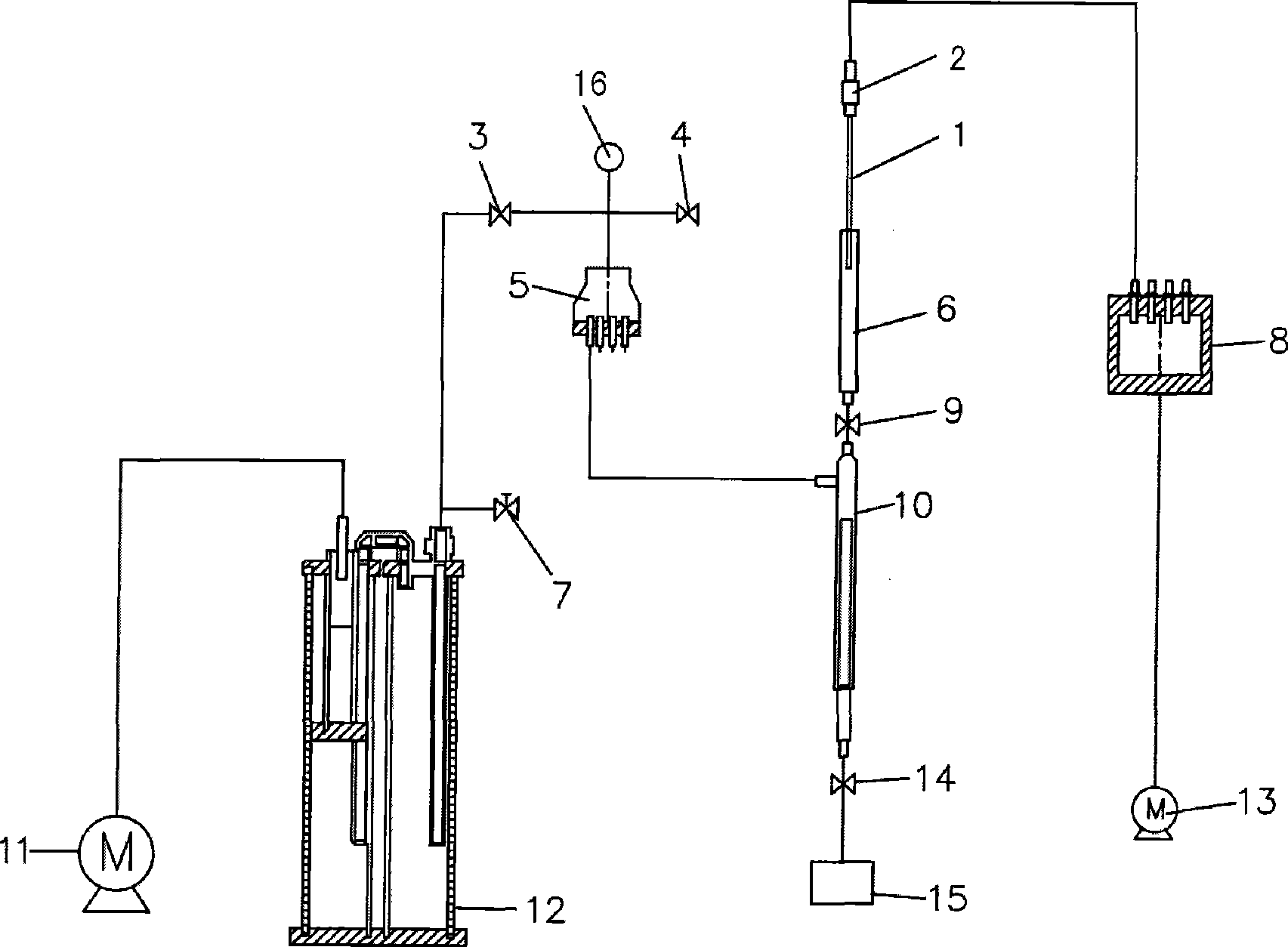

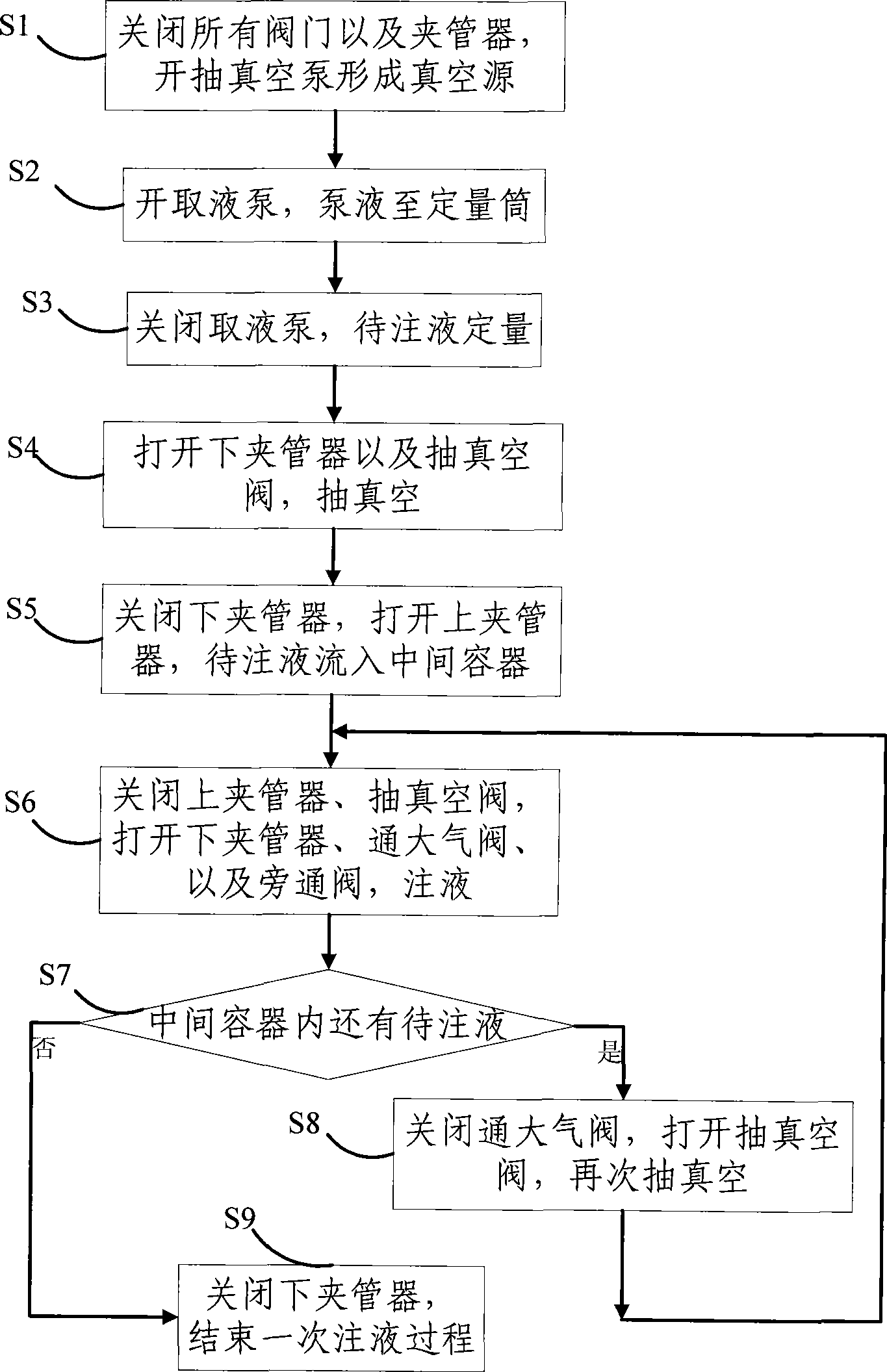

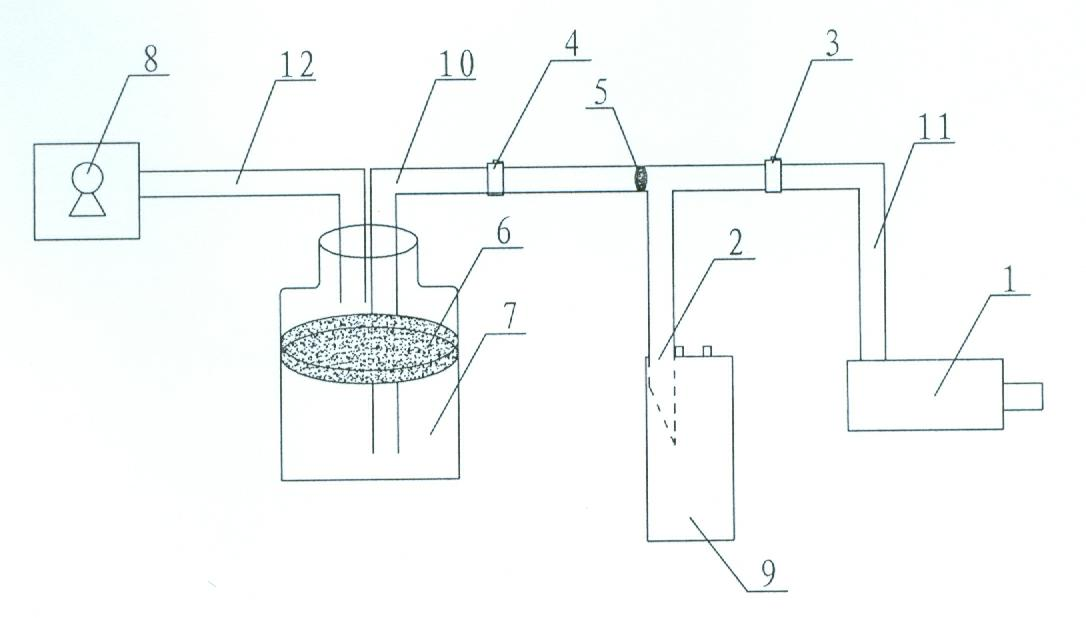

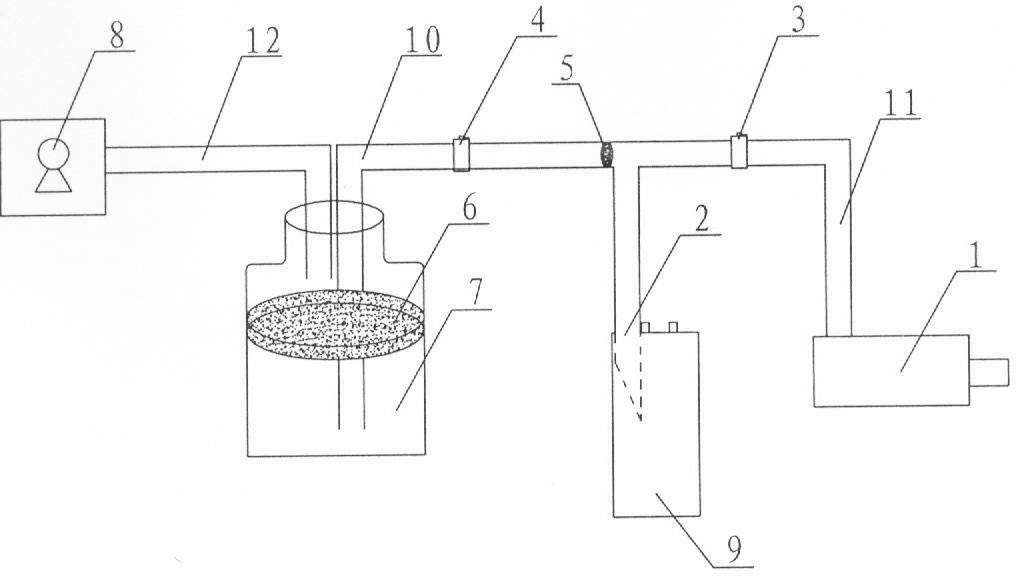

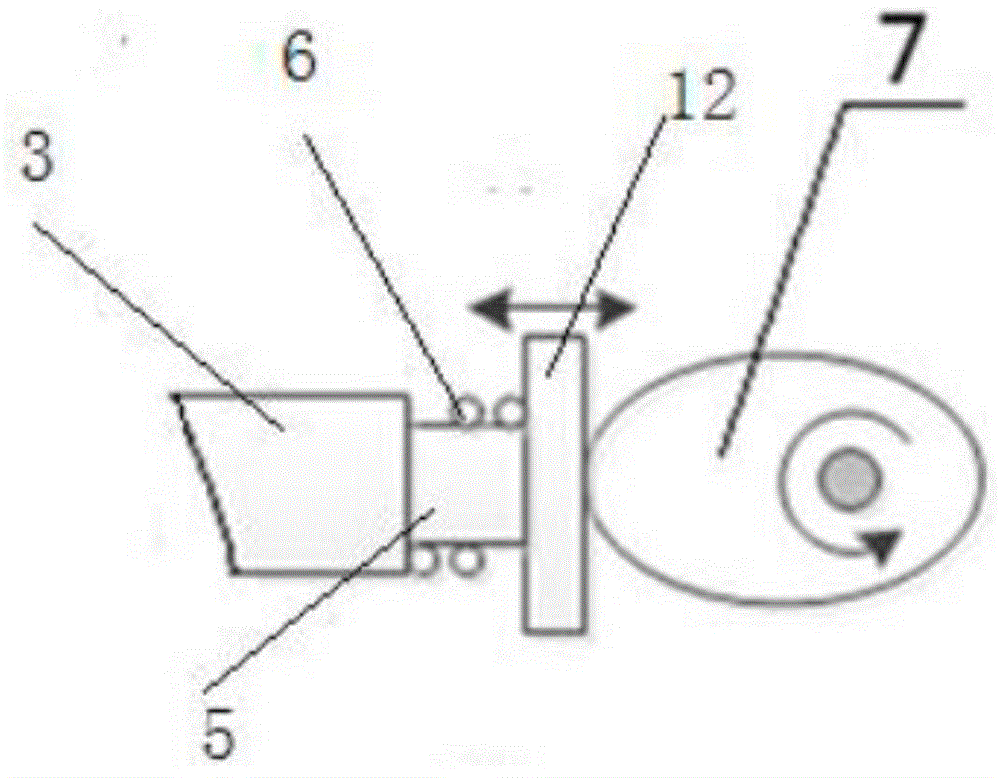

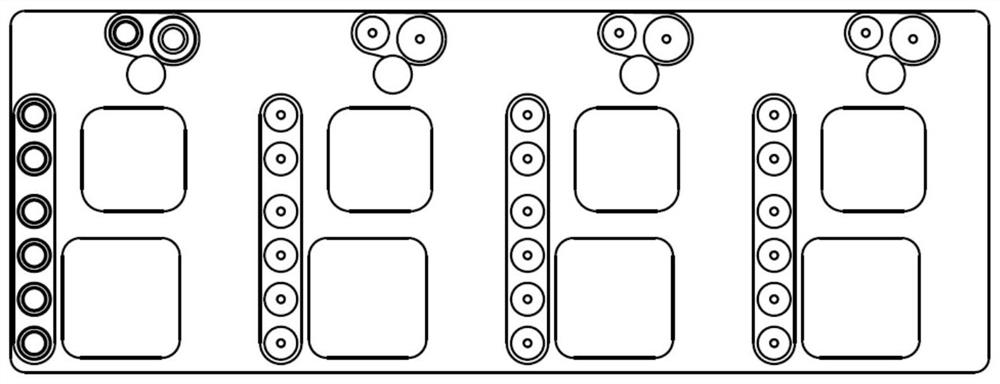

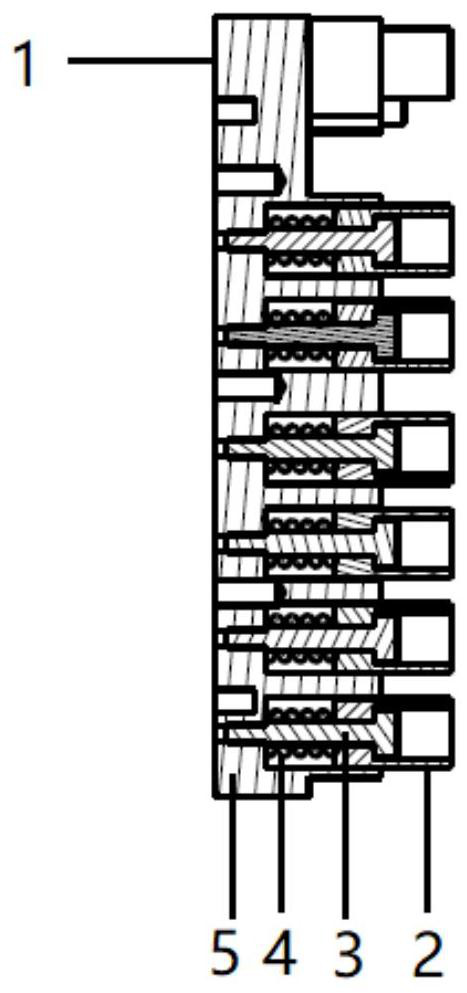

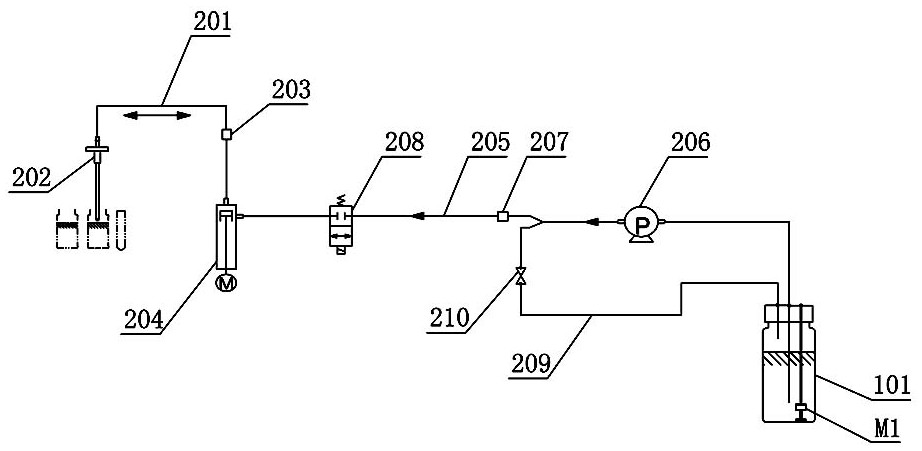

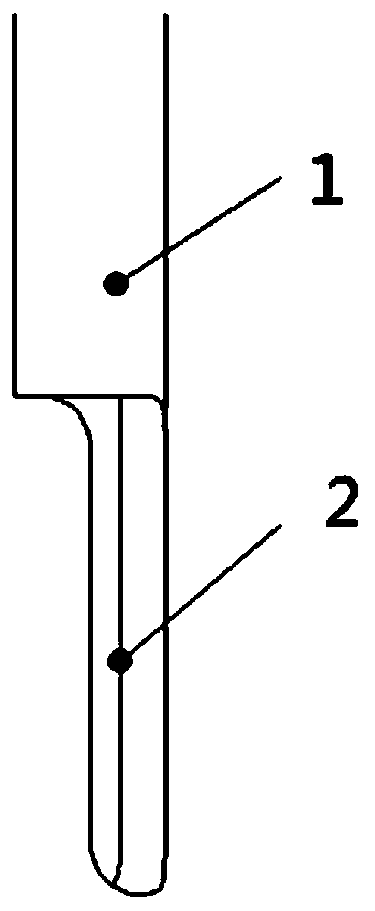

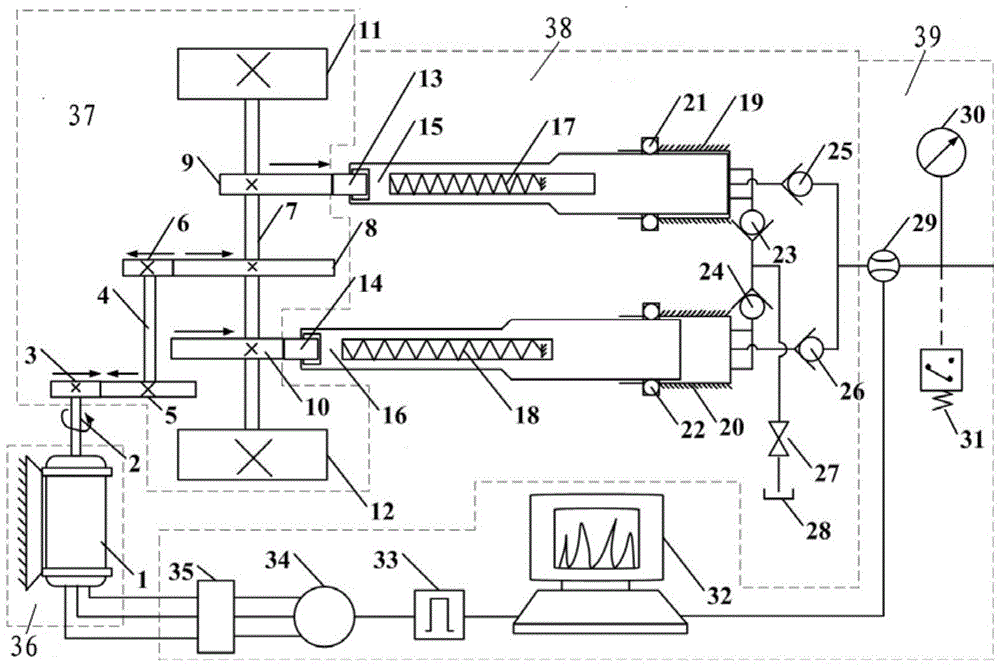

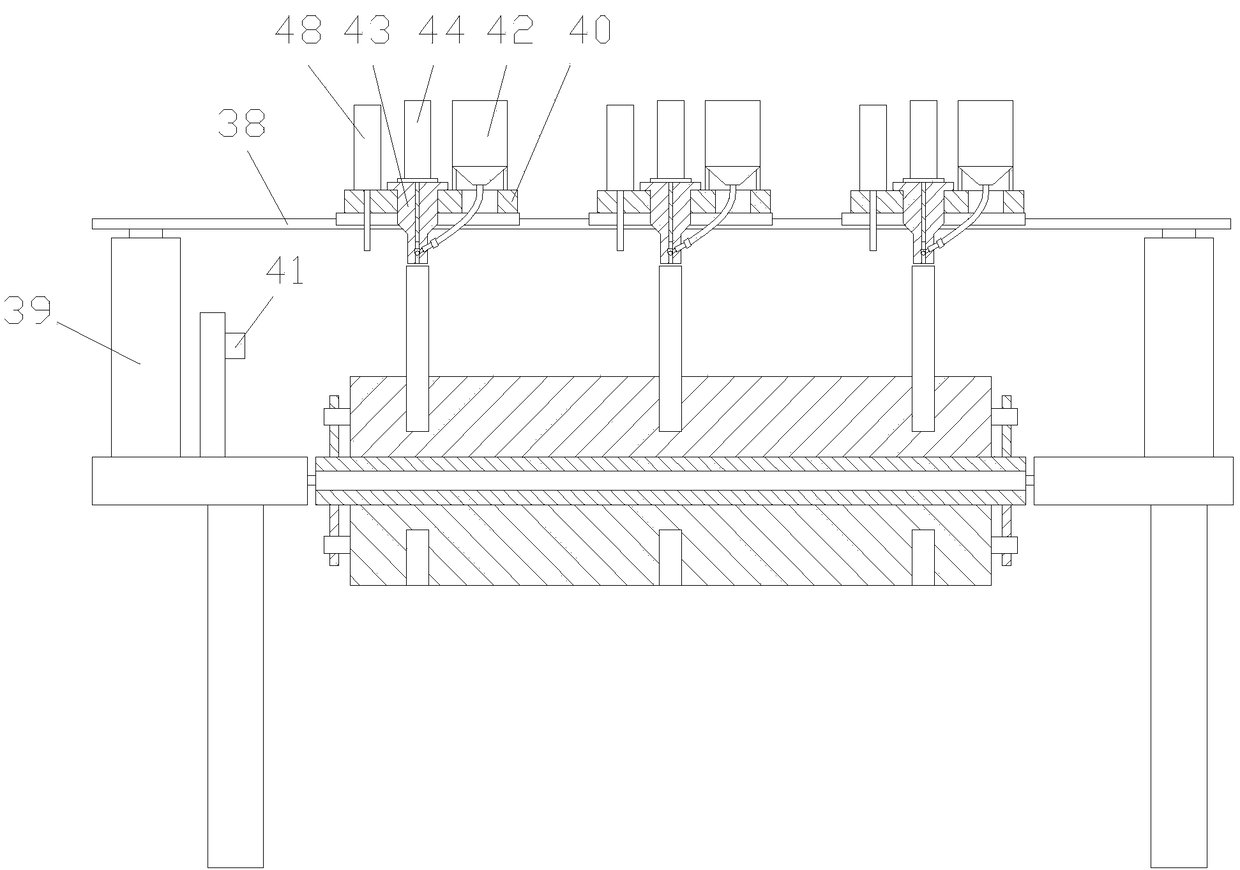

Pump suction type quantitative evacuation priming device

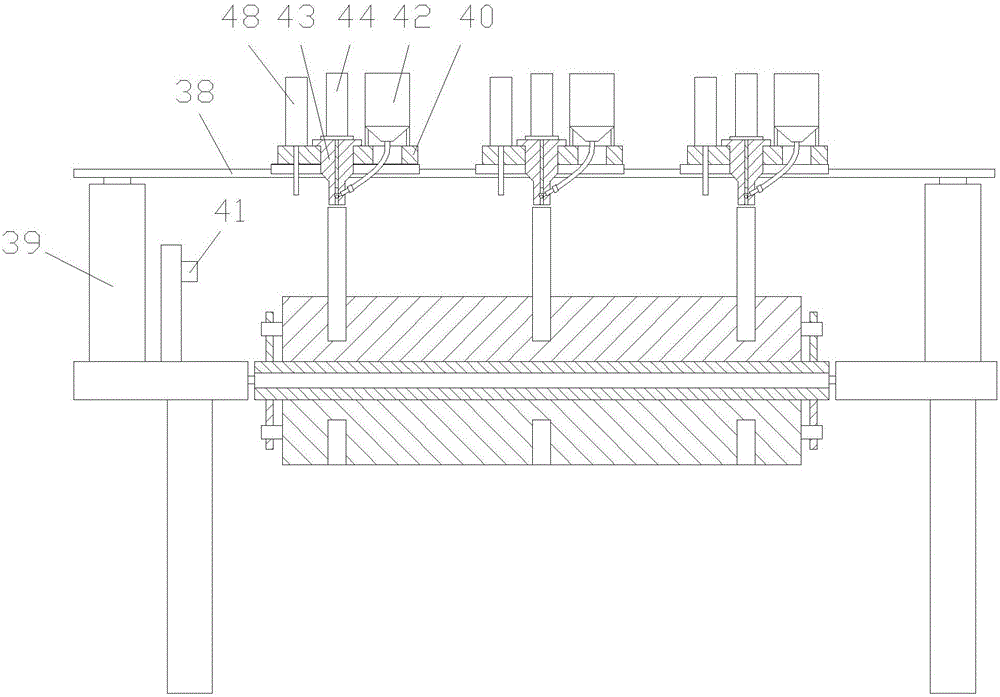

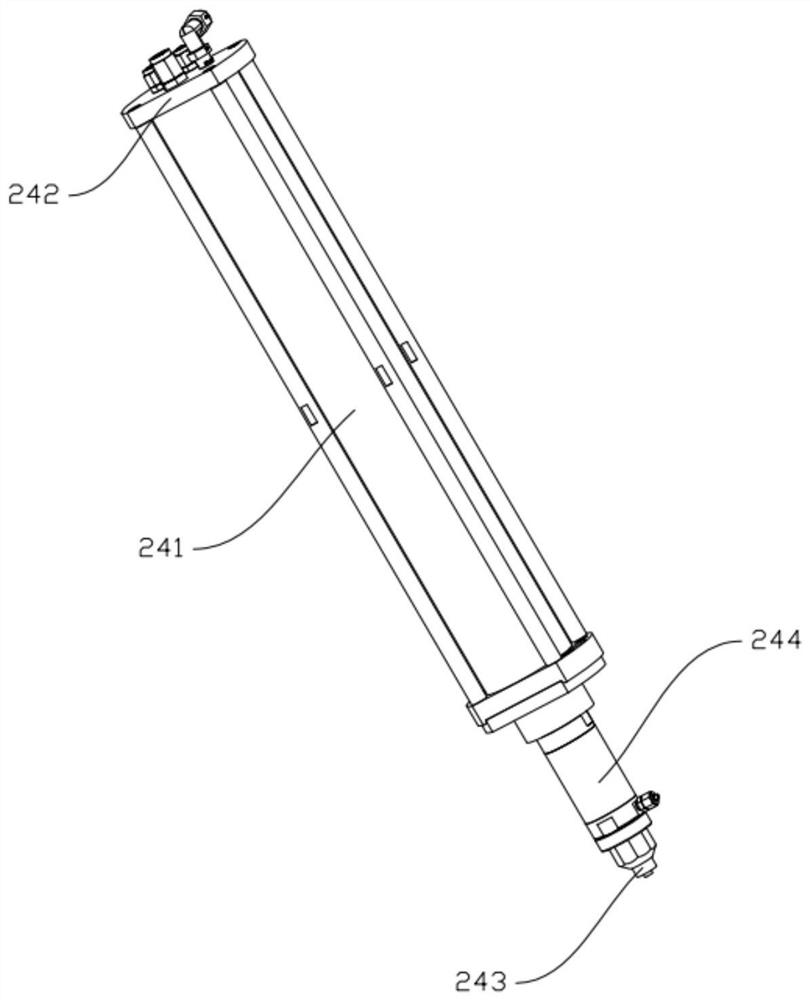

InactiveCN101465414AHigh injection precisionReduce wasteCell component detailsEngineeringAqueous solution

The invention relates to a pumping quantitative vacuum priming device, comprising a pumping quantitative unit and a vacuum priming unit which is connected with the pumping quantitative unit; the pumping quantitative unit comprises a quantitative cylinder (6), a pump liquid back-suction tube (1), a liquid-measuring adjustable level (2), a pump liquid buffer (8) and a liquid taking pump (13); the pumping quantitative unit realizes to quantitatively pump liquid to be poured; the vacuum priming unit comprises a middle vessel (10), an upper clamping device (9), a lower clamping device (14), a vacuum buffer (5), a vacuum bump (11), a vacuum valve (3), an atmospheric valve (4), a bypass valve (7) and a vacuum meter (16), thus realizing to pump the liquid to be poured, to pump vacuum and to charge the liquid to be poured. The pumping quantitative vacuum priming device has high precision and high efficiency, and is energy-saving and environmental-protection; in addition, the charging loop is easily to be expanded; the device is suitable for charging aqueous solution such as acidic electrolyte bath, alkali electrolyte and the like and flowing liquid such as oil with low viscocity and oily solution.

Owner:HUIZHOU XINKEHUA IND

Battery liquid-filling device

The invention discloses a battery liquid-filling device. The battery liquid-filling device is structurally characterized in that: an air extracting pump is sequentially and hermetically connected with an air suction pipe, a buffer bottle, an air extracting pipe, a liquid-filling pipe and a metering pump; the liquid-filling pipe is provided with an electromagnetic valve; the air extracting pipe is provided with an electromagnetic valve and a filter sheet; the neck of the buffer bottle is provided with a secondary filter sheet; and both the filter sheet and the secondary filter sheet are polytetrafluoroethylene or polypropylene porous filter sheets, the aperture is 2 to 60 microns, and the porosity is 70 to 85 percent. The device is simple in structure, convenient to operate and low in cost, is used for filling electrolyte for a lithium battery and a super capacitor, and can timely and fully discharge the gas in the battery so as to prevent the battery from swelling, shorten the liquid-filling time and improve the liquid-filling precision; and the device can be reused for a long term, and is economic and practical.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

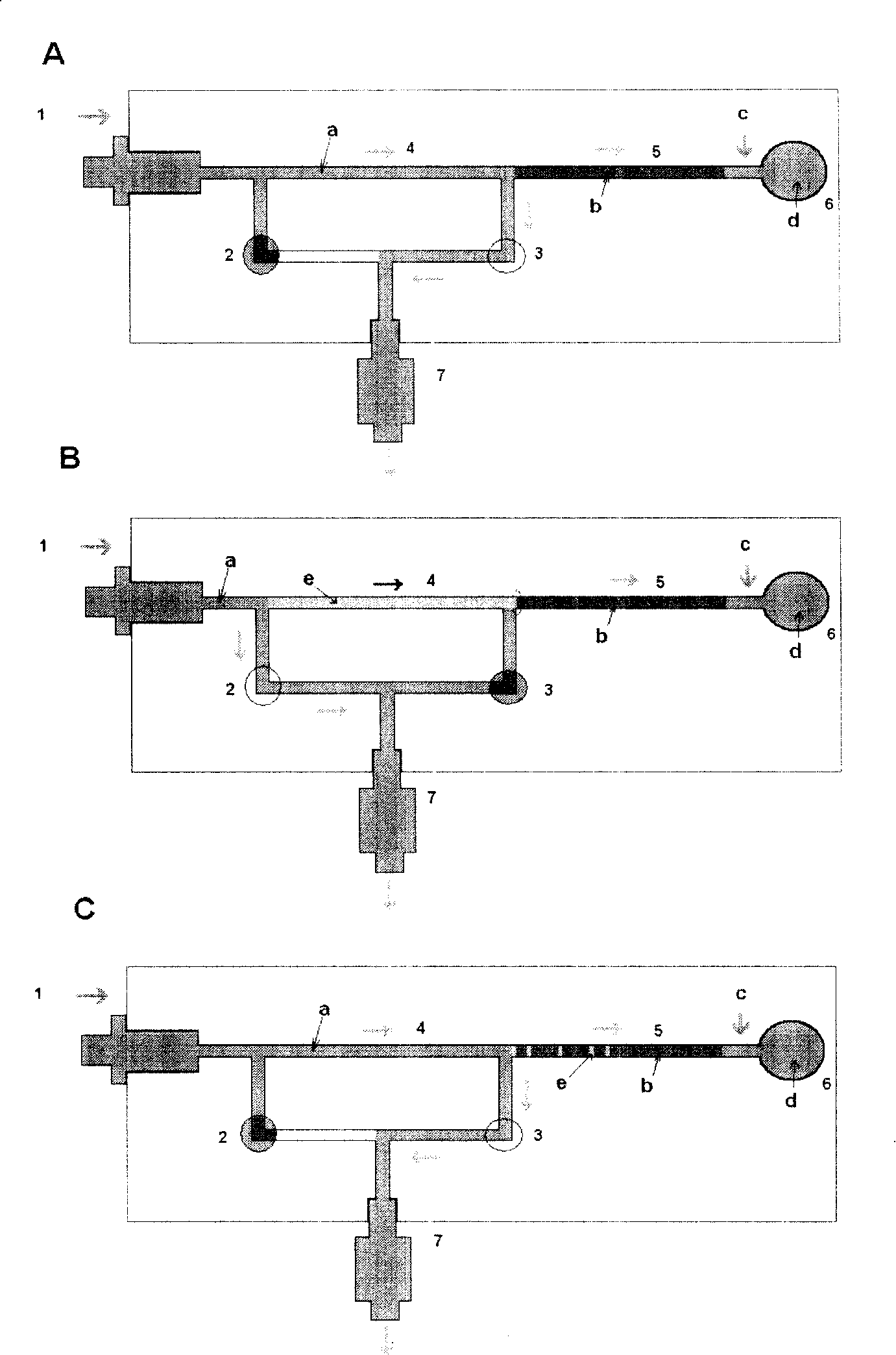

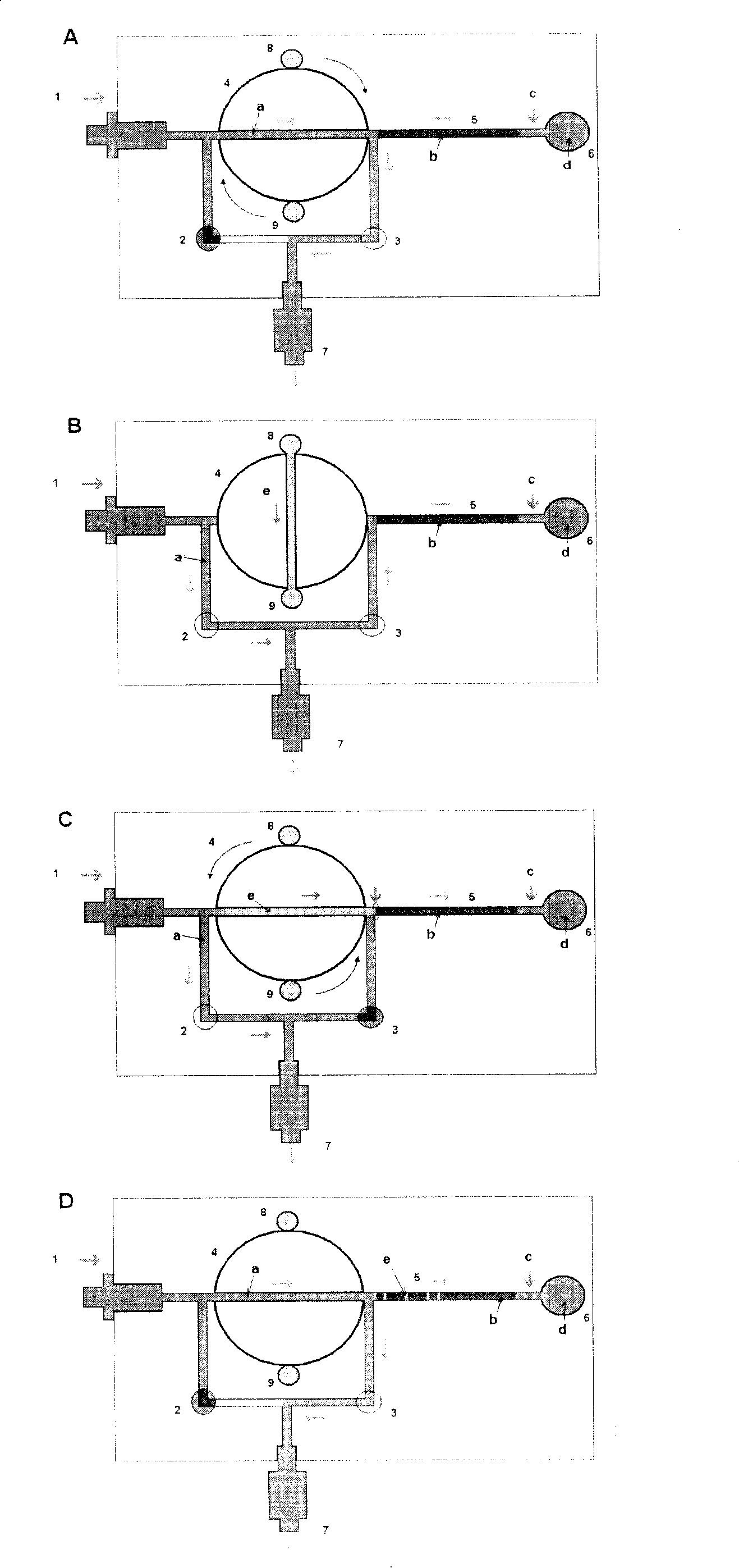

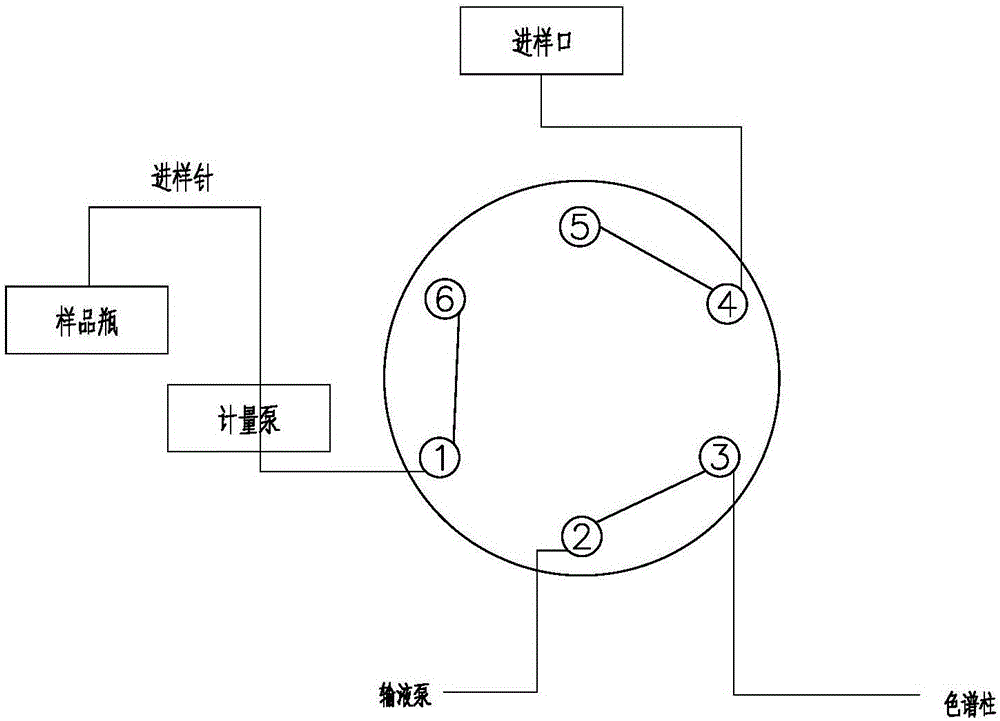

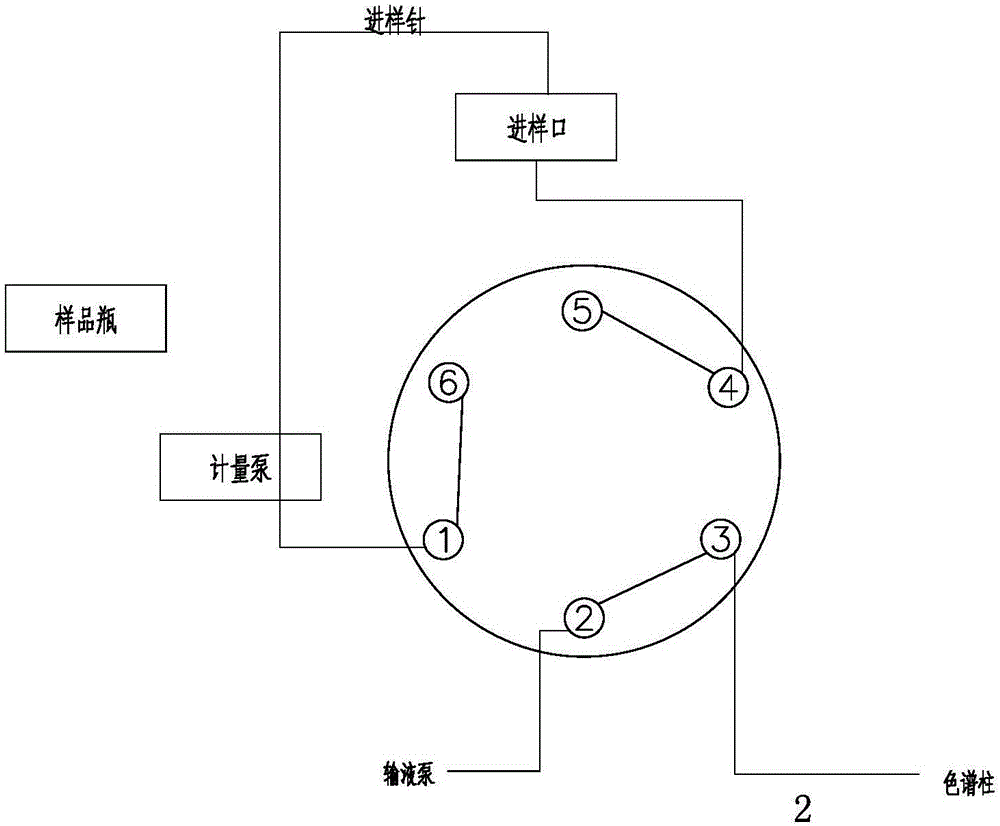

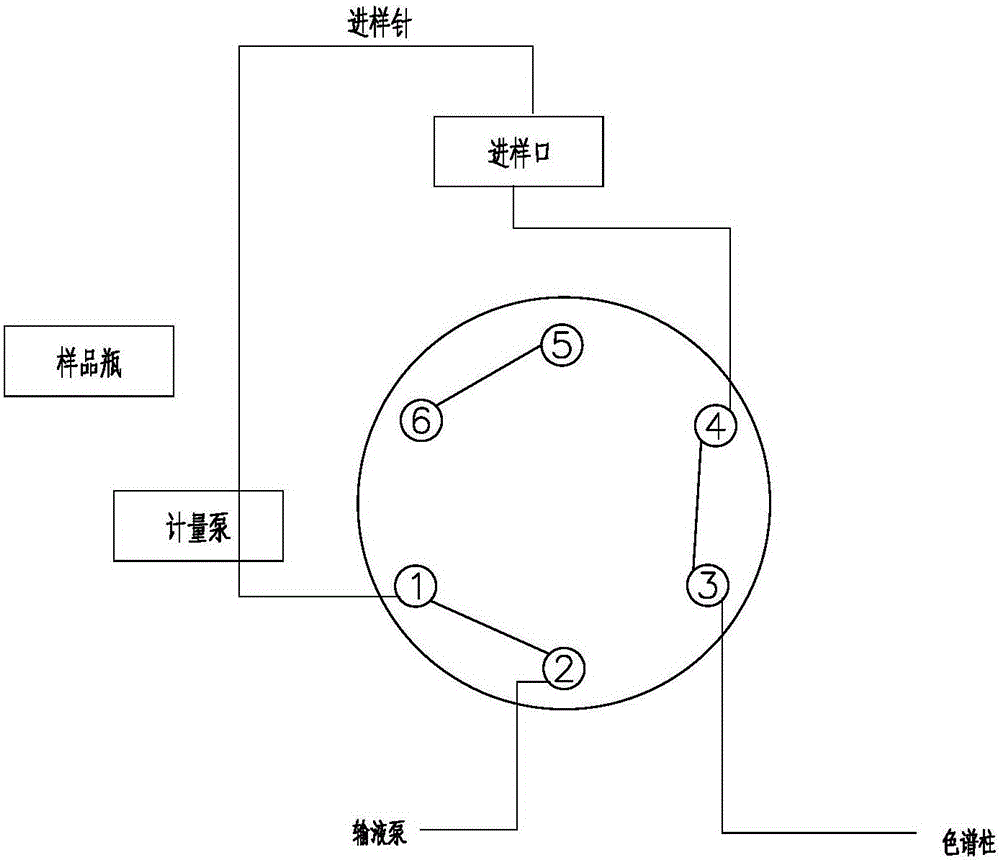

Large volume sample injection method and special chip in micro-current-control chip

InactiveCN101206227AEasy loadingPrevent proliferationComponent separationStationary phaseElectricity

The invention relates to a sample injection method of a micro fluidic chip system, in particular to a large-volume sample injection method and a special chip adopted in a micro fluidic chip, wherein, two or more than two shunt channels are arranged between a chip separation channel and a mobile phase inlet inside a micro fluidic chip system adopting fixed stationary phase; large-volume sample injection of the micro fluidic chip system is realized through controlling the switching and cutoff of the fluid inside the system. The method is suitable for large-volume sample injection inside a micro fluidic chip in electrochromatography mode, compression electrochromatography mode and liquid phase chromatogram. Moreover, the method has the advantages that: sample injection of large-volume sample inside a micro fluidic chip can be realized; the invention overcomes the gradient delay effect of the system, and is particularly suitable for gradient separation; moreover, the invention has the characteristics of simple strucuture, convenient operation, small dead volume, small pre-column effect and good sample injection repeatability, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lithium battery electrolyte injection system having electrolyte volatile gas absorption function

ActiveCN106058143AHigh injection precisionAvoid electrochemical performanceCell component detailsEngineeringBottle

The invention discloses a lithium battery electrolyte injection system having an electrolyte volatile gas absorption function. The lithium battery electrolyte injection system includes an electrolyte injection unit, a vacuumizing unit, a harmful gas absorption unit and the like. The electrolyte injection unit includes an intermediate belt conveying machine, a battery positioning mold, a lifting board, a first lifting air cylinder, a quantitative electrolyte injector and the like. A weighing and detecting unit includes a front weighing sensor, a rear weighing sensor and a reject conveying machine. The vacuumizing unit includes a seal cover, a first gas pipe joint, a vacuum sensor and a vacuum pump. The harmful gas absorption unit includes a second gas pipe joint, an exhaust fan and a harmful gas absorption bottle. The volume of an inner chamber of a quantitative cylinder in the quantitative electrolyte injector is equal to standard electrolyte injection quantity of the lithium battery, so that the volume of the electrolyte pushed out by the electrolyte injection cylinder is accurately equal to the standard electrolyte injection quantity of the lithium battery. The system has high injection accuracy. During the injection, the harmful gas absorption unit exhausts and absorbs harmful gas, thus avoiding environment pollution caused by the harmful gas.

Owner:重庆市中欣维动力科技有限公司

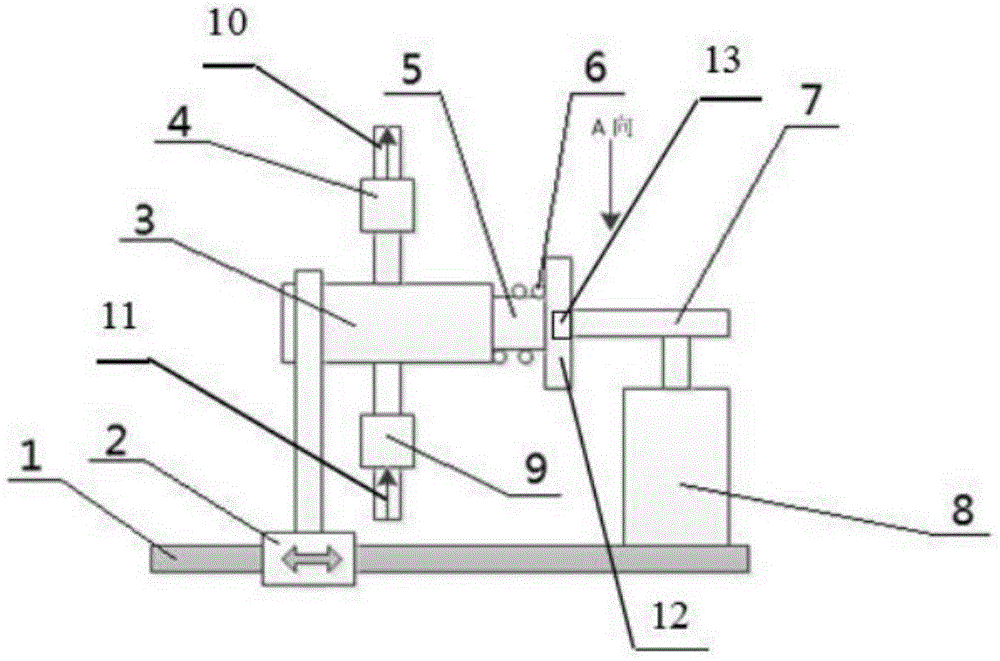

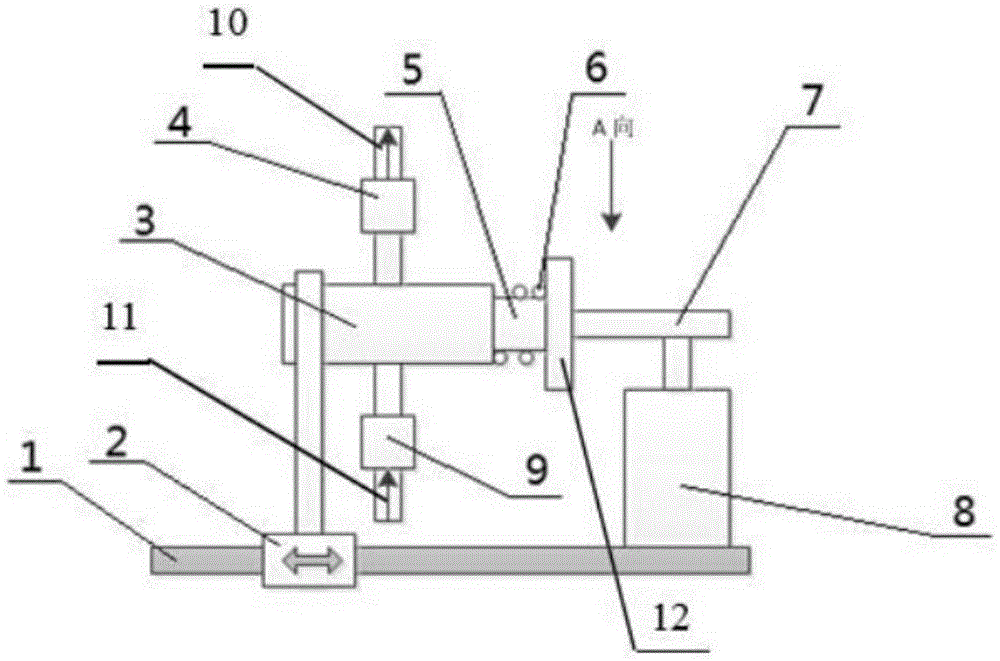

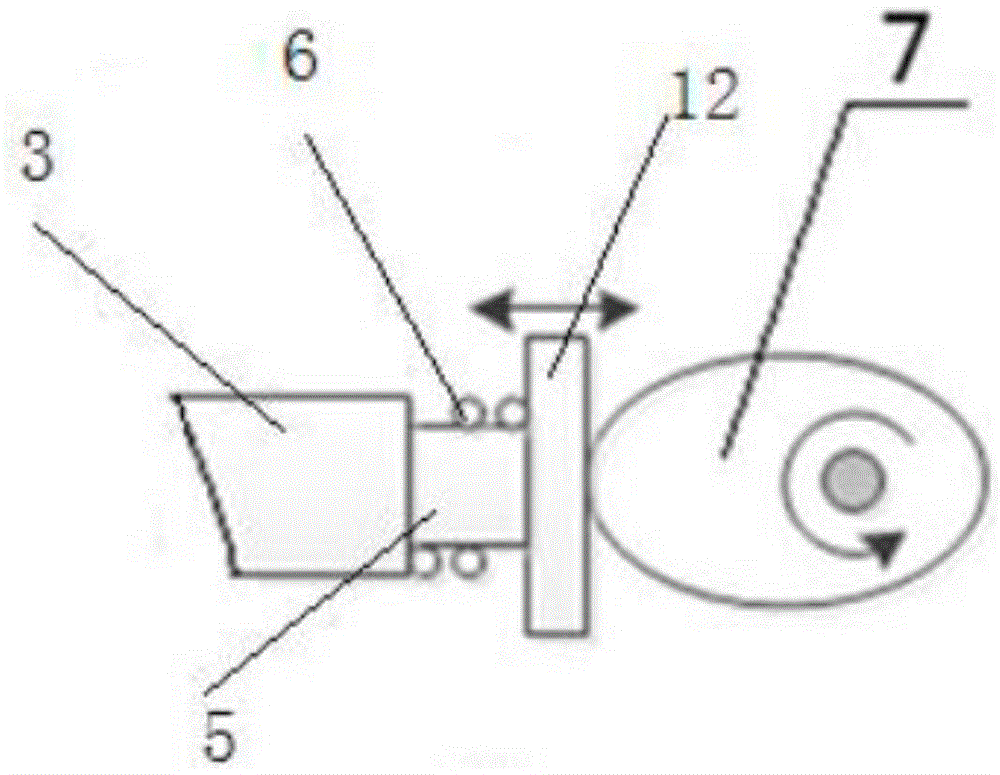

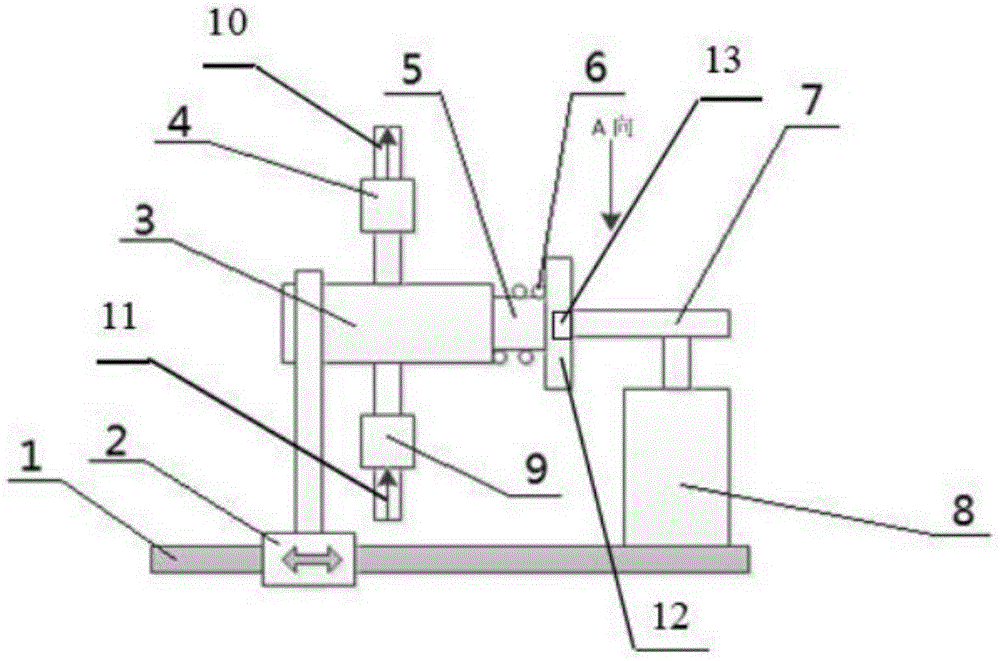

High-precision plunger type trace sampling pump

InactiveCN104653426ASimple structureHigh injection precisionPump controlPumpsMicroorganismCulture fluid

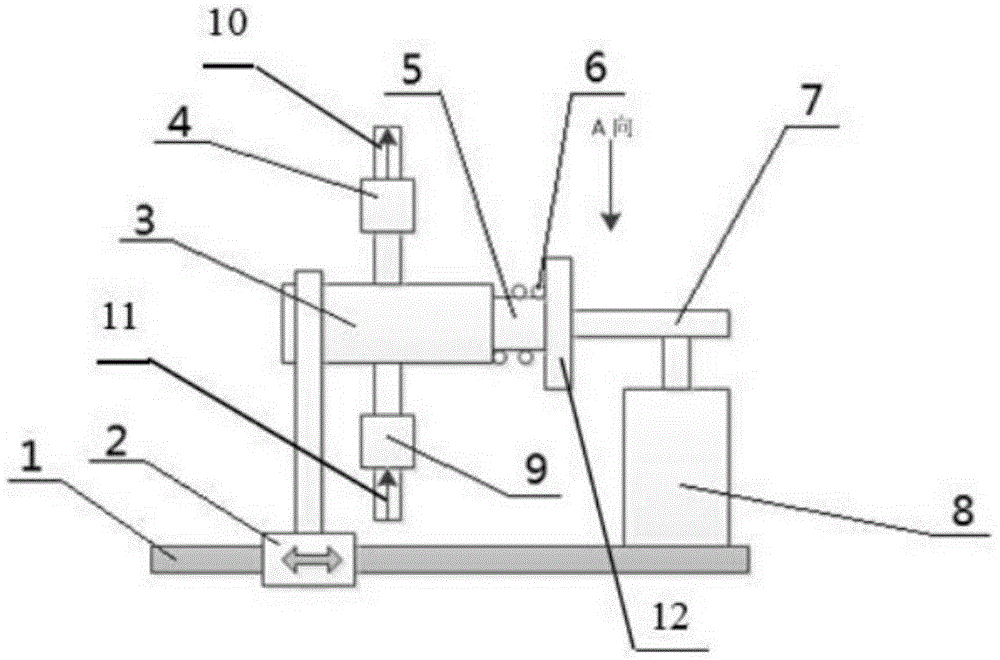

The invention discloses a high-precision plunger type trace sampling pump. Guide rails are horizontally arranged and are connected with the bottom end of a sliding bracket, so that the sliding bracket moves left and right on the guide rails; a plunger pump is arranged at the top end of the sliding bracket; a liquid inlet one-way valve and a liquid outlet one-way valve are respectively arranged in a liquid inlet and a liquid outlet of the plunger pump; one end of a plunger of the plunger pump is embedded inside the plunger pump; a separation-reunion plate is arranged at the other end of the plunger; a spring coaxially sleeves the plunger; two ends of the spring are respectively in contact with the separation-reunion plate and the plunger pump; a motor is fixedly placed; a cam is fixed on a driving shaft of the motor. The high-precision plunger type trace sampling pump disclosed by the invention has the advantages of simple structure, high sampling precision, adjustable trace, stable operation and low cost; the high-precision plunger type trace sampling pump is suitable for accurate sampling of an analysis instrument system and high-precision agent mixing, in particular for sampling detection of microbial culture solution.

Owner:河北雄安芯慧至上科技有限公司

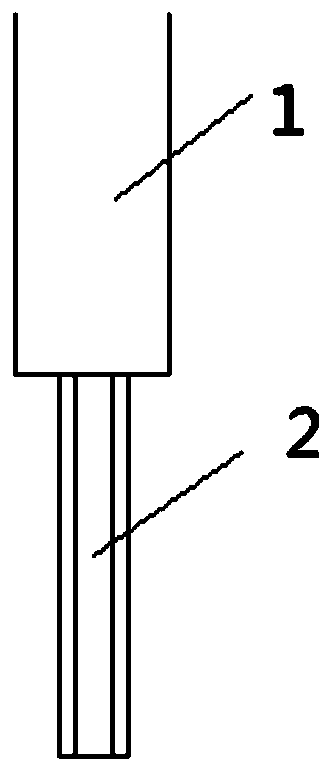

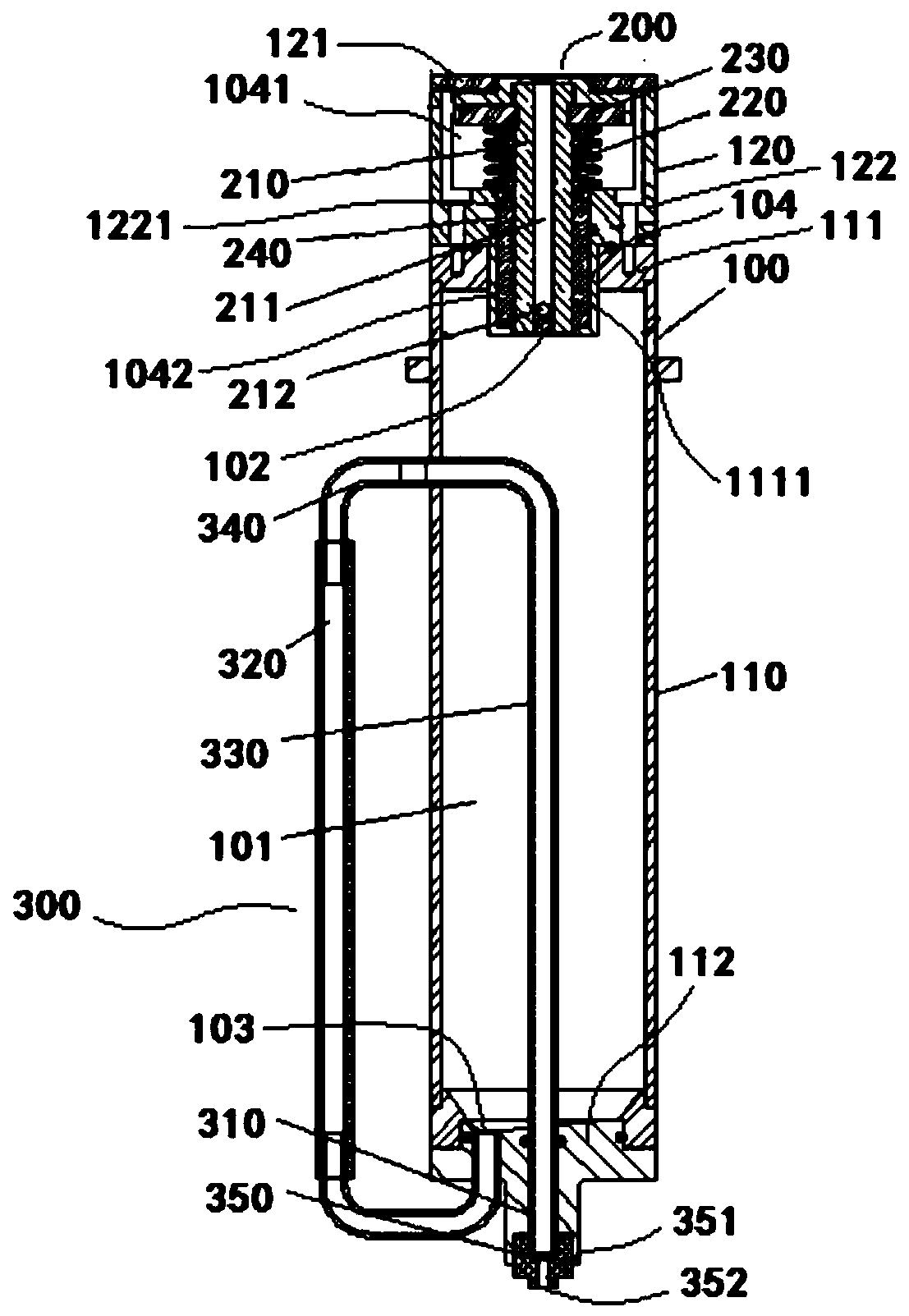

Liquid injection device and battery production system

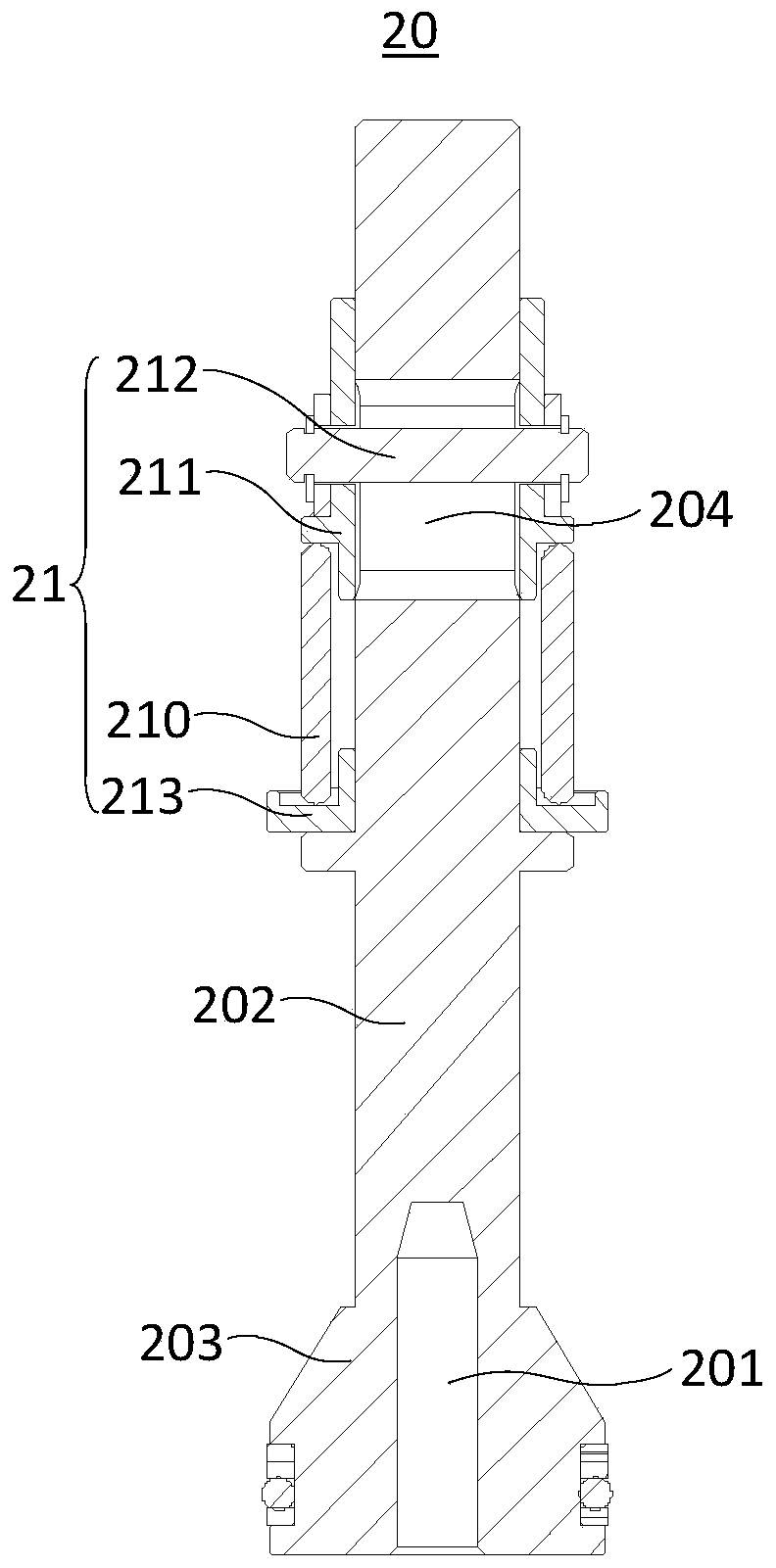

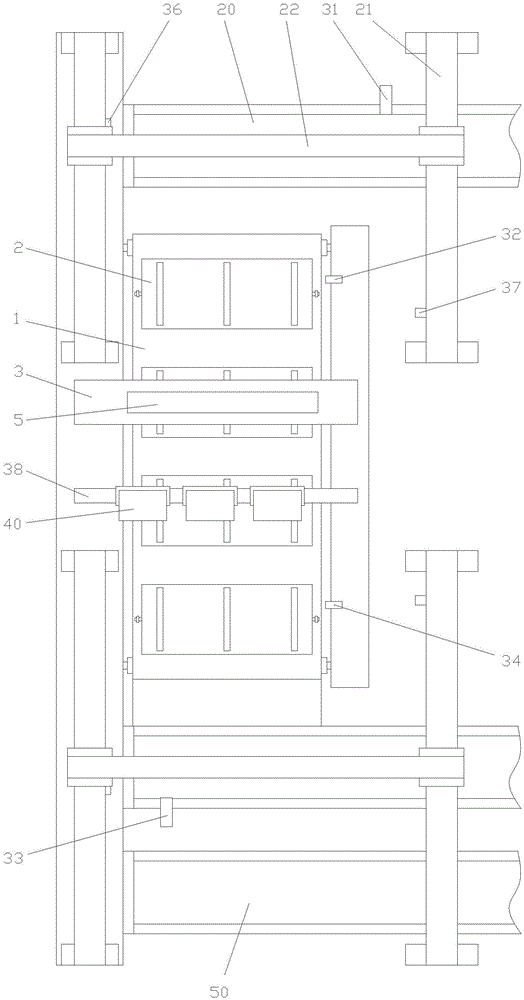

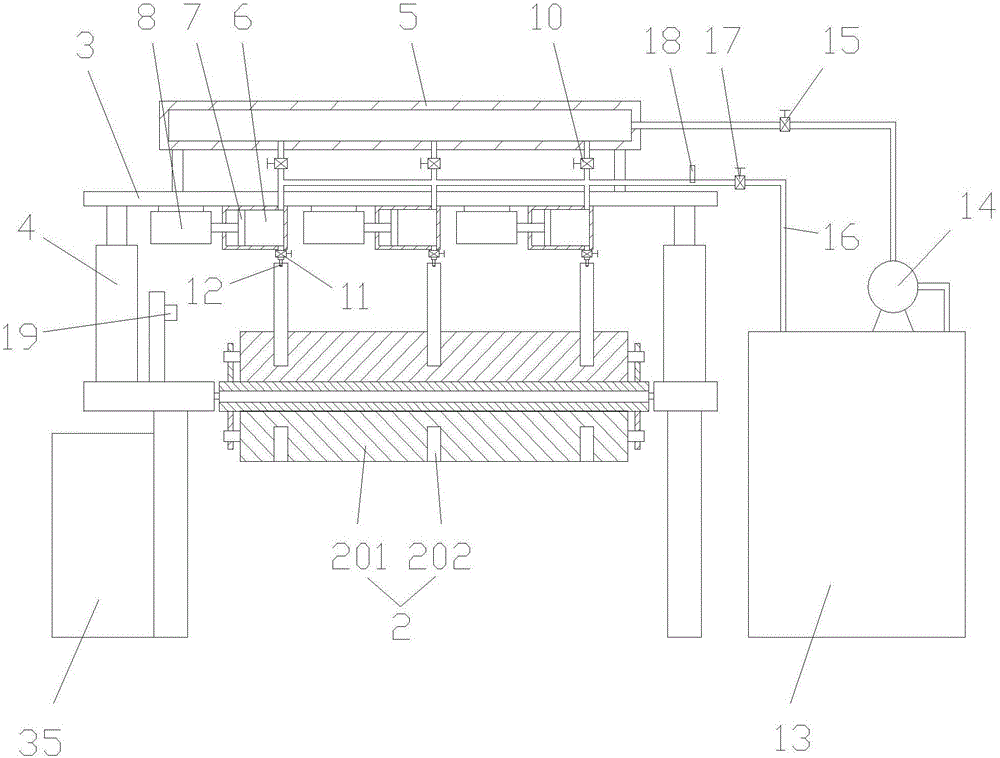

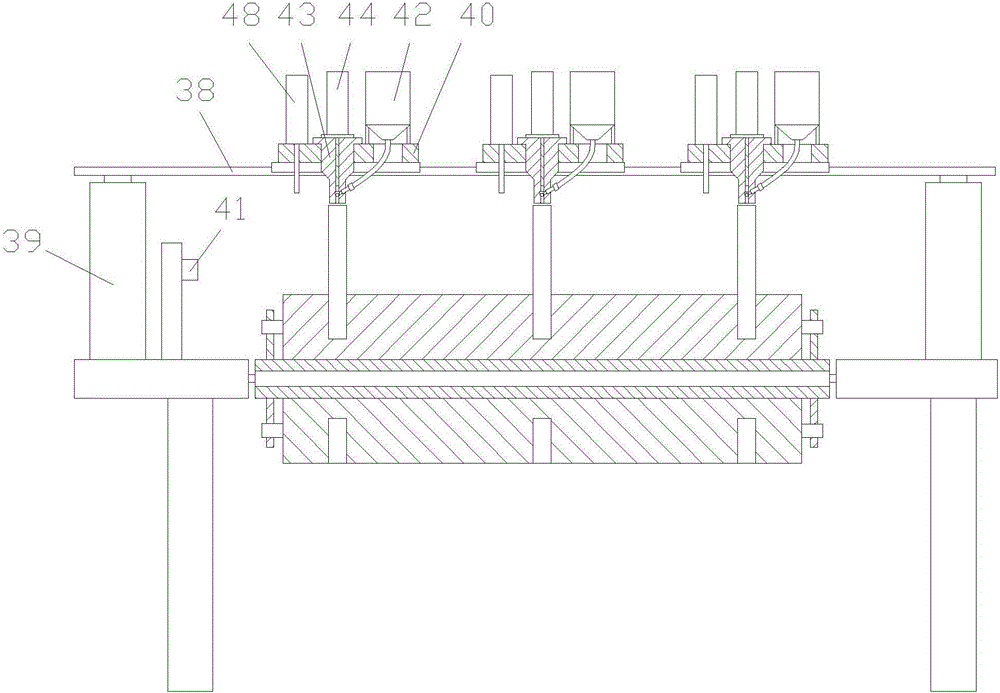

PendingCN110148703AHigh injection precisionShorten the injection timeFinal product manufactureCell component detailsEngineeringMechanical engineering

The invention discloses a liquid injection device and a battery production system. The liquid injection device comprises a liquid holding device comprising a liquid holding cup and a liquid holding cup base, wherein the liquid holding cup base comprises a connection base and a first liquid injection pipe and a second liquid injection pipe which are respectively extended outwards from the two endsof the connection seat and communicate to each other, the connection base is in seal connection with the bottom portion of the liquid holding cup, allows the first liquid injection pipe to be extendedinto the liquid holding base and allows the second liquid holding pipe to be exposed externally out of the liquid holding cup, and the connection base and the liquid holding cup form a holding cavity; a pressing has a reserved channel configured to avoid the first liquid injection pipe, the diameter of the reserved channel is larger than that of the first liquid injection pipe, the pressing rod is extended into the liquid holding cup through the top portion of the liquid holding cup, the periphery wall of the pressing rod is in sealing and sliding fit with the inner periphery wall of the liquid holding cup, the pressing rod is configured to press the liquid in the holding cavity into the first liquid injection pipe through the periphery wall of the reserved channel and the outer peripherywall of the first liquid injection pipe. Through arrangement of the pressing rod and the liquid holding component, the liquid injection device can improve the liquid injection precision and can shorten the duration of the liquid injection.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

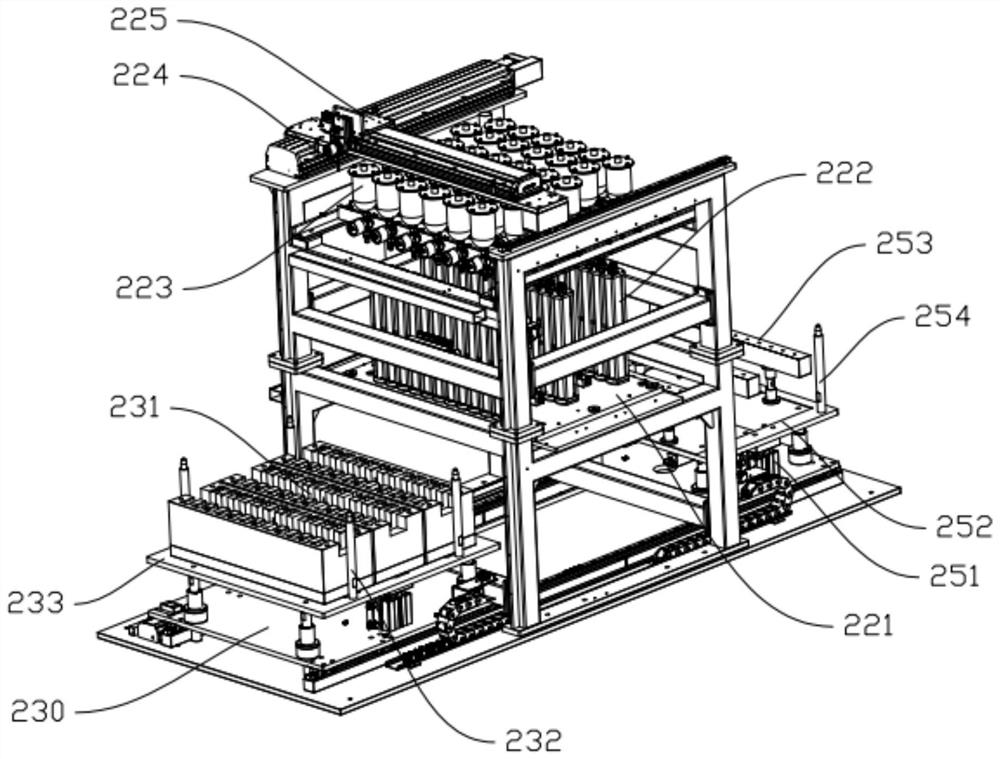

Lithium battery electrolyte injection system with self-checking function

ActiveCN106159186AHigh injection precisionIncrease productivityCell component detailsEngineeringLoad cell

Owner:重庆市中欣维动力科技有限公司

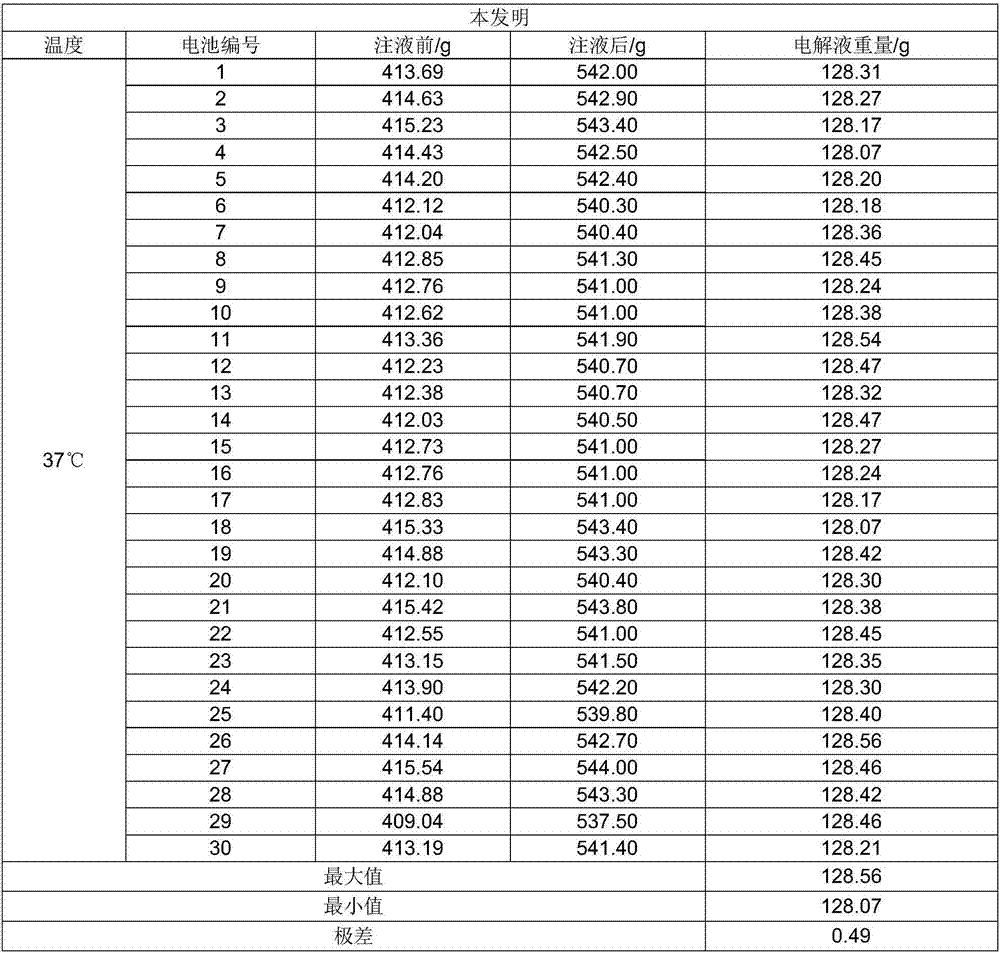

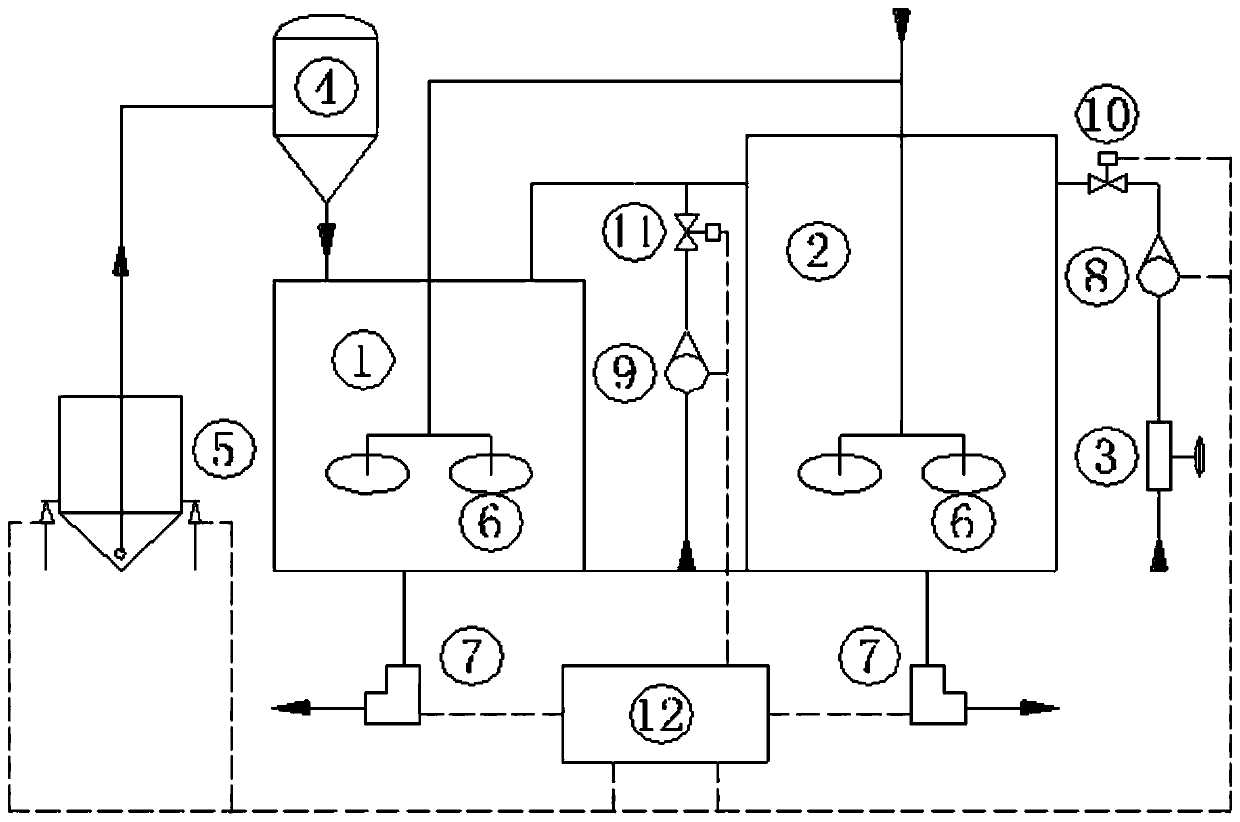

Constant-temperature heating and liquid injection device and method of lithium ion battery

PendingCN107464911AHigh injection precisionImprove stabilityFinal product manufactureCell component detailsBuffer tankInlet valve

The invention discloses a constant-temperature heating and liquid injection device of a lithium ion battery. The constant-temperature heating and liquid injection device comprises a first electrolyte heating tank, a second electrolyte heating tank, an electrolyte constant-temperature buffer tank, a liquid injection system and a lithium battery positioning fixture, wherein one end of the first electrolyte heating tank is connected with a first liquid inlet valve, the other end of the first electrolyte heating tank is connected with a liquid inlet in a side wall of the electrolyte constant-temperature buffer tank via a first electrolyte valve, and the bottom of the electrolyte constant-temperature buffer tank communicates with the liquid injection system via a third electrolyte valve. The invention also discloses a constant-temperature heating and liquid injection method of the lithium ion battery. With the adoption of the constant-temperature heating and liquid injection device for liquid injection of the lithium battery, the liquid injection accuracy and the stability of liquid injection quantity can be improved, the liquid injection quantity is free from the influence of an external environmental temperature, so that the liquid injection process capability is improved, and the production efficiency and the material utilization ratio are improved; and meanwhile, after an electrolyte is heated, the viscosity of the electrolyte can be reduced, the mobility and the infiltration performance of the electrolyte are improved, the liquid injection efficiency is improved, and the infiltration performance of the electrolyte is improved.

Owner:WANXIANG 123 CO LTD

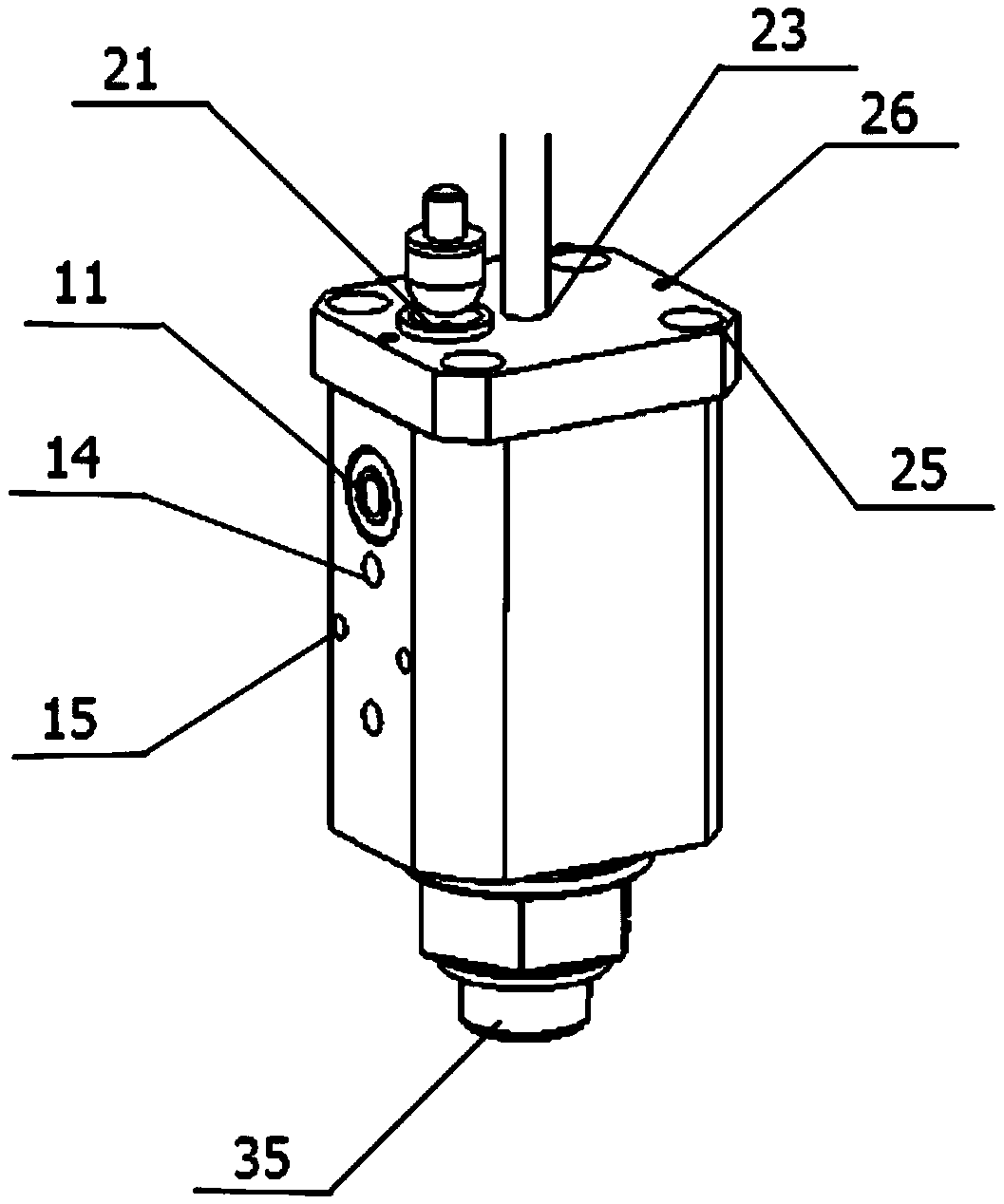

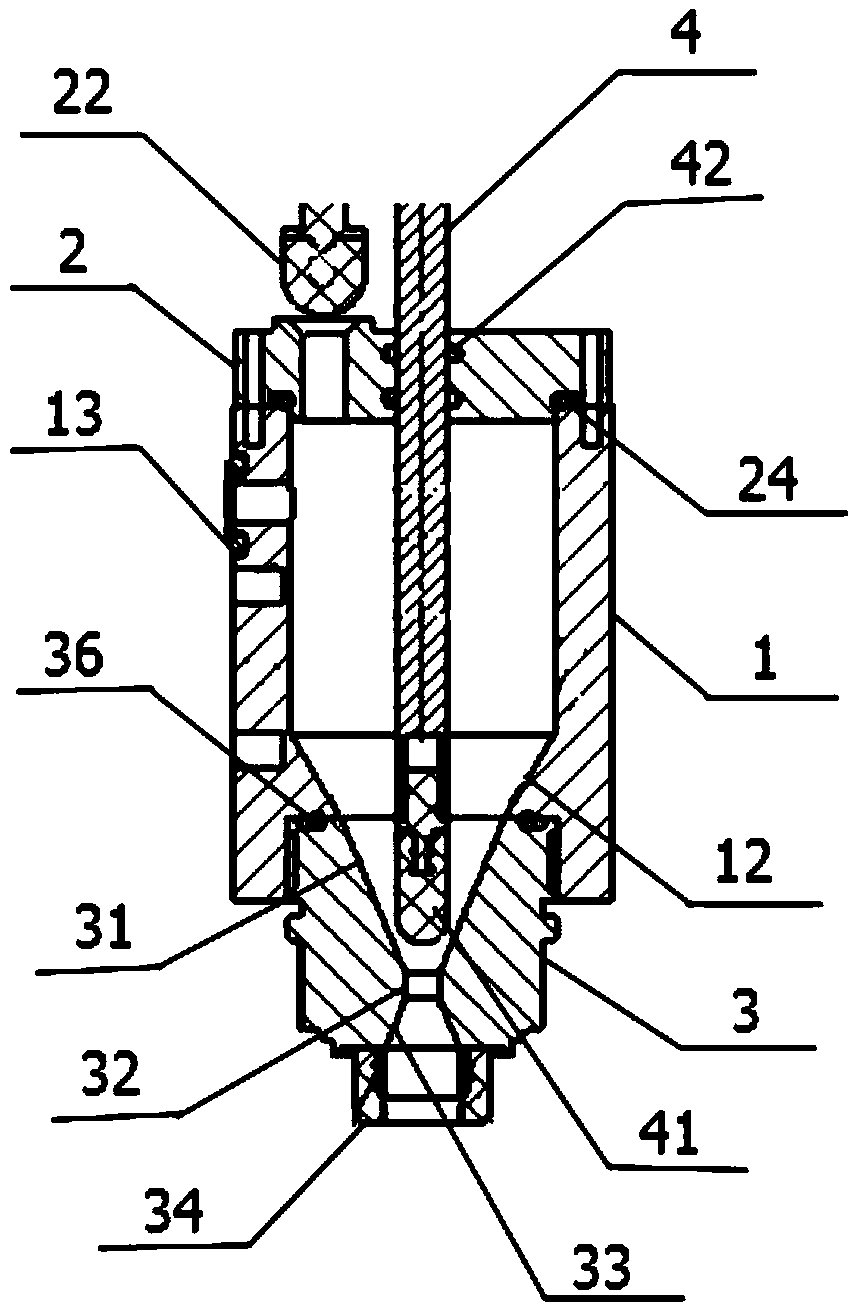

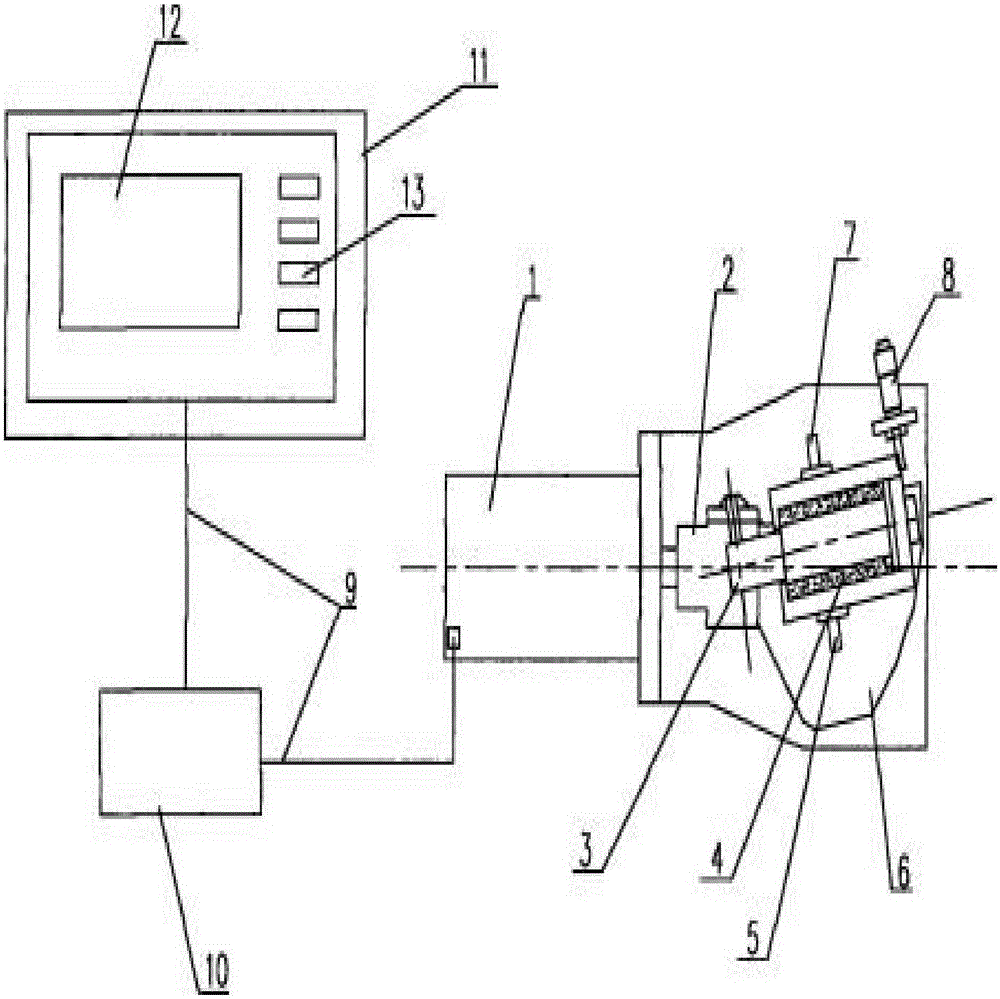

Automatic sampler of liquid chromatograph, and automatic correction method of sampling hole of automatic sampler

The invention belongs to the technical field of liquid chromatograph equipment, and in particular relates to an automatic sampler of a liquid chromatograph, and an automatic correction method of a sampling hole of the automatic sampler. According to the automatic sampler of the liquid chromatograph, a sealing ring seat mounting groove is formed in a sampling platform; a sealing ring seat is arranged in the sealing ring seat mounting groove; the sealing ring seat is provided with a sealing ring, and the sealing ring is fixed by a sealing ring cover; the sealing ring seat is provided with a sample tube hole; a through hole I is formed in the sealing ring cover, and a through hole II is formed in the sealing ring; a sample tube is arranged in the sample tube hole; the upper end of the sample tube is connected with the sealing ring seat, and the through hole II of the sealing ring is communicated with an inner hole of the sample tube; the sealing ring seat can be translated along the plane direction in the seal ring seat mounting groove, and drives the sealing ring and the sealing ring cover to move synchronously. The automatic sampler can enable a sampling needle to accurately enter the sampling hole and to be well sealed with the sealing ring in the sampling hole, so that the sampling accuracy of the sampler is improved, and the service life of the automatic sampler is greatly prolonged.

Owner:ZHEJIANG FULI ANALYTICAL INSTR

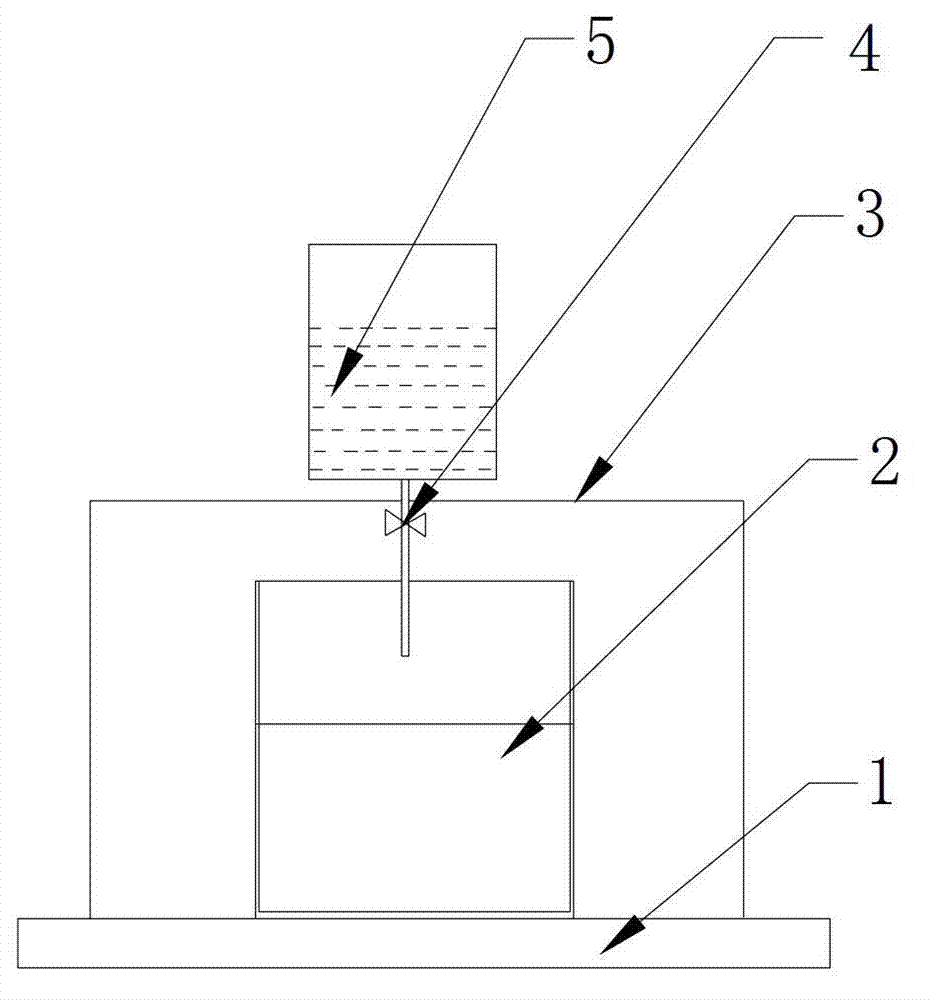

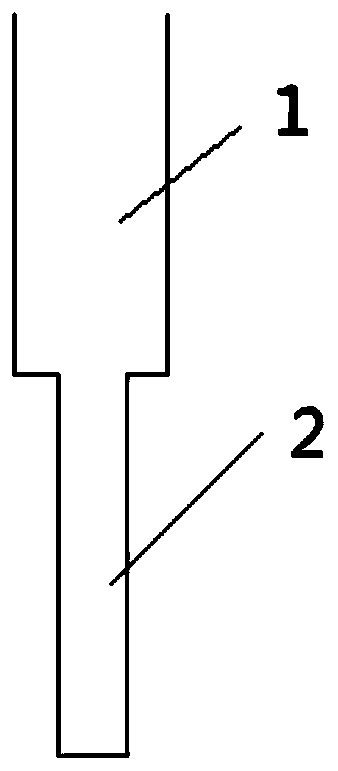

Battery electrolyte injection cup

ActiveCN105514340AGuaranteed tightnessResidue reductionCell component detailsEngineeringCircular surface

The invention discloses a battery electrolyte injection cup. The battery electrolyte injection cup comprises a cup body, a cup cover fixed to the cup body and an electrolyte injection nozzle fixed to the bottom of the cup body. An electrolyte inlet is formed in the cup cover, and a first sealing head is arranged outside the electrolyte inlet. A vacuum opening is formed in the side face of the cup body, and a first inverted conical surface is arranged at the bottom of the inner wall of the cup body. The inner wall of the electrolyte injection nozzle is sequentially provided with a second inverted conical surface, a circular surface and a first positive conical surface from top to bottom, wherein the second inverted conical surface is tightly connected with the first inverted conical surface, the bottom of the first positive conical surface is connected with an electrolyte injection sealing nozzle, and the electrolyte injection sealing nozzle is communicated with an electrolyte outlet. A sealing opening is further formed in the cup cover, a connecting rod is inserted into the sealing opening, and a second sealing head is arranged at the end of the connecting rod and used for being matched with the circular surface. The battery electrolyte injection cup is good in sealing performance, high in electrolyte injection efficiency and precise in electrolyte injection amount, leakage of an electrolyte and electrolyte residues in the cup body are effectively avoided, time and labor are saved during work, and the automation degree of battery production is greatly increased.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

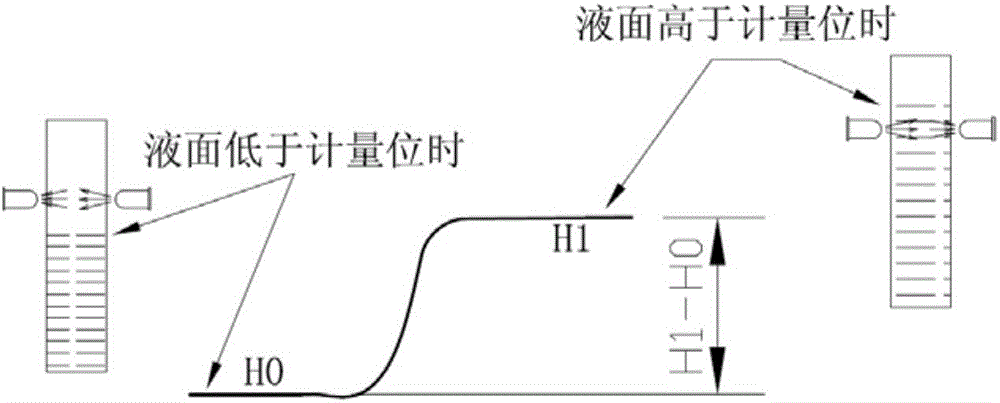

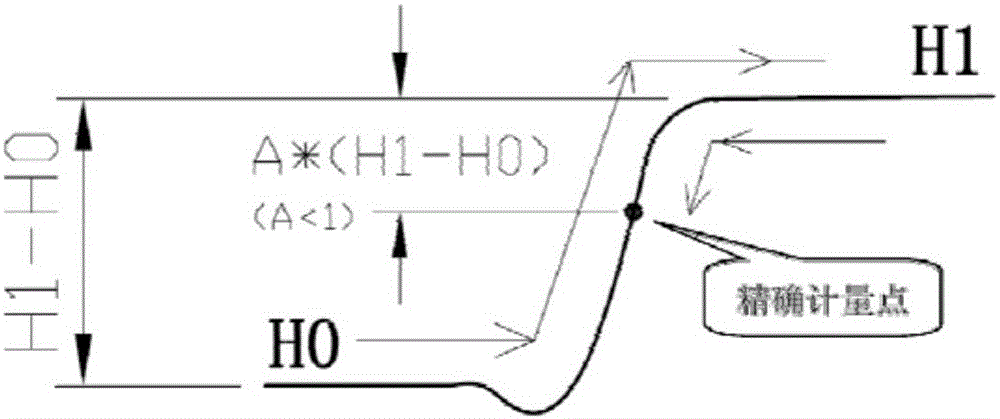

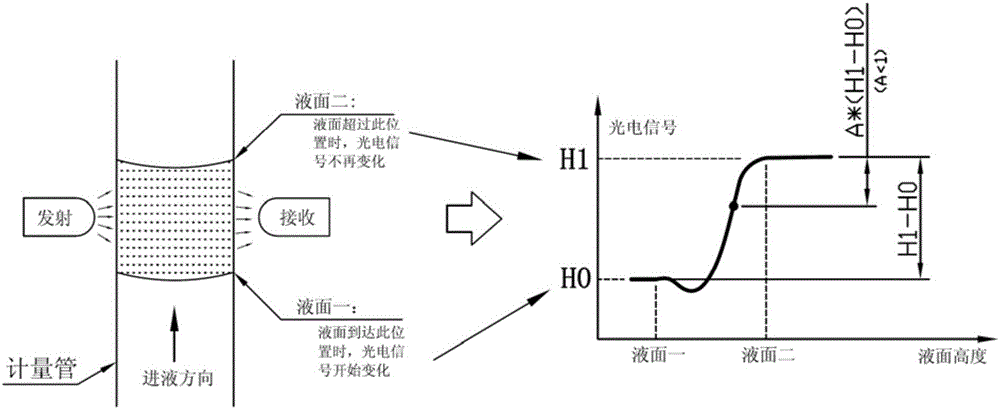

High-precision sampling method

The invention discloses a high-precision sampling method which samples on the basis of a photoelectric metering mode of a water quality online monitor. The method comprises the following steps: firstly, controlling a sampling liquid level to exceed a photoelectric metering level through the water quality online monitor; controlling the sampling liquid level to slowly return to the photoelectric metering level through the water quality online monitor; presetting a proportion A according to experience and waveform change features of optoelectronic signals when the sampling liquid exceeds the photoelectric metering level and returns to the photoelectric metering level, wherein the proportion A and the liquid level height have a corresponding relationship. According to the method, the fixed position to which the liquid level reaches can be accurately detected and controlled and the purposes of accurately metering and increasing the measuring repeatability can be achieved. The high-precision sampling method has the beneficial effects that the sampling precision of the water-base online monitor can be greatly increased, the measuring accuracy and the measuring repeatability of the water quality online monitor can be increased and the method is fit for the application occasion high in color and turbidity.

Owner:ANHUI WAYEE SCI & TECH CO LTD

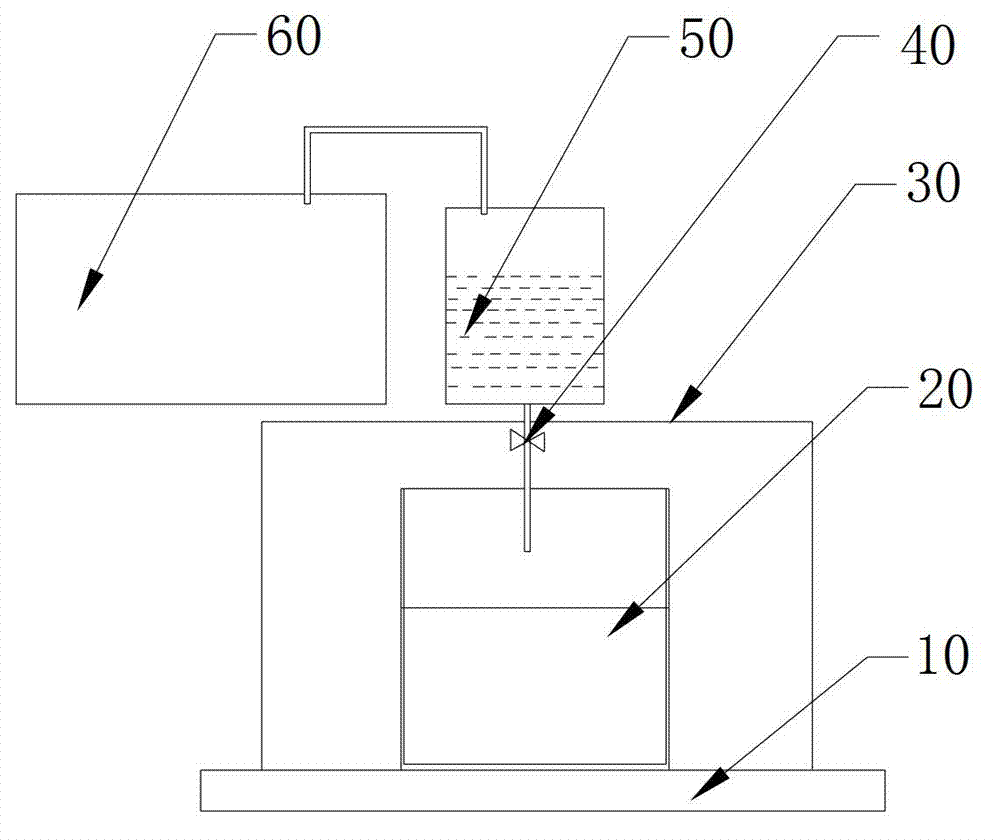

Liquid injection device and liquid injection production line

PendingCN114188678AGuaranteed accuracyAvoid it happening againFinal product manufactureLi-accumulatorsElectrolytic agentPhysical chemistry

The invention discloses a liquid injection device and a liquid injection production line, the liquid injection device comprises a feeding part and a liquid injection part, the liquid injection part comprises a fixing plate and a liquid injection cup, the liquid injection cup is arranged on the fixing plate, the feeding part moves relative to the liquid injection part, and the feeding part conveys a battery to the position below the liquid injection cup and enables the battery to be communicated with the liquid injection cup; the electrolyte in the electrolyte injection cup is injected into the battery, and the electrolyte injection cup is kept fixed before and after electrolyte injection, so that the electrolyte injection quality can be improved, and the electrolyte injection precision is ensured; the liquid injection cup is provided with a liquid injection opening and a liquid injection pipeline, the liquid injection opening and the liquid injection pipeline are used for guiding the electrolyte, and the liquid injection pipeline can guide the electrolyte into the liquid injection cup. The liquid injection pipeline is provided with the liquid outlet, the liquid outlet is obliquely arranged, the electrolyte flows to the inner wall of the liquid injection cup from the liquid outlet, the electrolyte flows downwards along the inner wall of the liquid injection cup, the electrolyte can be prevented from directly falling to generate bubbles, and the liquid injection precision of the electrolyte is guaranteed.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

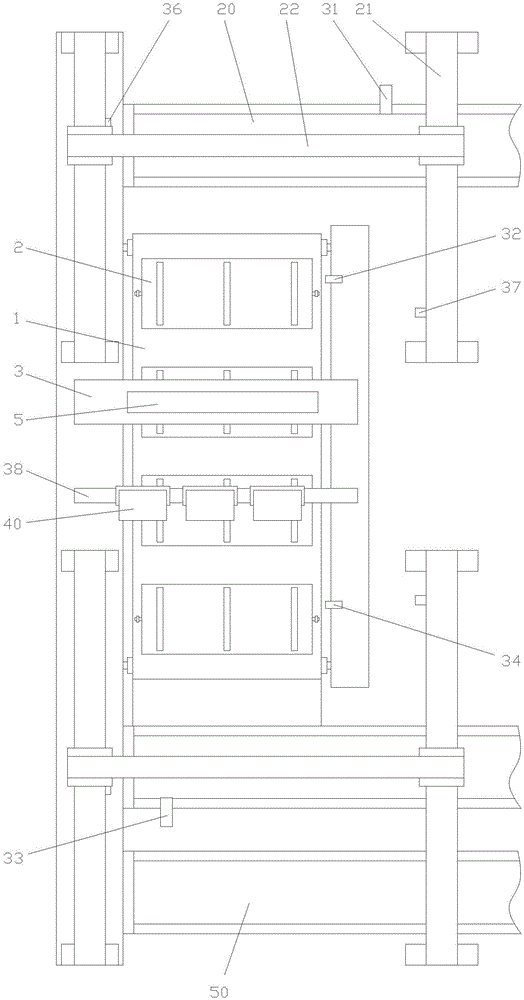

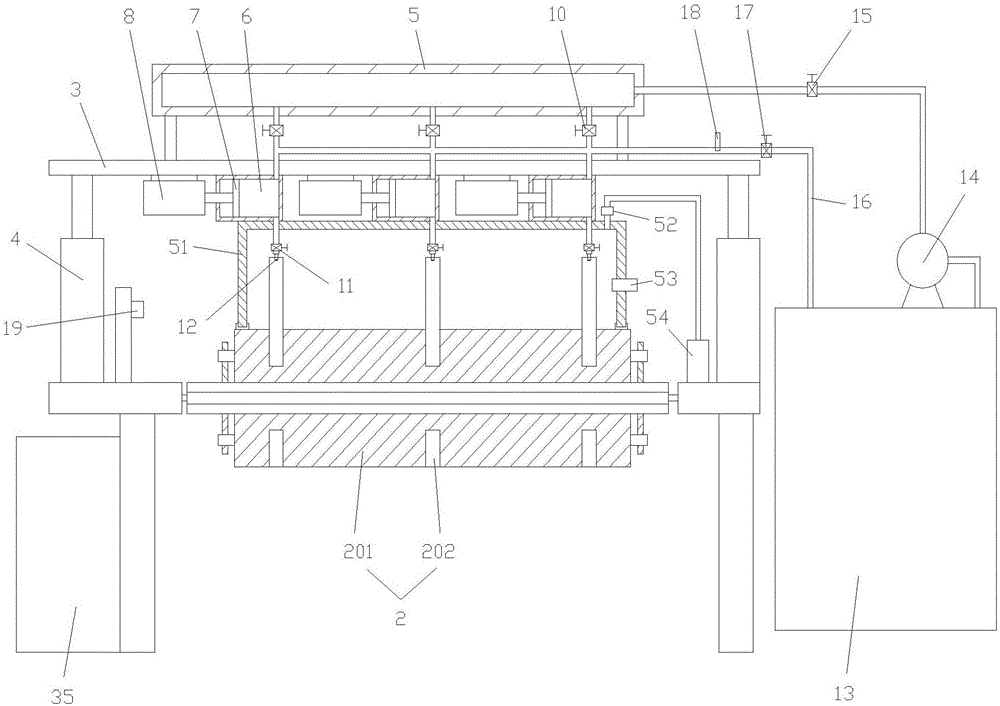

Liquid filling method for flexible package lithium ion battery

ActiveCN103247775AImprove injection efficiencyHigh injection precisionSecondary cellsCell component detailsEngineeringLithium-ion battery

The invention relates to a liquid filling method for a flexible package lithium ion battery. The liquid filling method comprises the following steps of: conveying the flexible package lithium ion battery and a battery clamp to liquid filling stations for positioning, pressing a liquid filling vacuum chamber downwards, and sealing the liquid filling vacuum chamber with the battery clamp; performing vacuumizing on the liquid filling vacuum chamber, a liquid filling cup, and a vacuum buffering tank communicated with the liquid filling cup simultaneously; after finishing the vacuumizing of the liquid filling cup, the vacuum buffering tank and the liquid filling vacuum chamber, switching on a mouth valve of the liquid filling cup to enable electrolyte in the liquid filling cup to flow out, so as to finish the liquid filling; and performing vacuum breaking on the liquid filling vacuum chamber, the liquid filling cup and the vacuum buffering tank, lifting the liquid filling vacuum chamber, and transferring the battery clamp and the flexible package lithium ion battery. According to the method, the vacuum buffering tank is additionally arranged, so that the stability when the electrolyte is filled in the battery during the liquid filling of the flexible package lithium ion battery is enhanced, and the liquid filling efficiency of the battery can be improved.

Owner:SHENZHEN LIDE TECH

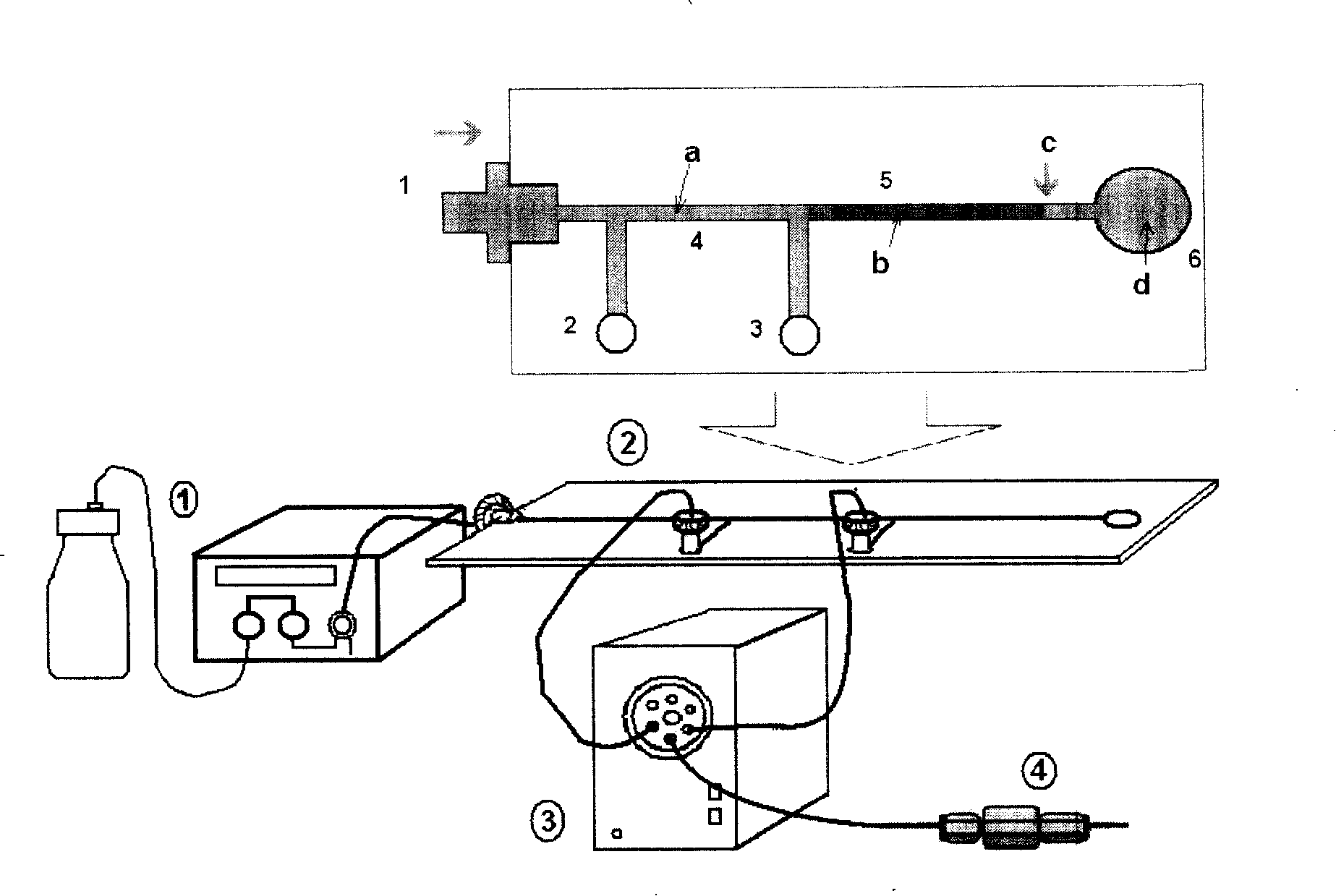

Sample injection mode for digital micro-fluidic chip

InactiveCN114100715ARealize automatic sample injectionAvoid inconvenienceBurettes/pipettesHigh fluxMechanical engineering

The invention discloses a sample injection method and device for a digital micro-fluidic chip. The sample injection device of the digital micro-fluidic chip mainly comprises a sample injection pressure head (1) and a driving mechanism (6) for driving the sample injection pressure head to move. And the sample injection pressure head (1) is used for injecting a reagent pre-embedded in the chip (12) into the chip (12). And the driving mechanism (6) is used for controlling the sample injection pressure head (1) to move so as to realize automatic sample injection. The sample injection mode has the advantages of high sensitivity, high accuracy, high flux, high integration level and the like, cross contamination is avoided in the whole process reaction, one-key operation can be achieved, and the two hands of an operator are greatly liberated.

Owner:JIANGSU LOGILET BIOTECH CO LTD

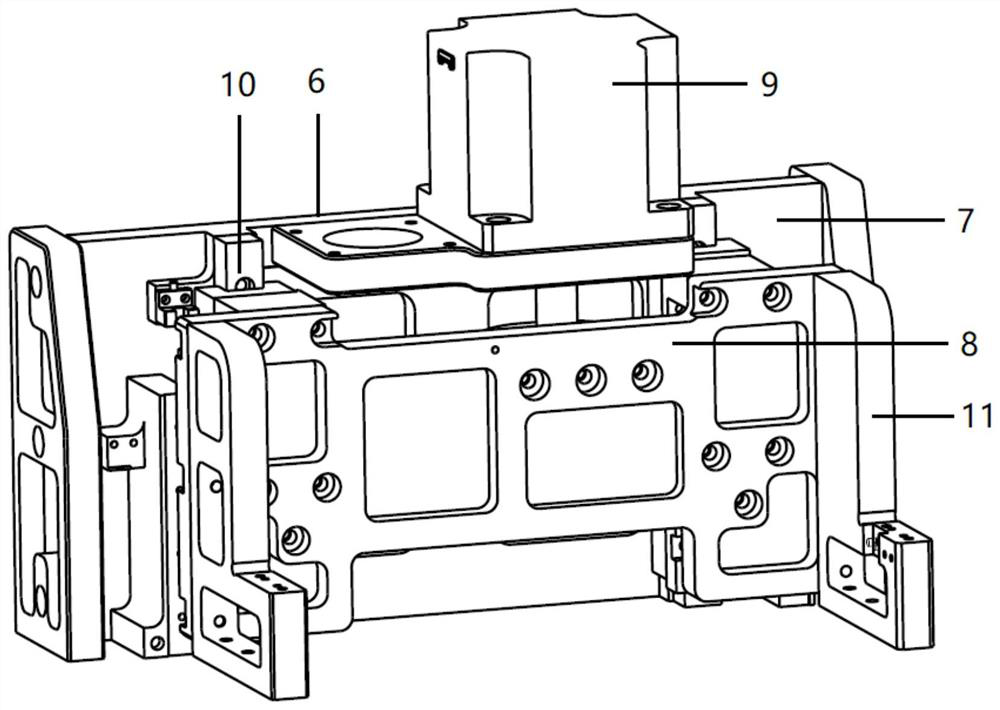

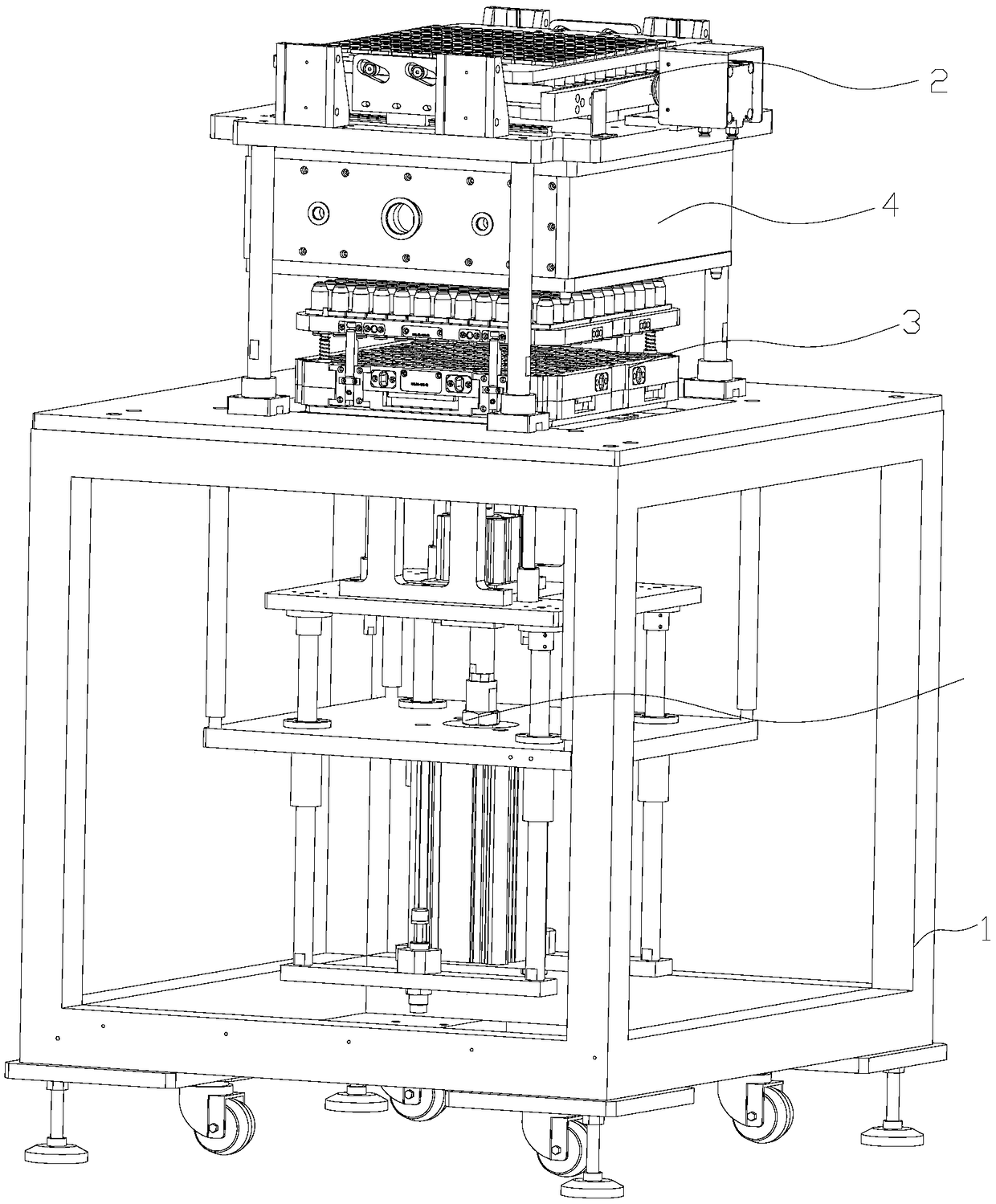

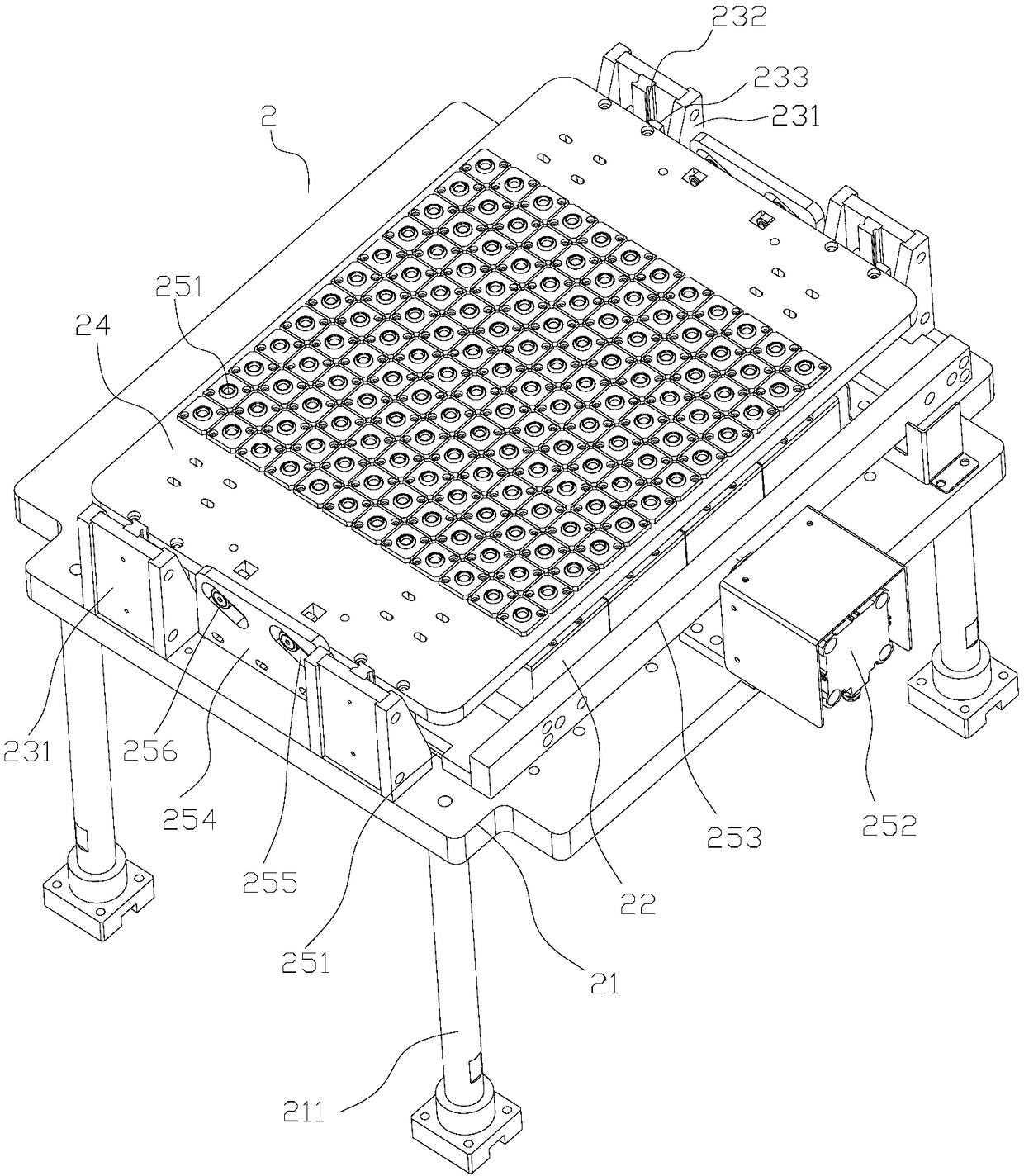

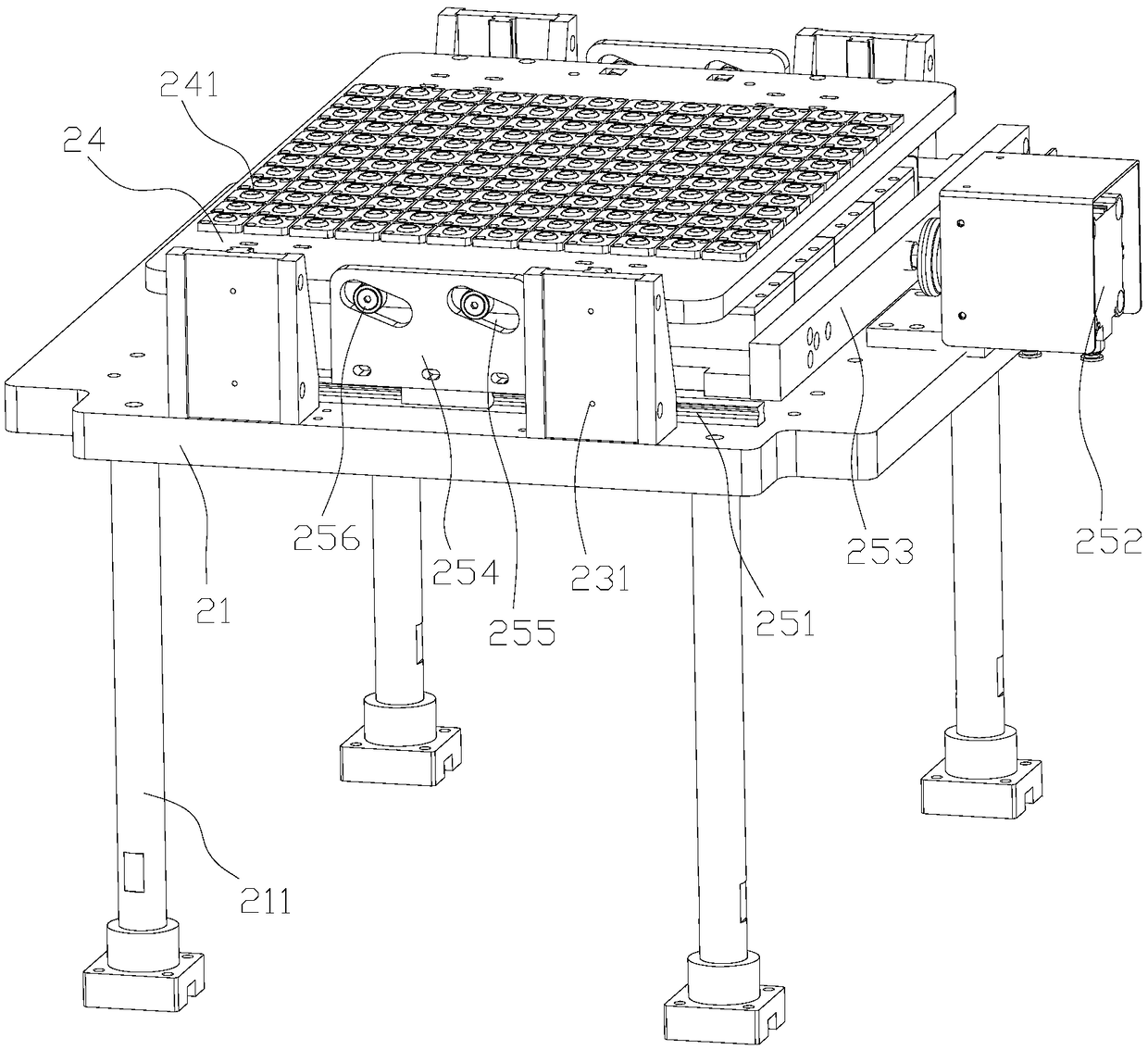

A battery vacuum injection device

PendingCN109065827AImprove injection efficiencyHigh injection precisionNon-aqueous electrolyte cellsFinal product manufactureEngineeringVacuum chamber

A liquid injection apparatus for battery vacuum is disclose, comprises a frame and an upper transition cup mechanism installed on the frame, a vacuum chamber, a lower transition cup mechanism and a lifting mechanism, wherein the upper transition cup mechanism comprises an upper transition cup, the lower transition cup mechanism comprises a lower transition cup and a battery carrier plate, and thelifting mechanism is used for lifting the lower transition cup mechanism into the vacuum chamber. The vacuum injection device of the battery has the advantages that the battery absorbs the electrolytequickly, the battery injection efficiency is high, the battery productivity is high, and the injection precision is good, which are not possessed by the prior art.

Owner:SHENZHEN LIDE TECH

Liquid path system for chemiluminescence analyzer

PendingCN111912998AGood cleaning effectAvoid sample or reagent carryoverHollow article cleaningCleaning using liquidsPhysicsPlunger pump

The invention discloses a liquid path system for a chemiluminiscence analyzer. The liquid path system comprises a sample adding system, a cleaning liquid injection system, a magnetic bead cleaning system, a liquid pumping system, a substrate liquid injection system and a discharging system. The automatic detection requirement of high-flux samples can be effectively met, the magnetic bead cleaningsystem and the sample adding system both have a self-cleaning function, each pump body of the multi-channel plunger pump of the magnetic bead cleaning system corresponds to one liquid injection branchpipe and one liquid injection needle, independent control over each liquid injection needle is achieved, the inconsistent liquid injection amount caused by different pipe resistances is effectively prevented, so that the liquid injection precision and the uniformity of the liquid injection amount are improved; meanwhile, the state of the tenth electromagnetic valve can be selectively switched inthe BF washing liquid injection and cleaning process, then self-cleaning of the magnetic bead cleaning system is achieved, crystallization caused by residual crystallization washing liquid in a pipeline is avoided, the liquid injection precision and the uniformity of the liquid injection amount are further improved, and the BF washing liquid can be prevented from being injected into the reaction disc to form crystal substances.

Owner:AUTOBIO LABTEC INSTR CO LTD

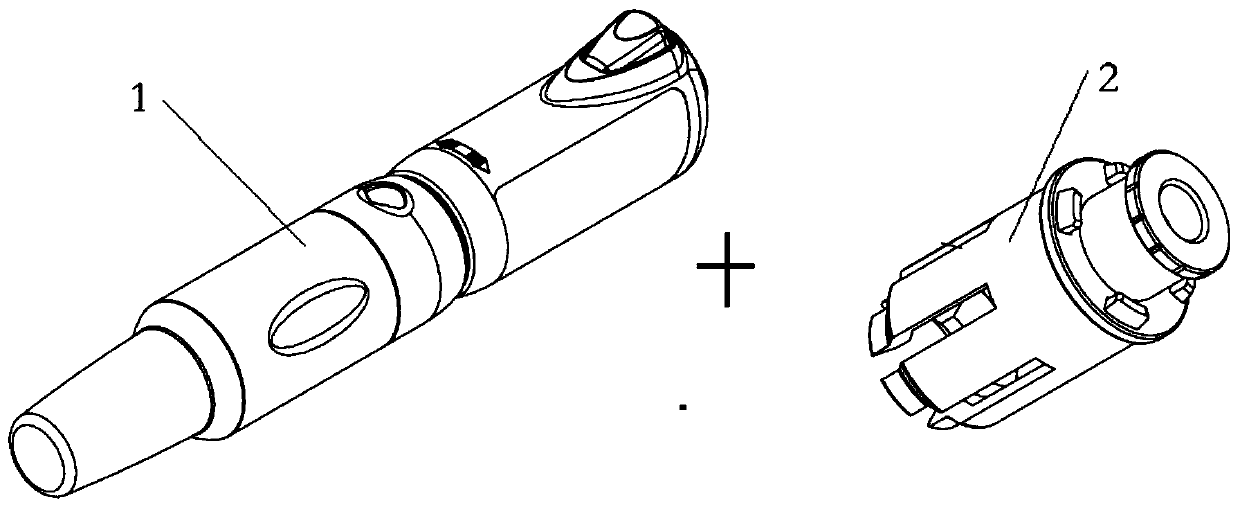

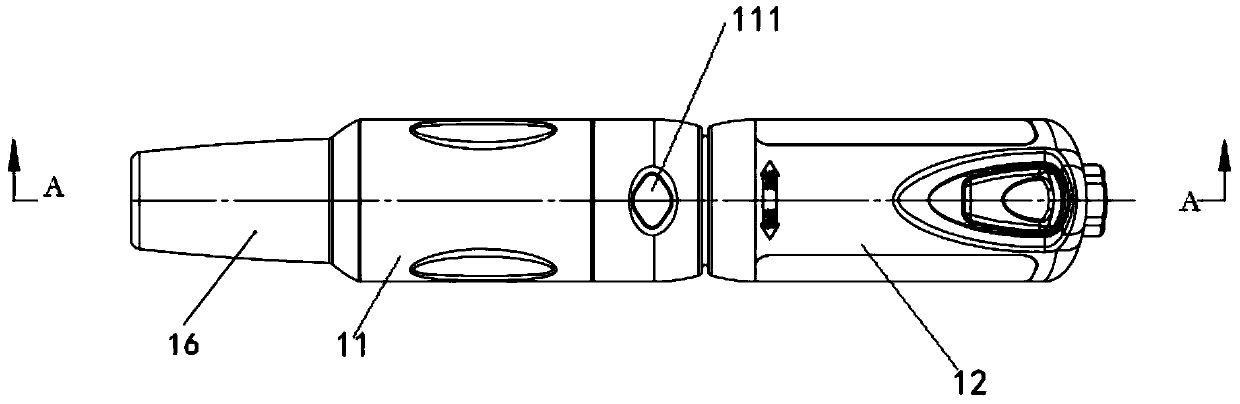

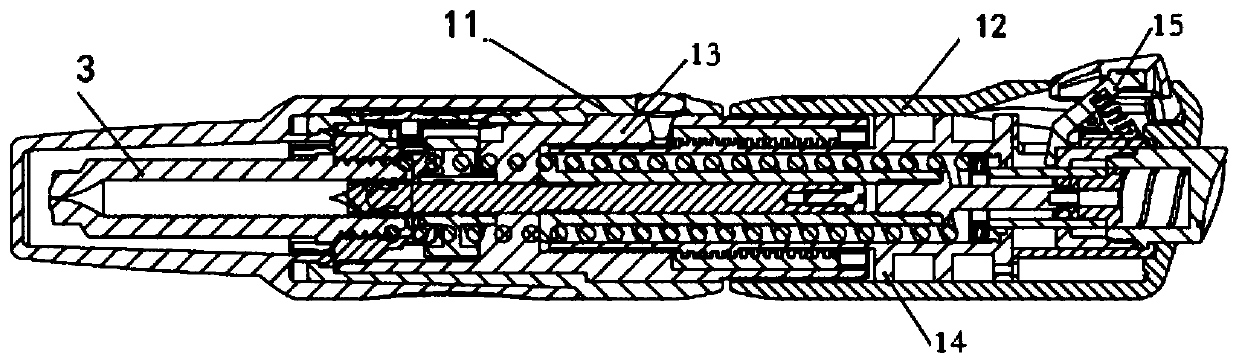

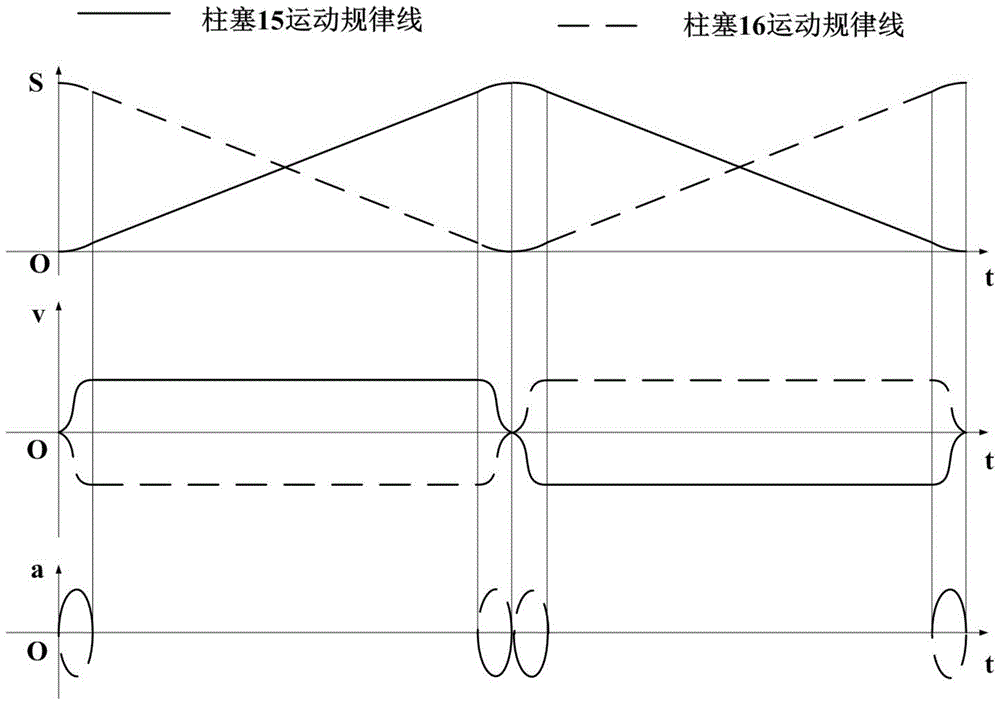

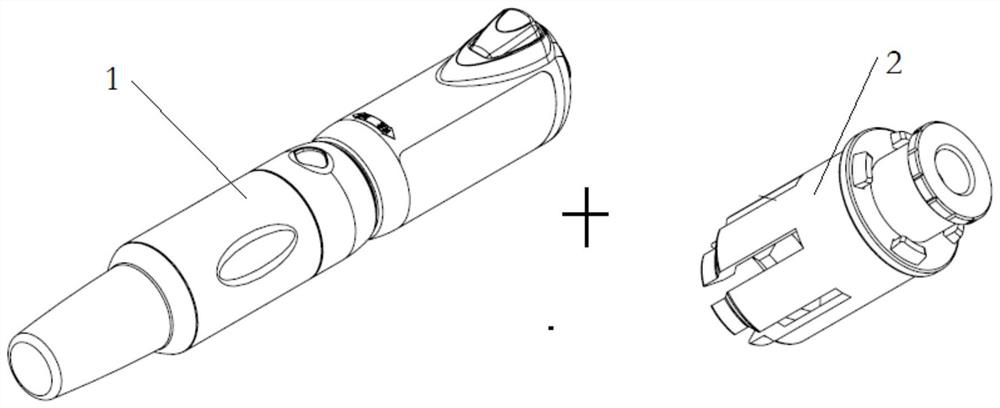

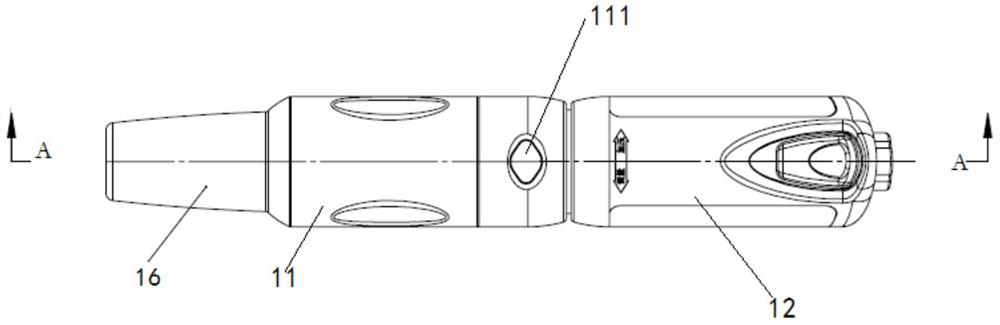

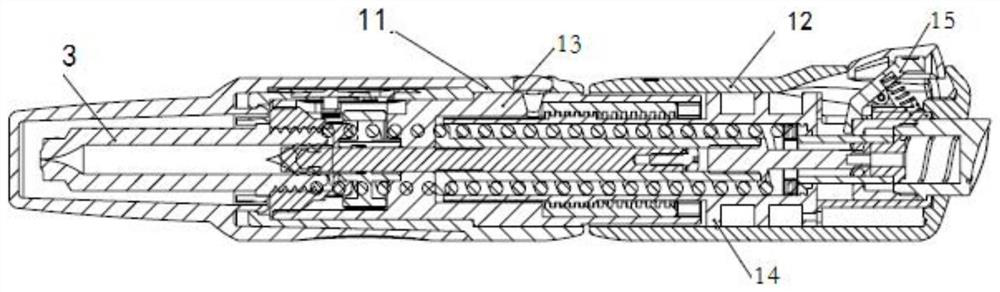

Portable needleless injector with accurate dosage

ActiveCN111544706AHigh injection precisionEasy to useAmpoule syringesJet injection syringesNeedle Free InjectionNeedle free

The invention discloses a portable needleless injector with accurate dosage. The portable needleless injector is composed of a thruster, a medicine pumping connector and a dosage medicine tube. The thruster is composed of an upper shell part, an adjusting part, an injection part, a lower shell part and a safety part. A medicine bottle in which liquid medicine is stored is inserted into the medicine pumping connector and is clamped and fixed by the medicine pumping connector. The front end of the dosage medicine tube is connected with the rear end of the medicine pumping connector, and an adjusting hand wheel in the adjusting component is rotated to pump liquid medicine and store the liquid medicine in the dosage medicine tube. During injection, the safety part is opened, the injection partis released, a push rod assembly in the adjusting part is pushed through a thrust spring of the injection part, and then a core rod and a piston in the dosage medicine tube are pushed to act, so thatliquid medicine in the dosage medicine tube forms thin liquid flow and is sprayed out through a spraying hole in the top of the dosage medicine tube. The liquid medicine dosage is accurate; the dosage of the thruster is adjustable, and gear shifting is reliable; the medicine pumping connector is high in adaptability; the liquid medicine injection precision is high; and the portable needleless injector is safe and reliable in use and convenient to carry.

Owner:易舒康(山东)生物科技有限公司

A micro-injection tube

ActiveCN106872642BHigh injection precisionReduce manufacturing costChemical analysis using titrationEngineeringMechanical engineering

Owner:BEIJING SDL TECH

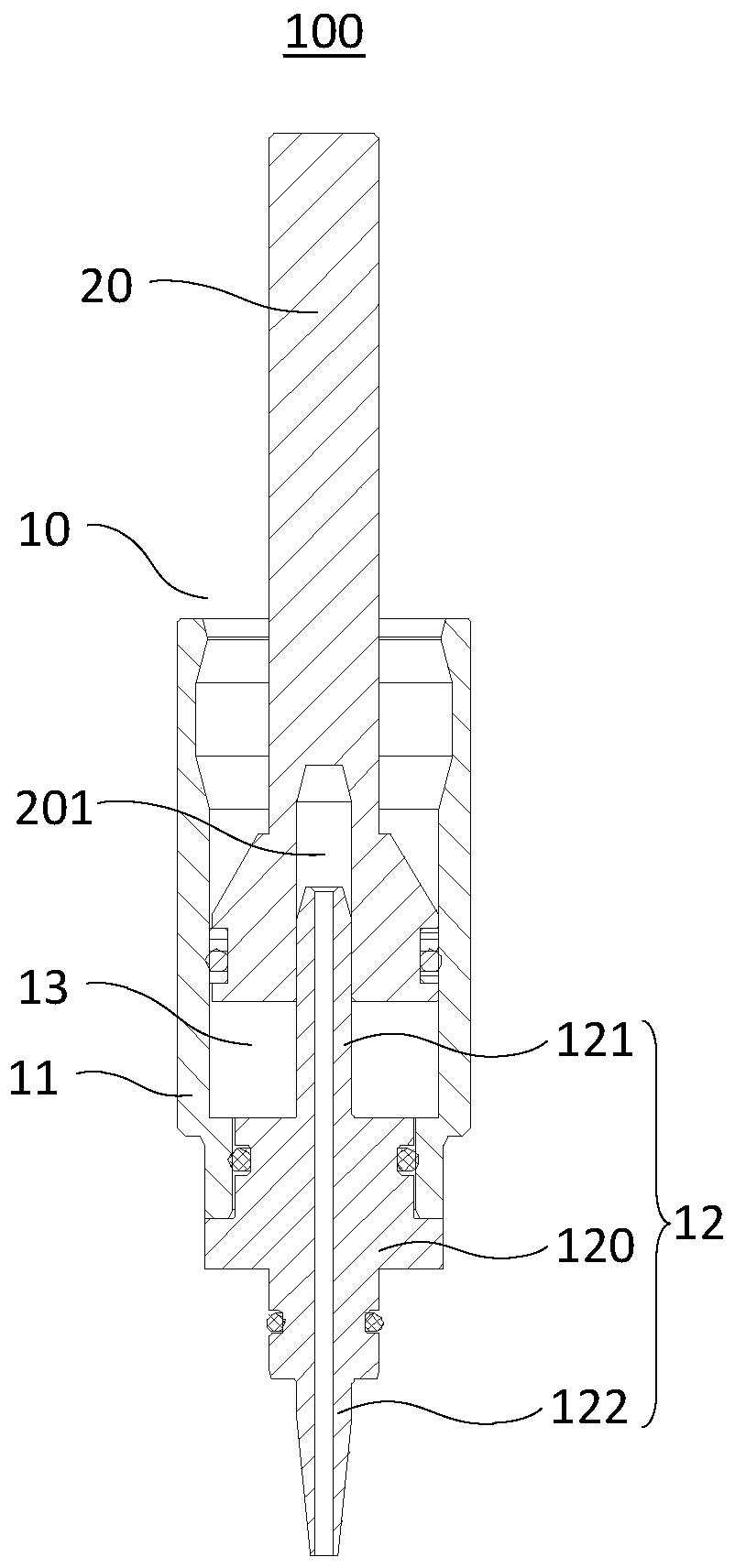

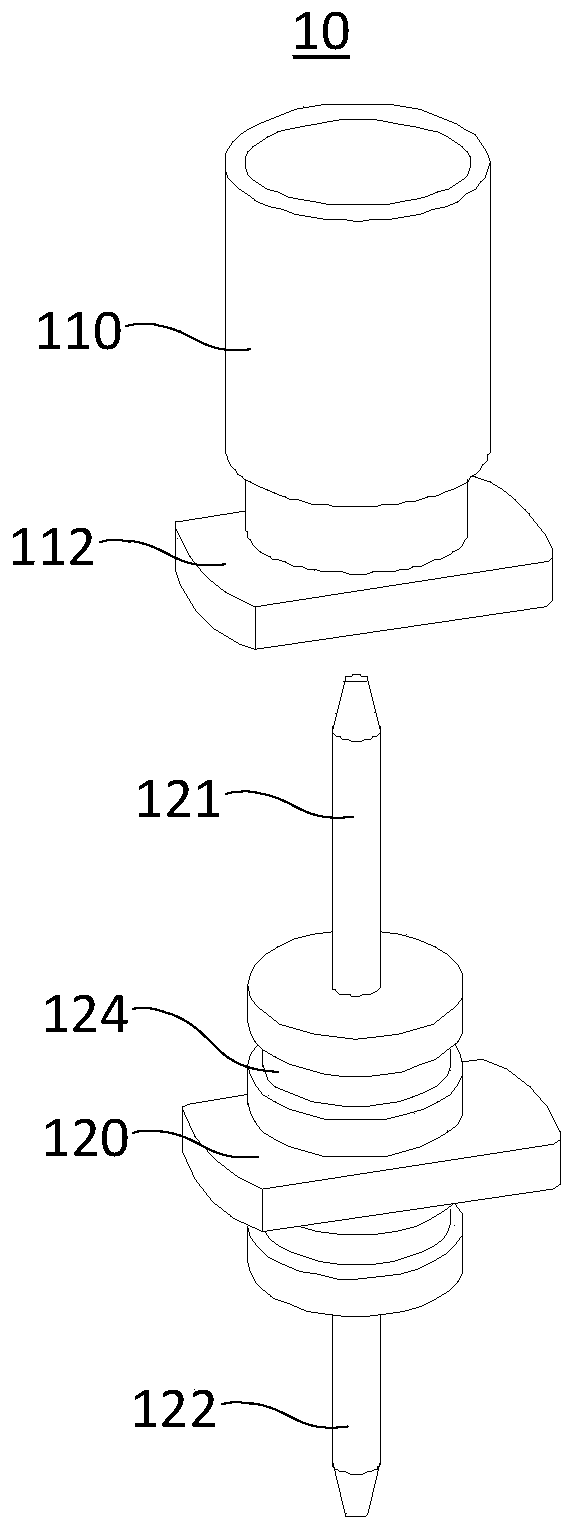

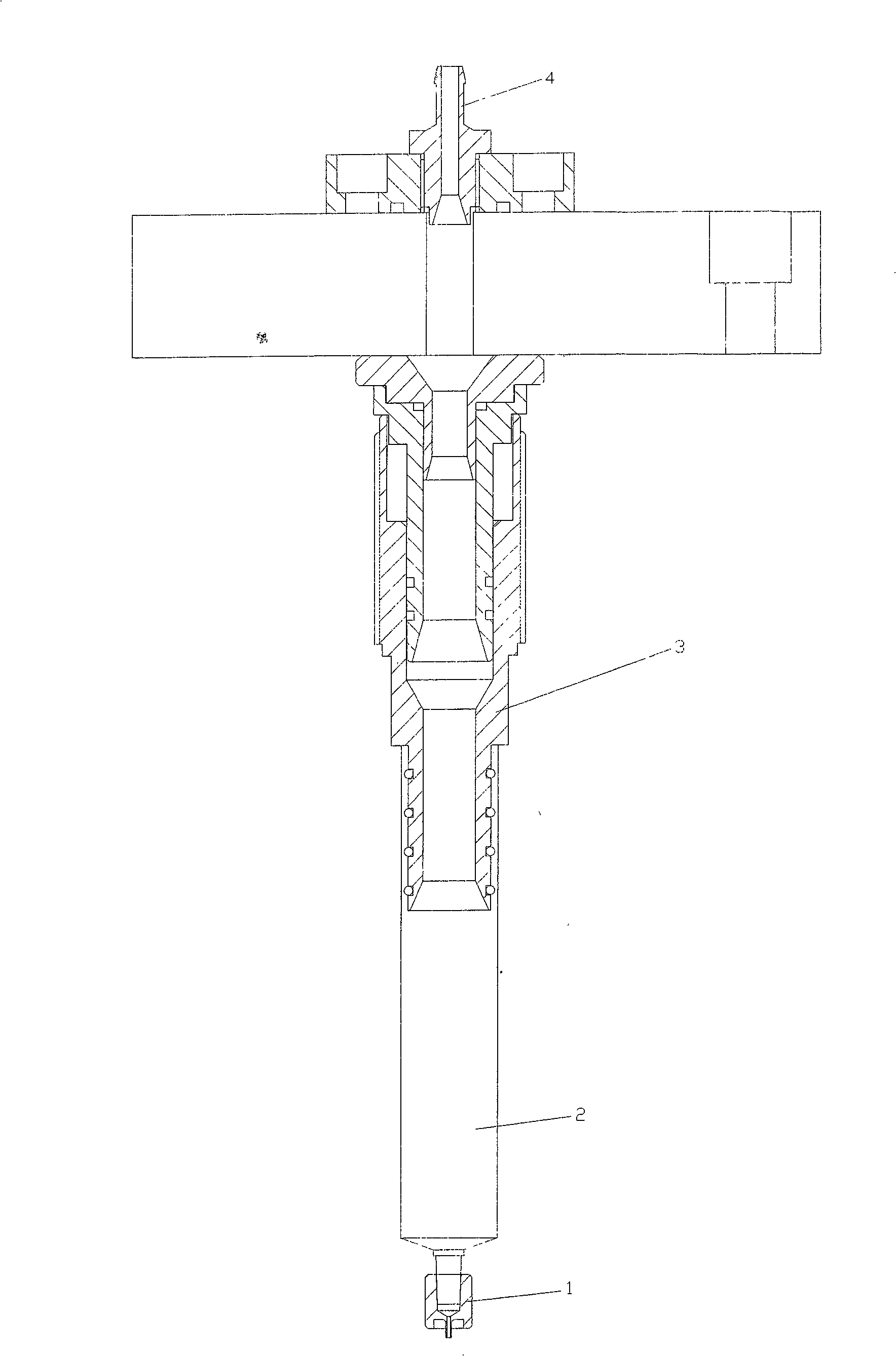

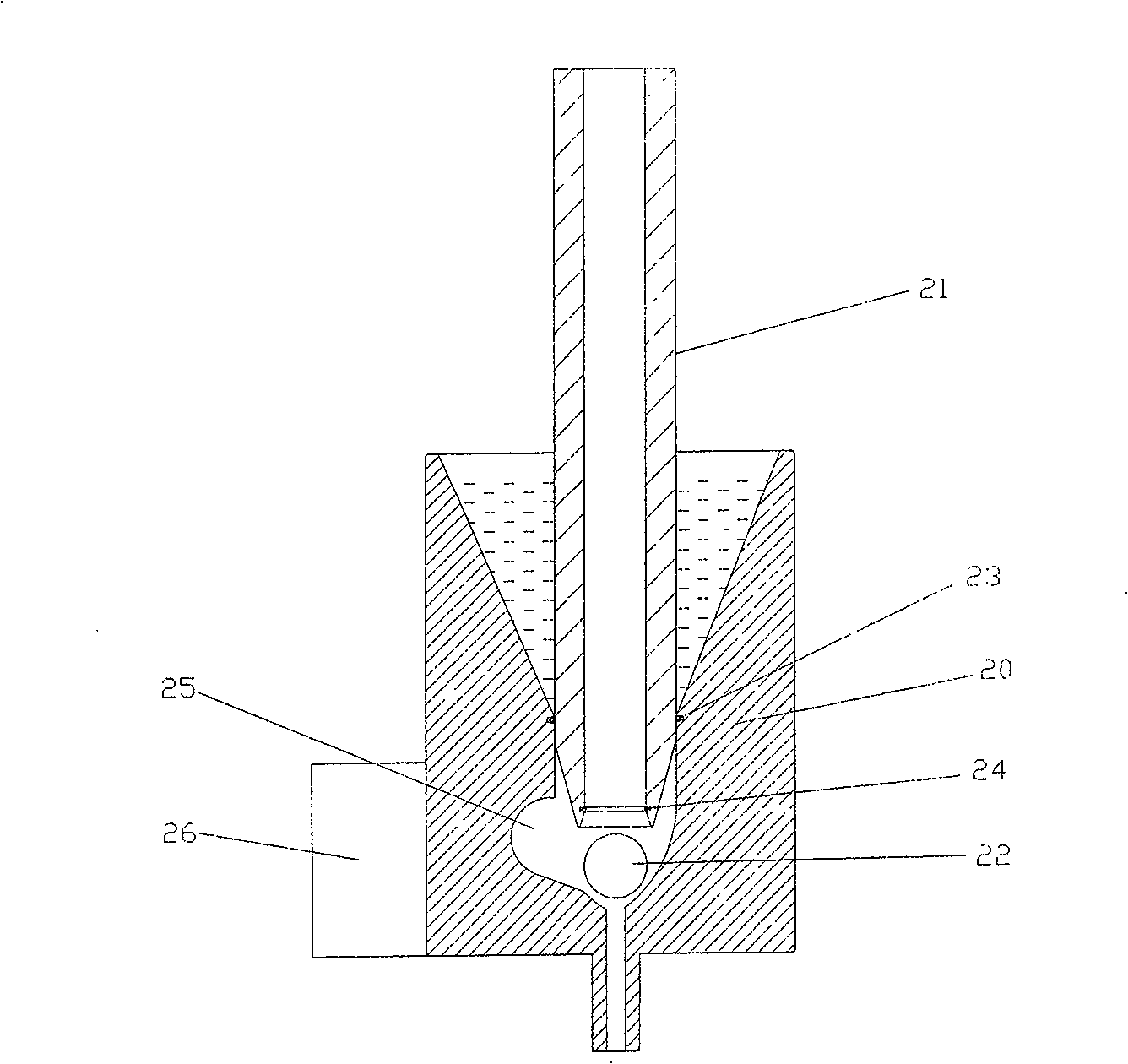

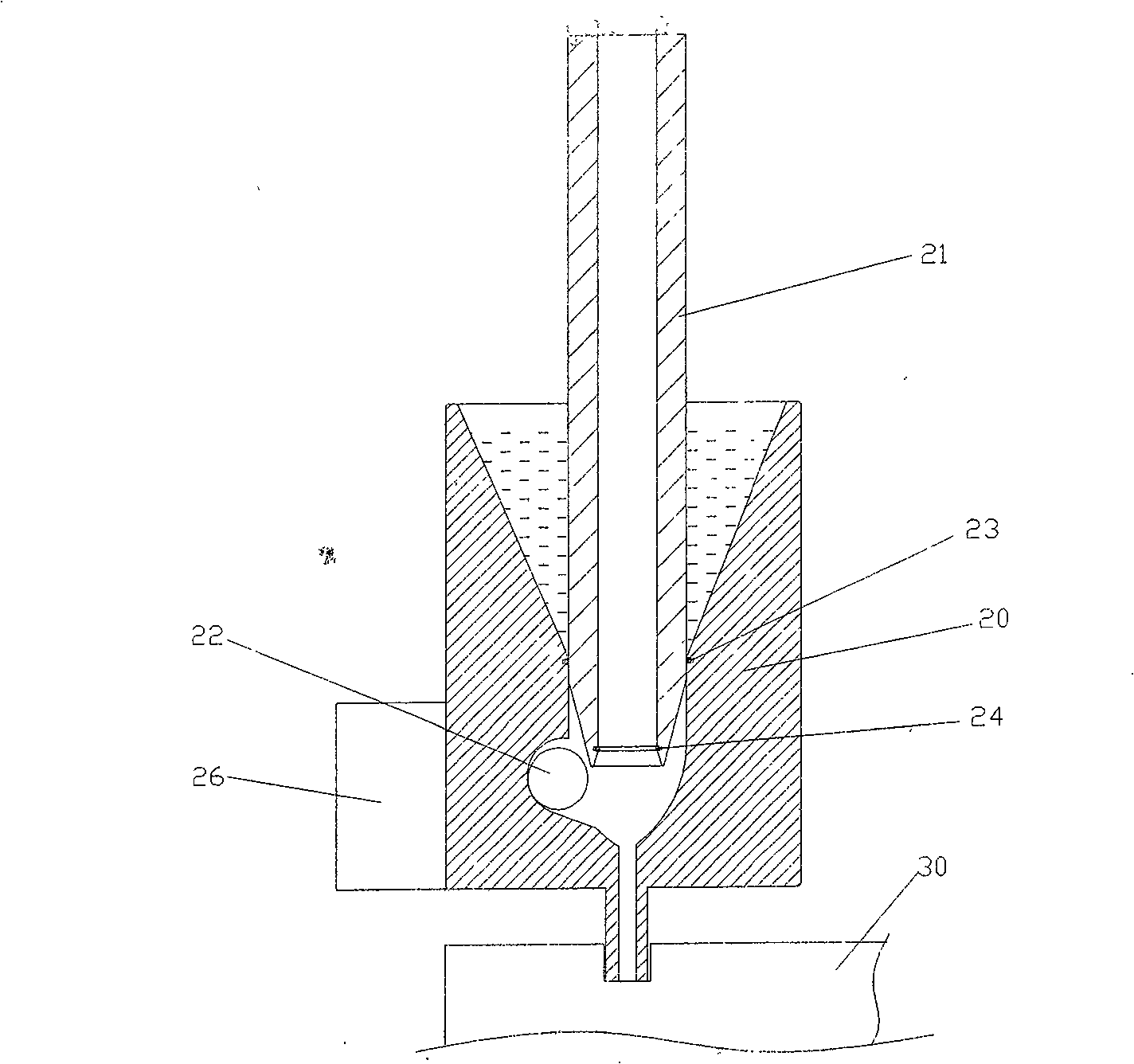

Filling syringe for battery and battery injector therewith

This is a cell needle and the injection device. The needle is of an inner cavum which is sealed in a vacuum needle and steel ball matching to the end of the needle. There is a concave part on the side wall of the cavum, and an electromagnet is installed to the position of the concave part.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Digital quantitative continuous injection pump

ActiveCN104033348BRealize infinitely variable speedAdjustable flow ratePumpsPositive-displacement liquid enginesCavitationSystem pressure

The digital quantitative continuous injection pump includes a power source, a transmission system, an actuator, and a control system. The power source outputs rotary motion, and the transmission system changes the speed of the rotary motion output by the power source, and then converts it into linear motion, and then drives the actuator The liquid in the container is sucked into the device, and then discharged from the liquid outlet. The control system is used to control the entire device, realize stepless speed change by controlling the pulse frequency, realize quantitative liquid injection by controlling the number of pulses, and improve the liquid injection accuracy by introducing flow feedback , Overload protection is achieved by introducing a pressure switch. By adjusting the speed of the stepping motor to control the flow speed of the fluid, the working pressure of the system is above the air separation pressure and saturated vapor pressure of the liquid, preventing cavitation, and greatly improving the stability of the system and the use of the device. life.

Owner:SICHUAN UNIV

A Portable, Needle-Free Injector With Accurate Dosing

ActiveCN111544706BHigh injection precisionEasy to useAmpoule syringesJet injection syringesNeedle Free InjectionNeedle free

Owner:易舒康(山东)生物科技有限公司

A high-precision plunger type micro-sampling pump

The invention discloses a high-precision plunger type trace sampling pump. Guide rails are horizontally arranged and are connected with the bottom end of a sliding bracket, so that the sliding bracket moves left and right on the guide rails; a plunger pump is arranged at the top end of the sliding bracket; a liquid inlet one-way valve and a liquid outlet one-way valve are respectively arranged in a liquid inlet and a liquid outlet of the plunger pump; one end of a plunger of the plunger pump is embedded inside the plunger pump; a separation-reunion plate is arranged at the other end of the plunger; a spring coaxially sleeves the plunger; two ends of the spring are respectively in contact with the separation-reunion plate and the plunger pump; a motor is fixedly placed; a cam is fixed on a driving shaft of the motor. The high-precision plunger type trace sampling pump disclosed by the invention has the advantages of simple structure, high sampling precision, adjustable trace, stable operation and low cost; the high-precision plunger type trace sampling pump is suitable for accurate sampling of an analysis instrument system and high-precision agent mixing, in particular for sampling detection of microbial culture solution.

Owner:河北雄安芯慧至上科技有限公司

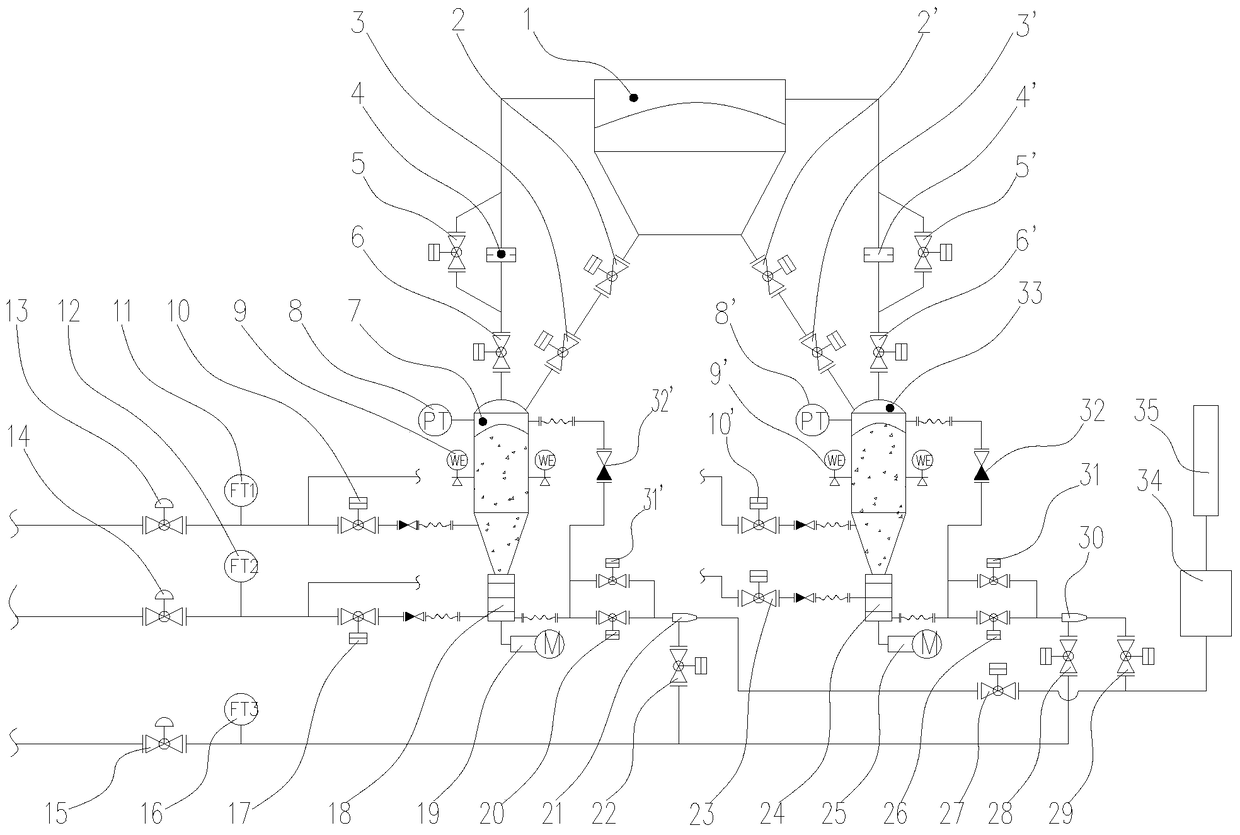

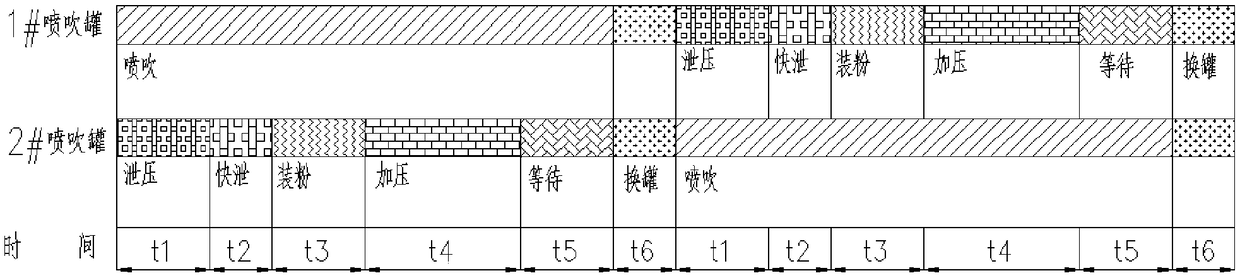

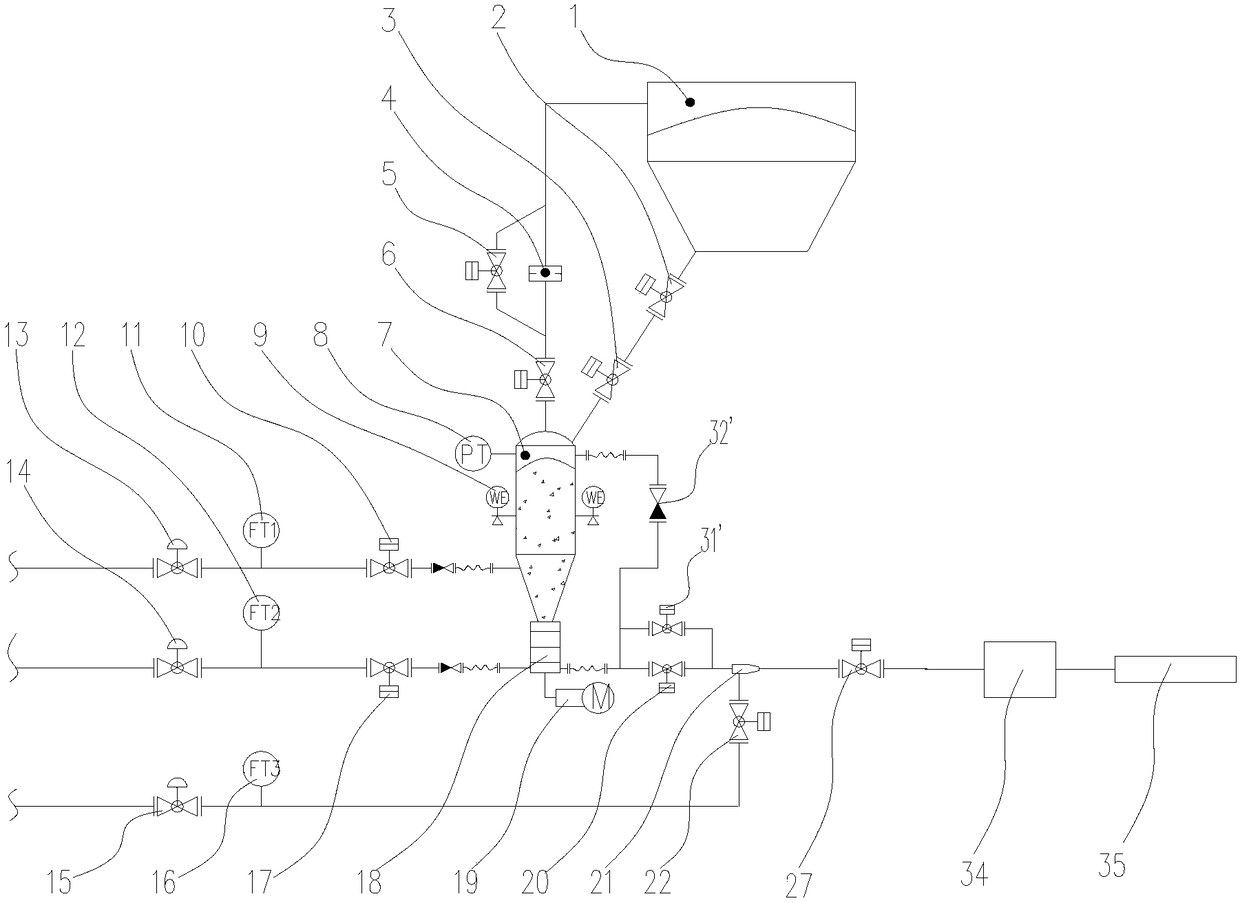

A blast furnace coal injection system and its control method

ActiveCN105177200BRealize separate controlHigh injection precisionBlast furnace componentsBlast furnace detailsPressure stabilizationEngineering

The invention provides a blast furnace coal injection system. The blast furnace coal injection system comprises an injection tank, a distributor, an injection gun and a coal powder bin communicated through pipes, wherein a quantitative feeder is arranged at the bottom of the injection tank; a coal powder main pipe is arranged between an outlet of the quantitative feeder and the distributor and the injection gun, and is provided with a coal outlet valve and a coal conveying valve; and a pressure homogenizing pipe is arranged between the coal powder main pipe and the top of the injection tank. An air source main pipe is divided into three pipes of pressure stabilization, injection and air replenishment, which are respectively connected with the injection tank, the quantitative feeder and the coal powder main pipe. A control method of the blast furnace coal injection system is as follows: while one injection tank injects, the other injection tank performs preparations of pressure relief, quick relief, powder loading, pressurization and waiting; after the injection of the first injection tank is finished, the tank is replaced; and then, the second injection tank enters the preparation process for alternate circulation. The quantitative feeder is mounted at the bottom of the injection tank, so that the injection precision is improved, the tank replacement fluctuation time is shortened, and necessary conditions are provided for stabilization of blast furnace production.

Owner:CISDI ENG CO LTD +1

Efficient liquid charge pump device for production of lithium iron batteries

InactiveCN105201772AMeet the use requirementsHigh injection precisionPositive displacement pump componentsPump controlHuman–machine interfaceLiquid-crystal display

The invention discloses an efficient liquid charge pump for production of lithium ion batteries. The efficient liquid charge pump device comprises a step motor, a connection sleeve, a ceramic plunger, a ceramic pump body, a liquid outlet, an inclined fixing mechanism, a liquid inlet, a micrometer depth gauge, data lines, a PLC (programmable logic controller) system, a man-machine interface operation system, a liquid crystal display screen and parameter setting buttons, wherein the step motor is horizontally arranged on one side of the inclined fixing mechanism and penetrates through the inclined fixing mechanism to be connected with the connection sleeve; the connection sleeve is connected with the ceramic plunger in a ceramic liquid charge pump; the ceramic liquid charge pump comprises the ceramic plunger and the ceramic pump body; the liquid inlet is formed in one side of the ceramic pump body, and the liquid outlet is formed in the other side of the ceramic pump body; the ceramic liquid charge pump is arranged in a cavity of the inclined fixing mechanism, and the micrometer depth gauge is arranged at the upper part of the other side of the inclined fixing mechanism and connected with the tail end of the ceramic pump body of the ceramic liquid charge pump; the PLC system is connected with the man-machine interface operation system and the step motor respectively through the data lines.

Owner:TIANJIN NENGXIN TECH

Method for achieving online blending of multi-grade hydraulic oil through intelligent injection control

InactiveCN110385085ARealize online automatic unloadingEasy to operateTransportation and packagingMixer accessoriesAutomatic controlSelf weighing

The invention relates to a method for achieving online blending of multi-grade hydraulic oil through intelligent injection control. A solid agent lifting machine has a negative pressure suction function, and can suck a solid powder drug from a solid agent measuring tank to a hopper of configuring of the solid powder drug, the solid agent measuring tank has a self-weighing function, and weighs thesolid powder drug falling in a solid agent dispensing tank in real time and feeds back to a control cabinet, a first instantaneous delivery passing through a fluid flowmeter can be fed back to the control cabinet through the fluid flowmeter connected with a liquid agent discharging pump, the first instantaneous delivery passing through the fluid flowmeter can be fed back to the control cabinet through the fluid flowmeter, a second instantaneous delivery passing through a mother liquid dilution flowmeter can be fed back to the control cabinet through the mother liquid dilution flowmeter, the solid agent dispensing tank and a liquid agent dispensing tank can be correspondingly mixed and stirred through an aeration disc of a pulse wind stirrer, the type and proportion of preparation of additives needed to be added in different formula hydraulic oil are stored in the control cabinet, agent adding pumps of corresponding dispensing tanks are automatically controlled to be started, and automatic adjustment is conducted according to dispensing change of hydraulic oil blending amount.

Owner:LUOYANG LVCHAO ENVIRONMENTAL PROTECTION TECH

Liquid injection cup device

PendingCN109786648AImprove reliabilityHigh injection precisionCell component detailsEngineeringLiquid injection

The invention discloses a liquid injection cup device comprising a vacuum cup, a liquid guide structure and a liquid draining structure; the liquid guide structure is hermetically arranged at an inlet; the vacuum cup is provided with a cavity for holding liquid and the inlet and an outlet communicated with the cavity; the liquid guide structure is movably arranged, a motion path of the liquid guide structure is at least provided with a communication position used for being communicated with the cavity via the inlet and a separation position used for exiting the inlet to be separated from the cavity; the liquid draining structure is hermetically arranged at the outlet, and used for draining the liquid in the cavity to a battery. The liquid injection cup device provided by the invention is good in sealing effect and high in reliability and liquid injection accuracy, and effectively solves the problem that the cost is high due to the fact that the rubber sealing ring needs to be changed periodically.

Owner:速博达(深圳)自动化有限公司

Lithium battery electrolyte injection system with self-test function

ActiveCN106159186BHigh injection precisionIncrease productivityCell component detailsEngineeringLoad cell

The invention discloses a lithium battery electrolyte injection system with a self-checking function. The lithium battery electrolyte injection system comprises a feeding unit, a middle electrolyte injection unit, a middle sealing unit, a weighing detection unit and a discharging unit, wherein the middle electrolyte injection unit comprises a middle belt conveyer, a battery positioning mould, a lifting plate, a first lifting air cylinder and a quantified electrolyte injector; the weighing detection unit comprises a front weighing sensor, a rear weighing sensor and a waste conveyer; and each of the feeding unit and the discharging unit comprises a belt conveyer, a straight sliding rail, a positioning air cylinder, a positioning block, a pickup air cylinder, a corner air cylinder and a vacuum chuck. According to the lithium battery electrolyte injection system, the inner cavity capacity of the quantified electrolyte injector is equal to a standard electrolyte injection amount of lithium batteries, so that the electrolyte amount pushed by an electrolyte injection air cylinder for each time is correctly equal to the standard electrolyte injection amount of lithium batteries, and the electrolyte injection precision is high; and the weighing detection unit can be used for detecting and monitoring the electrolyte injection quality, so that the unqualified products and fault problems of the electrolyte injector can be discovered in time and then the electrolyte injection quality is ensured.

Owner:重庆市中欣维动力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com