Sample injection mode for digital micro-fluidic chip

A microfluidic chip and digital microfluidic technology, applied in laboratory containers, chemical instruments and methods, measuring tubes/pipettes, etc., can solve the problems of high cost, complex overall control, and difficult manufacturing, etc. Achieve the effect of reducing detection cost, improving detection efficiency, and reducing sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Construction of sample injection device for digital microfluidic chip

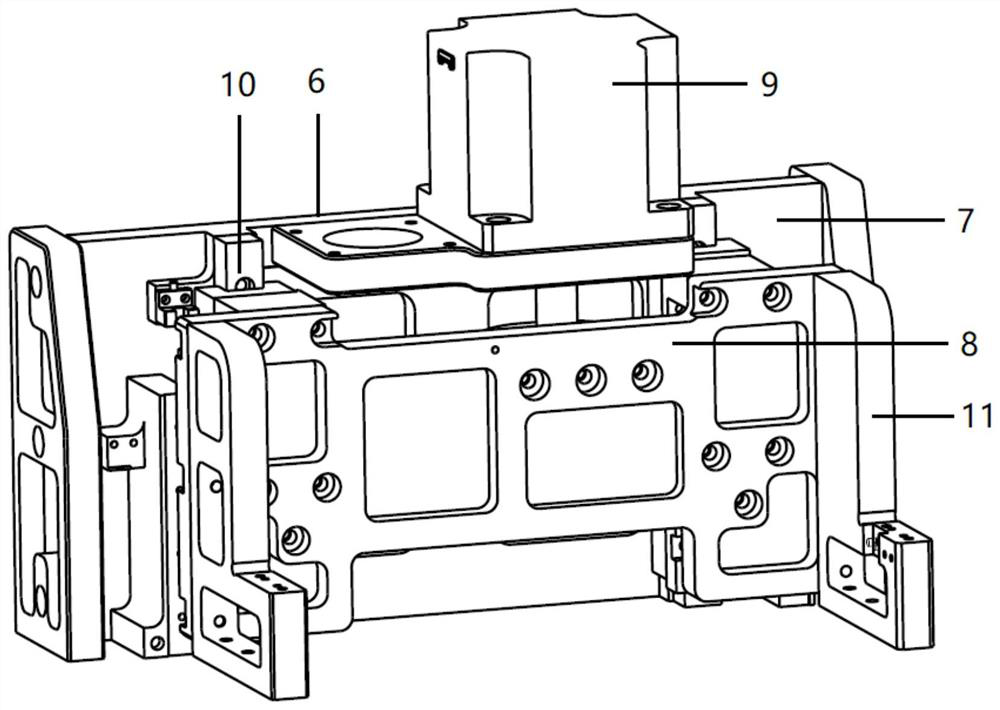

[0027] The sample injection device of the digital microfluidic chip mainly includes a sample injection pressure head 1 and a driving mechanism 6 for driving the movement of the sample injection pressure head. The sample injection head 1 is used for injecting the reagent pre-embedded in the chip 12 into the chip 12 . The driving mechanism 6 is used to control the movement of the sample injection pressure head 1 to realize automatic sample injection.

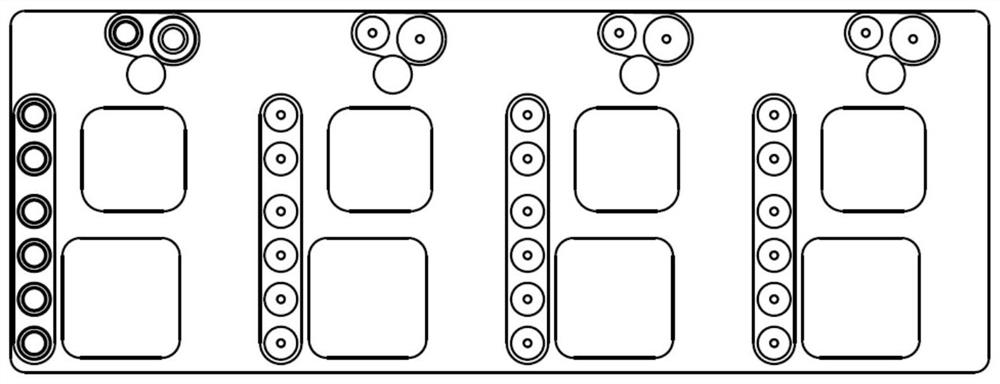

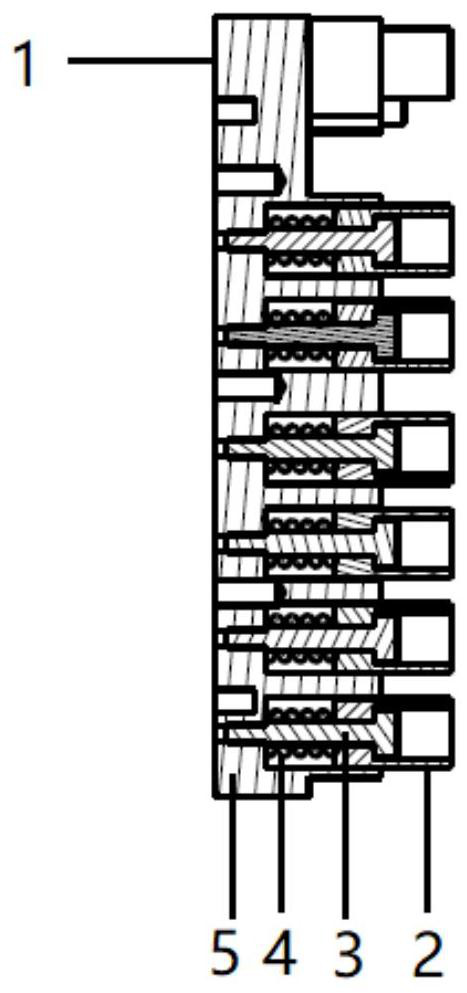

[0028] Figure 1-A with Figure 1-B The front view and cross-sectional view of the sample injection pressure head 1 are respectively shown. The sample injection pressure head 1 is composed of a plurality of pressure head bushings 2, plug screws 3, compression springs 4, and a sample injection pressure plate 5. The compression spring 4 is assembled between the sample injection pressure plate 5 and the pressure head bushing 2. There is a step...

Embodiment 2

[0037] Example 2: Sample injection method for digital microfluidic chip

[0038] Figure 5-A with Figure 5-B A front view and a cross-sectional view of the indenter bushing 2 fully injecting the reagent package in the microfluidic chip 12 into the chip are respectively shown. The movement of the driving motor 9 controls the movement of the injection pressure head 1. The pressure head sleeve 2 assembled in the injection pressure head 1 has an initial working position and a compression position when it is active. When the pressure head sleeve 2 is in the initial working position, it is driven by the drive motor. 9 Drive the sample injection pressure head 1 to move towards the reagent package sealed in the microfluidic chip until the pressure head sleeve 2 touches the reagent package and compresses the reagent package to cause it to break, and the reagent in the reagent package is injected into the chip. The compression spring 4 assembled by the pressure head shaft sleeve 2 pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com